Gas Dispersion Systems: Custom Designed, Engineered and Built

The Statiflo Gas Dispersion System (GDS) is a new concept for simultaneous mixing and mass transfer.

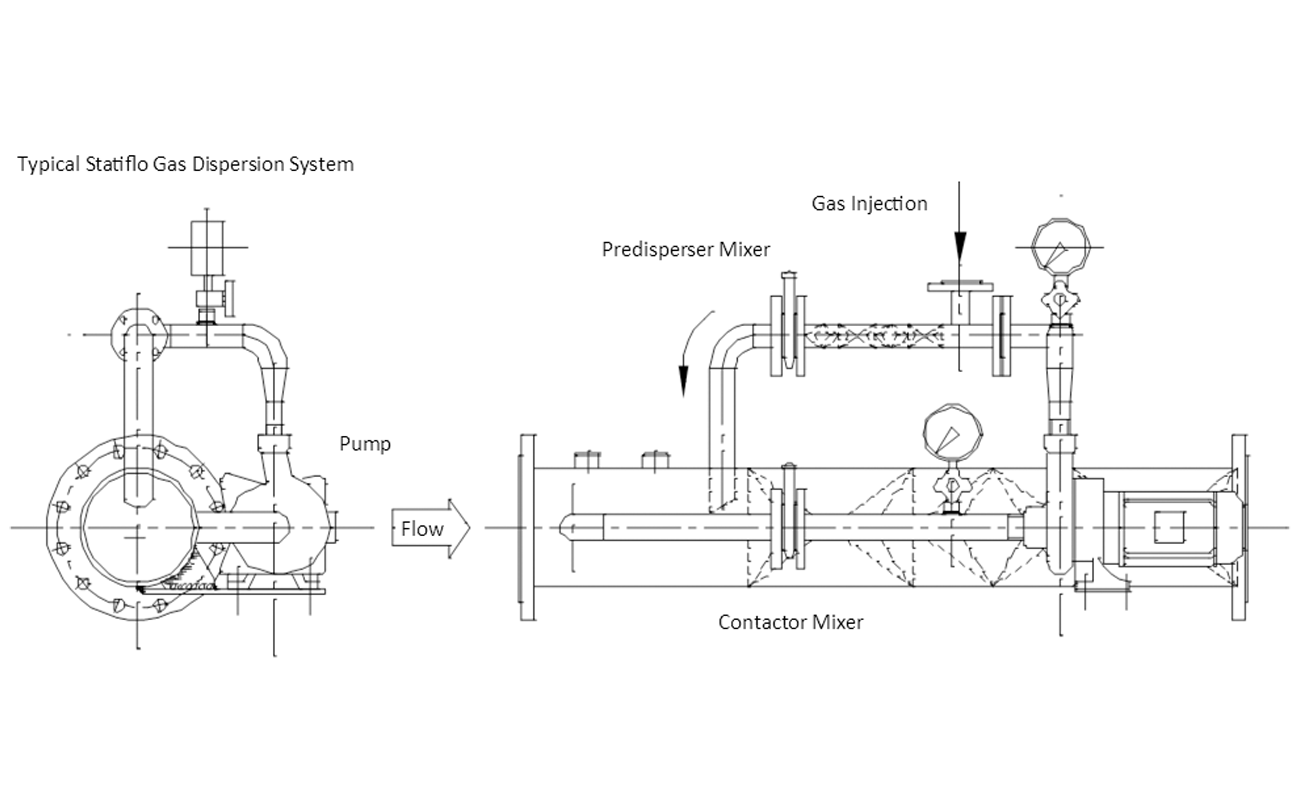

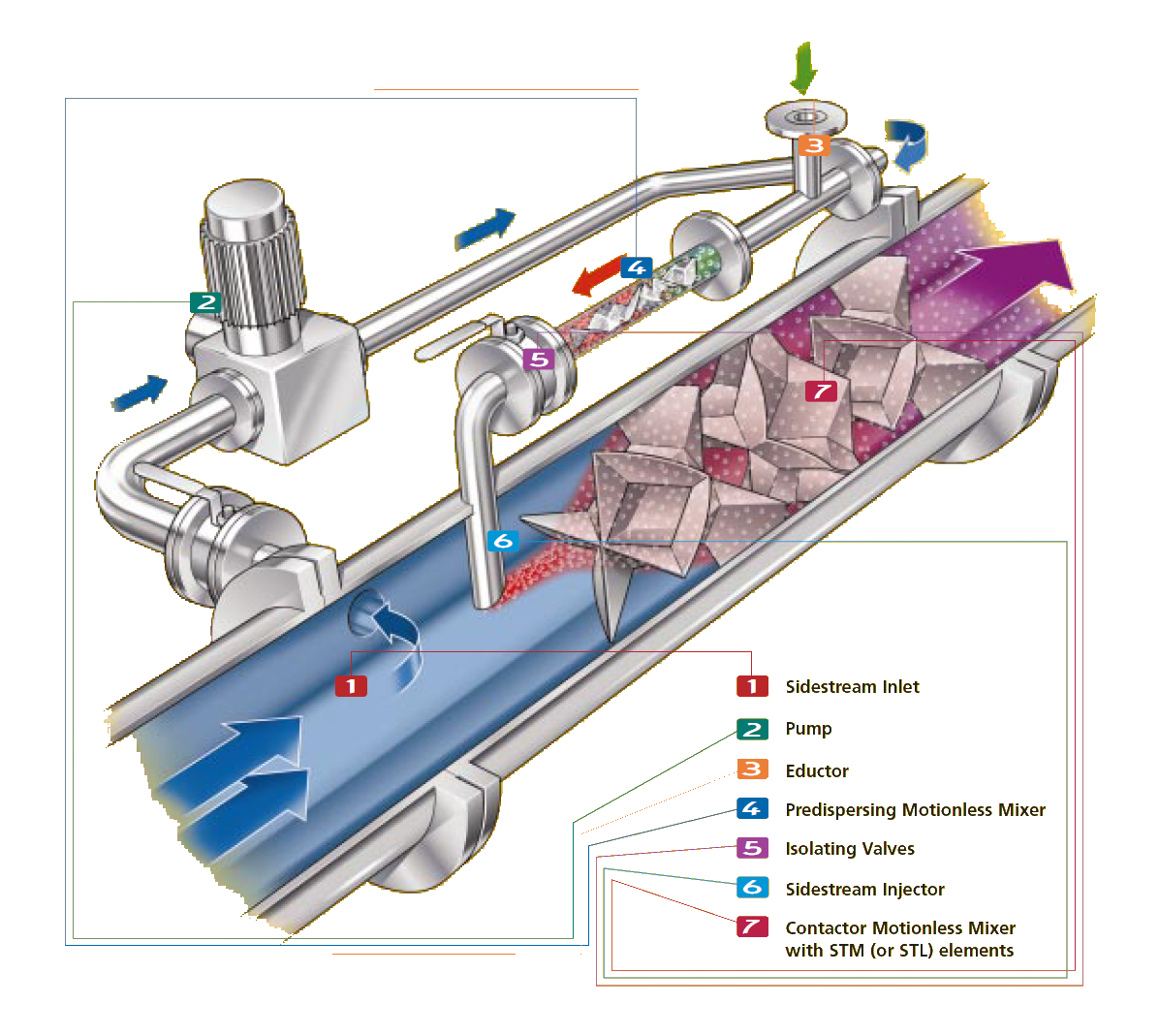

The Statiflo GDS is designed to overcome the difficulties associated with the use of a single static mixer. The system uses two different mixers, the first, in a sidestream, to form small gas bubbles and the second, in the main line to provide contact time and efficient mass transfer. As the gas bubbles are formed in a constant velocity sidestream, the gas bubble size is constant and independent of any variations in the main liquid flow.

The Statiflo GDS consists of:

- Main line mixer/contactor

- Sidestream equipment, including:

- Pre-disperser static mixer

- Gas eductor (if gas at low pressure)

- Centrifugal pump ( operating at constant flow rate)

- Sample point, valves, instrumentation, interconnecting pipework and stand-by equipment as required.

The sidestream gas/liquid dispersing equipment can be compactly side mounted directly on the contactor mixer or alternatively floor/skid mounted.

Typical applications include:

- Aeration of drinking water for iron, manganese and carbon dioxide removal

- Ozonation for disinfection of drinking water and waste water

- Ozonation for treatment of cooling tower water to disinfect and reduce scaling thereby offering better heat transfer efficiencies, lower blowdown volumes and decreased chemical usage.

- Ozonation for removal of disinfection byproducts (DBPs)

- Ozonation for removal of micro-pollutants such as pesticides

- Ozonation for odour and taste elimination

- Carbonation of mineral water

- BOD and COD reduction

Key benefits include:

- High mass transfer efficiency which does not decrease over time

- Low capital cost

- Low pressure drop

- Gas bubbles generated indepedently of liquid velocity in contactor

- Low energy consumption

- High turndown capability

- Compact design

- No moving parts except for centrifugal pump

- Minimal maintenance requirements

- Simple to operate with no special training required.

- Market-leading mixing element designs

Supplied with fixed STL elements (Series 600 contactor) or fixed STM elements (Series 650 contactor). Typically provided with a long element “pitch ratio” to increase contact time.

- Available for almost all pipe sizes

Diameters for the main line contractor from as small as DN200 (8″) with no theoretical upper limit. For the sidestream injection system, diameters as small as DN15 (1/2″) possible.

- Superior mass transfer achievable

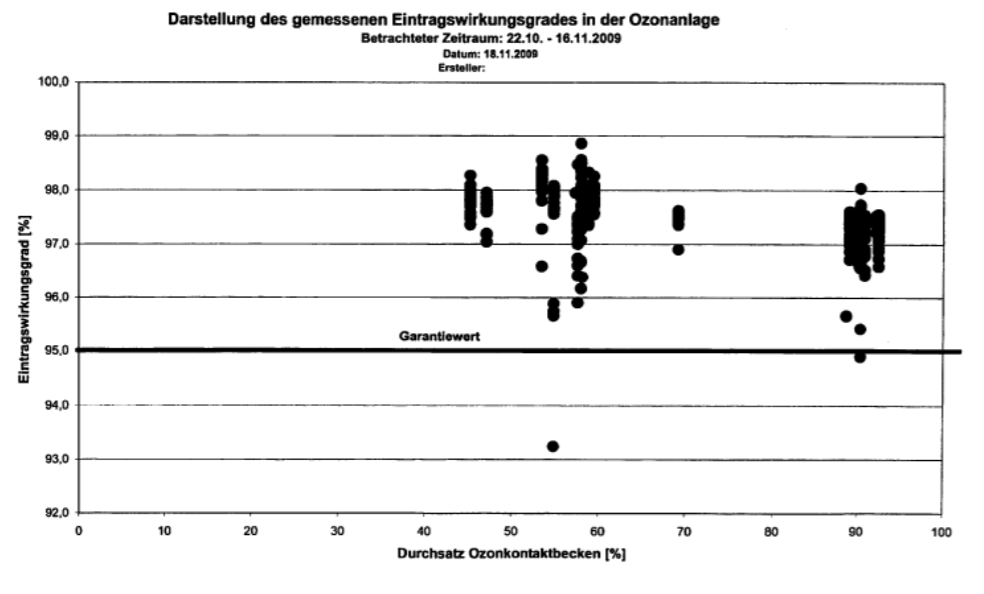

With the sidestream injection Static Mixer creating fine gas bubbles independent of variations in the mains flow, the highest levels of mass transfer efficiency between the gas and liquid phases are maintained across the entire flow range. Statiflo can guarantee a minimum mass transfer efficiency of 95%.

- Accessories to complement

Always supplied with take-off and reinjection connections on the main line. Sample points, valves, instrumentation, interconnecting pipework and stand-by equipment also supplied as required.

- Materials to suit your requirements

Generally supplied in 316L stainless steel but other commercially available materials can be supplied.

- Performance Guarantee

Every Statiflo Gas Dispersion System comes with guaranteed performance. Mass transfers of 95% minimum are guaranteed.

- Testing Standards

A full visual inspection is carried out on each unit before it leaves our premises, along with a dimensional check and any other testing which is required.

Optional tests available including hydrotest, radiography, magnetic particle inspection (MPI), Dye Penetrant Inspection (DPI), positive material identification (PMI) or ultrasonic testing (UT) are all available.

- Design Codes and Standards

Available design codes include ASME B31.3, ASME VIII div 1, AD2000 Merkblatt, PED2014/68/EU and many others to suit your requirements.

- Complete with Statiflo’s Standard Documentation Set

Your Static Inline Mixers will come complete with customised GA Drawing, 3.1 Material Certification, a Certificate of Conformity and one copy of our Installation, Operation and Maintenance Manual.

- Warranty Period

As standard, Statiflo offers a warranty of 12 months from plant commissioning or 18 months from equipment delivery, whichever is the sooner. Extended warranties can be supplied upon request.

- Spare Parts / Special Tools

The only moving part supplied with the Statiflo GDS is the centrifugal pump and stand-by units are available. Apart from the pump there are no moving parts so there is no requirement for expensive spares or special tools.

- Supervision for Installation and Commissioning

The ‘plug and play’ design means there is no requirement for supervision for installation or commissioning. The extremely simple installation is covered entirely by the Installation, Operation & Maintenance manual supplied with each order.

If you would feel more comfortable having guidance on-site, Statiflo can send one of our highly qualified engineers to guide and supervise the installation to give you the confidence that everything is done correctly.

Downloads

Mixer Sizing Questionnaires

Product Brochures

Application Notes

Gas dispersion system for the ozonation of drinking water

Gas Dispersion System: The inline dispersion of a gas in a large volume of liquid…

Case Study

Gas Dispersion Systems

Problem The inline dispersion of gases into large volumes of liquids is often performed using complex equipment, usually involving large…