TOPGEAR 630

TOPGEAR 630

TOPGEAR 630 is the perfect solution to jobsite plastic pipe cutting difficulties, where while safety remains one of the most important points, the cutting time is a key factor for productivity.

- CUT PRECISION

- SAFETY CONDITIONS

- OVILIZED PIPE CUTTING

- CUTTING CAPACITY PIPE WALL THICKNESS UP TO 80 mm

- USER FRIENDLY

Patent pending

With the aim of combining these two aspects Ritmo developed an innovative portable pipe saw for jobsite pipe cutting. Whatever the job-site...

APP - SET & GO! PRO

APP - SET & GO! PRO

"SET & GO PRO" a Professional application for smartphones and tablets (Android) that changes forever the way to work with the Ritmo Easy Life butt fusion machines.

"SET & GO PRO" Put together the ease of use, innovation and quality, in a system with the advantages of a CNC welding system, but reducing significantly the costs of it.

ADVANTAGES

It eliminates the expensive hardware of a data-logging and offer the highest quality at the lowest cost.

HOW DOES IT WORK?

Set-up the...

THE INSPECTOR

THE INSPECTOR

THE INSPECTOR - DATA LOGGING that controls, records and generates a PDF report of the entire welding process. The Inspector is an “open system” that can be used with Ritmo machines or others. The large graphic display allows an easy reading of welding reports. THE INSPECTOR is installed in a hard case made of PP, with protection degree IP 67. It is sold with a bag that contains the data logging and the battery charger with international adapters.

- Preloaded Major Welding Standard...

RID - internal debeader

RID - internal debeader

Internal Debeader by RITMO S.p.A. covering a range from Ø 90 up to 630 mm (3" IPS ÷ 24" IPS)

ADVANTAGES: Intuitive and easy to use, accurate, versatile, composed of few parts.

- Internal Debeader Head 90 - 110 mm

- Internal Debeader Head 125 - 160 mm

- Internal Debeader Head 160 - 200 mm

- Internal Debeader Head 225 - 315 mm

- Internal Debeader Head 355 - 500 mm

- Internal Debeader Head 560 - 630 mm

Internal Debeader Heand can be ordered separately too.

A complete kit set is...

RED - external debeader

RED - external debeader

RED - Ritmo External Debeader

Intuitive, Easy to use, Accurate, Versatile.

For pipes up to 1200 mm and sheets

External Debeader by RITMO S.p.A. covering a range from Ø 63 up to 1200 mm!

Designed to remove the external bead from a complete butt fusion welded joint.

The tool knocks onto the pipe bead, then alignment blocks slide against the pipe surface to guide it around the pipe

The blade cuts the under the bead and the handle helps pull the tool around the pipe, cutting the bead...

ROLLER 355

ROLLER 355

LIGHT - STRONG - ECONOMIC

This device is essential for supporting the pipes while they are being welded with the butt fusion machines.

The roller minimizes pipe friction and drag force independently of the jobsite conditions.

- ROLLER 355 can sustain pipes up to Ø 355 mm. (14” IPS).

Easy to use and light.

- ROLLER 355 can be used not only with HDPE, PP plastic pipes etc. but also with other materials such as rubber pipes, ferrous pipes etc. Mandatory requirement of smooth...

ROLLER 1000

ROLLER 1000

ROLLER 1000 is essential for supporting the pipes while they are being welded with the butt fusion machines.

The roller minimise pipe friction and drag force no matter which is the construction site condition.

- ROLLER 1000 which can sustain pipes from Ø 315 to 1000 mm. The structure is light weight, so it is easy to carry and use.

HS ROLLERS

HS ROLLERS

ROLLER HS, this device is essential for supporting the pipes while they are being welded with the butt fusion machines. The rollers minimise pipe friction and drag force no matter which is the construction site condition.

Special design for ALL TERRAIN and TRAILER LINE.

- HS ROLLER 250 which can sustain pipes up to Ø 250 mm 8" IPS

- HS ROLLER 355 with a working range up to Ø 355 mm 14” IPS

- HS ROLLER 630 with a working range up to Ø 630 mm 24” DIPS

- HS ROLLER 1000 with...

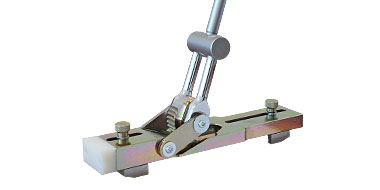

PIPE SUPPORT

PIPE SUPPORT

EASY TO USE

VERSATILE

UP TO Ø 400 mm; 1.5" ÷ 15,7"

With this practical piece of equipment, the pipe can be locked to let the operator carry out quickly and with precision all operations previous to the welding cycle, like cutting, pickling, scraping, etc. This support’s particular structure helps reach several inclination angles and heights, in order to better adapt to the requirements of the building site.

Locking takes place via a ratchet strap system, allowing safe and fast...