TRILOGIQ

Videos

Loading the player ...

- Offer Profile

- TRILOGIQ was founded in 1992 in Paris, designing and manufacturing modular systems for automotive companies. The success of the company’s service and products enabled it to grow steadily and it now has a presence in 19 countries around the world. It supplies many of the world’s leading manufacturing companies across a range of industry sectors.

TRILOGIQ composite products are revolutionizing the way materials are stored and handled, and opening up completely new possibilities for forward-thinking businesses. An extensive research and development program ensures that products are continually developed and improved to match customer needs.

With Lean methodology and principles now being applied in many businesses outside of the traditional manufacturing sector, TRILOGIQ’s value-added solutions are making a huge impact on efficiency, safety and profitability for businesses around the world.

Product Portfolio

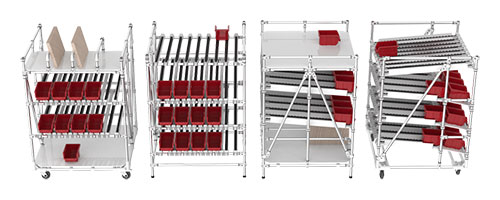

Flow Racks

COLLECTION N°15

Ergonomic picking flowracks with tilt picking

COLLECTION N°16

Ergonomic picking flowracks with low level return

COLLECTION N°35

Ergonomic picking flowracks with high level return empty

COLLECTION N°39

Ergonomic picking Flowrack with low level storage

COLLECTION N°43

Simple flow rack with top level return empty

COLLECTION N°56

Flowracks

COLLECTION N°57

Simple supermaket flowrack with low level storage

COLLECTION N°58

Tilt angle ergonomic flowracks with return empty on top

COLLECTION N°60

Simple flowracks with return empty level on top

COLLECTION N°61

Picking tilt table flowrack with low level return empty

COLLECTION N°64

Ergonomic picking flowrack with low level return empty

COLLECTION N°66

Tilt ergonomic picking flowrack with low level storage

COLLECTION N°17

Production flowracks with side return level

COLLECTION N°36

Table adjustable picking flowracks

COLLECTION N°40

Compact live storage

COLLECTION N°45

90° angle flowracks

COLLECTION N°73

Live storage with integrated workbench

COLLECTION N°78

Picking live storage with conveyor

COLLECTION N°96

Flowrack for small bins

COLLECTION N°97

Flowrack with adjustable picking table

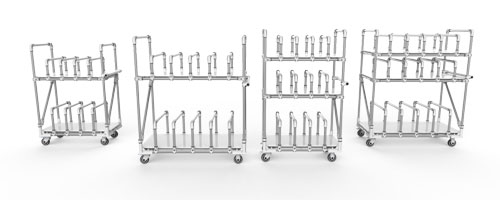

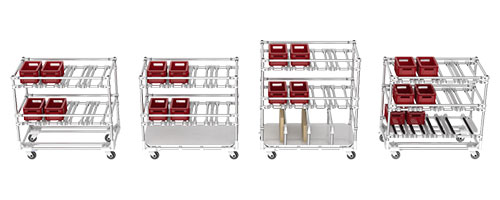

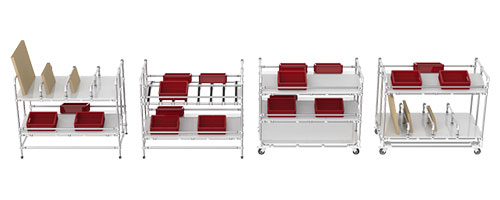

Trolleys

COLLECTION N°20

Transport cart for bins, KLT's and containers

COLLECTION N°21

Multiuse transport cart with door open / close

COLLECTION N°22

Tugger carts

COLLECTION N°27

Fully modular carts with flanges for totes, bins, cartons and containers

COLLECTION N°29

Transport and picking carts & trolleys with flanges

COLLECTION N°30

Side flanged simple cart & trolleys

COLLECTION N°31

Carts with roller-tracks for easy picking

COLLECTION N°34

Picking carts for KLT's, bins ans containers

COLLECTION N°33

Transport trolley for totes, bins, KLT's and containers

COLLECTION N°47

Simple logistic push cart

COLLECTION N°49

Logistic and transport cart with 3 flanges

COLLECTION N°65

Modular roll cart

COLLECTION N°72 Vertical storage cartons and packaging carts

COLLECTION N°74 Trolley

Compartment protection trolleys

COLLECTION N°6

E-commerce Carts

COLLECTION N°32

Compartment carts

COLLECTION N°63

Roll type carts

COLLECTION N°75

Push carts

COLLECTION N°77

Trolleys with information board

COLLECTION N°85

Telescopic levels picking carts

COLLECTION N°91

E-commerce distribution trolleys

Workstations

COLLECTION N°37

FIFO Frontal loading workbenches

COLLECTION N°46

Frontal loading workstations

COLLECTION N°48

Conveyer FIFO workbenches

COLLECTION N°50

Worktable with information panel

COLLECTION N°71

Modular & evolutive packaging station

COLLECTION N°4

Multifunction workbench

COLLECTION N°5

KLT workbench

COLLECTION N°8

Worktable

COLLECTION N°38

Control and packaging table

COLLECTION N°82

Worktables with conveyor

COLLECTION N°89

Simple worktable with top structure

COLLECTION N°90

Worktables with tool holder front board

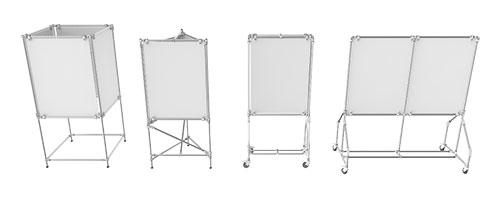

Display units

COLLECTION N°1

Diplays with ergonomic picking device

COLLECTION N°2

Display for KLT with flow guides

COLLECTION N°25

Frontal loading workstations

COLLECTION N°28

Ergonomic picking display and carts for various products and packagings

COLLECTION N°44

FIFO Display for KLT's

COLLECTION N°67

FIFO Display for KLT's with low level storage

COLLECTION N°3

Kitting trolleys

COLLECTION N°7

Logistic picking displays

COLLECTION N°9

Dual-side multiuse stands

COLLECTION N°10

FIFO Double side stands

COLLECTION N°52

Information boards

COLLECTION N°94

Optimized picking table stand

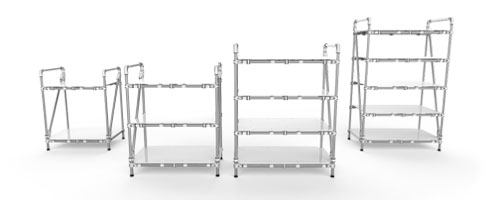

Shelves & Storage

COLLECTION N°53

Storage and transport for boards

COLLECTION N°14

Picking ergonomic shelves for bins, totes and cartons

COLLECTION N°26

Fully modular picking shelves for boxes, bins, totes, cartons and containers

COLLECTION N°68

Multi products modular shelves with flanges

COLLECTION N°76

Compartment shelves

COLLECTION N°70

Multi products modular shelves

Conveyors

COLLECTION N°23

V shape ergonomic picking conveyors

COLLECTION N°24

Classic flat conveyor for totes, bins, cartons and containers

COLLECTION N°59

Production FIFO conveyor with go/return level