- Offer Profile

- Steelhead Composites is a

world class advanced pressure vessel manufacturing company, based in the

heart of Golden Colorado (USA). Steelhead is dedicated to the manufacturing

of lightweight, high-strength vessels to be used for weight-sensitive energy

and fuel storage applications. Our specialties include lightweight bladder

accumulators, mobile CNG fuel storage and transport, gas bottles, aluminum

liners and accessories.

We also offer a full array of technical services in vessel design, metal spinforming, filament winding, prototyping and testing of custom high pressure vessel products.

HYDROGEN STORAGE

Hydrogen gas storage

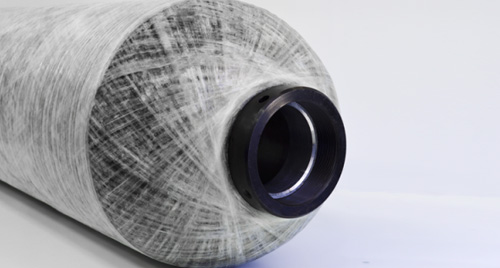

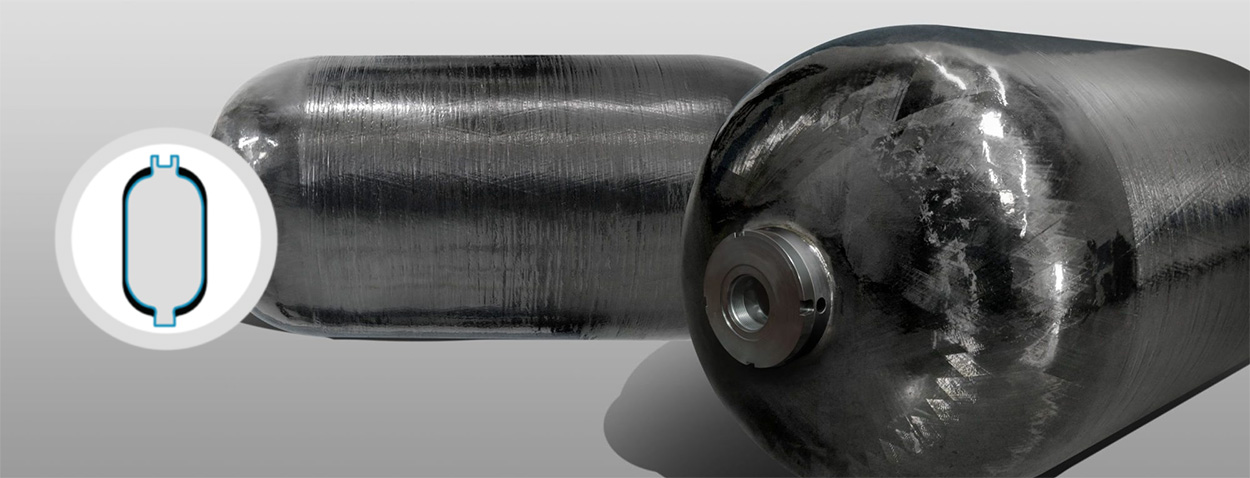

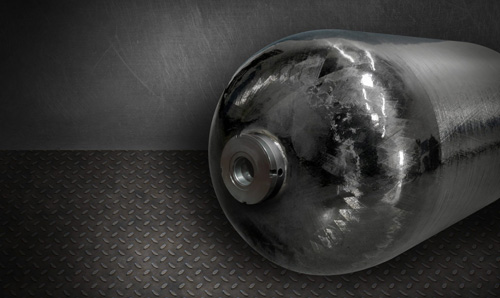

Steelhead Composites offers lightweight composite-overwrapped pressure vessels for high pressure hydrogen storage. Steelhead Composites’ Type 3 cylinders are made of robust, seamless aluminum liner completely over wrapped with durable epoxy-impregnated carbon fiber composite.

SUPERIOR STORAGE

Improved fast-fill due to great thermal heat capacity and conduction of Aluminum linerLOW PERMEATION

Metallic liner provides gas-tight containment of H2 gas with near zero permeationLEAK BEFORE BURST

All vessels are designed and tested to ensure that the Aluminum liner leaks under fatigue without causing catastrophic rupture- Weight optimized Type 3 Pressure Vessel

- Maximum Operating Pressure: 414 - 700 Bar

- Minimum Burst Pressure: 788 - 1575 Bar

- Safety: Benign leak-before-burst avoids catastrophic failure

- Liner: Seamless, impermeable 6061-T6 Aluminum

- Structural Shell: Carbon fiber and epoxy composite

- Protective Barrier: Glass fiber and epoxy composite

- High thermal conductivity and specific heat of Aluminum liner achieves a better fill capacity under fast-fill conditions

Hydraulic Accumulators

- Steelhead Composites offer lightweight, composite overwrapped hydraulic accumulators that are ideal for industries with weight-sensitive applications. These accumulators are one-third to one-quarter the weight of traditional steel accumulators, while offering the same functionality. The lightweight yet strong and durable construction of these accumulators results in high power density and the potential for much lower installation, maintenance and shipping costs.

BLADDER ACCUMULATORS

Bladder Accumulators are a family of compact, lightweight composite accumulators,

providing unmatched form and functionality for any weight-restricted applications where

mobility and strength are top priorities.

DIAPHRAGM ACCUMULATORS

-

The MicroForce series diaphragm accumulators are a family of compact, lightweight composite accumulators, providing unmatched form and functionality for any weight-restricted applications where mobility and strength are top priorities.

PISTON ACCUMULATOR

-

Steelhead’s patented piston accumulator combines the standard back-up bottle and piston accumulator into one unit, making the composite piston accumulator the lightest weight and most efficient piston accumulator product on the market.

Gas Cylinders

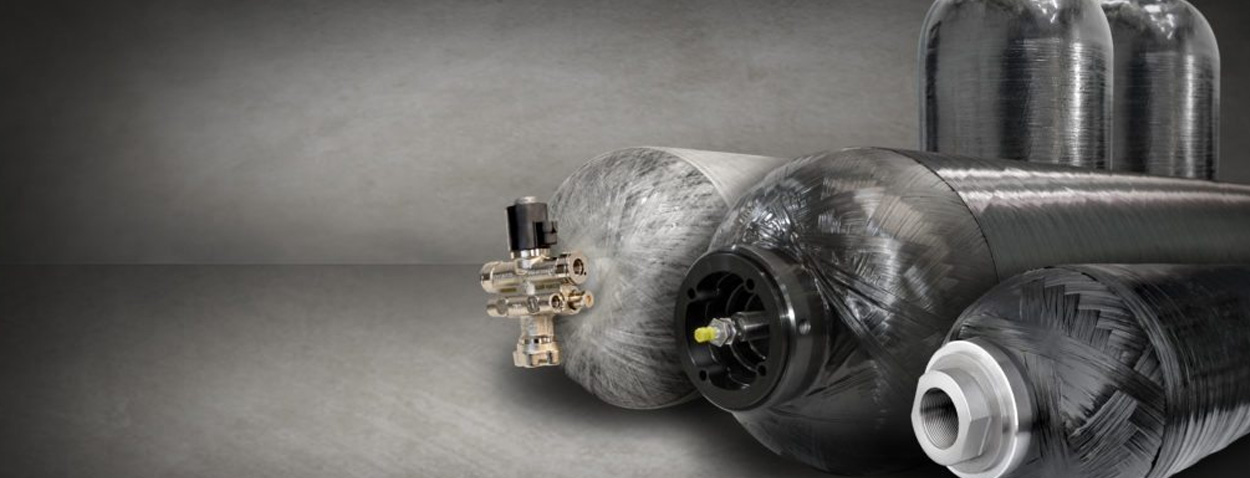

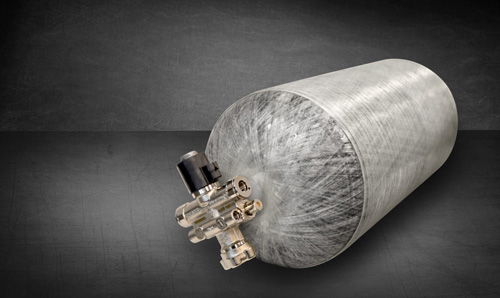

CNG Cylinders

- These small CNG Cylinders have been developed to fill the need for small commuter vehicles, luggage handlers, vehicles with under-chassis integration and customized enclosed-space application. Because of their construction using seamless aluminum liners, Steelhead Composites CNG cylinders can be counted on for being safe, gas-tight, robust and tough against impact and abuse. In addition, our cylinders can assure maximum fill capacity under fast fill conditions.

Gas Transport

-

Steelhead Composites compressed gas cylinders offer a variety of gas storage options perfect for many weight-sensitive and mobile applications. These lightweight composite cylinders can allow more economical transportation of compressed industrial gas and gaseous fuel from point A to point B.

Gas Back-Up Bottle

-

High capacity hydro-pneumatic accumulators that provide significant usable gas volume can be costly, heavy and difficult to manage. Gas charge cylinders storing gaseous Nitrogen typically are used to complement large accumulators and to improve their performance in the field. Lightweight composite cylinders can provide significant weight savings over traditional steel cylinders, especially critical to the off-shore and semi-submersible oil and gas platforms. Reduction in weight translates to transportation, operational and installation

cost savings as well.