- Offer Profile

- Proven components from

industry, combined with the latest approaches from research, have resulted

in a new generation of automated guided vehicle (AGV) systems:

The UNITR system – your advantages at a glance

- Short system installation time

- Simple, convenient operation through the web-based user interface

- Optimal adaptability to new company requirements

- Step-by-step expansion and integration of new tasks

- High mobility in existing buildings and narrow areas

- A high level of safety – type-tested piece of equipment

- Quality, robustness and reliability through high-quality, standardised components

AGV

-

When developing our solutions, the requirements with regard to everyday hospital routine are always central.

- Simple integration into existing or new buildings

- Use of environments with limited space

- Personal safety of the UNITR – type-tested – for opening up areas which have not yet been used, e.g. crossing public areas

- Reliability

- Minimal planning effort

- Inclusion of pre- and post-process steps

- Diverse interfaces for connection to other software systems

- Simple operation and maintenance of the unit

- Use of existing elevators

UNITR

-

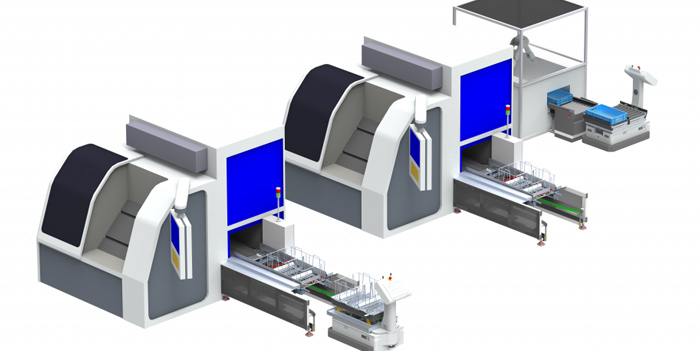

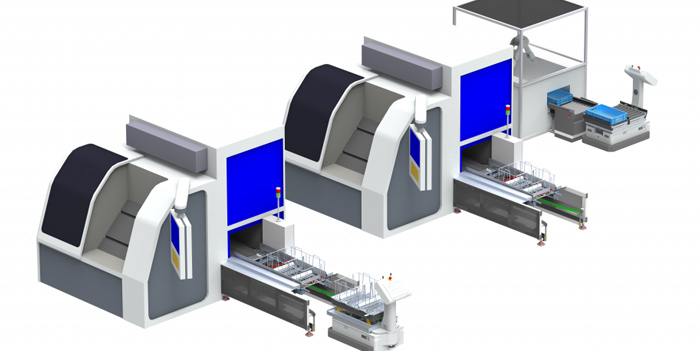

The UNITR is an autonomously navigating transport robot that can perform various transport tasks with specific add-on modules. Thanks to the automatic module change function, the robot can also change superstructure modules independently.

Our robot can be integrated into new or existing buildings without any structural adjustments. A system can be adapted and expanded as required.

Your advantages

- Person-safe, type-tested safety concept

- Easy operation and interaction via touchscreen, PC, tablet or smartphone

- Communication with the user via email/SMS

- Communication with building technology such as fire alarm system, elevator control, door controls, etc.

- Availability 18/24h (drive 9 hrs. at a time, then charge 3 hrs.)

- Max. load 200 kg

Applications

Healthcare

-

The development of our solutions always focuses on the customer's needs from everyday hospital life. Our robots navigate safely in zones with passenger, patient or industrial truck traffic as well as in public zones. Goods can be distributed in 24-hour operation and over several floors.

Your advantages

- Easy integration into existing or new buildings

- Utilization of environments with limited space

- Personal safety of the UNITR - type approved - for accessing previously unusable areas, such as passing through public areas

- Tools for monitoring and performance tracking of the system for all end devices

- Minimal planning effort, easy layout and process changes

- Integration of upstream and downstream process steps

- Multiple interfaces for connection to other software systems

- Simple operation and maintenance of the system

- Use of existing elevators

With the UNITR and the modular principle, MT Robot AG offers transport solutions for a wide range of requirements. The robot can automatically change superstructure modules in a module changing station and thus perform different tasks.

Industrie

-

The development of our solutions always focuses on the customer needs of the industry. Our robots safely navigate within warehouses, production and assembly zones and connect them with each other. We also automate the transport of goods in areas with passenger or industrial truck traffic and in public zones. Goods can be distributed in 24-hour operation and over several floors.

Your advantages

- Easy integration into existing buildings or new buildings

- Utilization of environments with limited space

- Personal safety of the UNITR - type approved - for accessing previously unusable areas, such as passing through public areas

- Tools for monitoring and performance tracking of the system for all end devices

- Minimal planning effort, easy layout and process changes

- Integration of upstream and downstream process steps

- Multiple interfaces for connection to other software systems

- Simple operation and maintenance of the system

- Use of existing elevators

With the UNITR and the modular principle, MT Robot AG offers transport solutions for a wide range of requirements. The robot can automatically change superstructure modules in a module changing station and thus perform different tasks.