TRAPO

Videos

Loading the player ...

- Offer Profile

- TRAPO AG develops and produces tailor-made solutions in the fields of conveying technology, robotic systems and automization. We set new standards worldwide - for flowing transfers in production and intralogistics.

Product Portfolio

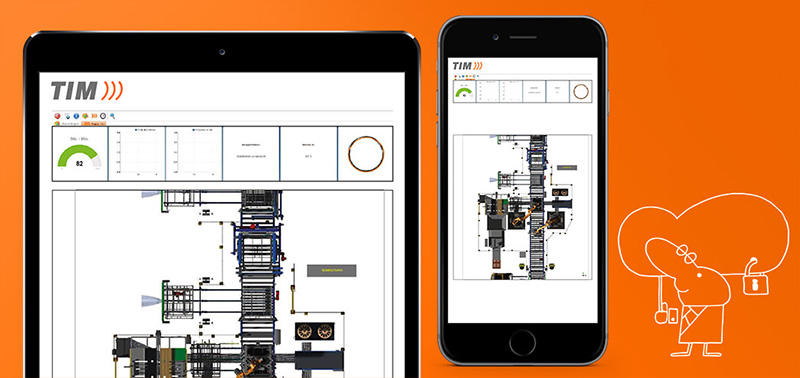

TIM ))) TRAPO INTELLIGENT MANAGEMENTSYSTEM

-

With the TRAPO Intelligent Managementsystem, TIM for short, customers have their production keyfigures in sight.

Limitless information

- The TRAPO AG developed, sectorindependent, customer-configurable data management system forms the central interface between production systems and TIM.

unique - intelligent - secure

-

Your advantages :

Increase in results

- Ergebnissteigerung

- Improvement in production times

- Effective time management

- Cost reduction

- Quality increase

System optimization- Anlagenoptimierung

- Logging of parameter changes

- Performance comparison based on the changes

- Optimization of energy requirement

- Higher capacity

- More effective systems

Limitless availability- Grenzenlose Verfügbarkeit

- Management-relevant data, retrievable worldwide

- Secure TRAPO cloud

- 24 hours online

Conveying technology

-

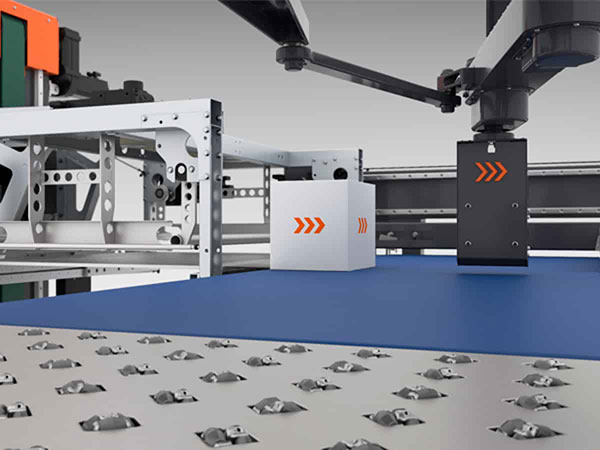

Going with the flow: Conveying technology from TRAPO

The conveying technology portfolio with which we respond to each assignment efficiently and flawlessly is as numerous and unique as your sector and your production lines.We raise sustainably the optimization potential for the material flow in your production.

We design and build according to your specifications from individual conveying element to complete conveying system. Acquaint yourself with and appreciate the latest conveying technology generation

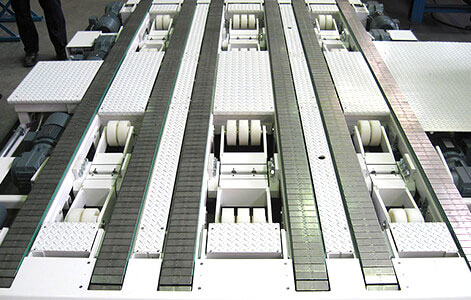

Modular belt conveyor

-

Modular belt conveyor – new standards in conveying technology

At 10m wide and almost 100m long we have, in accordance with the chain supplier, built the world’s largest modular belt conveyor.

This type of modular belt conveyor is perfectly suited to application in flow production. The personnel accompany the components on the belt and assemble the products there in the flow. Through the flow production on the modular belt conveyor assembly is characterized by an optimal structure and transparency.

The assembly times become significantly shorter. Deadlines become easier to plan and secure. A further advantage of our large assembly belt lies in the simple material feed and in the simplified intralogistics planning.

Transfer tables

-

Transfer tables – Innovation for rapid belt change

The time periods within which investments need to pay for themselves become ever shorter.

It is therefore all the more important that machinery and conveyors function reliably and can be repaired most promptly in case of a malfunction.

These tasks are frequently complex where transfer tables are involved which often need to be largely dismantled. This ever more important requirement has been met by TRAPO AG by the development of a new transfer table.

This table can be integrated into many roller conveyors. As standard, this is featured as a flat-belt transfer table. The application of roller chains however is also possible. After loosening just 4 screws a conveying element can be dismantled.

The belt is automatically slackened by loosening the screws and can be removed without any further effort and be replaced by a new belt. The tension of the new belt is performed automatically by tightening the 4 screws. The screws are accessible from above and are driven into a sleeve.

All-side roller conveyors

- Even swiftly convey the heaviest of payload weights.

Reject- and distribution stations

- High-performance mechanics optimize economic goods handling.

Turning- and accumulating tables

- We avoid unscheduled intermediate stops.

Belt conveyor

- Reliable conveying technology on an endless belt; many-sided adaptability.

Chain- and belt conveyor

- Security in goods conveying even in critical environments.

Slat-band chain conveyor

- We think around corners: with curved elements.

Roller- and vertical conveyors

- Untirable load-carrier for various production levels.

Robotic systems

-

All under control: Robotic systems from TRAPO

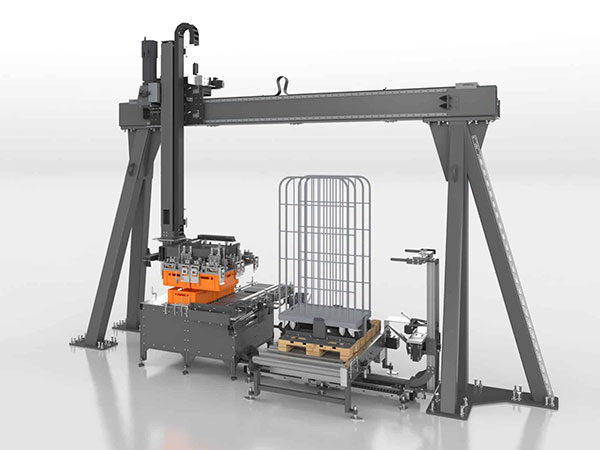

Our robot-based production systems are designed, produced and programmed precisely according to your specific requirements.

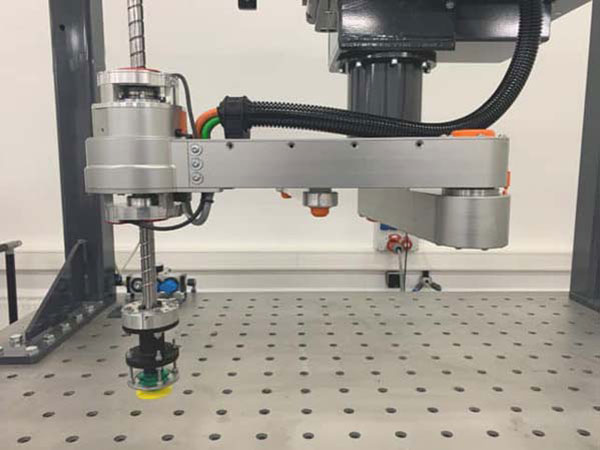

Picker-Robot

-

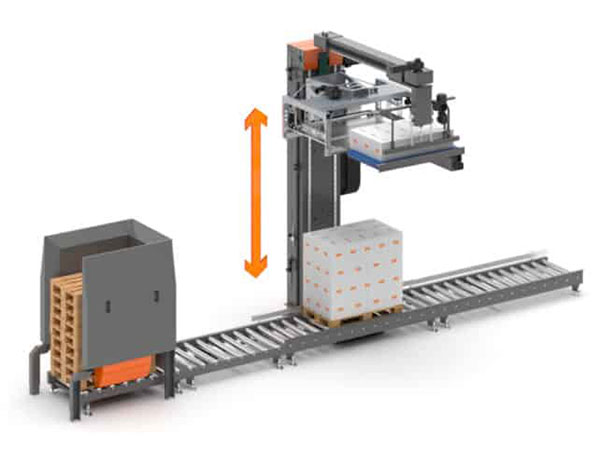

Our high-capacity portal palletizers act in a material-caring manner on three servo-linear axes within cubic space.

We develop, design and manufacture portal robots in our in-house production facility in Gescher-Hochmoor. We are a specialist in the high-care segment -with portal robots made of high-grade steel.

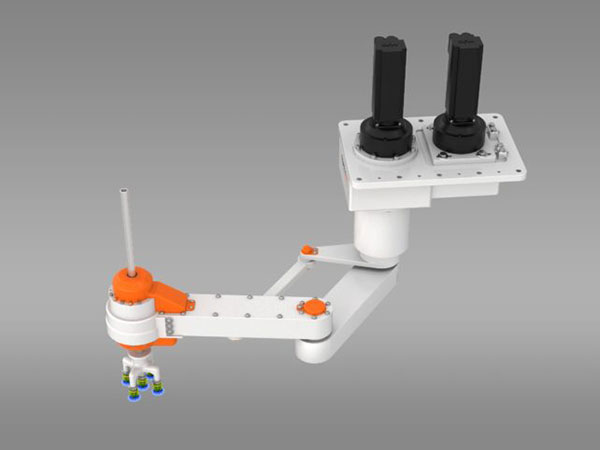

Packer-robot

-

Our robots optimize your palletizing procedures

Our robot applications sustainably optimize your palletizing procedures during production are are modifiable at any time.

They take from various positions, individually, in rows or in layers, small load carriers (KLT), cartons, sacks, cans, buckets, trays, cartons or barrels including wheels, in order to position, palletize or depalletize them.

Palletizing systems

- Our high-capacity portal palletizer acts on three linear axes within cubic space

Combination grippers

-

The time- and costly change of the grippers is dispensed with:

Combination grippers unite the performances of the vacuum gripper with those of the mechanical gripper. Decisive when several tasks need to be performed or limited space is available. They adapt to different products and in addition grip pallets, workpiece carriers, intermediate layers or lids.

Mechanical grippers

- Mechanical grippers are especially suitable where products cannot or may not be sucked up. In the form of clamping grippers or as product-caring, gripping, interlocking grippers they always have their product securely under control, even under hard acceleration.

Fork grippers

- Reversing fork grippers handle open vessels or large sacks. The products are received by their underside. The design of this gripper makes it possible to accept products from the roller-conveyor.

Vacuum grippers

- Smooth, sensitive air-impermeable goods are securely received by vacuum grippers by means of a vacuum pump and forwarded. Handling weights are increased by the number of suction units and suitable vacuum generation.

Magnetic grippers

- Magnetic grippers for ferro-magnetic materials receive their holding strength through permanent- or electromagnets. In operation, e.g. during fully-automatic sawing with adjacent picking area, in the handling of perforated plates, but also for gripping steel frames, workpiece carriers or other components made of ferro-magnetic steel. Magnetic grippers are wear-resistant and just need a suitable surface on the product in order to be able to grip it.

Needle gripper

- Needle grippers optimise the handling of unstable or air-permeable goods, such as textiles, stone wool, rubber slabs or materials of different thicknesses.

Automization

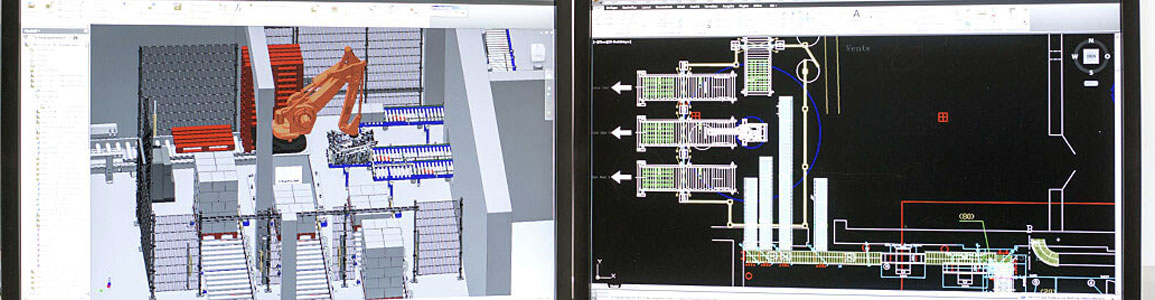

All under control: Automization technology from TRAPO

-

For an efficient conveying- and handling technology automization is a decisive factor. Whether it involves the mechanical concept, automization technology or the software: In close cooperation with you our engineers deliver innovative solutions which enthuse and - perfectly matched to one another - sustainably lead to efficient automization of applications in your production process.

We help to actively reduce energy costs

When designing components, value is always attached to sustainability. As such, depending on system layout, the DC-bus is joined up in order that energy is not transformed into heat through brake resistance, but directly into drive movement. Alternatively, regenerative units are employed in order that the energy is restored to the grid. Our solution - IT competence

-

Our software solutions for maximum individualization.

To awaken conveying systems we use high-performance software components which are individually matchable.

The drive level (SPS) is to a large degree covered by Siemens S7 and the TIA portal. Also Beckhoff, Eaton, Allen-Bradley and others form part of the scope of delivery in agreement with the customer.

The visualization level is similarly mainly covered by Siemens. There WINCC, WINCC flexible and the TIA portal are employed. As on the SPS-level, you benefit from our experience - here we also integrate products from other manufacturers in agreement with our customers.

The electrical drive technology is transformed largely by SEW components. Here, drive units e.g. Movimot, Movitrac, Movidrive are employed. Basically, the entire drive technology product range from SEW is offered, project-engineered, programmed and commissioned. In addition, solutions from Siemens, Danfos, Lenze and other manufacturers are among the delivery range.

Robot applications are principally realized with Kuka robots. Other manufacturers such as ABB, Fanuc, Okura and others will gladly be included according to individual client agreement.

Your benefits

TRAPO software development for robot- and plant-wide control- high plant availability levels

- Realization of modern coordinating control systems with connectivity to higher level process control systems as a basis for fully-automatic operation

- rapid and cost-efficient creation of programs with standardized software modules for robots and plant drives

- maximum functional security and minimized error rate

- standardized interfaces to all plant areas

- simple operation for operators and service personnel thanks to graphic and image representations as well as optical signals

- on behalf of clients, individual, product-specific programming of specified layer pattern

Palletizer and Depalletizer

-

Palletize and depalletize precisely with robot- and portal systems from TRAPO AG

Reliable, efficient and flexible

Benefit from our intelligent total solutions for palletizing and depalletizing of your products. Industial grippers, limited to certain integrated functions and precisely working robots are manufactured based on the image of the human hand and its capabilities.

Our robots and portals are equipped with the grippers best suited to your products and in addition take on tasks such as preparing empty pallets or placing intermediate layers. Thanks to correct image processing via scanner or cameras our robots can, if need be, even see.

They mesh perfectly with your work flows:- rapid

- space-saving

- precise

- and are unrivalled for reliability

We assume responsibility when our robot-based production systems are planned, designed, manufactured, programmed and commissioned. Efficient palletizing with greatest stability

-

Our fully-automatic palletizing solutions, depending on application requirements, manufactured based on portal or articulated-arm robots, work flexibly and reliably.

- Acceptance and positioning of the pack unit

- layer formation specified or optimized by TRAPO

- Pallet formation also with intermediate layer

- automatic empty-pallet feed

- Load security

- variable employment of robot

- Packing capacities of up to 70 products per hour

Gentle product handling with fully-automatic depalletizing

-

Our industrial robots accept your products gently and securely from all four sides of the pallet.

- Our industrial robots accept your products gently and securely from all four sides of the pallet.

- automatic placement and removal of pallets

- Highest capacity by gripping several pack units/part or complete layer

- Industrial robots accomplish their tasks at maximum speed

- flexibly employable for various packing formations

- automatic recognition by scanner or cameras and sorting

- single origin depalletizing and storing

Case studies

-

Experience meets trendsetting technology

Competently and sensitively, TRAPO AG, as a plant constructor in conveying, handling meets the high, individual demands of most modern manufacturing and informs about the needed prerequisites within the framework of project management.

Quality innovations from the conveying technology, robotic systems and automization technology give our case studies. Through images, concepts and results they show concrete applications, process optimizations sector by sector.