Navigation : EXPO21XX > MATERIAL HANDLING 21XX >

H02: AGVs Automated Guided Vehicles

> Skilled Euroimpianti

Skilled Euroimpianti

Videos

Loading the player ...

- Offer Profile

- Euroimpianti S.p.A.: 40

year’s growth designing systems for the world market

Production

The history of palletizing systems has gone hand in hand with the growth and development of the Company, which started with traditional palletizers, passed to polar machines and then to anthropomorphic robots. From 1992 has added to production a new product line for Automatic Guided Vehicles.

Present production

Palletizing Systems based on:

• CARTESIAN ROBOT: SKILLED ANT 101, OGS 250, CGS-800, CGR 1000/2000;

• SCARA ROBOT: SKILLED 504;

• ANTHROPOMORFIC ROBOT: SKILLED 304, 603 and 604;

Automatic Guided Vehicles (AGV, LGV):

• SKILLED LGV (Laser Guided Vehicles);

• AUTOMATIC TRUCK LOADING SYSTEM;

Turn-key end-of-line systems for the industrial automation.

Product Portfolio

Palletizing systems

-

The automatic palletising/palletizing process consists of all those activities necessary to stack many different types of products on a pallet or on a slip-sheet (unitizing) in an automatic and optimized way.

Our Skilled robots have been designed to handle this task and are well known in the Industry to be extremely efficient and reliable.

The perfect design (with some Italian influence, which never hurts) gives a character to our robots and makes them compact, safe, friendly and complete of the best software for palletizing solutions that you can ever find on the market.

Skilled 101

- SKILLED ant 101 is a very simple palletizing robot that requires no installation; it has a modular construction and can be adapted to any pre-existing product conveyor and packaging line. SKILLED ant 101 can be trasported in a standard container and, on delivery, the machine is completly assembled and ready for use.

Skilled 304

- The SKILLED 304 is a 4 axis articulated arm type robot with 310° degree work area access. It is the best of the European Technology: German innovative “muscle” from KUKA with components in carbon fibre composite (CRP) for lightness with strength and the electronic & software “brains” from SKILLED by EUROIMPIANTI for accuracy and convenience.

Skilled 504

- The SKILLED 504 is an electromechanical robot with articulated cinematic structure type SCARA with 4 interpolated axes, and a working area of 360°.

Skilled 603

- The SKILLED 603 is a 4 axis anthropomorphic type robot with 360 degree work area access. It is the best of the European Technology: components in carbon fibre composite (CRP) for lightness with strength and the electronic & software “brains” from SKILLED by EUROIMPIANTI for accuracy and convenience.

Skilled 604

- The SKILLED 604 is a 4 interpolated axis articulated arm type robot with 360 degree work area access. it is the best of the European Technology. The innovative Italian design highlights the powerful and agile aluminium structure; electronics is based on the highest international standards while the software is realised by EUROIMPIANTI with its 35 years specific experience in the palletizing robots sectors.

Skilled CGR1000

- The Skilled® CGR-1000 is designed to satisfy the most demanding material handling needs. With its hardy design and patented drive system the Skilled® CGR-1000 offers standard payloads up to 1000 Kg. In addition, the robot’s working area can reach 75 m long and over 15 m wide. This makes the Skilled® CGR-1000 the most versatile gantry for multi-SKU applications.

AGV

-

AGV is the acronym for Automatic Guided Vehicle and it identifies Driverless fork-trucks which are used in industrial applications to carry pallets and/or materials to/from programmed positions in production areas, in warehouses, in the dock area and now also capable to reach in and load trucks.

The AGV receives orders directly from the warehouse management system or similar systems which gives a priority list of missions which the AGV will carry out very efficiently, 24 hours/7 in total safety for anyone that happens to be in the area.

Skilled 800 LGV

-

SKILLED 800 is a Laser Guided Vehicle system which, together with the palletizing systems SKILLED ROBOTS, allows complete ”end of line” automation. This results in cost savings and significant improvements in production management.

SKILLED 800 offers the following advantages:

- transportation of different products and pallets, coming from different production lines, from and to the storage and trucking area (with total exclusion of conveyor work);

- thanks to its modularity the system can easily be adapted to future production needs;

- extremely easy installation at customer’s site, that saves productivity time;

- compliance with the current safety rules and regulations.

Skilled RGV 900

-

SKILLED RGV is a vehicle system that has been created from the same project as that for the Laser Guided Vehicles (LGV’s) and its operation is therefore based on the same general principles. The vehicle drives along a straight rail at floor level, being used only and exclusively for movement in straight lines. Its integration with SKILLED ROBOTS palletisation systems makes it possible to achieve complete end-of-line automation, with considerable cost savings and assured increases in production management efficiency.

The SKILLED RGV is able to guarantee the following advantages:

- Complete pallet handling towards wrapping and/or storage with simultaneous automatic feeding of empty pallets and slip sheets to the palletising cells.

- Modular system, bringing great flexibility should enlargement be required in the future.

- The absence of electrical connections and the possibility of sinking the rails into the floor make access to the production lines easy for operators and vehicle drivers.

- Perfect compliance with the safety laws and standards in force.

Skilled 800

-

SKILLED 800 is a Laser Guided Vehicle system which, together with the palletizing systems SKILLED ROBOTS, allows complete ”end of line” automation. This results in cost savings and significant improvements in production management.

SKILLED 800 offers the following advantages:

- transportation of different products and pallets, coming from different production lines, from and to the storage and trucking area (with total exclusion of conveyor work);

- thanks to its modularity the system can easily be adapted to future production needs;

- extremely easy installation at customer’s site, that saves productivity time;

- compliance with the current safety rules and regulations.

Skilled 1000

-

SKILLED 1000 is a Laser Guided Vehicle system which, together with the palletizing systems SKILLED ROBOTS, allows complete ”end of line” automation. This results in cost savings and significant improvements in production management.

SKILLED 1000 offers the following advantages:

- transportation of different products and pallets, coming from different production lines, from and to the storage and trucking area (with total exclusion of conveyor work);

- thanks to its modularity the system can easily be adapted to future production needs;

- extremely easy installation at customer’s site, that saves productivity time;

- compliance with the current safety rules and regulations.

Skilled 1400

-

SKILLED 1400 is a Laser Guided Vehicle system which, together with the palletizing systems SKILLED ROBOTS, allows complete ”end of line” automation. This results in cost savings and significant improvements in production management.

SKILLED 1400 offers the following advantages:

- transportation of different products and pallets, coming from different production lines, from and to the storage and trucking area (with total exclusion of conveyor work);

- thanks to its modularity the system can easily be adapted to future production needs;

- extremely easy installation at customer’s site, that saves productivity time;

- compliance with the current safety rules and regulations.

Skilled 1400 XL

-

SKILLED 1400 XL is a Laser Guided Vehicle system which, together with the palletizing systems SKILLED ROBOTS, allows complete ”end of line” automation. This results in cost savings and significant improvements in production management.

SKILLED 1400 XL offers the following advantages:

- transportation of different products and pallets, coming from different production lines, from and to the storage and trucking area (with total exclusion of conveyor work);

- thanks to its modularity the system can easily be adapted to future production needs;

- extremely easy installation at customer’s site, that saves productivity time;

- compliance with the current safety rules and regulations.

ATL Automatic Truck Loading

-

ATL is the acronym for Automatic Truck Loading and it refers to the automation of loading trucks and trailers with products using several different types of Automated Guided Vehicle systems.

After an important experience with the LGV in different areas, winning the customer’s confidence and based on the increasing demand for automation in the dispatch area, Euroimpianti has developed and integrated its ATL technology using the flexibility of the Skilled LGV equipped for vision-guidance.

Manufacturing industries such as food & beverage, paper, tissue-paper, automotive, chemical-cosmetic and pharmaceutical, dairy, electrical, glass, tobacco and all general manufacturing automotive use ATL systems. Automatic Truck Loading

-

Automatic Truck Loading (ATL) system

Based on the huge end of line automation experience and considering the increasing demand for automation in the dispatch area, EUROIMPIANTI has developed an ATL technology (Automatic Truck Loading) using the flexibility of its LGV (Laser Guided Vehicles) with a bi-dimensional scanner able to work autonomously in the loading bays area and load the product pallets on to lorries.

Heavy Duty Gantry Robot

-

C&D Skilled Robotics specializes in manufacturing gantry robots for custom automation needs. Advantages that can be gained by employing a gantry robot include:

- Large payloads. (in excess of 2,000 pounds.

- Large work envelope

- Multiple robot heads working cooperatively in the same workspace

- Linear or Area gantry styles to best meet the floor space constraints

- The ability to palletize many (100+) Skus under the same robot

- Flexible programming to simplify operation

- Open design allows access to all hardware for easy preventative maintenance

- Optional telescoping vertical mast for low ceiling height applications Skilled CGR1000

- The Skilled® CGR-1000 is designed to satisfy the most demanding material handling needs. With its hardy design and patented drive system the Skilled® CGR-1000 offers standard payloads up to 1000 Kg. In addition, the robot’s working area can reach 75 m long and over 15 m wide. This makes the Skilled® CGR-1000 the most versatile gantry for multi-SKU applications.

Industry Sectors

Automotive

-

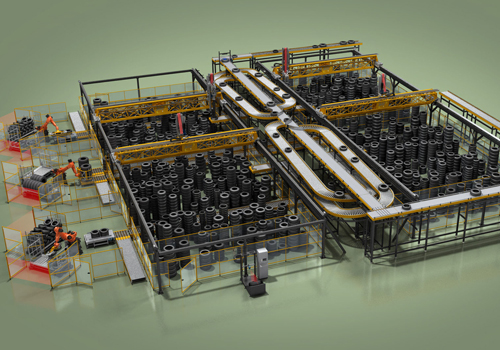

Thanks to the great experience of C&D Skilled Robotics (our subsidiary in USA) which has been servicing the tire and rubber industries since 1964, we have a wide variety of applications in the automotive industry. Our continued commitment to customer service and product innovation has made us a leader in automation for these industries. Solutions for the automotive industry include:

- Car rims palletizer

- Finished Tire Palletizer

- Finished Tire Intermediate Storage System

- Tire Building Robots Green

- Tire Storage System Green

- Tire Press Delivery System

- Tire Tread Palletizer Rubber

- Bale Loader Rubber

- Bale Unloader

Beverage

-

We have a wide variety of applications for the beverage industry. The solutions provide for this industry include the palletizing, depalletizing and handling of bottles, boxes, crates, bundles, shrink-wrapped packs, tetra-pet packs, trays, cartridges etc. for the following products:

- Coffee and tea

- Fruits juices

- Soft drinks

- Wine

- Spirits

- Water

Chemicals

-

The solutions provide for this industry include the palletizing, depalletizing and handling of bags, bottles, boxes, bundles, coils, crates, drums, jerry cans, pails, shrink-wrapped packs, tanks, tin cans, trays, etc. for the following products:

Chemical

- Adhesive tape, Ink cartridge

- Plastic products (coils, trays, sheets, etc.)

- Paint, Stretch film, Fertilizers

- Chemical liquids, Chemical powders

- Hot melt, Industrial oil, Chemical spray

Cosmetical

- Cosmetics, Personal care, Shampoo

- Soap, Tooth paste

Pharma

- Glass vials, Hygiene disposables

- Medical devices, Pharmaceutical products

Electrical

-

The solutions provide for this industry include the palletizing, depalletizing and handling of boxes, bulks, bundles, shrink-wrapped coils, etc. for the following products:

- Bulbs

- Electrical cable

- Lamps

- Satellite dishes

- Loudspeakers

- Transformers

Food

-

Our company has great experience in the food industry and consequently it has a wide variety of applications. The solutions provided for this industry includes the palletizing, depalletizing and handling of boxes, bags, bundles, shrink-wrapped packs, tin cans, trays, etc. for the following products:

- Biscuits and cookies, Bread

- Snacks, Chocolate & Confectionery, Sugar

- Cereals, Pasta, Rice, Pizza

- Frozen food, Sea food

- Dairy products, Instant soup

- Fresh food, Dried food

- Meat-ham

- Food powder (mixes for cakes, desserts, ect.)

- Coffee and tea

Paper

-

The solutions provide for this industry includes the palletizing, depalletizing and handling of boxes, bundles, heavy duty paper bobbins, shrink-wrapped packs, stripped paper reams, etc. for the following products:

- Books

- Carton reams

- Carton slip sheets

- Flat carton boxes

- Handkerchiefs

- Paper reams

- Paper reals

- Napkins

- Toilet paper

Tobacco

-

The solutions provide for this industry includes the palletizing, depalletizing and handling of boxes, bundles, shrink-wrapped packs, etc. for the following products:

- Cigarettes

- Tobacco

Warehouse Logistics

-

The proper management of warehouse logistics provides that every available space inside a store is used in the most effective and productive.

The presence of laser-guided vehicles and palletizing systems SKILLED ROBOTS, completely automates every process on the storage of goods and their handling, significantly reducing the costs of inventory management and increasing the efficiency of production. According to the clients need, a Skilled LGV in the ATL system, can withdraw one or more pallet form a production withdrawal point, from a deposit area or, furthermore, from a different floor of the establishment (with elevator) and unload it in the destination lorry, with a high repetitive precision.