- Offer Profile

-

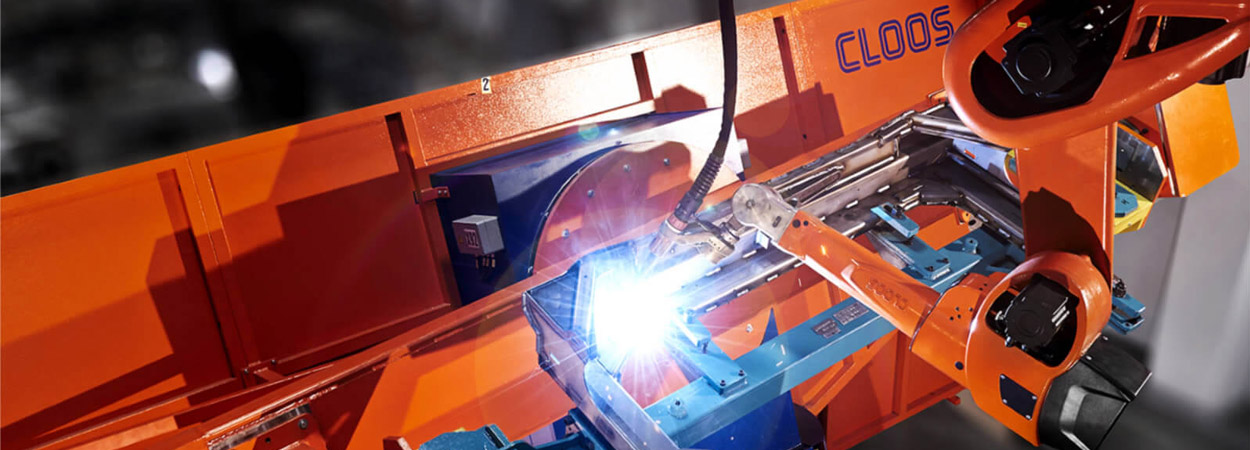

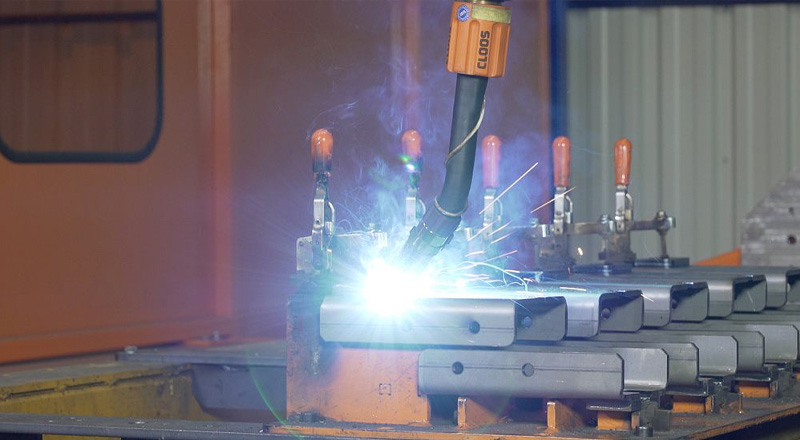

CLOOS develops, manufactures and delivers innovative solutions to more than 40 countries worldwide. With our QINEO®, the new generation of welding machines for manual and automated applications, and QIROX®, the system for automated welding and cutting, our product range covers the entire spectrum of arc welding technology. Our product portfolio includes intelligent software, sensor and safety technology solutions – all of which are customised to meet your specific needs and requirements! Leadership and competence equals process automation and welding at its best. Whatever your needs are, we “Weld your way.”

We offer optimised solutions with maximum efficiency and a high degree of welding and cutting products that are customised to your application: And we have been doing this for over 100 years!

Virtual CLOOS Showroom

-

The new virtual CLOOS showroom: Experience the CLOOS highlights!

C-Gate

-

Industry 4.0 enabled - the digitisation platform for your company: Access information from your welding production in real time!

Welding automation solutions and applications

-

CLOOS develops, manufactures and delivers innovative solutions to more than 40 countries worldwide. With our QINEO®, the new generation of welding machines for manual and automated applications, and QIROX®, the system for automated welding and cutting, our product range covers the entire spectrum of arc welding technology. Our product portfolio includes intelligent software, sensor and safety technology solutions – all of which are customised to meet your specific needs and requirements! Leadership and competence equals process automation and welding at its best. Whatever your needs are, we “Weld your way.”

Your applications are our focus

We offer optimised solutions with maximum efficiency and a high degree of welding and cutting products that are customised to your application: And we have been doing this for over 90 years!

Individual solutions by CLOOS

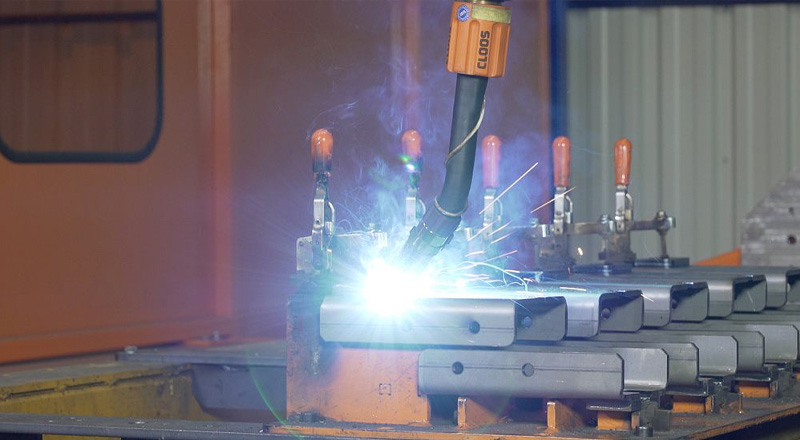

MAP Maschinen- und Apparatebau Produktions GmbH

-

- Component: Platform

- Processes: Vari Weld

- Material: Steel

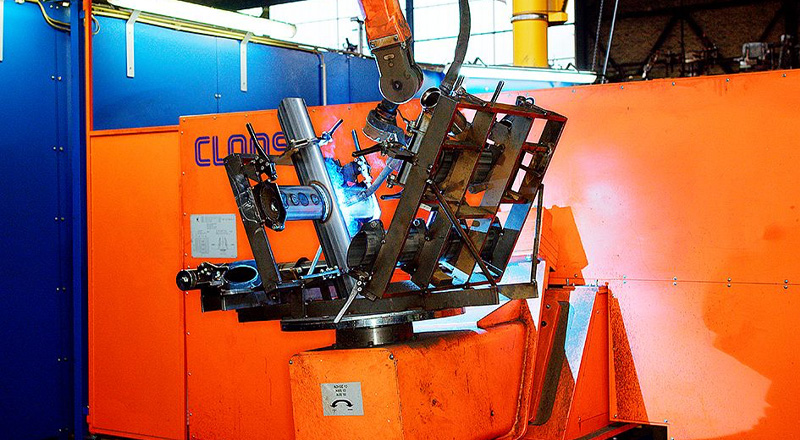

Change to automation at MAP

The MAP Maschinen- & Apparatebau Produktions GmbH increases their investments in automated production technology. Last year, the Rathenow company commissioned three new CLOOS robot systems. Thus MAP accelerates the production processes and increases the quality at the same time.

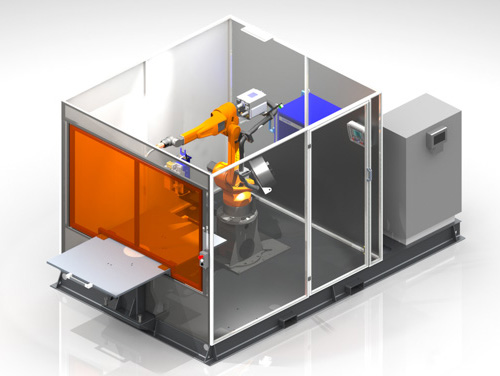

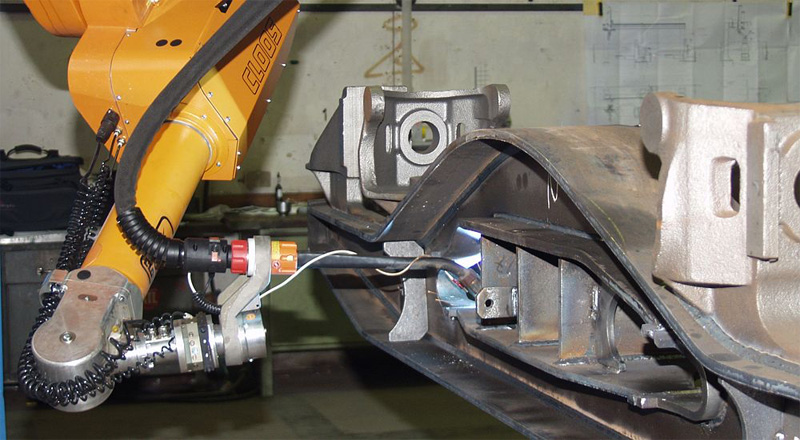

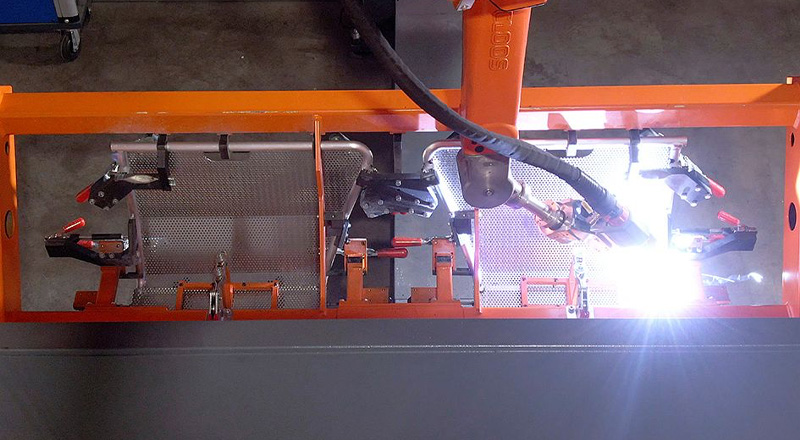

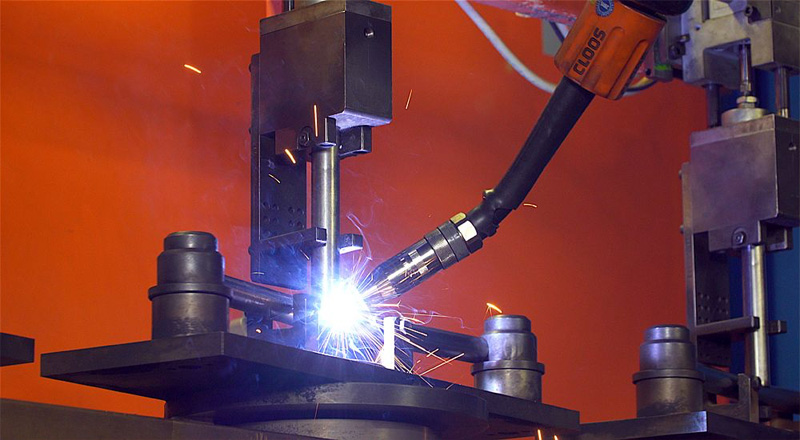

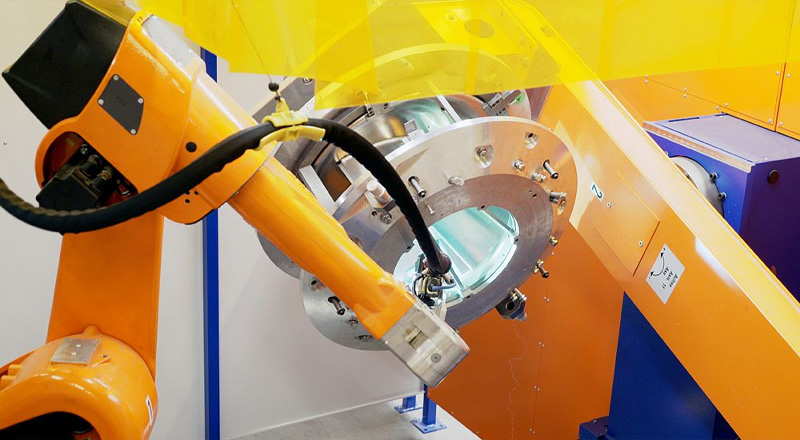

In the 2-station compact system a QIROX QRC-350-E welding robot welds different components. The large range of the seven-axis robot both simplifies and speeds up the welding of the partly complex workpieces. The robot is mounted in overhead position on a C-frame at a floor-mounted linear track. A carriage moves the robot in horizontal direction.

Bieber Industrie SAS

-

- Component: Machine Base Frame

- Processes: Speed Weld

- Material: Steel

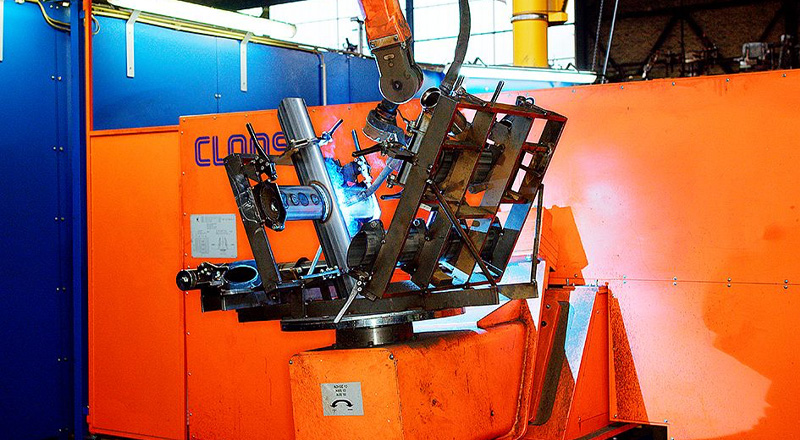

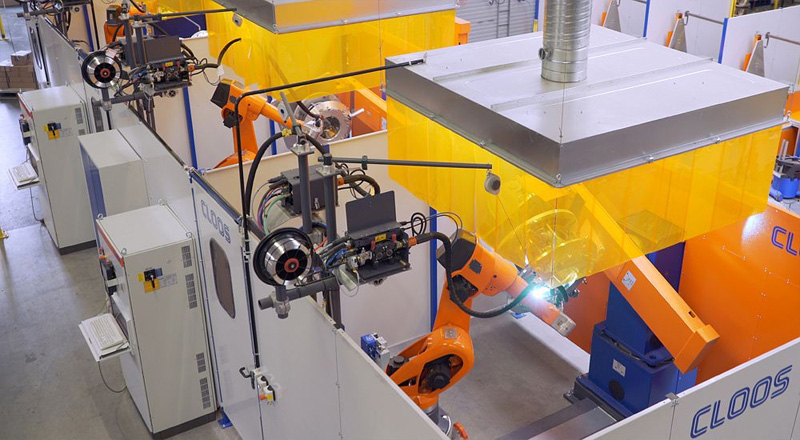

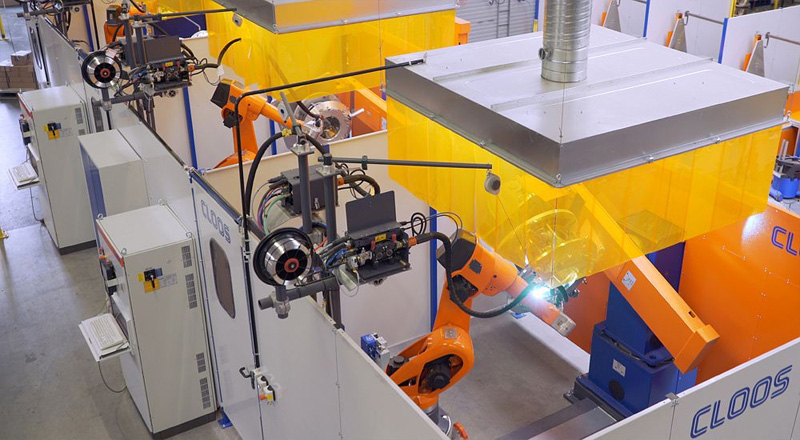

Bieber trusts in flexible high-tech welding robots

As a contract manufacturer for international market leaders in various industries, Bieber Industrie has relied on welding technology from CLOOS for more than 20 years. The latest system from 2019 now welds the complete grate trough for waste incineration systems. The QIROX QRC-350 robot is mounted here in overhead position on a linear track with vertical and horizontal stroke. The workpiece positioners bring the component into the perfect position for welding. It has a horizontal swivelling axis with an L-shaped extension arm. The extension arm contains a vertical rotary axis with a faceplate which serves for holding the workpiece. The robot is fitted with a torch changing system. This allows the use of different welding processes – depending on the application. In addition, the robot system is equipped with an arc sensor to compensate for any component tolerances.

Glüpker Blechtechnologie GmbH

-

- Component: Chassis

- Processes: Vari Weld

- Material: Steel

Two-station robot system at Glüpker

Glüpker Blechtechnologie welds components for commercial vehicles with a two-station robot system by CLOOS. The two QIROX welding robots are mounted overhead on a C-shaped frame. Both robots are equipped with a seventh axis. The large range simplifies and accelerates the welding of the complex workpieces. The system also includes a 2-station workpiece positioner with vertical change and vertical rotation with counter bearing. The workpiece can be turned into the optimum processing position by a horizontal turning axis. The counter bearing stabilises even long workpieces during welding. The station change is made by a vertical rotation. Due to the two-station design, robot welding in one station and loading of the components in the other station is simultaneously possible.

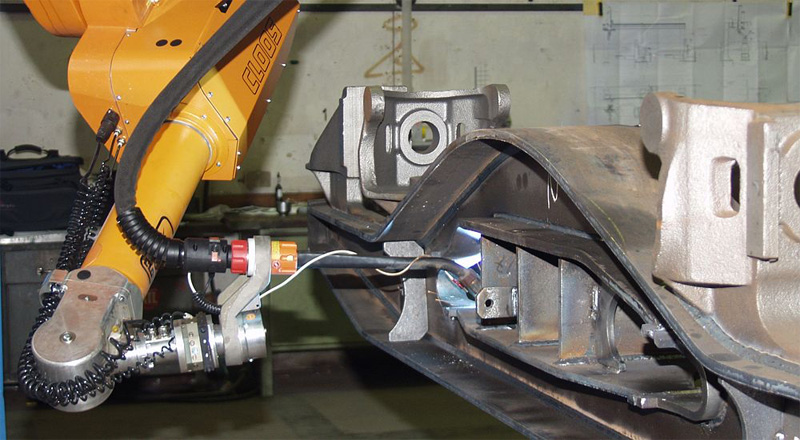

Tatravogonka

-

- Component: Bogie

- Processes: Tandem Weld

- Material: Steel

Two-station robot system reduces the production times

Many of the modern 4-axes goods wagons on two-axis Y bogies travel on rails all over Europe. Container wagons, wagons to transport coils, tanks and gas containers etc., almost everything travels on Y bogies. The automation of the welding processes considerably reduces the production times. At the same time high-quality weld seams are achieved. The two-station robot system always swivels and turns the bogie frame into a perfect welding position. An overhead-mounted linear track with vertical stroke enlarges the robot working range and allows the change between the two welding stations.

Kuhn S.A.

-

- Component: Discs for Mowers

- Processes: Vari Weld

- Material: Steel

Kuhn trusts in the new QIROX QRH-280-6 welding robot

Compact, quick and highly dynamic: For more than 30 years Kuhn S.A. has trusted in the automated welding technology of CLOOS. At its French headquarters in Saverne, the agricultural machinery specialist recently put the new QIROX QRH-280 welding robot from CLOOS into operation. As the heart of a CLOOS compact cell, the new robot has been welding different small parts for the Kuhn agricultural machines since summer 2015. The new welding robot attracts attention because of its compact design which saves production area on one hand and guarantees a very good accessibility to fixtures. The welding robot is also particularly fast and dynamic, In total, Kuhn was able to reduce the cycle times for welding the small parts for agricultural machines by 15 percent.

AGCO Fendt GmbH

-

- Component: Safety cabs

- Material: Steel

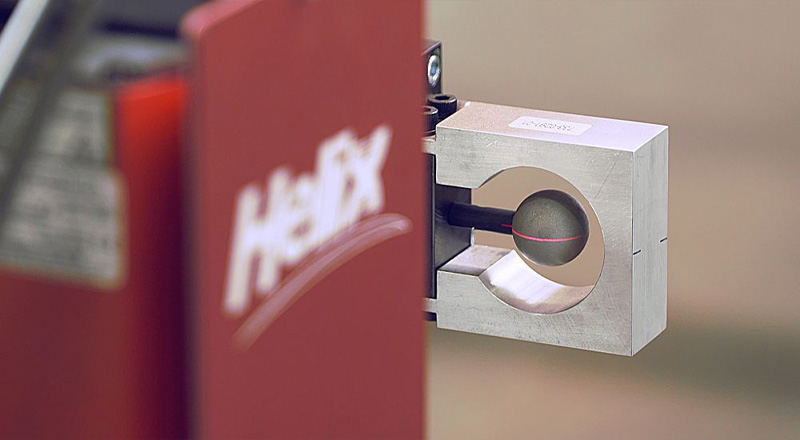

Quality test with QIROX robot at AGCO Fendt

CLOOS robots are not only used for welding tractor cabs at AGCO Fendt. In the test cell, fully welded tractor cabs from the new line are measured in 3D and tested for tolerances. The heart is a CLOOS QIROX QRC-410 welding robot which is mounted on a base and equipped with modern sensor technology by Perceptron. During the testing process, the robot moves to defined points on the cab and measures them. The software displays precisely which points are being measured and whether the individual points are within the permitted tolerance. which are only sent for further processing after successfully passing the inspection.

muli cycles GmbH

-

- Component: Bicycle frame

- Processes: Motion Control Weld

- Material: Steel

QIROX robot welds compact cargo bikes

For welding cargo bikes, muli-cycles in Cologne relies on an automated solution by CLOOS. Thanks to the flexible design of the system and the use of different welding processes such as MoTion Weld and Vari Weld, the robot can weld different steel and aluminium components with consistently high quality. The robot system consists of two opposite welding stations, each of which has a horizontal swivelling axis with an L-shaped extension arm. The counter bearing stabilises even long workpieces during welding. The station change is made by a horizontal rotation. Because of the 2-station arrangement, the machines can be loaded mutually. The heart of the system is the QIROX QRC-350-E robot. The 6-axis articulated arm robot has an excenter axis 7 which is integrated between robot base and centre point of axis 1. The seventh axis extends the working range for optimal positioning of the welding torch.

Kohl & Sohn Rheinisches Press- und Ziehwerk GmbH

-

- Component: Cover

- Material: Steel

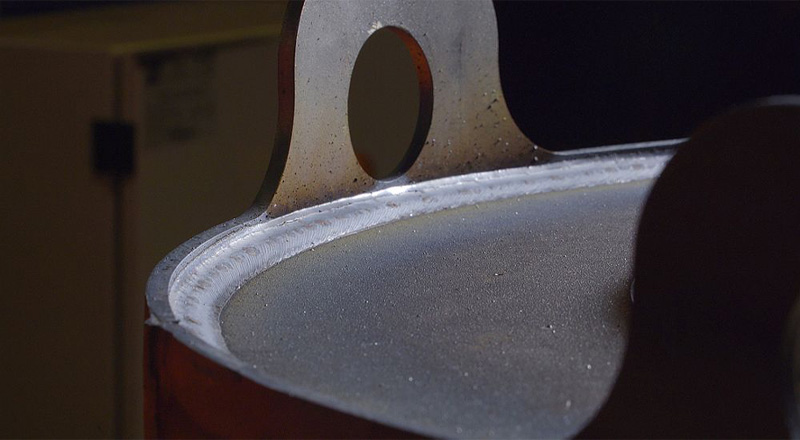

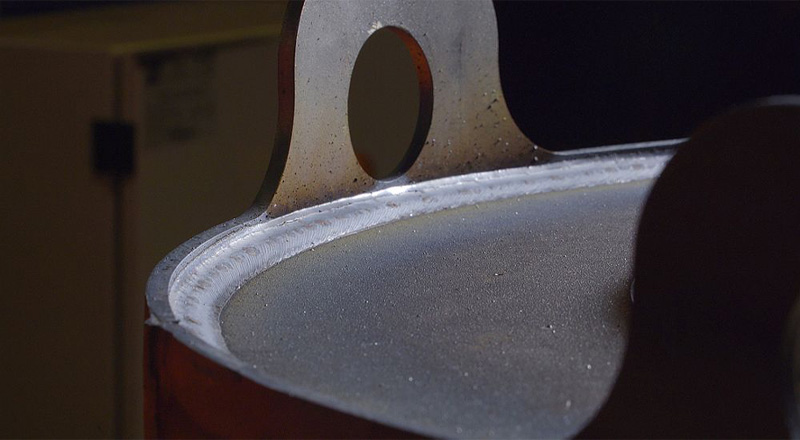

Automated grinding of battery covers

For the production of battery covers of forklifts, Kohl & Sohn relies on automation solutions by CLOOS. After the automated welding process, the components are ground roughly and finely on a 2-station system. By switching to automated grinding, Kohl & Sohn benefits in particular from the reliable and reproducible quality. The robot is equipped with a tool changing system for maximum flexibility. So different grinding applications can be used depending on the application. The abrasive media are exchanged quickly, easily and automatically in a changing station. The CLOOS Grind Control Interface GCI 1.0 allows simple and intuitive control of contact pressure, rotational speed and feed and extensive diagnostics possibilities.

Henan Junton Vehicle Co., Ltd.

-

- Component: Gear Box

- Processes: Speed Weld

- Material: Steel

Chained system with automated storage system

The industrial vehicle specialist Henan Junton Vehicle welds crane supports and smaller rotating towers with a highly complex chained system. The system consists of four QIROX QRC-410-E welding robots and a storage system. The fixtures are manually loaded. Then the employee scans the bar code at the fixture and it is temporarily stored in the storage system. As soon as the appropriate welding robot is available, a carriage placed on a floor-mounted linear track gets the workpiece and takes it to the welding station. After welding, the carriage picks up the workpiece again and temporarily stores it for cooling down. When the component is cold, it is automatically brought to the unloading station. After unloading, the empty fixture is transported back to the temporary storage. Due to the automated logistics solutions, errors because of a wrong component allocation can be avoided completely. Thus Junton saves much time, space and costs. Furthermore, the cycle times were considerably reduced.

H.K. Heun GmbH

-

- Component: Water Tank

- Processes: TIG Weld

- Material: Chrome-nickel

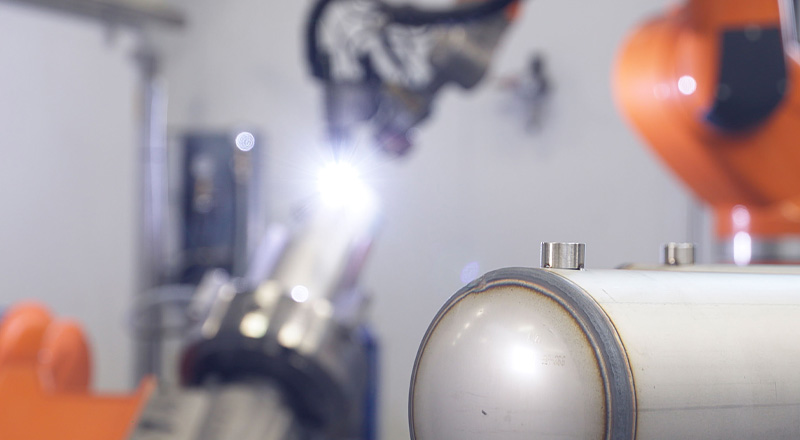

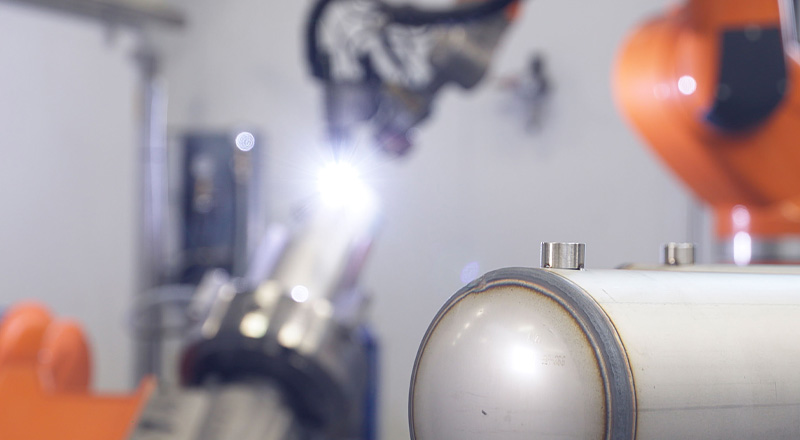

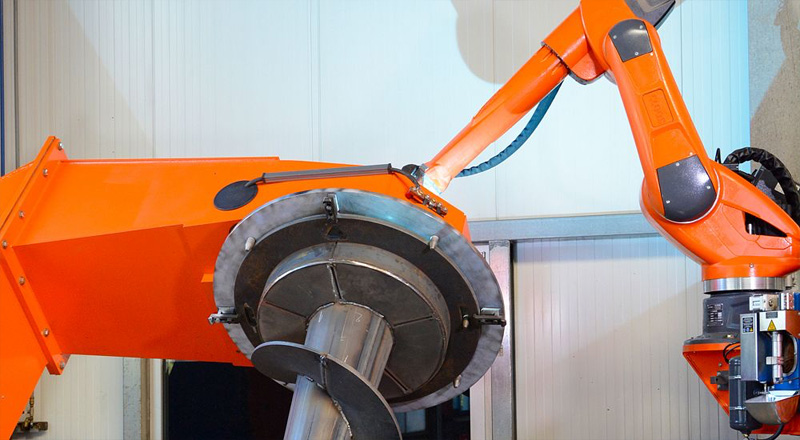

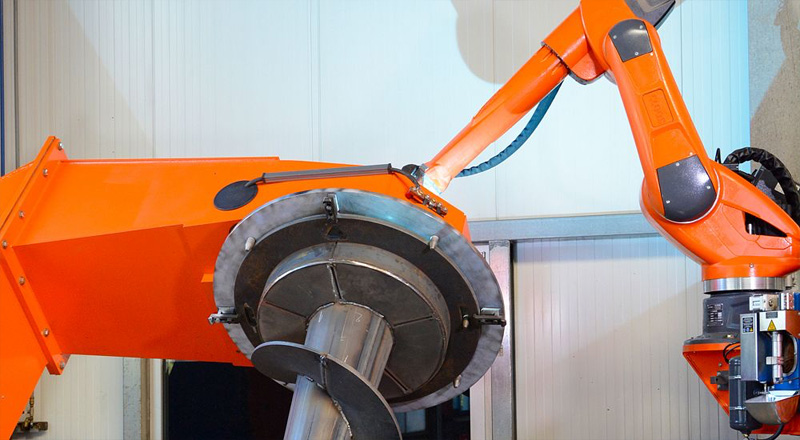

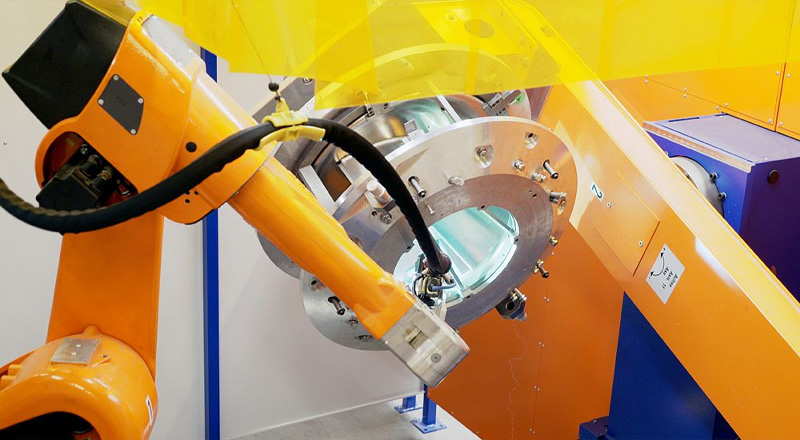

TIG Welding robot for tank construction at Heun

The Heun group has trusted in the CLOOS welding technology for decades. This QIROX robot welds circular welds for tank containers using the precise and clean TIG process. Due to the change from manual to automated welding, the company is now able to produce higher quantities within a shorter time. In the past, it took 25 minutes to weld the tank containers manually. Today the robot only needs 12 minutes to weld the same component using the TIG weld process. Apart from the quicker welding time and the reduced production costs the component quality could be further increased due to the exactly reproducible welding results.

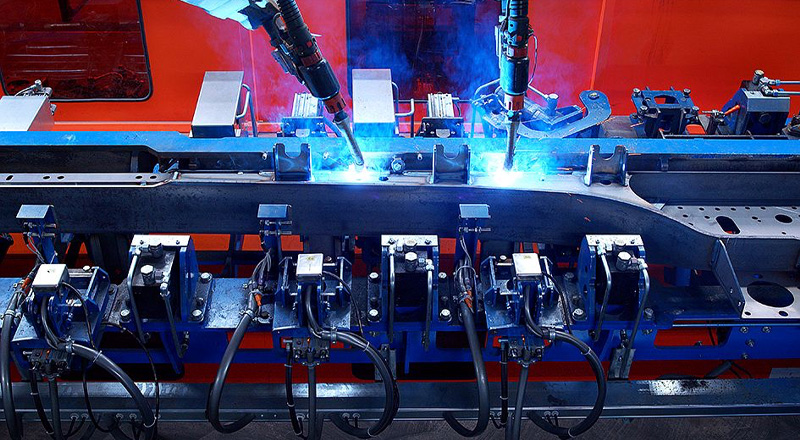

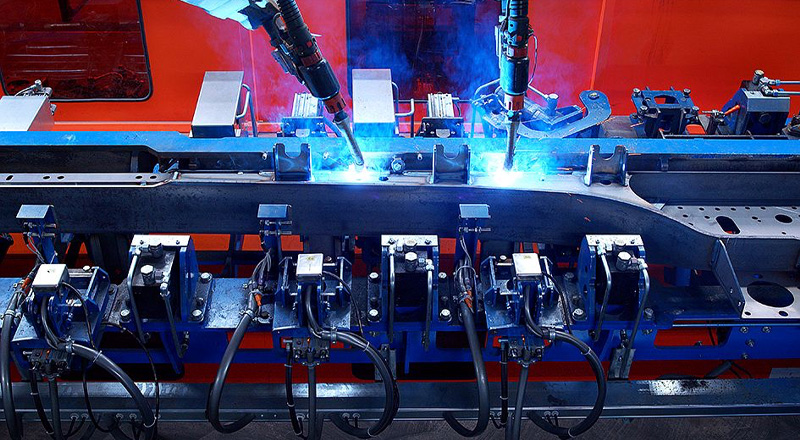

Albert-Frankenthal GmbH

-

- Component: Rollers for Printing Machines

- Processes: Speed Weld, Tandem Weld

- Material: Steel

CLOOS robot welding system for efficiency and flexibility at Albert-Frankenthal

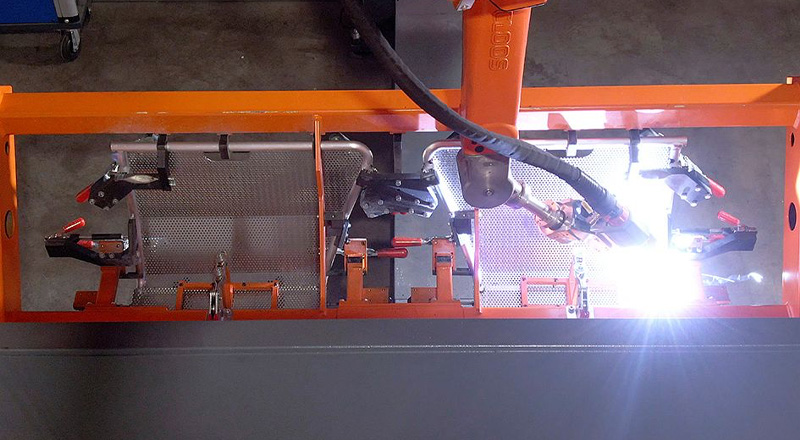

The CLOOS robot system consists of two stations: Whilst the robots at one station weld the workpiece, the person on the other side removes the welded parts and loads the devices again. The two QRC-350 welding robots are mounted overhead to a vertical stroke and can be moved on 12 m gantry from one side to the other. Thus the robots can weld either together at one station or parallel at both station which increases the system flexibility enormously. Small batch sizes or bigger series, the system can weld different roller types up to a workpiece length of 4.0 m. The welding robots are fitted with two welding torches: Whilst the bent single wire torch is used for welding small, segmented and difficult-to-reach welds, the straight tandem torch can perform long straight welds at high speed.

Puky Co. KG

-

- Component: Bicycle handlebar

- Processes: Vari Weld

- Material: Steel

QIROX robots weld frames for children's vehicles by Puky

Puky has always represented "unique safety" in children's vehicles. In the case of welding, the company has trusted in technologies by CLOOS for many decades. Recently, Puky put two new QR-CC-6 compact cells by CLOOS into operation At this system the QIROX robots weld frames for the children's bicycles. The use of the two new compact cells guarantee a high process reliability and an excellent product quality.

Halder Werkzeuge GmbH und Co. KG

-

- Component: Soft-Face Mallet

- Processes: Vari Weld

- Material: Steel

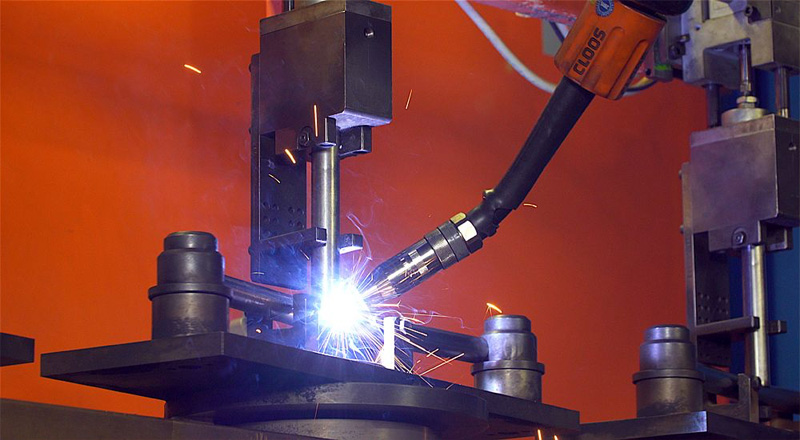

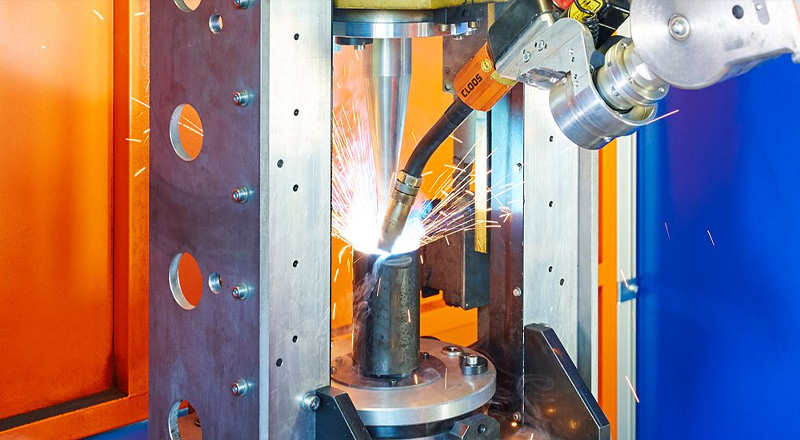

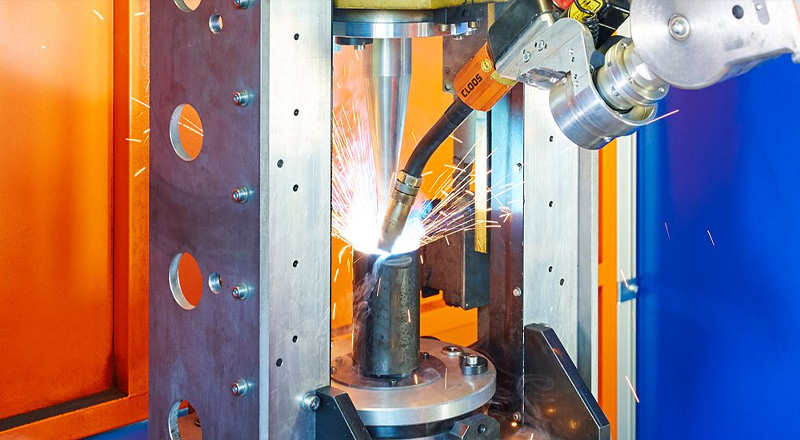

Compat robot cell for process safety and top quality at Halder

The Halder family company has been producing soft-faced hammers for over 75 years and is the world leader in this product segment. Recently, the Hidden Champion has automated the entire welding process for the soft-faced hammers made at the Baden-Württemberg site in Achstetten. The new, compact QIROX QR-CC-6 robot cell produced by CLOOS guarantees constant quality and reproducibility. It does not require much space and could be easily integrated into the production. From sensors to controller and safety technology the compact cell is a tailor-made unit with components which match each other optimally. The cell has a two-station positioner with turning/swivelling movement.

H+G Entsorgungssysteme

-

- Component: Machine housing for Omnivoes

- Processes: Vari Weld, Speed Weld

- Material: Steel

QIROX robot welds machine housings at H&G

For many decades Carl Cloos Schweisstechnik GmbH in Haiger and H&G Entsorgungssysteme GmbH in Burbach have maintained a trustful cooperation. The heart of the new CLOOS system for automated welding of screw compactors and machine housings for waste disposal systems is a 6-axes QIROX QRC-410 welding robot. The robot is mounted on a rotating vertical stroke and has a tactile arc sensor. The system consists of two stations which are equipped with a 1.5 ton workpiece positioner each. In one station the machine housings are welded, the screw compactors are welded in the other station. The new CLOOS robot system optimises the efficiency and the quality quality of the welding production.

Orion Bausysteme GmbH

-

- Component: bicycle parker

- Processes: Vari Weld, Speed Weld

- Material: Steel

QIROX robot ensures optimum welding quality at Orion Bausysteme

Due to the use of a compact welding robot system, Orion achieves optimum welding results at a reduced production time when welding bicycle parking systems and canopies. The heart of the new system is the QIROX QRC-410-E welding robot. The seventh axis considerably extends the working envelope of the robot and allows an optimum welding torch positioning. The 2-station WP-DH-TC-5 kN workpiece positioner with horizontal change and vertical rotation with counter bearing consists of two opposition stations. The two-station design allows robot welding in one station and loading of the components in the other station. By using the automated welding technology, the company achieves precisely reproducible welding results and an excellent product quality.

Zhenghou Coal Mining

-

- Component: Link for Hydraulic Roof Suport

- Processes: Speed Weld

- Material: Steel

Robots increase productivity at Zhengzhou Coal Mining

Increasing demands for productivity and quality in combination with rising wages and a lack of well-trained specialists present new challenges for China’s industrial companies. That is why the Zhengzhou Coal Mining Machinery Group Ltd. has commissioned 25 automated welding systems from Carl Cloos Schweisstechnik GmbH in the last 5 years. By investing in the modern robot welding systems, Zhengzhou Coal Mining was able to speed up the production processes overall by more than 50 percent and at the same time achieve exactly reproducible results.

Stahl- und Metallbau Ihnen GmbH & Co.KG

-

- Component: Platform

- Processes: Speed Weld

- Material: Steel

7-axis robot facilitates and accelerates the welding process at Ihnen

Ihnen Stahl- und Metallbau GmbH realises demanding steel construction projects all over the world. The robot system welds big components - in this case platforms for wind energy converters - with a weight of up 5 tons and a length of 7.5 meters. The 7-axis welding robot has a large working envelope. This facilitates and accelerates the welding of the complex components because the robot can be easily guided around corners or into niches.

Viessmann Werke Berlin GmbH

-

- Component: Heating Boiler

- Processes: Rapid Pulse Weld, Vari Weld, Speed Weld

- Material: Heat-resistant steel

CLOOS - Innovative Innovative welding and handling technology at Viessmann

The Viessmann Group relies on innovative production technologies worldwide. At its Berlin site, a new robot system from CLOOS not only carries out welding, it also handles the boilers. — the positioner grips and clamps the boiler automatically to bring the workpiece into the optimum position for welding, loading and unloading. When one side has been fully welded, the positioner rotates the boiler automatically to weld the other side. The new system can flexibly process a range of boiler types. Since the boilers are automatically rotated directly in the system and the component tolerances are automatically compensated for during the welding process, the set-up and cycle times — and thus also the production costs — are also reduced considerably.

gym80 International GmbH

-

- Component: Fitness equipment

- Processes: Vari Weld, Speed Weld

- Material: Steel

QIROX robots weld fitness equipment

Quality and durability - these are the hallmarks of gym80 International GmbH's strength training, fitness, medical and performance equipment. The top manufacturer has relied on the welding robot systems of CLOOS for more than 20 years. In 2003, gym80 started automated welding production with two robot systems from CLOOS. Today, various components are welded with a total of eight QIROX compact systems. By using automated welding technology, gym80 has been able to significantly increase the number of pieces produced in recent years. Several components can be welded with each compact system. As a result, gym80 can now manufacture a much wider range of products while at the same time reacting more quickly and flexibly to individual customer requirements. In addition, the automated welding technology ensures excellent product quality, as the robots achieve precisely reproducible results.

LTI-Metalltechnik GmbH

-

- Component: Fan

- Processes: Cold Weld

- Material: Aluminium

Chained robot system with intelligent shuttle solution at LTI Metalltechnik

LTI Metalltechnik relies on a chained CLOOS robot system for welding fan wheels. The system has four loading and unloading stations in addition to three welding stations. An intelligent shuttle system connects the individual stations with each other. Via a magnetic code on the jig, the shuttle can identify the correct welding station for the component during loading. The three welding cells each have a workpiece positioner with rotating and swivel movement to bring the component into the optimum welding position. The new robot ssystem has enabled LTI to double its welding speed in the production of fan wheels. There are additional time savings due to the fully automatic workpiece handling. Furthermore, the robots ensure maximum process reliability

Individual solutions from CLOOS

Steel construction

Systems Engineering

Commercial vehicles

Railway vehicles

Agricultural machines

Automotive industry

Industrial vehicles

Construction machinery

Aviation industry

Mechanical engineering

Metal construction

Containers

Construction suppliers

Mining

Production of energy

Heating and air-conditioning technology

Furniture industry

Electrical industry

CLOOS Welding processes

-

Increased efficiency due to modern processes

Process diversity in perfection - With a large range of proven and innovative welding processes we offer solutions for the future.

Control Weld - Through thick and thin

-

The Control Weld process covers the whole range of controlled MIG/MAG welding and is suitable for different applications. The classic MIG/MAG process offers a stable metal transfer from short arc to spray arc. At low power a short arc forms which is particularly advantageous when joining thin components and out-of-position welds. With regard to spray arc, this process has more energy and there is more heat input in the base material. There are only few spatters due to the small, short-circuit proof metal transfer which also results in less rework.

MoTion Vari Weld - Excellent welding quality at fine plates

-

MoTion Vari Weld is particularly suitable for fine plate applications and applications in the lowest capacity ranges. The welding process provides advantages everywhere where special demands to weld surface and appearance are made. MoTion Vari Weld is a combination of the proven CLOOS Vari Weld process and reversing wire. In the process, the wire is drawn back and forward at a frequency of up to 180 Hz which results in an extremely high process stability to the lowest capacity range. You avoid extensive reworks due to the minimised formation of spatters and powder residues. Due to these characteristics MoTion Weld is particularly suitable for applications in the additive production.

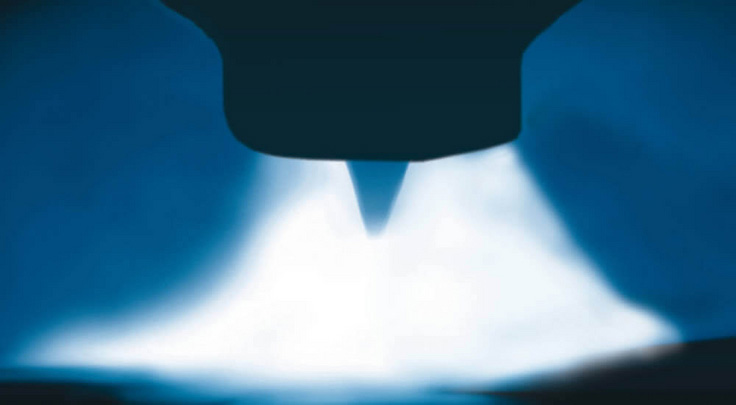

Speed Weld - Pulsed arc process for rapid welding

-

Speed Weld is used in all sectors of metal machining. The voltage-controlled MIG/MAG pulsed arc process allows a very high arc pressure even under demanding conditions. With Speed Weld you achieve high welding speeds because of the highly powerful arc. You benefit from the excellent weld quality due to the deep penetration. You avoid extensive reworks as spatters and undercuts are reduced to a minimum.

Vari Weld - for aluminium welding and MIG brazing

-

Vari Weld is a MIG/MAG pulsed arc for a very wide range of applications. The current-controlled MIG/MAG pulsed arc process allows controlling the penetration profile at a multitude of materials and applications. The material characteristics remain nearly unchanged, particularly in the case of heat-sensitive materials. You avoid extensive reworks as spatters are reduced to a minimum. So you achieve optimum welding results even under demanding conditions.

Fine Weld - Finest weld seams for excellent quality

-

Fine Weld is an energy-reduced, current-controlled MSG short arc process for mixed gas and CO2 welding. Due to the minimised spatter formation, Fine Weld is suitable particularly for thin, coated plates and fine visible weld seams. The stable arc is characterised by an optimum gap-bridging ability and can be mastered excellently in all welding positions. With Fine Weld, the lowest possible current flows in an arc phase before a drop short circuit occurs. When the liquid wire end comes into contact with the molten pool, a molten bridge should form as free as possible. For this purpose, the current is reduced even further for a short time. The short-circuit current which is then significantly increased to generate the pinch effect is very quickly reduced to low values again shortly before the short circuit is resolved, i.e. before the molten bridge is separated. As a result, the power in the newly ignited arc is kept low and the molten pool remains quieter due to the lower arc pressure. A short, uncritical current pulse afterwards ensures optimum drop formation at the end of the wire. With Fine Weld, you reduce the workpiece distortion through the controllable heat input. You avoid extensive reworks due to the minimised spatter formation.

Rapid Weld - That's what efficiency looks like!

-

Rapid Weld is a focused high-capacity MIG/MAG spray arc and provides advantages wherever high penetration depths and a safe root fusion are required. The special control generates a very focused stable arc with a very high arc pressure. The one-knob-operation allows you to specifically model the penetration profile from small to wide. Due to the very small opening angle you reduce filler material and shielded gas. You obtain complete fusions due to the deep penetration. You reduce the welding time as considerably less welding layers are necessary.

Rapid Pulse Weld - Save with high pressure

-

Rapid Pulse Weld is a focused high-capacity MIG/MAG pulsed arc, and provides advantages wherever high penetration depths and a safe root fusion are required. Especially for manual applications, the pulse control ensures a high arc pressure even in the case of stickout changes. The one-knob-operation allows you to specifically model the penetration profile from small to wide. Due to the very small opening angle you reduce filler material and shielded gas. You obtain complete fusions due to the deep penetration. You reduce the welding time as considerably less welding layers are necessary.

Cold Weld - Welding with minimum heat input

-

Due to the optimum heat input, Cold Weld is perfectly suitable for demanding materials. Cold Weld combines a pulsed arc arc with AC technology. Due to the adjustable AC part you can individually control the heat input into the component. With Cold Weld you can get higher welding speed as you increase the deposition rate at a lower heat input. The optimum heat input has a positive effect on the component and material characteristics. You keep the original material properties because of the minimised heat input. You reduce the component distortion and avoid extensive reworks. You compensate material tolerances due to the good gap bridging ability.

Tandem Weld - Powerful welding times two

-

Tandem Weld can be universally applied either for thin or for thick plate welding. In the Tandem Weld process, two arcs burn in a common molten pool. The process is based on two electrically separated processes which match each other perfectly. This possibility opens up a multitude of combinations. The front wire ensures a safe penetration, the back wire quickly fills big joints with filler material. The high deposition rate can result in both weld speed and volume filling. Therefore, Tandem weld is suitable for thin and for thick plates. With Tandem Weld you reduce your welding times due to the high deposition rate. You reduce the component distortion and avoid extensive reworks thanks to the low heat input. You compensate material tolerances due to the good gap bridging ability. You benefit from the wide range of applications as Tandem Weld can be used for many materials and thicknesses.

Grinding – Maximum efficiency for your production processes

-

In addition to welding technology, grinding and polishing are among the key machining operations in numerous industries and sectors. The applications are extremely diverse. Use also our solutions for automated grinding and polishing. The robots offer consistently high quality – even in 24/7 operation. You also benefit from shorter cycle times, minimised costs and increased productivity.

Choose from the wide range of customised grinding solutions that achieve an optimum surface quality with reliable force control and the necessary sensitivity. The constant contact force reduces abrasive consumption and noticeably reduces the cleaning effort thanks to the integrated extraction system. The innovative grinding systems are suitable for surface processing of almost all materials.

Laser Cut - Excellent cutting quality at extremely high speed

-

The Laser Cut process strongly restricts the arc and generates a small focussed spot with a very high energy density. This energy melts the material and due to the kinetic energy of an additional cutting gas the molten metal is removed out of the groove. Laser cutting is characterised by an excellent cutting quality, an extremely high cutting speed and a very good automation capability. Depending on the requirement different laser types with different characteristics can be used.

MoTion Control Weld - For fine plates and additive production

-

MoTion Control Weld is particularly suitable for fine plate applications and applications in the lowest capacity ranges. The welding process provides advantages everywhere where special demands to weld surface and appearance are made. MoTion Control Weld is a combination of the proven CLOOS Control Weld process and reversing wire. In the process, the wire is drawn back and forward at a frequency of up to 180 Hz which results in an extremely high process stability to the lowest capacity range. You avoid extensive reworks due to the minimised formation of spatters and powder residues. Due to these characteristics MoTion Weld is particularly suitable for applications in the additive production.

Root Weld - Stable and insensitive

-

Root Weld is an energy-reduced, controlled MIG/MAG short arc which is suited for the special requirements of root welding or thin plate welding. where out-of-position welds and varying gap widths often arise. Compared to the standard short arc, Root Weld is considerably quieter and produces less spatters.. Due to the improved process control, Root Weld is more stable and can thus be perfectly controlled even in the lower capacity range.. With Root Weld you reduce the workpiece distortion because of the lower heat input. You avoid extensive reworks due to the minimised spatter formation. You always achieve optimum welding results as the arc is resistant to external influences.

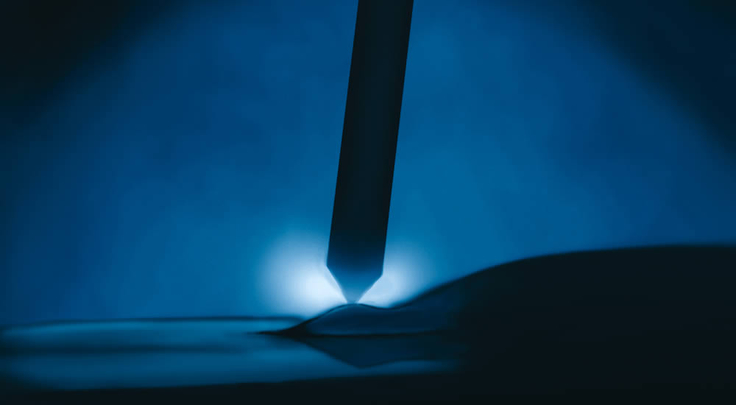

TIG Welding process – Clean, precise and reliable

-

TIG Weld is particularly suitable for demanding welding connections and is used in industry as well as in workshop and trade. Furthermore, the flexible process is the perfect choice for repair welding. During TIG Weld, the arc burns between the non-melting tungsten electrode and the workpiece. You can use either direct or alternate current in different variants. And you can use TIG Weld with or without filler material. The separation of the important parameters option allows the decoupling of the welding capacity from the filler metal supply. Thus, you can perfectly adapt the welding parameters to your individual welding task. A considerable increase of the welding speed is possible by using further process variants as for example high-frequency pulse. You avoid extensive reworks due to the high-quality, spatter-free weld seams. Do you wish a reliable welding process for excellent welding quality? Then rely on TIG Weld by CLOOS!

Laser Weld - High welding speed and excellent weld quality

-

Laser Weld provides advantages particularly in the case of sensitive materials. Laser Weld creates a restricted light beam characterised by a very high energy density. The energy melts the material and allows welding. With Laser Weld you increase your productivity due to highest welding speeds. You obtain high-quality welds thus improving the quality of your components due to the specific energy input in the base material. Do you wish a future-oriented process for maximum efficiency and quality? Then rely on Laser Weld by CLOOS!

Laser Hybrid Weld – As efficient as never before

-

Laser Hybrid Weld is perfectly suitable for long, straight weld seams. Laser Hybrid Weld combines a laser beam with a MIG/MAG welding process in one common process zone. You benefit from the advantages of both welding processes. A restricted light beam with focus on the weld is created which is characterised by a very high energy density. The laser beam penetrates the material deeply and forms a keyhole. The MIG/MAG arc following the laser stabilises the process, supports a perfect joining of the edges and improves the gap bridging ability. The main advantages of Laser Hybrid Weld are a deep penetration, low heat input and perfect side wall joints. With Laser Hybrid Weld you increase your productivity due to highest welding speeds. You need less filler material because of the reduced number of welding layers. You reduce the component distortion and avoid extensive reworks thanks to the low heat input. You accelerate your whole production process by means of the reduced weld preparation.

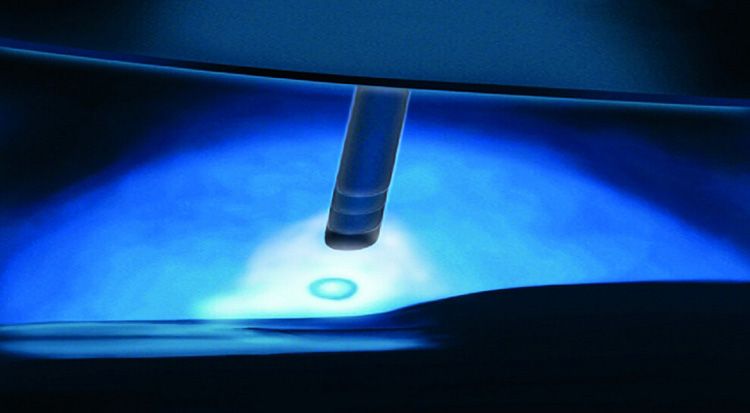

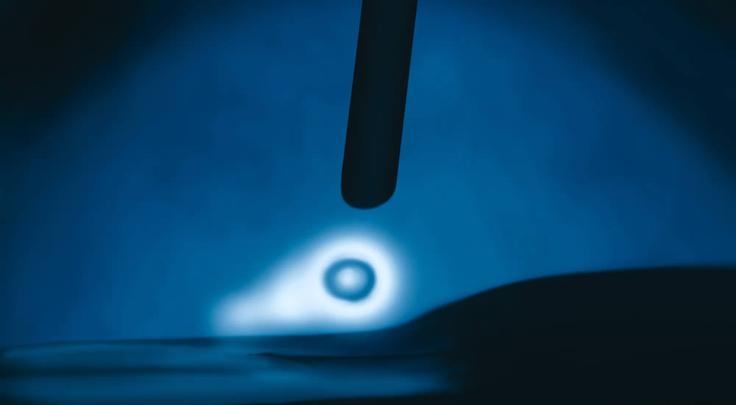

Plasma Cut - Perfectly suitable for robot applications

-

In the case of Plasma Cut the electric arc generates a plasma jet which is very restricted by a special nozzle and a focusing gas. Due to the high thermal arc energy and the high kinetic energy of the additional plasma gas the metal melts and is removed out of the cutting groove. The main advantage of this process is a very small heat-affected zone, a very good cutting quality and a high cutting speed. Due to the low heat input the component distortion is reduced to a minimum. The Plasma Cut process is perfectly suitable for automatio

Welding Products

QINEO – High-quality welding machines for manual and automated applications

-

QINEO, are the high-quality welding power sources by CLOOS which have been developed specifically for Commercial and industrial welding purposes. They meet every demand of manual and automated welding. Moreover, the modular QINEO system allows individual solutions which can be adapted to your specific production requirements and objectives. From capacity class to special equipment, each QINEO is customised and supplemented by a comprehensive accessories program and matching services.

Product Series

MIG/MAG | MIG/MAG Pulse | MIG/MAG AC | MIG Brazing | TIG Liftstart | TIG AC/DC | TIG DC QIROX – Automated welding and cutting with system

-

The system solution for automated welding and cutting: QIROX comprises all solutions for automated welding and cutting. Due to its modular design, the QIROX system allows scalable solutions which can perfectly match your production requirements. The QIROX system includes the robot technology, positioners, safety technology, software, sensors and the interface to the process technology. It is completed by an extensive range of options and complementary services.