- Offer Profile

- Swisslog designs, develops and delivers best-in-class automation solutions for forward-thinking health systems, warehouses and distribution centers. Swisslog is a global organization with 2,500 talented employees in more than 20 countries on four continents and customers in more than 50 countries. Headquartered in Buchs/Aarau, Switzerland, the Swisslog group is organized into two business units, Healthcare and Warehouse & Distribution Solutions (WDS).

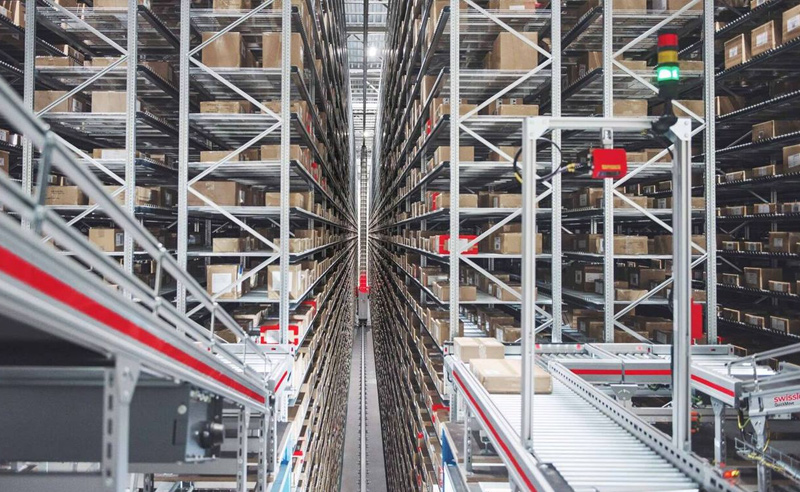

Automated warehouse systems from a single source

-

From the traditional high bay warehouse to innovative robot-based material handling solutions. Swisslog offers you a wide range of traditional and out of the box technologies for automated warehousing that provide quality, flexibility and efficiency.

Modular, flexible and software-driven material handling technologies

Every company has different logistics and supply chain requirements. Our automated warehouse solutions are perfectly customized to your needs and guarantee the optimal flow of goods at a low cost per pick.

It doesn’t matter what you are looking for, we offer the materials handling technology that perfectly meets your needs from receiving to shipping. Automated storage & retrieval systems to increase efficiency and quality in warehousing

-

From the traditional high bay warehouse to innovative robot-based storage solutions. Swisslog offers you a wide range of traditional and advanced technologies for automated storage and retrieval of pallets and smaller goods, such as cartons or bins. These fully automated systems boost warehouse quality, flexibility and efficiency.

Modular, flexible and software-driven ASRS for maximum efficiency

Are you looking for an effective automated storage and retrieval system to overcome your warehousing challenge?

Limited space, an awkward warehouse building, increasing inventory or turnover in unusual shapes or sizes can all make it difficult to find the right ASRS solution. Multiple factors need to be considered when choosing the right solution. Automated storage solutions need to be scalable while maximizing space and performance. Staying flexible enough to respond to changing market requirements is also essential, as when new products launch, demand increases and regulations change.

Space costs you money! Swisslog always finds the most effective solution with the best price-to-performance ratio, transparent processes, and the greatest flexibility. You can respond to changing business conditions at any time by adjusting capacities when you need to accommodate increasing throughput. Automated pallet warehouse to maximize throughput and optimize energy use

-

From the traditional high bay warehouse to innovative robot-based storage solutions. Swisslog offers you a wide range of traditional and advanced technologies for automated storage and retrieval of pallets and smaller goods, such as cartons or bins. These fully automated systems boost warehouse quality, flexibility and efficiency.

Modular, flexible and software-driven ASRS for maximum efficiency

Are you looking for an effective automated storage and retrieval system to overcome your warehousing challenge?

Limited space, an awkward warehouse building, increasing inventory or turnover in unusual shapes or sizes can all make it difficult to find the right ASRS solution. Multiple factors need to be considered when choosing the right solution. Automated storage solutions need to be scalable while maximizing space and performance. Staying flexible enough to respond to changing market requirements is also essential, as when new products launch, demand increases and regulations change.

Space costs you money! Swisslog always finds the most effective solution with the best price-to-performance ratio, transparent processes, and the greatest flexibility. You can respond to changing business conditions at any time by adjusting capacities when you need to accommodate increasing throughput.

PowerStore: High density shuttle system for pallet warehousing

-

Compact storage with PowerStore shuttle system

The modularity of the PowerStore pallet shuttle system enables storage of up to 60% more pallets compared to manual systems. It can also be individually tailored for all shapes and sizes of warehouse buildings.

PowerStore pallet storage systems can be used in a wide range of environments, from -30°C in frozen food storage to 50°C. It can be used in buildings with unusual shapes. The modular design of the PowerStore system opens up completely new possibilities for automation in existing warehouses.

What makes Swisslog’s PowerStore unique?- Swisslog has invested more than 40 years of global experience to optimize a system with extremely high throughput and the utmost in reliability.

- We offer systems that feature highly accurate laser positioning, ensuring optimal positioning 100% of the time.

- PowerStore control software is fully integrated in Swisslog’s SynQ suite of warehouse management software and designed to work seamlessly with customers’ WMS and host systems.

- Low-height carriers save storage space while still enabling industry-leading lift heights. This allows for normal pallet deflections and minimizes the need for troubleshooting within the rack.

Vectura: Stacker crane for your sustainable pallet warehouse

-

Efficient storage with Vectura stacker cranes

The Vectura crane is unbeatable in every dimension.

It performs equally well in temperatures as low as -30°C in a frozen food warehouse or in ambient environments as high as +50°C. Depending on the storage density and throughput requirements of your warehouse, it can handle one, two or more loads in single, double, triple and multi-deep layouts.

What makes Swisslog’s Vectura stacker crane so unique?- Vectura is pretested and shipped in modules which are easily assembled on–site. That means that the roof of the warehouse doesn’t need to be removed. This ensures a rapid installation and minimal risk of disruption to existing operations. One crane can be assembled in one day.

- Swisslog production technology uses automated welding robots and submerged powder welds that increase the life span of welds for optimum long-term performance.

- All chassis undergo heat treatment after welding, which removes stress from the material. This reduces the pressure and ensures a longer lifetime.

- Unique mast design enables low weight, which dramatically reduces energy consumption of up to 20% compared to other pallet cranes.

- Power Module for lift and horizontal movements benefits from regenerative energy from one drive directly to the other. This means that the crane uses its movements to generate more energy.

- Vectura can be configured to provide regenerative braking energy that can be used to power freezers and other energy-consuming warehouse equipment. An optional power unit supplies excess energy back to the main power supply system. This means that vectura can use the generated energy for other devices.

- Flexible software module for smart integration into your existing IT infrastructure and optimal material flow.

Mini load ASRS for your light goods logistics

- A dynamic, space-saving and flexible solution for the small parts storage in light goods logistics: whether in bins, boxes or containers, the automatic mini load ASRS system is designed for the efficient storage of small and medium-sized items with high throughput.

Mini load ASRS: a future-proof investment

Highly flexible automated mini load warehouses

In the environment of robotics, digitalization and individualization, performance in mini load ASRS is more important than ever, especially in e-commerce, retail or multi-channel sectors. Choosing the right automation solution depends on several factors:

- Shape, size and height of the warehouse

- Number of different products in the warehouse

- Number of products to be stored and retrieved

- Number of products stored and retrieved per week, day or hour

CarryPick: Flexible and modular storage and order picking system

-

The CarryPick storage and order picking system adapts to changing customer demands

CarryPick is an innovative automated storage and picking system designed for multi-channel intralogistics. A swarm of mobile vehicles (KMP600), developed by Swisslog and KUKA, navigates via a grid to deliver mobile racks to workstations for picking and reducing the travel path for workers.

The workstations are safe and configurable to your requirements. They also reduce the picking error rate thanks to pick-by-light and pick pointer. Users benefit from an intuitive workstation interface making it easy to use and ensuring smooth processes.

What makes Swisslog’s CarryPick system unique?- Smart software solutions with improved algorithms to optimize the way items are allocated for storage and picking.

- Integrated into Swisslog’s Software SynQ. In addition to the core processes you get access to analytical tools. These will help you to better evaluate and make smart decisions in your warehouse.

- Our certified safety system ensures a safe working environment for your employees.

- Intuitive and ergonomic work stations ensure easy and error-free operation with touch screens and pick- and put-to-light.

- Perfect for those starting an online, retail or omnichannel business: CarryPick can also be financed via leasing, renting or pay-by-pick to reduce your investement risk.

AutoStore: Space saving storage and order picking system for small parts

-

Storage and picking in one compact robot system

AutoStore is a unique and simple solution that uses robots and bins to quickly process small parts orders. It provides better use of available space than any other automated system thanks to its unique design that enables direct stacking of bins on top of each other and storage of multiple SKUs in a single bin.

Over time, the system automatically learns which products have a higher rotation, storing them on the top layer to ensure faster picking times.

Why use Swisslog’s expertise with AutoStore?- Most experienced AutoStore integrator with more than 85 projects implemented and 100 new orders worldwide.

- System easily integrates into other Swisslog subsystems including conveyors, robots and software, thanks to predefined standards.

- Ready for future growth: AutoStore can be used with manual picking stations or combined with Swisslog’s ItemPiQ robot cell, giving you the option to automate picking step-by-step.

- Integrated into Swisslog’s Software SynQ. In addition to the core processes you get access to analytical tools. These will help you evaluate better and make smart decisions in your warehouse.

- Proven algorithms, processes and ergonomic operator screens enable maximum performance from the overall system. Standard connection to SAP/EWM ensures reduced integration costs and increased flexibility in labor planning.

CycloneCarrier: Dynamic shuttle storage and retrieval system for small loads

-

Efficient storage, fast picking and order consolidation

CycloneCarrier is an automated shuttle system for storage of small loads. The shuttle system is designed for applications where high throughput and excellent availability are essential, for example in Retail & E-commerce for returns handling, replenishment or buffer for order consolidation. The shuttle offers double to quadruple deep storage of totes, trays and cartons. CycloneCarrier is suitable for chilled storage environments. To reduce the number of aisles, the shuttle can be built up to 150 m long and 25 m high. Vehicles are available in two versions with load handling devices in either fixed or adjustable width to handle different product sizes.

Why go with Swisslog’s dynamic shuttle system CycloneCarrier?- Shuttle with plug and play functionality reduces implementation time during operation, service and extension.

- Seamless integration into other subsystems, thanks to predefined standards, operating realization time and costs.

- Durable wear parts minimize running costs.

- Reduced failures thanks to a sophisticated load handling device. Clearance between cartons in depth is checked and telescopic arms can be adjusted independently, if necessary, to safely pick up cartons that are damaged or have moved out of position.

- Quick and easy access to the aisles for maintenance.

- Ability to shut down aisles by maintenance levels increases system uptime.

- CycloneCarrier’s standard software module gives access to a number of business intelligence tools that help optimize the shuttle’s performance.

- Future-proof: Increase performance by easily switching from a goods-to-person to a goods-to-robot system.

Tornado: A versatile miniload crane for automated warehousing

-

The Tornado Miniload crane serves a wide range of applications

Swisslog’s Tornado miniload crane features modern control technologies and a patented light mast (aluminium) connected with bending resistant cross beams for dynamic movements. It is ideal for reserve storage and replenishment of manual picking zones, as well as feeding goods-to-person pick stations directly.

The tornado miniload crane is fit to cover a huge variety of products in ambient and chilled environments.

What makes Swisslog’s Tornado so unique?- Minimized footprint – Miniload cranes can be build up to 24 m high making better use of space. This is complemented by aisle lengths of up to 150 m.

- Storage density is further improved by short run out zones.

- System can easily be integrated with other Swisslog subsystems including conveyors, robots and software, thanks to predefined standards.

- Easy access to drive components for quick service and maintenance thus minimized downtime.

- Standard and customized versions of load handling devices available.

- Reduced operational costs thanks to low energy consumption with patented lightweight aluminum construction of the mast.

- Future-proof concept with CartonLoader in case of unknown future load dimensions.

- Safe handling of a wide range of goods in terms of type, size, weight and quality.

- Controls are integral part of Swisslog’s software SynQ. In addition to the core processes you will get access to analytical tools. These will help you to better evaluate and make smart decisions in your warehouse.

Flexible and scalable transport systems for your automated warehouse

- From conveyor systems to innovative automated guided vehicles, Swisslog offers a wide range of traditional and advanced technologies for the transportation of pallets, cartons, bins, trays and even odd-sized loads. These fully automated systems guarantee 100% integration with your warehouse to optimize the flow of materials.

Smart transport systems easily adapt to your warehousing needs

Looking for an integrated automated transport system to overcome your warehousing challenge?

Choosing the right transportation system doesn’t just depend on the type of products you want to transport. The storage system you want to use, throughput and the flexiblity that is required in your business are all key factors.

At Swisslog we take your unique requirements into account and design the automated transport system that meets your exact needs. Whether it’s an AGV, monorail or conveyor based system, we take the best from our technology portfolio to offer the most flexible and cost-effective solution for your business.

AGV: The mobile solution of the future

-

Swisslog has been implementing customized AGV solutions for more than 45 years. Automated guided vehicles are significantly more flexible than fixed installations, and are also demonstrably lower cost above a certain layout size.

AGV: The flexible alternative to fixed installations

Working with our AGV suppliers, we find the best automated guided vehicle solutions for your enterprise, whether it is a standard forklift, a side forklift, a counterbalanced forklift, or a straddle AGV. We implement all types of vehicle, whether using a conveyor table or a platform vehicle. We can also integrate different types of AGV into the same layout.

An AGV system is an efficient and flexible transport solution with many advantages:

- Automated guided vehicles are widely used in several business sectors including: Industry, Pharma, Hospital, Food & Beverage, Retail, and E-Commerce

- Efficient solution for transports from A to B, with or without warehouse manager

- Ideal for mid-range to large distances up to medium material flows

- High redundancy when having several vehicles

- No fixed installations necessary in the layout

- Readily extendible at any time

- Guaranteed flow through times for material flow

- Reduction in staff

- High reliability and availability

- High return on investment (ROI), especially for 3-shift operation

Monorail: Fast and efficient electrified system for pallet transportation

-

Gentle and noiseless transportation of pallets

Faster and more efficient than conveyor systems, Monorail is a flexible, high capacity electrified system for gently transporting pallets and roll cages over longer distances. Traveling at up to 2 m/sec it can handle more than 600 pallets per hour.

Monorail can be used in deep freeze temperatures down to -30°C and ambient up to 40° C. It carries loads of up to 1,500 kg. Longer twin loads elements can carry 3,000 kg.

What makes Swisslog’s Monorail so unique?

Our modular design is flexible and adaptable to your warehouse needs:- More than 25 years' experience implementing integrated Monorail systems.

- Also available as an integrated part of complete Swisslog systems like Caddypick.

- Standardized spare parts widely available for easy, reduced-cost sourcing.

- Flexible SynQ software modules for smart integration into existing IT environments.

- Continuous communication makes the system more flexible when assigning load transports to vehicles and re-routing.

- EMS vehicles have shock-absorbers between the trolley and hanger to absorb centrifugal forces after curves or switches to increase performance.

ProMove: Efficient and fully automated pallet conveyor

-

Dynamic conveyors for greater warehouse efficiency

With its flexible design, the ProMove pallet conveyor can be configured to meet a wide range of requirements for automated pallet transportation.

It can be used in temperatures from -30°C to 50° C.

ProMove conveyors can carry loads up to 1,500 kg, and up to a total of 4,500kg with three loads on one longer element. This means that fewer elements need to be used to build a system, and fewer elements mean less investment cost and less maintenance.

What makes Swisslog’s ProMove so unique?- Compact conveyors with reduced energy consumption and configurations adaptable to your warehousing needs.

- Compact design fits into tight layouts. High strength thanks to the structure of the conveyor sides.

- Ability to adapt system elements for specific projects.

- High efficiency motors (Standard SS-EN 60034-30-1) with adjustable speed.

- Motor sizes are adapted to each project to suit the actual load weight, friction and required throughput.

- Unique drive technique that ramps speed up and down to help keep loads stable. This technology also optimizes energy consumption, reduces wear and prolongs the service life of the transporter.

- Rigid construction allows long distance between legs for easy cleaning of floors.

- Flexible software module for a smart integration and optimal material flow.

QuickMove: Flexible, modular conveyor system for small loads

-

Modular conveyor system for your small loads warehouse

The QuickMove conveyor system can transport a wide range of small loads like totes, trays and cartons of up to 50kg.

This modular system connects your warehouse and makes sure that you have a smooth material flow. The conveyor system provides an additional layer of safety and reliability for transporting critical goods, ensuring they reach their destination on time.

What makes Swisslog’s QuickMove conveyor system so unique?- Swisslog has a long experience in the implementation of conveyors for customers in different industries worldwide.

- Integrated into other Swisslog subsystems like AutoStore, CycloneCarrier or Tornado.

- Smart Software Integration: Full visibility and access to your conveyor’s data with proven standard interfaces.

- Efficient integration with a 3rd party ERP, WMS or WCS or any type of automation.

- Integrated cable channels for easy installation.

- Reduced downtime with a smart maintenance concept: Very few tools are required for maintenance and installation.

- Easy top access for maintenance of belt conveyors and clip assembly for rollers.

Picking & palletizing solutions that minimize costs

-

Flexible picking and palletizing for maximum efficiency

Picking and palletizing make up to 60% of warehouse operational costs. New technologies are changing boundaries all the time and with robots being able to take over more and more tasks from operators, it is possible to increase throughput in goods-to-person (GTP) picking, for example.

Swisslog always selects the most effective solution for the unique needs of your business with the best price-performance ratio, transparent processes, and greatest flexibility. This allows you to respond to changing business conditions, adjust capacity and increase throughput as needed.

Our experts will always help you select the optimal picking or palletizing method for your business.

Besides the number of orderlines and the number of products, many other aspects can influence the solution. This includes family grouping, delivery times, ABC-curves and product size, just to name a few.

In addition to that, there are multiple picking technologies in which Swisslog has many years of experience.- Pick-by-Voice

- Pick-by-Light

- Pick-by-RF terminals

In addition, Swisslog is developing innovative picking solutions like HoloPick - a HoloLens-based picking method.

CaddyPick®: Semi-automated case order picking solution

-

Faster than manual picking solutions

CaddyPick is a semi-automated order picking of mixed case pallets or roll cages applicable in ambient temperature and chilled warehouse zones. CaddyPick is a mixture between a person-to-good and a zone-to-zone picking solution with monorail vehicles – the Caddy – transporting the order unit (pallet or roll cage). The Caddy moves through the picking aisles automatically.

Why use Swisslog’s CaddyPick semi-automated case order-picking?- Streamlined and more efficient processes due to automated hauling, putaway and replenishment function.

- Significant improvement of order filler performance due to automating the order start and order finish functions.

- Team approach to the picking function also increases system performance.

- Error-free picking through weight monitoring and easy pick dialogues on the pick displays.

- Quiet working environment in a palletjack-free working environment.

- Caddy vehicles can travel to any of all pick slots without losing pick efficiency.

- Safe picking environment: Security sensors on each vehicle cause less accidents than with manual fork lift trucks.

Fast & ergonomic goods-to-person picking

-

Goods-to-person single-item picking delivers products to a static pick station. The picker removes the products, which are then added to a specific pallet or tote order. Swisslog’s goods-to-person picking solutions are based on proven principles to

boost efficiency, maximize storage space and make it virtually impossible to pick the wrong product and/or quantity.

Compact and flexible storage and picking system: AutoStore

CarryPick: Flexible & scalable storage and picking system

Storage systems for goods-to-person picking

CarryPick: Flexible & scalable storage and picking system

The modular and flexible system transports racks to ergonomic picking stations. It is also ideal for handling returns.

Storage systems for goods-to-person picking

Our intelligently connected technologies provide ergonomic GtP picking solutions. Learn more about our automated storage systems.

Robot-based picking & palletizing for higher warehouse performance

-

Swisslog’s robot-based solutions combine KUKA robots and Swisslog’s intralogistics knowhow. They are designed to reduce operational costs and improve warehouse efficiency.

Robots improve your warehouse efficiency

Customer requirements for goods diversity, individualization, freshness, and delivery speed are constantly growing. ItÂs no longer same day delivery, itÂs next hour delivery. Picking and palletizing make up to 60% of your warehouse operational costs, and are the most time consuming processes in your warehouse. Workers to do it are becoming harder to find nowadays too. Only a very high degree of automation and self-learning smart-data systems can meet todayÂs diverse and growing demands.

ItemPiQ: Efficient robot-based automated item picking for order fulfillment

-

Efficient and reliable order picking with ItemPiQ

With ItemPiQ, item picking for e-commerce, retail and pharmaceuticals can be fulfilled rapidly and accurately. The robot cell is designed to handle repeated piece picking, error-free. The robot is operational 24/7 and can pick and place products from a source into a target bin or carton. This allows companies to better cover seasonal peaks such as Black Friday and the Holiday season. Thanks to the robot-based order picking, operating costs can be reduced in the long term and staff shortages overcome.

ItemPiQ’s intelligent vision system recognizes and picks a large variety of items. It identifies the grip points of unknown articles, greatly simplifying the learning process.

Thanks to its multi-function gripper, the robot can handle a wide variety of common products in retail, e-commerce and pharmaceutical industries weighing up to 1.5 kg. Depending on size, weight, product-to-robot system and storage method, ItemPiQ can pick up to 1,000 items per hour.

What makes Swisslog’s ItemPiQ truly unique?

ItemPiQ is unparalleled in its flexibility and intelligence:- ItemPiQ can easily cope with changing assortments. Its multifunctional gripper can handle a wide range of diverse products thanks to four different grasping methods, selected according to the products being picked and placed.

- ItemPiQ sets the base towards artificial intelligence: Our intelligent vision system is able to detect unknown items, simplifying the teaching process.

- ItemPiQ can be easily integrated with the AutoStore automated storage system.

- ItemPiQ is seamlessly integrated with SynQ software to ensure reliable operation.

- ItemPiQ can be combined with Swisslog's existing intralogistics solutions, such as AutoStore and CycloneCarrier.

- Thanks to a standard interface, ItemPIQ can be connected to any WMS system.

ACPaQ: Fast and reliable automated mixed case palletizing

-

ACPaQ mixed case palletizer grows as you grow

ACPaQ is universally applicable for fully automated order picking of mixed case pallets. Store-friendly pallets are automatically built in distribution centers using the combination of proven Swisslog technology, such as the CycloneCarrier light goods shuttle system, conveyor systems and high performance de-palletizing and palletizing robots from KUKA. It is configured using modules and is scalable for mid-size and large distribution centers handling up to 500,000 cases per day.

Flexible and intelligent warehouse execution systems for future-ready logistics

-

Creating a new era of flexible and data driven automation solutions with WMS/WES software solutions

Agile and future-oriented software is the critical key for companies to adapt to market changes today and in the future and keep their warehouse operations optimized at all times. Swisslog’s software management systems embed intelligence in the operation, and synchronize the performance of automated logistics systems in the era of Industry 4.0 and IoT. Together with KUKA, it is our vision and mission to deliver a software solution that enables companies to optimize not only warehouse performance, but also their entire value chain.Swisslog's software execution systems are at the heart of the digital revolution in intralogistics automation. Whether you are following a strategy with our powerful SynQ platform or prefer the SAP EWM suite. Our solutions are paving the way for Industry 4.0, connecting processes, humans and robotics.

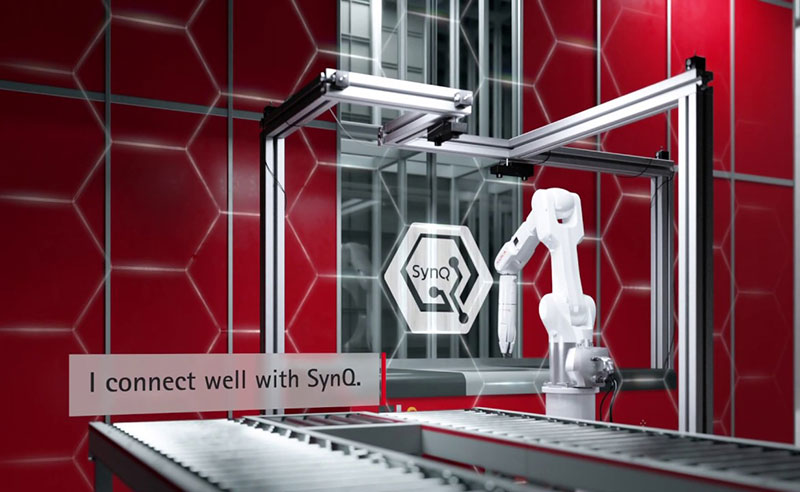

SynQ: Modular warehouse management system for optimized logistics processes

-

Stay ahead of your competition with a smart WMS

SynQ stands for Synchronized Intelligence and is a modular, service-oriented software platform for warehouse management and material flow orchestration. SynQ gives you the precise functionality you need to optimize your warehouse operations. It literally embeds intelligence in the operation and synchronizes the performance of your automated and manual warehouse equipment in the best possible way. It encompasses warehouse management (WMS), material flow (MFC/WCS), and automation control systems (ACS) functionality, along with an array of business intelligence tools to boost your warehouse performance. SynQ will help your company to embrace the era of digitalization and stay ahead of your competition.

SAP EWM: Integrated Warehouse Management Solution by Swisslog

-

Reduced number of interfaces in your Warehouse with a seemless SAP EWM

integration

SAP EWM is a highly standardized and efficient warehouse management system for manual and automated warehouse solutions with material flow functionality that allows the direct connection of PLC-level controls.

SAP EWM can be run as an embedded module integrated in the SAP ERP S/4 HANA landscape or as a decentralized system. The advanced functions improve operational processes and increase transparency in the warehouse.

Our industry expertise for your business challenges

- At the core of our business is a strong commitment to solve the supply chain challenges of our customers. As experts in global industries such as Retail & E-commerce and Food & Beverage, we help businesses grow by finding the best possible solutions for specific logistics operations. Our consulting and system knowledge is backed by years of experience and the robotics know-how of KUKA. Together, we form a global, full-service provider of automation and Industry 4.0 solutions to offer you the same competitive advantages: quality, innovation and technology.

Dynamic and agile beverage warehouse automation

-

Flexibility to respond to a changing beverage market

Product lines are diversifying with more new drinks and flavors, while store orders are becoming smaller and more frequent. Regulatory and product safety requirements are tightening with increasing demand for freshness and convenience.

Only flexible and agile automation can fulfill the requirements of the fast-changing beverage industry.

Swisslog’s solutions for the F&B industry are specifically designed to meet the needs of this changing market. Agile, scalable designs provide the flexibility you need from production to point of sale.

Fresh and frozen food: Can your warehouse keep up with changing demands?

-

Flexible, tailor-made automation for the food industry including cold storage warehousing

Agile and scalable, Swisslog automated warehouse solutions for ambient and frozen food provide the flexibility you need from production to the point of sale.

Designed around the unique requirements of your temperature controlled operation, each installation ensures freshness and quality, while reducing costs and order fulfillment time.

Pharmaceutical logistics: Are your warehouse operations Track&Trace compliant?

-

Improve efficiency and reduce risk with Track&Trace software

Swisslog pharmaceutical warehouse automation solutions enable pharma enterprises to meet government regulations and industry best practice, including FDA, GMP, GAMP 5, GSP, & GDP.

We use in-depth analysis of your business combined with our own intralogistics expertise, insuring your pharmaceutical supply chain is fully compliant in the most flexible and cost efficient way. You can benefit from a fully track&trace compliant SynQ software platform .

Logistics automation for retail, e-commerce & multichannel

-

Flexible modular technology and software

Online shoppers require greater personalization. Therefore, warehouse managers must now consider split case picking, multiline item sorting and fast turnaround times.

We listen to and understand the unique needs of every business. Our standardized technology is then individualized to provide a bespoke solution that is highly flexible and scalable.

Our modular but standardized software meets the key requirements for both pure e-commerce platforms and retail chains, with functionalities such as returns handling, promotions and other value add services.

Other industries

- We support customers all over the world and provide best-in-class automation solutions for industries as diverse as Banking, Automotive, Home & Personal Care and Tobacco.