OC Robotics

Videos

Loading the player ...

- Offer Profile

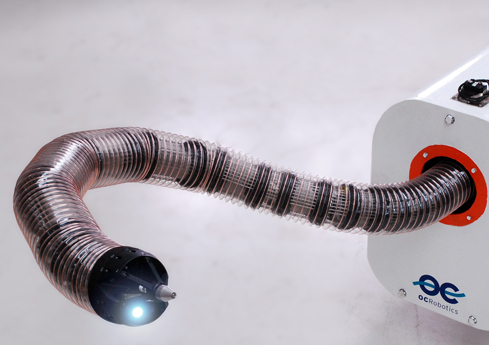

- OC Robotics are world leaders in confined space automation - our snake-arm robots are designed specifically for remote handling operations within confined or hazardous spaces. Where snake-arm robots excel is in their long, slender and flexible design; they can effortlessly fit through small openings and around obstacles. They do not have prominent elbows that potentially snag or cause damage to sensitive equipment and they are easily manoeuvred into position and retracted back without disturbing their environment.

Product Portfolio

Snake-arm Robots

-

Snake-arm robots are highly flexible robots ideal for working in confined and hazardous spaces.

Driven by wire ropes, and controlled by OC Robotics’ proprietary software, snake-arm robots are able to traverse cluttered environments and conduct activities such as inspection, fastening and cleaning when integrated with off-the-shelf or custom design tools.

Snake-arm robots are ideally suited for confined and hazardous applications, as the motors, electronics and control systems are situated outside of the environment, with only the arm itself being deployed into the work space.

Snake-arm robots are designed with a hollow core, allowing cabling, hoses and other equipment associated with the tool to be routed through the centre of the arm.

Spatial Snake-arm Robots

-

Spatial snake-arm robots are designed with two degrees of freedom at each joint, allowing the arm to 'snake' through the environment.

For applications where access is through a thick wall or ‘dead’ area, a rigid base link can be integrated with the arm – this not only improves the reach of the arm, but also maintains the articulated section for work inside the environment where its dexterity and flexibility are required.

Spatial arms are often mounted on linear introduction axes from which they are deployed. For hazardous environments, the snake-arm can be sleeved and pressurised, preventing dust and dirt from damaging the arm. The sleeve can also be used for radioactive environments to prevent the ingress of contamination.

OC Robotics has a standard suite of products which includes the Series II, X125 spatial snake-arm system.

Planar Snake-arm Robots

-

As well as spatial snake-arm robots, OC Robotics has also designed and developed planar snake-arm robots.

Planar snake-arm robots, as the name suggests, are only able to articulate in one plane. Planar snake-arm robots can be mounted on mobile vehicles or multi degree of freedom introduction axes allowing the arm to roll, yaw and pitch to provide the same coverage that could be achieved with a spatial arm.

The advantage of planar snake-arm robots is their ability to coil around the actuator pack, making them relatively compact. This makes them ideal for applications where space is limited, preventing the installation of a linear axis required for a spatial snake-arm.

Bespoke Solutions

Bespoke Solutions

-

Innovation is one of OC Robotics' key strengths. Our engineers have a wealth of experience & expertise designing and realising cutting-edge technology, providing our clients with complete bespoke solutions.

OC Robotics has developed bespoke tools for a wide range of applications, including inspection, remote handling, swaging and water-jet cleaning. We also work closely with tool experts, integrating their products with our robotic systems.

For some applications, the mobility of a robotic solution is key. OC Robotics has experience in the design and build of bespoke mobile vehicles and integration with off-the-shelf systems.

Series II, X125 System

Series II, X125 System

-

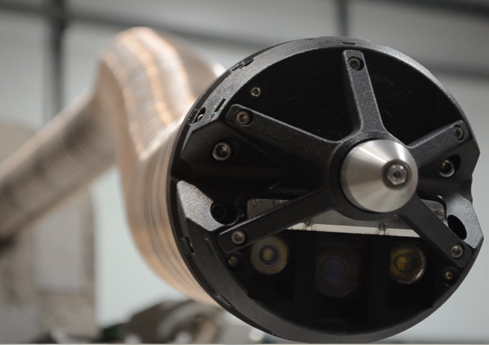

With 225 degrees of cumulative bend and an independently controlled tip, this highly flexible snake-arm robot can perform essential tasks in areas beyond human reach.

Increased Payload

Through an extensive process of research and development, the Series II, X125 snake-arm has increased payload capacity from previous snake-arm designs.

Range of Tools

A range of end effectors applicable to many different applications are available. These include cameras, lighting and high-pressure water-jet cleaning heads.

Protective Sleeve

The snake-arm robot can be sleeved, providing protection from harsh or contaminated environments, without restricting the robot's motion.

Easily Maintainable

With through life costs in mind, the system has been designed with easily serviceable and replaceable parts.

Proven Reliability

The snake-arm robot actuator packs have expected lifetimes of tens of thousands of hours, while the easily replaceable arms have been proven to have lifetimes in demanding industrial applications exceeding 4000 hours.

LaserSnake2

-

LaserSnake2 is a collaborative R&D project running from 2013 to 2016, combining robots and lasers to create safe, cost efficient tools for high-hazard confined spaces.

The project is led by OC Robotics, and includes TWI, the National Nuclear Laboratory, ULO Optics and Laser Optical Engineering as partners.

The project is part funded by Innovate UK, the Department for Energy and Climate Change, and the Nuclear Decommissioning Authority.