- Offer Profile

More efficiency with Transport Robots

Automated Guided Vehicles (AGVs) and Systems make a significant contribution to the optimisation of processes in intralogistics. They ensure that the right part is always in the right place at the right time. When using transport robots you increase the productivity of your company significantly.

ek robotics is one of the European market leaders in the field of AGVs. We have more than 50 years of experience in the industry and have already installed more than 10,000 vehicles in more than 1,000 systems worldwide. We are convinced that we can find the optimum solution for your intralogistics processes!

AUTOMATED GUIDED VEHICLES - AGV

-

More efficiency with Transport Robots

The right part at the right time in the right place - that's what transport robotics does almost by itself. With the use of transport robots, also known as Automated Guided Vehicle (AGV) Systems, we optimise material flow and storage systems safely and quickly.

The ek robotics vehicle types differ according to criteria such as design and the corresponding load range. In the design phase, the selected vehicle type is then combined with the appropriate load handling equipment. We are not limited by the number of vehicles in a system. And of course it is essential to match the vehicle selection and the system to the customer's requirements. INFINITE TRANSPORT SOLUTIONS

-

WE DELIVER TURNKEY AGV SOLUTIONS FOR YOUR INDUSTRY

We provide turnkey AGV solutions for almost all industries, whether in assembly, production supply or disposal, order picking, warehousing or area linking. With more than 50 years of experience in the field of automation, we offer intelligent logistic solutions ranging from standardized AGV up to to 100% customer-specific transport robots based on industry-proven components.

ATS - Automated Material Transport Systems

-

We optimize your hospital logistics! With driverless systems for the automatic transport of goods (awt), we secure the supply of wards, sterile departments and nursing areas of your facility - even over several floors.

References

TUSCANY HOSPITALS, ITALY

ek robotics has installed new ATS systems in four hospitals across Tuscany (Pistoia, Prato, Lucca and Massa). 44 transport robots are responsible for supplying approx. 1900 beds on the wards with not only meals for the patients, but also the transport of medicines, laundry and waste according to a fixed schedule.NEW ROYAL ADELAIDE HOSPITAL, AUSTRALIA

With a local partner, ek robotics has equipped the most modern hospital in Australia, the New Royal Adelaide Hospital, with 25 fully automated AWT robots. Working to a precise plan, the 25 AGVs transport food, laundry containers, containers for sterile products and medical supplies.HERLEV, KOPENHAGEN, DÄNEMARK

With over 1,600 hospital beds, Herlev Hospital is the largest building in Denmark. Here, ek robotics has installed an ATS system with 11 vehicles that are responsible for transporting a wide variety of rolling containers.MOTOL, PRAGUE, CZECH REPUBLIC

With over 2400 patient beds, Motol Hospital is the largest in the Czech Republic. Here, the ek robotics service team looks after an ATS system installed in 1995 and ensures a reliable supply of meals to the hospital wards according to program-controlled planning. In addition, the ATS transport robots are responsible for waste and medication transport.

Block Storage

-

Without a bitter aftertaste: agv solutions for floor-level or block storage offering more flexibility for the beverage and food industry. Without additional costs for shelf installation.

References

MIELE, GÜTERSLOH, GERMANY

Heavy castings are required for production, which are fed to the production facilities fully automatically by the automated guided vehicle system. The racks with the cast components are targeted, safely and precisely controlled, stacked and unstacked in a block storage system with over 1,000 storage locations on 6 levels by 4 fully automatic SMART MOVE transport vehicles.ARLA FOODS, AYLESBURY, UK

The Aylesbury, UK production site of Arla Foods houses the largest fresh milk production in the world. As an integral part of the intralogistics, ek robotics supply’s 90 CUSTOM MOVE vehicles in the chilled store. Over 10,000 storage spaces are managed in this floor block warehouse by the ek robotics transport manager, which also ensures that the vehicle fleet performs its tasks with maximum efficiency..BREWERY, GERMANY

17 COMPACT MOVE vehicles from ek robotics supply the fully automated block storage system with over 10,000 storage locations of a well-known brewery in Germany. The AGVs are equipped with a double pallet handler attachment allowing transport of two pallets at the same time, stacking and de stacking them in a process-safe manner.PET BOTTLE PRODUCTION, GERMANY

Unstable and unevenly shaped products, such as stacked PET bottles or canisters, place high demands on transport and storage. ek robotics uses 3D camera technology for this, which evaluates the storage situation in real time with software developed by ek robotics. This enables the driverless transport vehicle to recognise the exact position of the goods to be transported and the pallets.

Order Picking

-

Transport robots support employees in internal order picking processes. The transport robots assemble certain partial quantities on the basis of shipping or production orders. The vehicle is called picking AGV, picker or gripper. Here it is possible to have particularly routine or time-consuming transports carried out by transport robots. In the future, efficiency will be further optimised, for example by allowing goods to be sorted while they are still in transit.

References

Since 2008, 15 Compact 300 vehicles from the CUSTOM MOVE product group have been supplying prefabricated components to a renowned truck and bus manufacturer in Germany's axle production department. The picking racks are transported by drive-under vehicles with lifting rams.

Assembly lines

-

Reaching your destination without congestion: individual agv transport systems with active or passive load handling devices. Workpieces can be mounted directly on the platforms or transported between the individual workplaces.

References

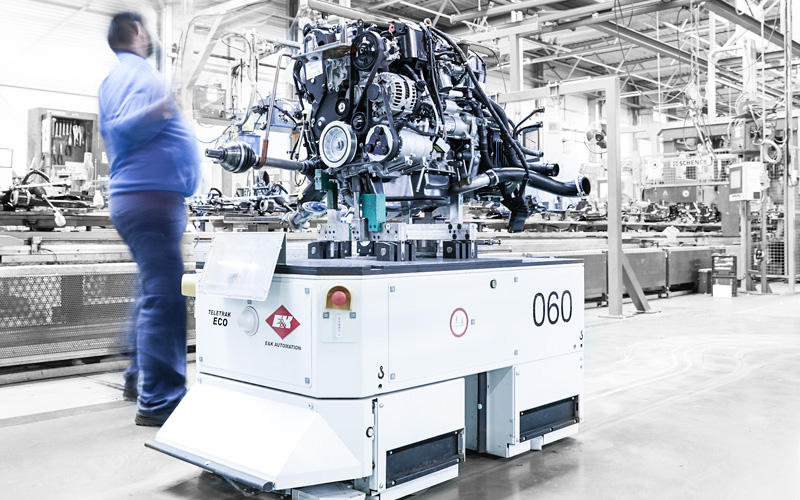

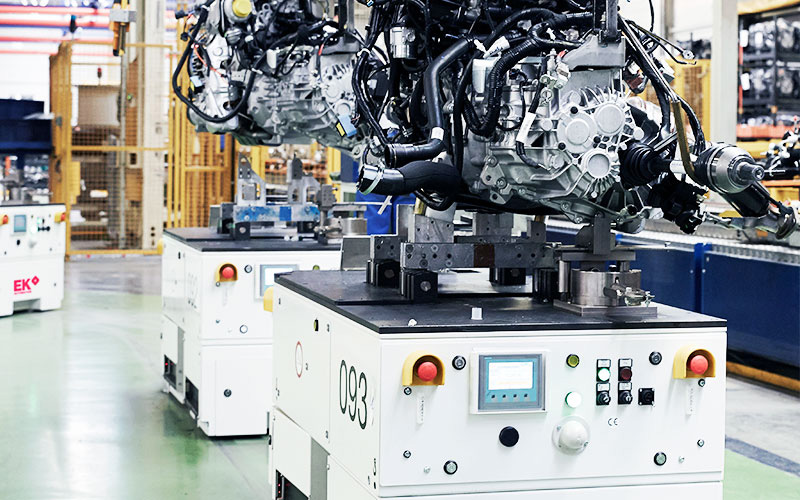

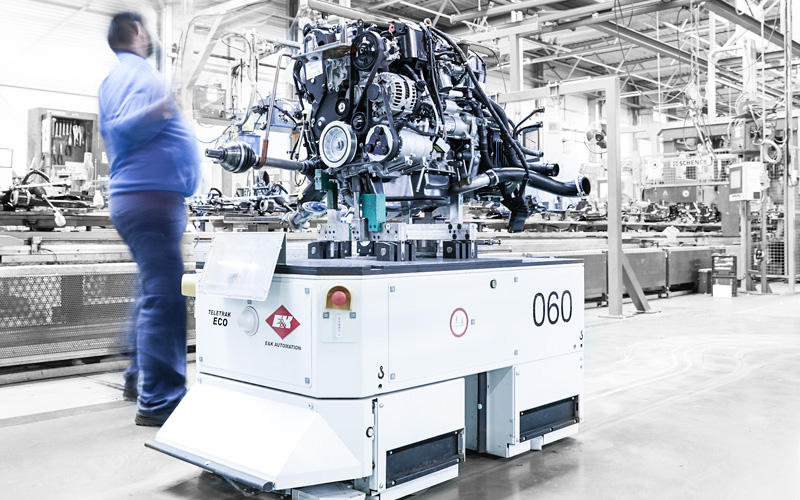

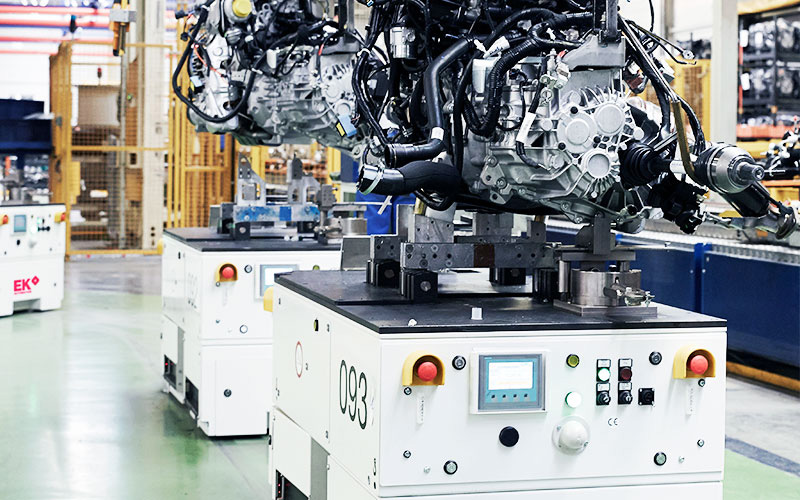

SML, GENK, BELGIUM

Over 100 ek robotics transport robots of the vehicle type CUSTOM MOVE are in use at the automotive supplier SML for the assembly of engines and axles. Within seven months, the transport robotics specialist designed and manufactured customised assembly vehicles and put them into operation during a 3-week shutdown. The engines and axles were delivered to the car manufacturer's SOP without interrupting production and just in time.OEM, CHINA

For flexible engine assembly, 130 ek robotics transport vehicles were designed, manufactured and commissioned on site at an automotive plant in China.With the transport robots designed by ek robotics, the engines can be lifted, rotated and tilted as part of the assembly steps. This ensures particularly efficient and ergonomic working for the various assembly activities.

Outdoor

-

For yard & hall: in the future, indoor and outdoor transport robots will reliably and efficiently manoeuvre between your production halls and warehouses wherever you previously had to transport goods manually.

References

JTI, TRIER, GERMANY

For the transport of special storage containers, the tobacco company JTI use driverless transport vehicles from ek robotics in combined indoor and outdoor operation.

The CUSTOM MOVE transport robots from ek robotics, developed for outdoor operation, can be used 365 days a year, 24 hours a day, regardless of the weather conditions, thanks to the fast-charging technology and LI-ION batteries.BAXTER, HECHINGEN, GERMANY

Since 2003, Baxter (formerly Gambro) has been using two fully automatic CUSTOM MOVE outdoor transport robots from ek robotics for the connection between the production building and the warehouse. By means of inductive track guidance and contactless energy transmission CPS, the driverless transport vehicles, specially designed for outdoor operation, are used.GEROLSTEINER MINERALBRUNNEN, GEROLSTEIN, GERMANY

Gerolsteiner has been using driverless transport systems from ek robotics since 2013. Five CUSTOM MOVE transport robots with robust weather protection cladding are used for the area link between production and warehouse in the outdoor area.

Shelf Storage

-

We stack for you with precision in block, row or support arm storage systems, which are loaded by transport robots. Many product-specific parameters determine whether a static or dynamic storage system is created on site.

References

FLOW RACK

With the COMPACT MOVE, ek robotics offers a very compact, powerful transport robot that can be flexibly adapted to customer requirements.

For the application at a leading manufacturer of deodorants, shower and hygiene products, the transport robots dispose of the production and feed it to different storage areas.

A special requirement is the operation of the flow rack system with transfer heights of over four metres. Thanks to the integrated fork tilter, the pallets can be delivered here at the required angle of inclination.

Tugger AGV

-

Efficient towing! With fts drive trucks, which enable transports even over long distances while towing drive-less trailers, this is possible! A more than forward-looking solution for the transport of large loads.

References

MILK-RUN, COMMISSIONING, CZECH REPUBLIC

An automotive supplier uses four ek robotics SMART MOVE P30C tow tractors for parts picking in the supermarket and assembly line supply. The tractors have a capacity of 3,000 kg and pull four trailers simultaneously.

Narrow-Aisle Storage

-

We continue to look higher and higher. Even where other suppliers have long since reached the end of the line due to constriction or lack of space. You can make full use of our agv transporters with swivel or telescopic forks – at heights of up to 14 metres.

References

DAW

The HEAVY MOVE VNA is a modular transport robot from ek robotics that can also be optimally used in narrow aisles. The driverless transport vehicles are compact, weight-optimised and individually adaptable to the inventory warehouse applications.

Error-tolerant load cycles are ensured by the 3D camera technology developed by ek robotics. This ensures that the pallets can be safely stored and retrieved despite many tolerances, such as uneven floors, yielding shelves or pallets.DDH

In the area of narrow-aisle warehouses, ek robotics offers fully automated solutions with transfer heights of up to 14 metres. The transport robotics specialist automates conventional manual narrow-aisle stackers with the appropriate navigation technology and sensors which enables process-reliable load cycles even at high heights.GEROLSTEINER

ek robotics also offers suitable fully automatic solutions for use in a mobile racking system, e.g. for storing packaging materials with a lower load turnover. In this way, an optimal space utilisation ratio is achieved.

ek robotics designs individual solutions for each mobile racking system, which are responsible for the storage of pallets or even long goods with lengths of up to six metres. Depending on the configuration of the system, the transfer heights can be up to 10 metres or more.

Heavy load

-

We can handle it for you! Up to 50 tons - we have the right vehicle for the transport of heavy loads.

References

PACKAGING MATERIAL, CARDBOARD BOXES, OUTDOOR

In its new plant of Tricor Packaging & Logistics in Bad Wöridshofen, two impressive ek robotics CUSTOM MOVE heavy-duty transport robots transport entire swap bodies for trucks. The swap bodies weighing almost 12,000 kg, are picked up by the omnidirectionally travelling AGV vehicles in a covered transfer zone in the outdoor area in an error-tolerant manner, using a lifting device and transported to the production for loading.

Special Solutions

-

For us, you are unique! Especially when it comes to agv transport vehicles for specific project requirements, such as extreme temperatures, weights or hazard risks. We design one-of-a-kind vehicles that will last for decades.

References

CERAMICS INDUSTRY

Customised transport solutions and the highest engineering skills are combined in ek robotics' CUSTOM MOVE transport robots. We implement almost every task in a customised way so that the individual production processes of our customers can be served with an automatic transport system AGV.

For example, the ek robotics CUSTOM MOVE transports a tunnel kiln rack loaded with ceramic products weighing up to 16,000 kg, lifts them, tilts the forks for transport and transports them safely to their destination - without any problems.GE JENBACHER

The manufacturer of gas engines and combined heat & power units INNIO Jenbacher has been relying on twelve CUSTOM MOVE transport robots from ek robotics for many years. The area-moving assembly platforms are equipped with a swivel device for ergonomic assembly on the gas engines, which weigh up to 25,000 kg.The passage of the assembly line takes place in a clocked manner. When assembly is complete, the CUSTOM MOVE vehicles reverse back to the start to be loaded with the next engine block.AUTOMOTIVE SUPPLIER, PAINTING, HEAVY DUTY

Customised transport solutions combined with the highest engineering skills: CUSTOM MOVE transport robots from ek robotics. Almost every task is customised in such a way that the customer's individual production processes can be served with an AGV driverless transport system.

For example, the area-moving CUSTOM MOVE transports painting racks which are five metres wide and weigh up to 2,200 kg as well as lifting them up to a height of 4.5 metres - a 'can't do' doesn't exist.

AUTOMATED GUIDED VEHICLES

-

The right goods at the right time in the right place - driverless transport systems give you just that. With the use of transport robots, also called automated guided vehicles (agvs), we optimise material flow and warehouse systems safely and quickly.

VARIO MOVE

- VARIO MOVE - FOR EFFECTIVE OPTIMISATION OF YOUR TRANSPORT AND MATERIAL FLOWS.

VARIO MOVE: NEW BENCHMARK IN TRANSPORT ROBOTICS

- Powerful and efficient. Safe and precise. Sustainable and economical. The VARIO MOVE is characterised by decades of experience, uncompromising quality standards, the will to break new ground and the latest technology. Designed for the sustainable optimisation of your transport and material flows, the fully automatic transport robot fulfils a wide range of transport requirements. The modular concept, maximum availability, maintenance-friendly design and an exceptionally long-life cycle ensure sustainable cost and competitive advantages for you.

TRANSPORT ROBOT WITH HIGH LIFT: VARIO MOVE L

- The fully automatic high-lift transport robot VARIO MOVE L has a sophisticated, modular construction, maintenance-friendly design and optimised chassis for safe load cycles at heights of up to 5,000 mm along with a high load capacity of up to 1,600 kg.

TRANSPORT ROBOT WITH COUNTERBALANCE: VARIO MOVE CB

- Function in perfection: The universal drive unit in the VARIO MOVE CB is combined with modular stepped load modules, for an automatic counterweight transport robot. Available with cantilever forks and a high payload of up to 1,600 kg depending on the intermediate module. All in all, a compact, powerful and reliable transport robot.

HIGH-LIFT TRANSPORT ROBOT WITH EXTERNAL RADAR ARMS: VARIO MOVE AS

- Inspired expertise: With its external wheel arms, the VARIO MOVE AS transports special load carriers and closed pallets. The short wheelbase enables the AGV to perform fully automated transports with a small turning circle - even in narrow production areas and racking systems. With the standardised portfolio of lifting masts, the VARIO MOVE AS can carry loads up to a height of 5,000 mm and a load capacity of up to 1,600 kg.

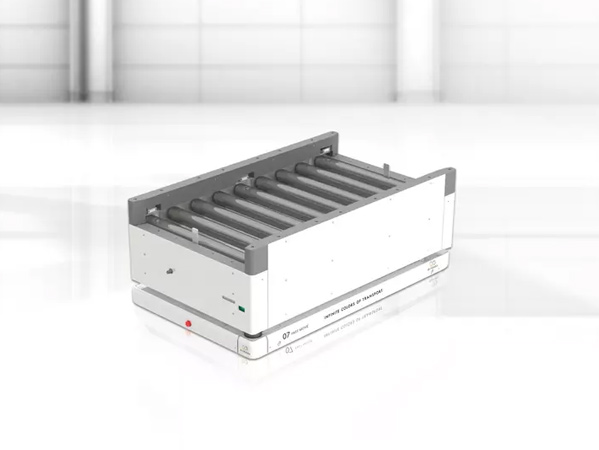

AUTOMATIC CONVEYOR TECHNOLOGY: TRANSPORT ROBOT VARIO MOVE CT

-

Efficient design, as it should be: Connected to the drive module via a universal interface, the VARIO MOVE CT can be adapted to almost any individual and special task. In the process, the drive module can be combined with one or more roller or chain conveyors -as well as being equipped with additional features, such as load hold-downs, if desired and required.

Extremely powerful transport robotics with possible travel speeds of up to 2m/s.

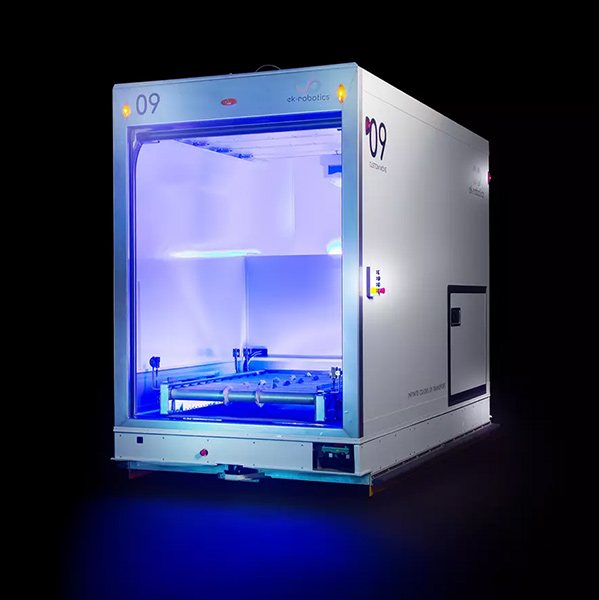

AUTOMATIC CONVEYOR TECHNOLOGY: TRANSPORT ROBOT VARIO MOVE CTO

-

Intelligent technology that moves. Specially designed for high-performance plants, the VARIO MOVE CTO has 1 to x conveyors paired with an omnidirectional chassis. Thanks to its high manoeuvrability, the transport robot can be used efficiently even in narrow production areas.

A wide range of additional safety and equipment options make the VARIO MOVE CTO an indispensable AGV partner in daily operations when it comes to optimally implementing your tasks and meeting the demands.

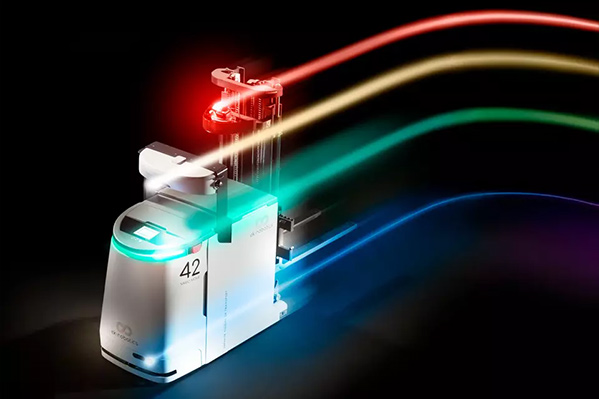

FAST MOVE

-

ULTRA SMART. ULTRA FLEXIBLE. ULTRA FLAT.

This maximum mobility vehicle is scalable in size and can perform various transport tasks completely independently due to a multitude of different load handling devices. With an overall height of only 13 cm, a load capacity of 1,000 kg and a travel speed of up to 2 m/s, FAST MOVE establishes a completely new performance class in transport robotics.

Smart, automated production, that exploits Industry 4.0 requires intelligent, networked and flexible material flow solutions as well as the targeted transport of goods. The fully autonomous, ultra-flat FAST MOVE transport robot from ek robotics is highly mobile, individually scalable and versatile - and thus THE transport robot for industry 4.0.

The flexible, autonomous, scalable transport platform.

The FAST MOVE:- can move freely in all directions

- enables faster load cycles

- solves space problems

- is an ultra-flat vehicle

- moves loads up to a weight of 2000 kg

- reaches speeds up to 2 m/s

- can be modularly adapted to any task

- allows scaling of the chassis in 100 mm steps

FAST MOVE HUB 30

-

Small but mighty: This FAST MOVE is only 14 cm high, but has all the essential features of a "full-grown" transport robot.

With the ek hybrid navigation system, the AGV navigates over the contours of its environment. Where this is not possible, the FAST MOVE uses personal protection scanners and reflectors to reach its targets with the utmost precision.

360° protective field in PLd, WLAN and a LI-ION high-power energy system are further highlights of this ultra-flat, omnidirectional mobile transport platform.

Powerful for use in a chemical plant, among other applications.

We at ek robotics stand by our promise and offer endless solutions for your individual task.

FAST MOVE HUB 140

-

The trolley transport takes place in the area of GLT transports for the supply and disposal of assembly lines.

The FAST MOVE Hub 140 was designed to lift transport racks high enough for the safety scanners to perform a 360° safety check around the transport robot.

Intervention protection in the lift table and PLd 360° protection round off the FAST MOVE with WLAN and LI-ION fast charging technology.

Quite nimble: With the 100% omnidirectional chassis, the AGV vehicle reaches a travel speed of up to 2m/s!

FAST MOVE ROLLER TRACK 50

-

Did you know that FAST MOVE stands for Flexible Autonomous Scalable Transport Platform? And this is where the transport robot comes into play as a customised load handling device.

In this example, eight conveyors are individually controlled and are thus able to deliver individual KLTs to their destinations precisely and in the right order -

100% more efficiently than any swarm intelligence.In addition, the FAST MOVE has special features such as omnidirectional chassis, LI-ION energy system and maximum performance in 24/7 continuous operation.

FAST MOVE ROLLER TRACK 50

-

Would you like a little more? The FAST MOVE is individually scalable in its dimensions - the omnidirectional transport platform aka FAST MOVE can be constructed up to a length of two metres.

In a customised set-up for 2 KLT load carriers, empty containers are exchanged on level 1 and full containers on level 2 at the same time. This is an effective process that saves valuable time during the load cycle.

As you can see: ek robotics offers an infinite number of solutions for your individual material flow control.

FAST MOVE ROLLER TRACK 90

-

The FAST MOVE RB 90 is particularly compact - with a roller conveyor for Euro pallets or GLTs up to 1,000 kg, it is only marginally larger than the loading equipment or transported goods – and with the highest flexibility and omnidirectional manoeuvrability.

For the use of pallets or GLTs with a load weight of up to 1,000 kg, the FAST MOVE RB 90 is the optimal choice.

360° protective field in PLd, WLAN and a LI-ION high-performance energy system are further highlights of this very compact omnidirectional moving transport platform.

ULTRA SMART. ULTRA FLEXIBLE. ULTRA FLAT.

SMART MOVE

-

High-quality workmanship, sophisticated equipment and high price awareness do not necessarily have to be a contradiction. Here comes the smart move product family: series-produced industrial trucks as driverless transport systems that offer cost-efficient transport solutions for all industries.

With more than 25 years of experience in the automation of series-produced vehicles from well-known manufacturers of industrial trucks, ek robotics equips the vehicles with navigation and control systems and holistically adapts the entire system to the customer's requirements. Since these systems work with prepared modules, ek robotics offers a cost-effective entry into the technology of automated guided vehicles for many applications in different industries. Short planning and commissioning times, fast deliveries as well as flexible adaptation options are further advantages that speak for the use of series vehicles. Ek robotics series devices are offered as tractors, low-lift vehicles or high-lift vehicles.

-

OUR TOPSELLER: SMART MOVE L14 / L16

-

With the SMART MOVE L14 and L16 driverless transport vehicles, you can be ready for anything in the future. The automated high-lift truck from ek robotics can store and retrieve goods on shelves up to heights of over 4 metres.

Even the basic model offers features that leave little to be desired with laser navigation, a LI-ION energy system and personal protection scanners in both directions of travel.

A UNIVERSAL TRANSPORT AND STACKER FORKLIFT: THE SMART MOVE L 06 - 16 AC

- With four smart move AC models available, ek robotics offers a selection of transport robots that are designed for most transport tasks. With load capacities from 600 kg, to 1,600 kg, the AGVs have a variety of different options such as, laser navigation, LI-ION energy system and personal protection scanners in both directions of travel which are included in the basic equipment.

SMART MOVE CUSTOM

-

You have special requirements and are looking for individual solutions? Rely on the many years of expertise of ek robotics! With our SMART MOVE CUSTOM, we ensure your SMART MOVE vehicles meet your individual requirements.

This means that you do not have to do without mechanical load restraints, hold-downs or centreing devices, nor do you have to do without special sensor systems. For us, efficient AGV solutions are no problem.

IN FIELD SERVICE: SMART MOVE OUTDOOR

-

With the SMART MOVE OUTDOOR, we offer an automated series industrial truck that can also be used for a short time in the outdoor area or courtyard of your factory premises.

The special feature: With an additional sensor system and personal protection device, the SMART MOVE vehicles can connect several hall areas with each other, even if there are a few metres of open space between the halls.

CLASSICS - SMART MOVE ERC 214 AND 216

- ek robotics has been automating series devices since 1997. Models from the very beginning such as the SMART MOVE ERC 214 and 216, which, like the SMART MOVE L14 in the basic version, feature laser navigation, LI-ION energy system and personal protection scanners in both directions of travel.

CUSTOMIZED SOLUTIONS: SMART MOVE ERE 225

-

he driverless low-lift truck SMART MOVE ERE 225 is supplied ex works with short or long forks and transports up to 2,500 kg in automatic mode. In addition to the forks for two pallets, ek robotics also offers special sizes of forks with a length of over 3,000 mm..

DRIVERLESS TRUCK: SMART MOVE P40 & P60C

- Are you looking for a towing vehicle that impresses with its pure transport performance? The SMART MOVE P40C and P60C meet this requirement without any "ifs and buts". The SMART MOVE P40C and P60C automated transport robots from ek robotics carry trailer loads of up to 6,000 kg and thus offer high transport performance at low cost.

COMPACT MOVE

-

Are you looking for a reinforcement that will take the strain off you when optimising your material flow processes? With the compact move, ek robotics offers you a particularly compact counterweight ftf with scalable performance data for automatic handling of a wide variety of loading aids.

In the future, rely on a real team player with the standard agv for medium-heavy loads: with the standardised driverless transport vehicle series compact move, we offer you a robust, manoeuvrable, as well as particularly service-friendly and thus economically sustainable agv solution. This allows you to transport your products driverless and cost-efficiently.

COMPACT MOVE CB 10 COUNTERBALANCE

-

The COMPACT CB 10 is a powerful and economical counterbalance vehicle. It has been developed for many years of continuous operation with high availability.

The COMPACT MOVE 10 has a modular additional weight system with which it can be adapted to different load capacities of 1,000 kg or 1,200 kg, depending on the customer-specific task. For example, this compact transport robot is used in the production logistics of an international manufacturer of deodorants. The COMPACT MOVE 10/12 is optimally suited for use in the tight space between the production lines and was additionally equipped with lateral safety scanners for this purpose.

COMPACT MOVE CB 16

-

The COMPACT MOVE 16 has a load capacity of up to 1,600 kg and, thanks to its robust design, is available for continuous operation, e.g. in a printing plant.

Especially in the production of printed products or packaging, a wide variety of loading aids are required. Here, the COMPACT MOVE with its variably adjustable forks offers the possibility to transport pallets on the fork tip in order to buffer them closely one behind the other in a space-saving manner. This is how the AGV from ek robotics achieves the highest efficiency, e.g. in the shipping area.

COMPACT MOVE CB 25

-

The COMPACT MOVE 18 / 25 is a real powerhouse, especially for block storage.

For block storage in a brewery, the COMPACT MOVE is optimised with 4 forks for handling two pallets at the same time. For the transport of single pallets, the forks can simply be moved together.

In addition, the COMPACT MOVE uses hybrid navigation from ek robotics. Thanks to the precise laser navigation, it is able to transport the pallets at high speed, with the magnets in the block storage aisles and, thanks to its 3D camera system, the COMPACT MOVE 18/25 can place the pallets safely on or off at a distance of 5.5 metres without any errors. Absolutely unique!

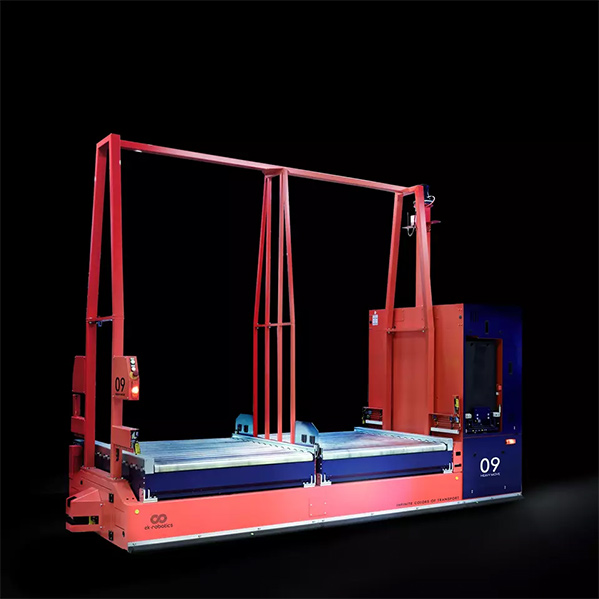

HEAVY MOVE

-

Whichever way you turn it: with its wide range of load suspension devices, the heavy move is a particularly flexible machine that can cope with heavy loads or special challenges.

A universal driverless transport vehicle for high lift applications.

Advantages of the HEAVY MOVE:

- Proven basic design, individually adaptable thanks to modular design

- Roller conveyors or chain conveyors - the load handling attachments can be adapted to your needs

- Laser navigation - the market-leading and flexible navigation without any ground installation

- User-friendly touch panel with graphic diagnostic display

- Trolleys for diagonal and transverse travel

- Optimally suited for multi-shift use thanks to energy system with automatic battery change or automatic battery recharging

- Individual security packages for every application

- Payload of up to 4,000 kg

HEAVY MOVE ADVANTAGES AT A GLANCE

- Our HEAVY MOVE can be configured with any load handling device. Whether roller conveyors or chain conveyors (up to 6 units) - the proven basic design of the transport robot means that only the load handling attachment needs to be adapted. The HEAVY MOVE is designed for high lifts up to 12 metres, medium-heavy loads and area-moving trolleys. This way, you secure customised transport robotics that safely moves you and your material flow without risk. The flexible trolleys allow diagonal and transverse travel, and flexible navigation is provided by integrated market-leading laser technology with no ground installation required. Our battery system is variable and enables automatic changeover or recharging. Individual safety packages can be installed for effective accident prevention. A payload of up to 12,000 kg is possible without any problems.

HEAVY MOVE 01

- The HEAVY MOVE offers endless choices for different lifting masts. With the HEAVY MOVE, you always have a suitable solution if you want to lift, store or stack particularly high or heavy loads. Transfer heights of over 10,000 mm and load weights of 6,000 kg are no problem for the variable HEAVY MOVE. And of course, you can adapt the lift masts to your individual task with the appropriate forks or attachments.

HEAVY MOVE 02

- The infinite variety of applications of the HEAVY MOVE is also reflected in its use in narrow aisle systems. With the HEAVY MOVE VNA, ek robotics offers a customised solution for special challenges. The HEAVY MOVE is individually designed with swiveling push forks or telescopic forks - depending on how your warehouse is designed or planned. We carry out load cycles from floor level to over 10,000 mm with the HEAVY MOVE and offer a technical solution for the compensation of multiple tolerance requirements with our 3D camera system.

HEAVY MOVE 03

-

The HEAVY MOVE also offers an infinite variety of solutions in the food industry for your very special production challenge.

For example, in addition to the appropriate load handling device, we also offer individually designed load restraints, whether passive or as active hold-downs for the transport of large racks with unstable products.

And if hygiene requirements demand it, the parts that come into contact with the product or the entire load handling device are made of stainless steel.

HEAVY MOVE 04

-

The HEAVY MOVE also feels at home in the automotive industry - as equipped with a plate conveyor for transporting the infinite variety of load carriers in car manufacturing.

These area-moving HEAVY MOVE transport robots transport different racks up to 3,600 mm long at 1,500 mm width and weights of 2,500 kg - at speeds of 2m/s.

This allows the production cells to be optimally linked and integrated into the logistics process.

HEAVY MOVE 05

-

The HEAVY MOVE shows its variability and performance particularly when it is equipped with several load handling devices and can thus transport 2, 4 or even 6 pallets at the same time.

Even with loads of 5,000 kg, the HEAVY MOVE achieves high travel speeds of 2 m/s and offers extraordinary efficiency for your intralogist needs especially with long transport routes.

HEAVY MOVE 06

-

The art of engineering combined with creativity and experience - this is how we develop suitable solutions together with you - even if you require special adaptations.

Our solutions are just as infinitely diverse as your products are.

As here in the awning production - the up to 6 m long racks with customised awnings and their raw materials are safely transported by our HEAVY MOVE to the production lines and dispatch on schedule.

CUSTOM MOVE

- THE CUSTOM MOVE COMBINES THE SUPREME DISCIPLINES IN SPECIAL-PURPOSE TRANSPORT ROBOTICS.

- Proven basic design, individually adaptable thanks to modular design

- Roller conveyors or chain conveyors - the load handling attachments can be adapted to your needs

- Laser navigation - the market-leading and flexible navigation without any ground installation

- User-friendly touch panel with graphic diagnostic display

- Trolleys for diagonal and transverse travel

- Optimally suited for multi-shift use thanks to energy system with automatic battery change or automatic battery recharging

- Individual security packages for every application

- Payload of up to 4,000 kg

CUSTOM MOVE 01

- As here in the paper industry, transporting parent rolls or impression cylinders with loads of up to 32,000 kg. At the same time, the automated guided vehicles always travel highly dynamically and move over a wide area. This is because even in the production of larger rolls, there is only limited space available for intralogistics. Therefore, we at ek robotics optimally combine our robust and durable mechanical engineering with state-of-the-art control and navigation technology as a multitude of different customer requirements necessitate an infinite number of solutions.

CUSTOM MOVE 2

-

In the chemical industry, large quantities of plastic fibres are produced for protective suits, for example. We always work with you to find a solution that suits your requirements. This is also the case here with product access for employees on the CUSTOM MOVE area-moving transport robot.

FOUR WAY FORKLIFT: CUSTOM MOVE

- For an automotive supply company in southern Germany, ek robotics transports large racks with body parts to be painted using the CUSTOM MOVE series transport robot. Here, various picking and production areas are interlinked with a fully automated painting line. The focus is not only on vehicle design but also on integration into the customer's individual process landscape.

CUSTOM MOVE 03

- The focus is on hygiene and cleanability, especially in food production. For this purpose, as an expert for stainless steel vehicles, we also offer fully automatic transport robots. This also applies, to the transport, storage or weighing of cheese. Thanks to high-precision weighing cells in the forks designed by ek robotics , weighing and dosing when mixing the raw cheese takes place directly on the vehicle. Transport robot becomes production robot.

CUSTOM MOVE 04

- Special process requirements are also made in the pharmaceutical industry, among others. Here, highly sensitive products are manufactured for humans, which is why the qualification process for the AGV system is the focus of our customers. With many years of experience in the pharmaceutical industry, ek robotics offers a reliable partner for the safe implementation of sensitive processes. As here, for example, with a vehicle for weighing pharmaceutical raw materials 24/7, 365 days a year.

CUSTOM MOVE

OUR TECHNOLOGY FOR YOUR AGV

WHAT IS AN AGV?

-

AGV AND AGVS

An automated guided vehicle (AGV) is a floor-bound conveyor with its own traction drive. It is automatically controlled and guided without contact. Driverless transport vehicles are used for material transport - for pulling or carrying conveyed material, with active or passive load handling devices.Automated guided systems (AGS) are in-plant, floor-based conveyor systems with automatically controlled vehicles. Their primary task is to transport materials, but not people. They are used both inside and outside buildings.

AUTONOMOUS TRANSPORT ROBOTS - A KEY TECHNOLOGY OF INDUSTRY 4.0.

-

Autonomous transport robots are a key technology of Industry 4.0!

Industry 4.0 technologies enable outstanding growth opportunities and competitive advantages - also for Germany as a business location. Forecasts assume that companies will be able to significantly increase their productivity by means of Industry 4.0. Other areas will also change fundamentally. For example, dangerous jobs and laborious activities will be eliminated and new professions and jobs will be created in their place. As during Industry 3.0, society will strive for and, as is already the case in Germany, experience full employment in the fourth industrial revolution.

Translated with www.DeepL.com/Translator (free version)

NAVIGATION

-

NAVIGATION IS AN ESSENTIAL FUNCTION OF THE TRANSPORT ROBOTS AND CONTROLS THE DIRECTION AND SPEED OF TRAVEL IN REAL TIME BASED ON POSITION AND DESTINATION.

On the basis of the transport task and the given framework conditions, we select the most suitable navigation type for the application. Our multisensor-capable control base enables the use of hybrid systems and a wide variety of control types. Our flexible systems are easily modifiable and expandable. Navigation from ek robotics is thus a long-term and safe innovation.

PRECISE. SAFE. FLEXIBLE.

We are the only supplier of AGV conveyor technology that can realise and combine all types of navigation. With our systems, you always have the direction and speed of travel of the transport robots in view. When choosing the type of navigation, we are completely guided by the conditions on site.

AUTOMATIC LOAD HANDLING

-

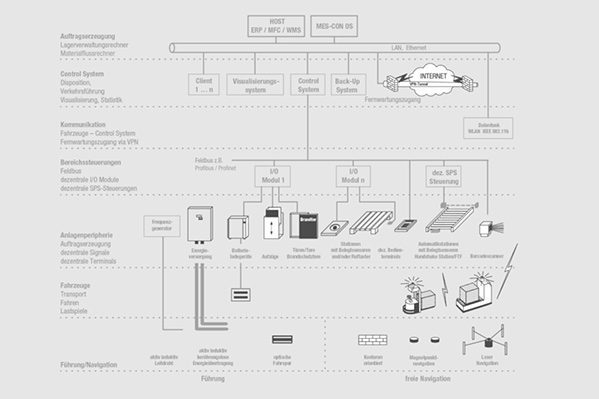

THE COMPONENTS AND OPERATION OF THE AGV'S MASTER CONTROLLER

Our PLC and PC based control systems are built on a long proven software system that is continuously developed and adapted to the most modern requirements.

THE COMPONENTS AND OPERATION OF THE AGV'S MASTER CONTROLLER

-

Our PLC and PC based control systems are built on a long proven software system that is continuously developed and adapted to the most modern requirements.

SAFETY

-

OUR TRANSPORT SYSTEMS - SAFE WITH SAFETY

PERSONAL PROTECTION

Our transport robots are equipped with state-of-the-art safety technology. With their adjustable warning and protective fields; the personal protection scanners enable use even at high travel speeds of up to 2m/s. In narrow aisles, our automated guided vehicles may be used at a much higher speed. Here, the safety scanners with larger protective fields from our partner SICK are used. By means of an anticipatory warning field, the contactless safety scanners ensure gentle braking and thus protect the transported goods. At ek robotics, personal protection is a top priority and is ensured accordingly with the scanners used.OBSTACLE RECOGNITION

For optimal obstacle detection, we equip our transport robots with state-of-the-art safety technology. The scanners provide full-surface protection in the direction of travel and brake accordingly in the event of obstacles. Mounted on the side of the vehicle or in the upper vehicle area, the scanners provide additional protection against suspended loads or manual intervention. With a wide range of combination options, we equip your transport robots with suitable scanners and provide all-round protection for your very individual tasks.3D OBSTACLE RECOGNITION

Three-dimensional obstacle detection can be achieved both by equipping the transport robots with several 2D scanners and by using 3D cameras or 3D scanners. This way your individual transport vehicle detects possible obstacles long before a collision can occur. In addition, we offer combinations of various safety scanners and 3D cameras - completely individual and specific to your requirementss