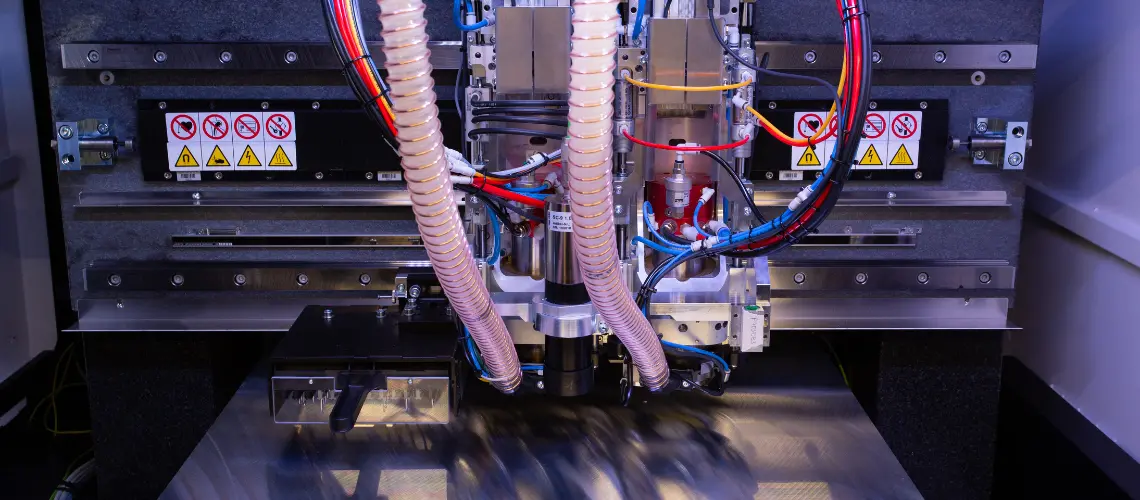

Mechanical Micromachining

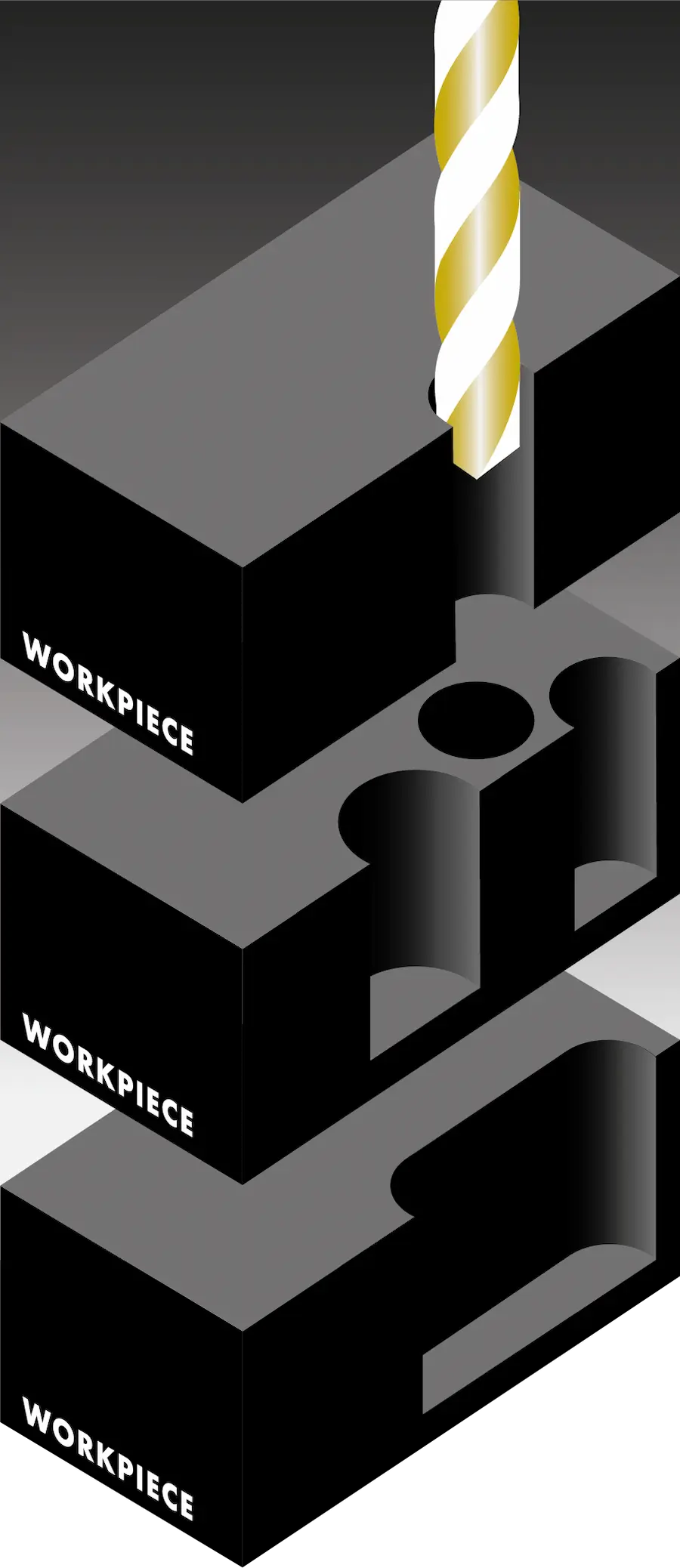

Mechanical μ-machining technology enables highly detailed shapes and removes material of a workpiece with miniature wearable tools.

Posalux high-tech 2.5D micromachining solutions are tailored for mass production and mainly dedicated to the electronics industry.

Function

Mechanical micromachining, commonly known as micromachining, is a specialized manufacturing technology that involves the use of micro tools, such as micro-endmills or drillbits, with geometrically defined cutting edges. This subtractive fabrication process crafts devices or features with dimensions in the micrometer range. It mirrors traditional machining in approach but operates on a distinctly smaller scale, necessitating specialized equipment and techniques to define microscale structures or components. Mechanical micromachining provides:

- Flexibility

- Cost-effective solution for small-batches

- Complex geometry

- Reduced waste

- Integration

- Scalability

- Direct production

Drilling and routing of composites and non-ferrous materials for printed circuit boards (PCB) industry

Test socket guide plates micro machining (drilling, milling cutting) for semiconductors testing industry

What material can be micro-machined with Mechanical Micromachining Technology?

Metal alloys

- Aluminium

- Brass

- Bronze

- Non ferrous metals

- Stainless steel

Precious metal

- Copper

- Palladium

- Titanium

- Tungsten carbide

- Irridium

Bio-metal

- Bio-compatible material

- Nitinol

Engineering plastics

- PEEK

- Polymers

- S1000

- Torlon

- Vespel

- PPS

- Miproplate

Ceramics

- Ceramics

- Hard ceramic

- Photoveel IIs

- Si3N4

- Silicone nitride

- Zirconia

- Silicone carbide

- SiC

Metal

- Hardened metal

- Hardened steel

- Steel

Multi substrates material

- IMS

- Metal baked

- PCB laminates

Composite Materials

- Delitt

- FR4

- FR5

What are the capabilities of Mechanical Micromachining Technology ?

- X, Y and Z axes with linear motor drives

- Controlled depth drilling and routing processes (blind holes, floating, mapping, polishing, etc.)

- Accuracy ±15 microns

- Axes acceleration up to 4g

- Diameter/depth ratio 1/10

- Up to 12 spindles per machine

- Up to 12’000 tools embedded

- Software with Posalux intuitive MMI

- Dual versions with two identical machining units are available

What is specific to the drilling operation?

- Blind hole to surface

- Backdrilling

- Prehole (Large diameters)

- Variable Pecking

- Adjustable slots

- Substrate drilling Ø<0.1 mm

What is specific to the routing operation?

- Pinless

- Cavity routing referred top surface to innerlayers

- Mapping

- IMS

ULTIMATE

ULTRASPEED

Let’s discuss your

µ-machining operations

If you are looking for a high-tech production system as well as a partner to process state-of-the-art micromachining, you are in the right place.

Discover more technologies

Electrical Discharge Machining - EDM

With the Electro-Erosion μ-machining - EDM technology, material is removed from a workpiece by current discharges between electrode and anode.

FEMTOsecond LASER

The FEMTOsecond LASER μ-machining technology consists of ultra-short pulses that hit the workpiece to vaporize a small amount of material.

.webp)

.webp)