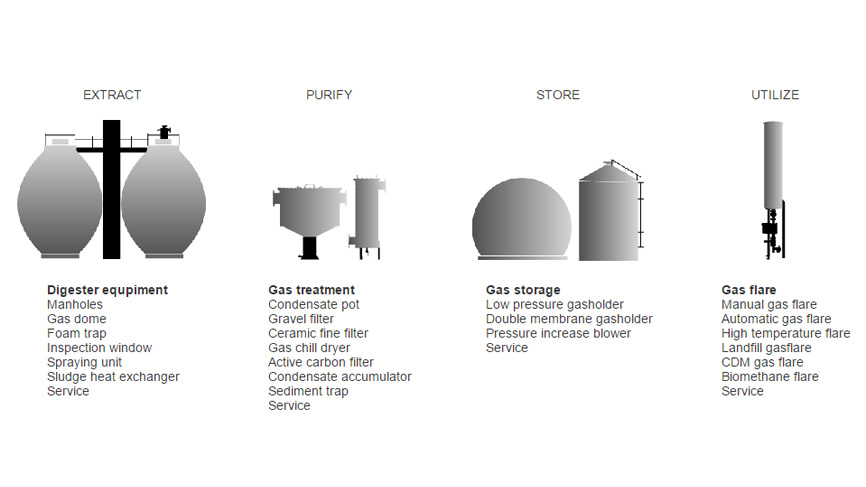

- Offer Profile

- ennox biogas technology

Manufacturer of gas technical components for bio, sewage and landfill gas plants.

Wherever gas is produced from biogas plants, landfills and sewage plants, cleaned or used, we stand ready to service our customers and build long term partnerships by delivering:- professional consulting services

- high-quality and ecological products

- rapid delivery

- comprehensive customer

- service and support

EXTRACT - Digester equpiment

Gas dome GAD

-

The gas dome or gas cover is used first and foremost as the basis for various attachments for digesters, i.e., foam traps, gas extraction units, safety devices, mixers, measurement units etc., and secondly as an access point into the digester. For both applications the gas dome should be adequately dimensioned in order to meet all requirements.

ennox gas domes comprise of a base unit with a single or multiple sealing collar joint, which is mounted hermetically tight into the concrete digester roof. The cover is then mounted to the base unit along with all required accessories.

Every gas dome can be configured according to the customer’s unique application requirements. We guarantee a thorough and professional consultation – from the technical specification through to the final design.

ennox gas domes are manufactured almost entirely from 1.4571 stainless steel; some add-on components may be manufactured from alternative materials such as gunmetal (red bronze) or black steel (generally aluminium or magnesium is forbidden).Highlights

- Best possible design according to customer requirements

- Diameter and sealing collar customisable

- Robust and maintenance free

- Manufactured from stainless steel

- Made in Austria

Options

- Height, diameter and design customisable

- Assembled components can be supplied

- Mixer flange upon request

Foam trap FDS

-

Foam traps on digesters serve for the visual recognition of foam build-up on the sludge surface.

Should foam be detected a spray film is generated through a spraying unit, which eliminates the foam on the surface of the sludge, thus, preventing the ingress of foam into the pipework.

ennox foam traps can be delivered either as a manual or fully automatic unit, as well as with an under/over pressure safety valve.

Manufactured entirely from 1.4571 stainless steel.Highlights

- Simple, maintenance free construction

- Reliable and safe foam recognition with inspection windows and light curtain (ATEX suitable)

- Including cleaning nozzles for the inspection windows

- Connection for under/over pressure valve available

- Manufactured entirely from 1.4571 stainless steel

- Made in Austria

Options

- Semi or full automatic

- Dust cover for sensors available upon request

Spraying unit PSD

-

The spraying unit serves to combat the accumuation of surface contaminants and buildups without opening the digester.

With a special nozzle in combination with the correct water pressure, a powerful water jet is generated, which, either completely destroys oating sludge or directs it towards an oating sludge door.

Manufactured from stainless steel, the ball joint from plastic.

Highlights

- Can be freely rotated or angled

- Including stainless steel nozzle and ball valve Robust and maintenance fre

- Manufactured entirely from stainless steel

- Made in Austria

Options

- Screwed or welded construction as required

- Selectable swingarm

- Water connection as required

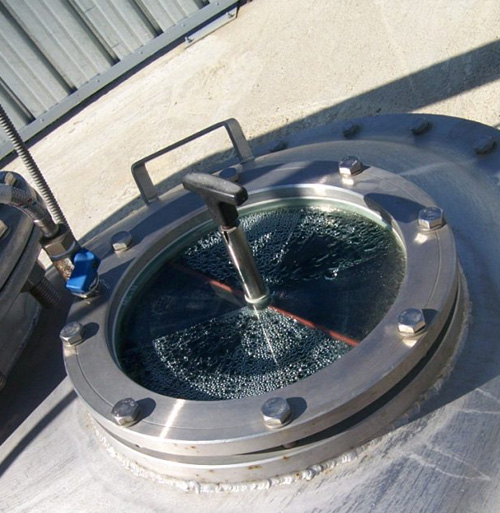

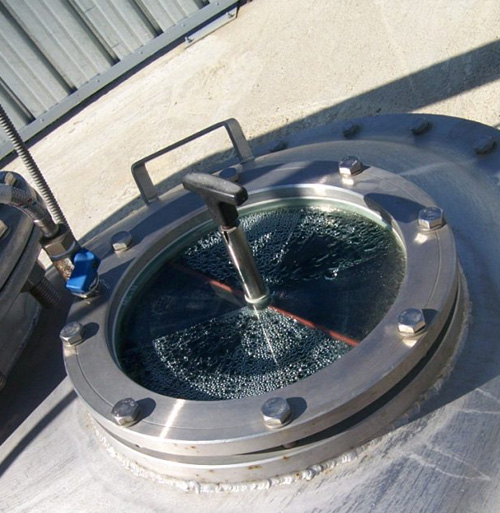

Manholes MHR, MHL and MHL2

-

Manholes in digesters, Biogas reactors or other concrete containers serve to allow unrestricted and safe access as also an entry point for materials and other components. They also serve as an inspection point which can be quickly opened and closed.

Manholes can be tted with sensor openings or other additional xtures for measurement components.

ennox manholes can be supplied in a variety of sizes and designs. ennox manholes are manufactured entirely from 1.4571 stainless steel. ennox provides you with the most modern designs for either lateral or top assembly:

Roof manhole MHR*

Manholes with a screwed cover and handle. The base unit is installed hermetically tight in the top of the digester, either directly cast (concrete reactor) or welded (steel digester).

An air tight seal between the lower part and the cover is achieved with an NBR o-ring seal.Highlights

- Simple, maintenance free design

- Simple operation with special connectors

- Operation using little effort with swing arm

- No dirt and contamination build-up due to convex form

- Digester pressure up to 4 bar, max. Temperature 100 °C

- Completely manufactured from 1.4571 stainless steel

- Made in Austria

Options

- Additional sleeves for the connection of sensors etc.

- Freely selectable frame size

- Frame matched to digester wall curvature

Inspection window IW

-

Inspection windows are used for the monitoring of the processes inside the digester without the need for opening.

ennox inspection windows can be installed laterally in the digester wall, on the roof, or built into the top face.

Accessories available upon request include covers, spraying units, lamps or cameras.

The windows are shatter-proof and extremely stable. The frame is manufactured from 1.4571 stainless steel.

Highlights

- Flexible implimentation due to multiple installation possibilities

- Robust and maintenance free

- Windows are shatter-proof and stable

- Manufactured entirely from 1.4571 stainless steel

- Made in Austria/Germany

Options

- Wide range of accessories including lamps, wipers, cameras and spray units

PURIFY - Gas Treatment

Active carbon filter carboNOX

-

Biogas can contain large quantities of poisonous hydrogen sulphide depending upon the fermentation process and which input materials are used. This gas can cause permanent damage to gas engines or other consumers of the biogas.

Depending on concentration, the majority of the hydrogen sulphide gas can be effectively removed by using an ennox active carbon filter.

We provide you with active carbon filters either as single or double units, according to the size of the system. The filters can be easily installed between the biogas reactor and the consumer. They are maintenance free and user friendly.

Depending upon the sulphur content, the content of hydrogen sulphide in the biogas can be removed to the detection threshold.Highlights

- Optimal removal of hydrogen sulphide and siloxane from the biogas

- Increase in efficiency of the biogas system

- Reduction of maintenance costs of the consumer

- TÜV certificate

- Cost saving and environmental use

- Low pressure drop, optimal suiting to actual operating conditions

- Simple design, maintenance free and user friendly

Options

- Used for the removal of unpleasant odours in emmissions

- Retrofitting of existing systems

- EEG Bonus for Formaldehyde removal

Ceramic fine filter CFP

-

Before the coarse filtered bio or sewage gas can be fed to the gas consumer it is normally passed through a ceramic fine fillter. Here the gas is passed through a ceramic or reclay unit with a pre-determined pore diameter.

Fine particles < 150 – 210 μm and condensate vapour are effectively removed. This eliminates any possible damage to components further on in the gas processing line.

A variety of filter materials and filter sizes can be provided to meet the exact requirements of the application.Highlights

- Simple, maintenance free design

- Low pressure loss

- Differential pressure indication with u-pipe gauge

- Easy access through screwed cover

- Removal of condensate water via siphon

- Manufactured entirely from 1.4571 stainless steel

- Made in Austria

Options

- Various filter materials according to the application

- Inlet and outlet connections for pressure gauges

- Use of an automatic condensate removal system

Condensate accumulator COA

-

The condensate accumulator is used for both the collection of condensate water within the gas system and for drainage.

Normally the condensate accumulator is integrated directly into the lowest point of the pipework by means of a flange connection. The condensate water flows into the collection container and is drained either through a ball valve, or automatically with a condensate drainage unit.

The condensate accumulator is available in two sizes, according to the requirements of the system.Highlights

- Simple, maintenance free design

- No pressure loss

- Drainage of condensate water either

manual or automatic - Manufactured entirely from 1.4571 stainless steel

- Made in Austria

Options

- Use of a condensate automatic drainage unit

- Inspection window or level indicator

Condensate pot COP

-

The condensate pot serves for the removal of condensate vapour or water occurring in the gas system.

The gas flows through the condensate pot where it is channelled within the pot through a separation chamber. The reduction in gas flow velocity and the influence of temperature fluctuations cause the water vapour in the gas to condense and collect at the bottom of the pot.

The condensate pot can be delivered in various sizes according to the capacity of the system.

Highlights

- Simple, maintenance free design

- Low pressure loss

- Easy access through screwed cover

- Removal of condensate through siphon

- Manufactured entirely from 1.4571 stainless steel

- Made in Austria

Options

- Additional bushings for sensors etc.

- Use of an automatic condensate removal system

- Inspection windows or level indicators possible

Gas chill dryer GCD

-

Biogas, sewage gas and land fill gas contains not only water vapour, but also a whole host of additional impurities such as hydrogen sulphide, NH3 and siloxane, which, when processed in the utilization system can not only lead to a reduction in efficiency, but also result in damage of the system.

The dehumidification of the gas before processing is a basic preliminary requirement in order to permit an efficient usage of the biogas and an investment in the sustainability of the utilization system. The gas engines are effectively protected and maintenance requirements considerably reduced.

With the ennox gas chill dryer the gas to be processed is passed through a heat exchanger where the cooled gas can expel any moisture which is then collected as condensate. The condensate can be removed either with a siphon or condensate pump.

According to the technical requirements of the installation a post-warming or an economical and ecological energy recovery system can be implemented into the system.

The gas chill dryer is available in various sizes and power ratings according to the requirements of the system.Highlights

- Optimal preparation of the biogas for processing

- Increase in efficiency of the biogas system

- Reduction of maintenance costs for the consumer

- Cost saving and environmental use

- Modular and compact design

- Low pressure drop, optimal specification for the operating conditions

Options

- Condensate removal with pump

- Installation of a post-heater, which uses the heat generated by the engine to heat the cooled gas sinking the relative humidity

- Heat recovery with the use of an integrated heat exchanger – energy saving

- Installation of a pre-cooling for reduction of the energy requirements and operating costs

Gravel filter GFR

-

The gravel filter enables the coarse filtration of the biogas by passing through a gravel layer. Foreign particles, foam and condensate are removed and channelled to a drainage point.

The filter can be easily accessed through a screwed cover for cleaning. Contamination can be easily removed without the need for opening the cover by rinsing with water.

The gravel filter is available for various volume flow rates and pressures.

As an option we provide accessories i.e., gravel removal flange or differential pressure gauge.Highlights

- Simple, maintenance free design

- Low pressure loss

- Easy access through screwed cover

- Automatic removal from condensate water

- Inlet and outlet connections for pressure gauges

- Manufactured entirely from 1.4571 stainless steel

- Made in Austria

Options

- Gravel removal opening through screwed ange

- Equipped with pressure gauges for differential pressure indication

- Rinse system with ball valve and spray nozzle

Sediment trap SET

-

The sediment trap removes sediment particles or condensate water which may accumulate in the gas system.

The contaminated and/or saturated gas is set into a spiral motion within the container by a special inlet nozzle.

The heavier particles and water collect on the side walls of the unit, where they then accumulate at the bottom of the container. Drainage can be achieved either manually or automatically.

The units are available in various sizes with accessories.Highlights

- Simple, maintenance free design

- Low pressure loss

- Easy access through screwed cover

- Removal of particles or condensate

water with ball valve tap - Manufactured entirely from 1.4571 stainless steel

- Made in Austria

Options

- Additional connections for sensors

- Siphon for drainage

- Assembly of rinse systems

- Inspection window or level indicator

STORE - Gas Storage

Low pressure gasholder NOXstore

-

For the temporary storage of bio or sewage gas in a zero pressure environment conforming to the technical norms (DVGW, ÖWAV, SUVA, safety regulations for agricultural biogas systems SWA…). The gas holders are available in various storage capacities ranging from 10 – 7,500m3.

The storage of the biogas/sewage gas is made in a cylindrical gas bag which is freely hung in a building or silo. The silo serves in this case as an effective supporting and protective construction. The outside surface of the silo can be powder coated in any colour specified by the customer.

The gas bag is manufactured from a high quality polyester membrane (non- flammable, fungus repellent and methane/UV resistant) utilizing the most modern frequency welding techniques.

We can provide, according to the most stringent safety requirements, various additional systems for level indication, hydraulic and mechanical pressure regulation, explosion proof measuring systems as well as pressure boosting stations.

ennox offers not only the design, construction and installation of the gas storage system, but also the subsequent on-going inspection and maintenance of the system by fully qualified and authorized personnel.Highlights

- Robust design with long lifetime

- Gas balloon can be replaced

- Short assembly time, low maintenance

- Equipped with hydraulic under/over pressure safety system as standard

- Existing buildings (concrete silos…) can be utilised

- Available in various sizes

Options

- Colour as per customer specification

- Various level measurement systems, ATEX if required

- Blower station EX Zone 1 available

- Additional mechanical over pressure device as an option

- Extensive range of accessories (condensate drain, gravel pot, measuring systems…)

- Maintenance and periodic service by fully trained and authorised personnel if required

Double membrane gasholder NOXstore DM

-

The double membrane gasholder is made up of two spherical shaped polymer membranes (other forms are also possible), lying one inside the other. The external membrane is maintained in a stable form with the use of an air blower. The external membrane then serves as protector for the inner membrane against the influence of environmental factors such as wind or snow.

The biogas is contained within the inside polymer membrane. The pressure generated by the blower is transferred evenly over the inside membrane. This maintains a constant system pressure within the biogas reactor.

Double membrane gasholders are available in various sizes, pressure classes and construction types. The design and specification of such systems is carried out according to the individual application requirementsHighlights

- Robust design with long lifetime

- Various storage forms and sizes up to approximately 5000 m3

- External membrane with inspection window

- Strong and resistant membrane material

- Short assembly time

- Supplied with hydraulic pressure maintaining valve as standard

Options

- Colour according to customer requirements

- External membrane can be customised (i.e., with Logo)

- Technical calculations and specification of the storage supporting construction

- Can suit various system pressures

- Various systems for level measurement, ATEX upon request

Pressure increase blower RAV

-

Digesters and biogas reactors are normally designed and built to cover relatively low system pressures due to cost implications. In order to carry out effective cleaning of the system, operation of a consumer or transfer of the biogas, it is necessary to increase the operating pressure in the pipework.

We supply our customers with radial ventilators for the increase in system pressure in biogas operations, either as an individual unit or as a complete blower station with all internal pipework and instrumentation.

The ventilators can be either directly driven or with equipped with a belt drive. They are suitable for ATEX zone 1. The flowrate can be infinitely adjusted by using an optional frequency inverter. The radial ventilators are suitable for flowrates up to 2000 m3/h and a pressure increase up to 160 mbar (or 320 mbar with a multi-phase system).Highlights

- Suitable for ATEX Ex- Zone 1

- Flat characteristic curves guarantee defined operating levels

- Robust design with long lifetime

- Low maintenance

- Available for various pressures and flowrates

Options

- Complete blower station with pipwork available • Blower with direct or belt drive

- Multi-phase upon request

- Flowrate regulation with frequency inverter

- Weather and acoustic protection covers

UTILIZ - Gas Flare

Automatic gas flare NOXmatic / NOXmatic NANO

-

The NOXmatic comprises the most up-to-date quality gas are technology ensuring the safe, efficient and environmentally friendly combustion of gases from landfill, bio and sewage gas systems.

Depending on the application parameters and the required combustion characteristics, the ares are supplied as either low or medium temperature units supplied with the required additional burner technology. For special requirements i.e., landfill gas application, the customer can implement our innovative and low emission NOXtor burner.

The NOXmatic are is equipped with its own programmable controller, resulting in all ignitions, monitoring and safety functions are carried out independently by the are. The complete control / monitoring system is housed in its own cabinet.

We deliver these systems worldwide with capacities ranging from 100 kW to 20 MW.Highlights

- Exceptional price/performance ratio

- Low acoustic and emissions according to TA-Luft 5.4.8.1a2

- Partially contained or contained combustion

- Fully automatic control, flame monitoring and ignition

- Certified armatures

- Incl. ATEX- deflagration security

- Operating range 1 : 3

- Manufactured entirely from stainless steel

- Made in Austria

Options

- Equipment for CDM applications

- Winter packet (frost protection for armatures)

- Multi level burner = wider operating range

- NOXtor for environmentally friendlier combustion

- Flame temperature monitoring

- Pressure control

- Large combustion chamber and are cap

- Own gas blower and accessories

- Spare parts set

Biomethane flare NOXmatic BM

-

The modern preparation of biogas to more efficient, use and transport friendlier biomethane becomes more and more popular.

During preparation of the biogas, removal of CO2 and other basic components of the gas resutls in a dramatic change of the gas specific Wobbe Index and therefore new requirements for specification of the flare burner.

ennox gas flares can be specially configured for the burning of biogas and biomethane. The fully customized burner technology and combustion chamber design guarantees an efficient and environmentally friendly combustion of the gas.

The complete ennox reange of accessories i.e, compressor station, temperature monitoring and winter packet can of course alse be used with the biomethane gas flare.Highlights

- Fully automatic, monitored gas are according to TA Luft

- Burner configuration for the combustion of biomethane and biogas

- Customer specific solutions

- Global experience with an international team

- Made in Austria

Options

- Gas cleaning equipment (condensate drain, various lters)

- Gas pressure boost blower, complete station upon request

- System specification and planning, supervision

Flares for pyrolysis gas, syngas and wood gas

-

In general the design for those flares is the same as for our standard flares. In accordance with the project-specific requirements (for example special gas composition, high gas temperatures or pollution) specific technical solutions and equipment are added. In principle all pyrolysis gas flares are individually customized, designed and calculated.

All syngas flares have an own supporting burner or pilot burner as well special burners respectively combustion chambers. According to the requirements of the project special flare control systems, safety devices and fitting equipment can be delivered.

High temperature flare NOXtreme

-

The high temperature are is the further developed NOXmatic are for the safe and low-emission combustion of land ll, bio or other special gases within a temperature range from 1000 – 1200 °C.

In this temperature range the oxidising gas com- ponents are fully processed, thus greatly reducing the formation of nitrogen oxides.

With a special burner technology and combustion chamber according to mass, the necessary “hot” zone is generated inside the combustion chamber, guaranteeing a high temperature combustion.

In addition, the NOXtreme and all components used from the NOXmatic are manufactured entirely from stainless steel. The air feed for combustion as well as the temperature control can be achieved fully automatically upon request.

NOXtreme gas ares are configured according to the individual requirements of the customer.Highlights

- High temperature combustion in the required temperature range for the complete processing of all oxidising components in the gas reducing the formation of nitrogen oxides (NOx)

- Combustion chamber outer lining from ceramic

- Fully customisable burner configuration

- Combustion chamber technology from specialists

- Fully automatic control, flame monitoring and ignition

- Made in Austria

Options

- Manual or automatic regulation of the combustion temperature

- Equipment for CDM applications

- Winter packet (frost protection for armatures)

- Multi-level burner = wider operating range

- Pressure control

- Own gas blower incl. accessories

- Spare parts set

Landfill gas cleaning and safe incineration

-

Every year, millions of tons of household garbage and other refuse are deposited in landfills around the world. Biochemical decomposition processes of organic bonds in these landfills produce up to 150 – 250 m³ of landfill gases per tonne of household garbage.

Due to a methane content of up to 60%, landfill gas ranks number six on the list of climate-disrupting methane producers worldwide, but it is also an important source of energy with enormous potential if used sensibly.

Up to a content level of approximately 40% methane, landfill gas may still be recovered usefully in modern block heating plants. The important factor in this case is an effective and project-specific pre-cleaning process for the gas.

We can help by providing you various gas cleaning systems, gas drying systems, and activated carbon filters, and pressure increasing stations. The components may be used as individual models or delivered as a complete system that is built into a container.

Landfill gas featuring less than 40% methane content is no longer sensible for use as energy and may be incinerated in an environmentally safe manner in special enclosed ennox high-temperature gas flare systems. Toxic and ozone-harming components of landfill gas are destroyed thermally in the process.

For temporary uses or when technologically possible, open landfill gas flares may also be used. We will provide you the right gas flare for any application including the correct incineration process!

ennox is one of the world’s leading providers in the area of preparation and recovery of landfill gas, and its excellent know-how, flexible and enthusiastic engineering and production team is always ready for new challenges.

Manual gas flare ECO

-

The low-price solution for the price-conscious farmer!

Robust and compact manual gas flare for burning off biogas at agricultural biogas plants. Perfect for smaller new plants and for retro fitting to existing biogas plants.

The operation of the eco gas are with a fermenter pressure of 3 mbar is possible although a minimum operating pressure of 10 mbar is always recommended. The eco gas flare ignites at the press of a button plus simultaneous actuation of the manual flap. To end the ring cycle, the manual flap is closed again. Eco 100 – 400 is supplied as a complete kit and can be quickly assembled on site according to the assembly instructions and installed. With appropriate preparation (foundations), the are is ready for use after 1 – 2h of construction. Expansion to automatic operation is possible – appropriate retro fitting kits are available at short notice.Highlights

- Outstanding price/performance ratio

- Robust construction and simple assembly on site

- Parts in contact with the gas are made of stainless steel 1.4571

- All other components are made of stainless steel 1.4301

- Incl. ignition transformer and electrode ignition battery ignition on request

- Incl. flame arrester, anchoring