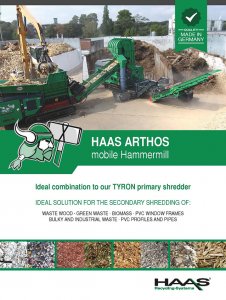

Mobile secondary shredding – resistant to impurities

The HAAS hammermill ARTHOS is resistant to impurities, so you will benefit from the best machine availability

ARTHOS moves forward effortlessly on tracks, even in the most difficult enviroments!

The popular hammermill is also available in a mobile version. On tracks, the machine for re-shredding pre-shredded material makes effortless progress even in the most difficult terrain!

Like the stationary version, this Viking is also equipped with the ballistic chute. Impurities, such as iron, non-ferrous material, etc., that enter the hammermill with the material are automatically separated. You do not have to stop the machine separately to remove the impurities, downtimes are thus significantly minimised and costs thereby reduced! Another highlight of the HAAS hammermill is the very simple screen exchange as the machine can be opened hydraulically. The operator has the possibility to change the screen basket within a very short time and thus to vary the size of the output material.

In combination with the TYRON pre-shredder, the ARTHOS thoroughly and quickly shreds wood waste, green waste, refuse derived fuels and PVC waste to < 30-150 mm at any location.

Range of application

- Waste wood shredded

- Plastics shredded

- Wood chips

Product advantages

- Resistant against impurities due to flexible swinging hammers.

- Ballistic chute – Impurities will be ejected automatically with the ballistic chute developed by HAAS!

- Easy screen change system – Screen exchange in shortest time due to hydr. openable screen basket.

- Effortless exchange of hammers and hammer shafts

- Special HAAS hammer and counter-knife combinations minimize the fine fraction.

- Sturdy construction - Downtimes will be minimized and costs reduced.

- Homogeneous end product and exposure of ferrous and non-ferrous parts like nails and staples

- Very quiet, even with high performance

- Low fuel consumption

Range of application

Capacity up to 55 t/h!

In combination with our TYRON shredder, the ARTHOS hammermill reduces coarse pre-shredded material to the required particle size. The duo thoroughly and quickly shreds waste wood, green waste, RDF and PVC waste to < 30 (fine) to 150 mm (coarse) at any location. The end product is dependent on the hammer configuration and the screen basket system. We will be happy to present individual configuration solutions to you on request.

Only in combination with a primary shredder

Waste wood shredded

Waste wood shredded

Plastics shredded

Plastics shredded

Wood chips

Wood chips

Model overview

- ARTHOS 1600566 kW

Our hammermill ARTHOS 1600 is available in a mobile and a stationary version. We offer various optional features for your hammermill.

Options

Technical Data ARTHOS 1600

We will be happy to provide you with detailed technical information on our HAAS ARTHOS mobile hammermill on request.

- Infeed width 1.600 mm

- Rotor ø 1.200 mm

- Drive566 kW

- Capacity up to55 t/h

- Weight approx. 40 t

* Throughput based on an average grain size of 60 – 80 mm with a normal and continously feeding and average degree of impurities.

Pictures

You can use the mobile hammermill ARTHOS flexibly at various locations. The pivoting belt offers a high degree of comfort and flexibility during operation. We will be happy to provide you with further pictures and detailed information.

Videos

Downloads

Our brochure gives you an overview of the features and capacity of the HAAS ARTHOS 1600 mobile hammermill. We would be happy to provide you with detailed information in a personal consultation.

- FLYER (EN)

ca. 5.2 MB

ca. 5.2 MB