MLR

- Offer Profile

- MLR System GmbH is the specialist for Automated Guided Vehicles. Wherever it is necessary to efficiently plan and implement the transport of goods from A to B, we are the competent partner. We act holistically and responsibly, are familiar with the requirements in our core industries and, on request, also develop special transport solutions that are precisely adapted to the customer’s requirements and the goods being transported. Together with our partners from the ROFA Group, we stand for a perfect workflow and maximization of productivity with highly efficient use of resources.

Product Portfolio

AUTOMATED GUIDED VEHICLE SYSTEMS (AGV)

-

Master internal transport tasks more efficiently

Automate your material flow with us! AGV systems offer a highly flexible solution to do so, regardless in which environment or under what spatial conditions the system would find itself. Our portfolio includes forklifts, high-rack stackers, heavy-duty transporters and many other AGV solutions, including electric floor conveyors. All solutions are tailor-made – developed and implemented for your individual transport needs. Naturally, due to the fact that we are a general contractor, we also offer the fitting control system. Stackers and forklifts

Phoenix series

- The forklift vehicles from the Phoenix series come in three sizes: S, M, and L. The front designs are equipped with standardized components such as batteries, scanners, and drives. A variety of lifting gear, adjustable and telescopic forks, and roller conveyors are available as extensions. Optionally, the vehicles can be equipped with RFID readers, fork prong sensors, load measurements, or blue lights.

The modular design creates a link between the sometimes very different requirements in projects on the one hand, and the requirement of many customers for standard solutions. With the modular concept, vehicles can be designed for specific customer requirements quickly and cost-effectively.

Phoenix series characteristics:- Load: Standard up to 1,500 kg, special up to 4,500 kg

- Lifting height: 1,200 to 3,000 mm

- Safety equipment: safety edges, laser scanners with warning range based on speed, soft bumpers

- Energy supply: Lead, NiCd, LiMnCo, or LiFePo4 batteries

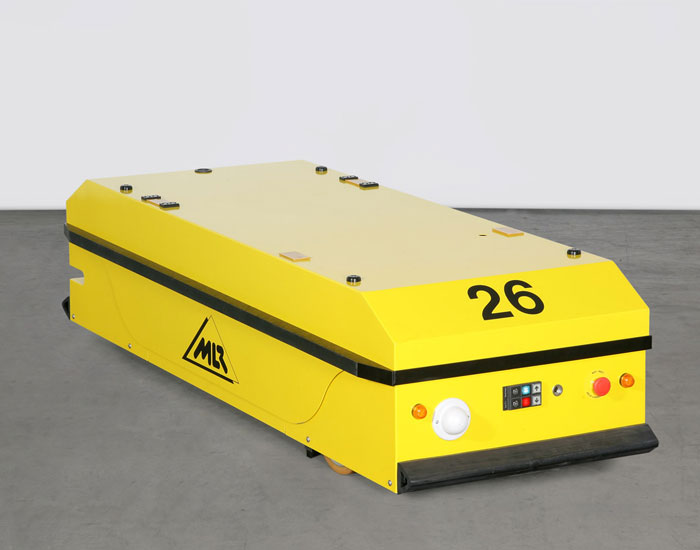

Tractors and platform trucks

Caesar series

- With the Caesar Hospital II, MLR has developed a compact, drive-under tractor for hospitals and clinics that is much shorter than and a third the weight of its predecessor. The 1.423 mm long stainless steel vehicle makes do with little space, has a small driving radius, and now fits even in small elevator cars. The low weight helps save energy and the quick-charging, maintenance- and gas-emission-free LiFePo4 battery makes short opportunity charges possible. The vehicle also has energy recovery and a sleep mode with wake up function. The tractors’s innovative energy concept now allows it to be used round the clock.

The intelligent transport vehicles travel completely autonomously, orient themselves by the natural building structure, and detect obstacles and people in their path. A powerful computer with an Intel processor and the Linux operating system serves as the control unit. A tablet can be connected directly to the vehicle via Bluetooth, WLAN, or USB cable. The vehicle in question is identified by camera and can be manually controlled, if necessary, using the intuitive, easy to operate interface. The tablet can be used to request diagnostics or perform maintenance on site.

Caesar series characteristics:- Load: Standard 150 kg – 63,000 kg

- Hauling capacity: up to 5,500 kg

- Safety equipment: safety edges, laser scanners with warning range based on speed, radar sensors, soft bumpers

- Energy supply: Lead, NiCd, LiMnCo, or LiFePo4 batteries

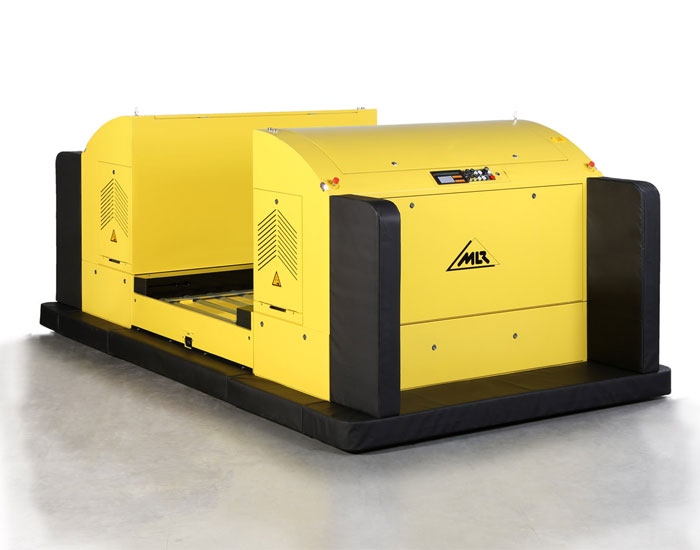

Heavy-duty transporters

Caesar series

- The driverless heavy-duty vehicles from the Caesar series transport large and heavy loads of up to 63 tons. The automated guided vehicle systems are designed for outdoor use in all types of weather.

Ceasar heavy-duty series characteristics:- Transport goods: workpieces, pressing tools, coils, boards, cast parts, steel beams

- Load: 1.4 to 80 tons

- Vehicle length: up to 8 m

- Optional extras: All-wheel steering, coil attachment

- Outdoor vehicles: Radar sensors

High-rack stackers

Mayesto series

- The driverless high-rack stacker from the Mayesto series are especially well suited for storing and retrieving pallets, lattice boxes, and other containers in high-bay warehouses. The automatic narrow-aisle stacker is equipped with a telescopic table whose forks extend to the left and right like on a stacker crane so it can store and retrieve loading units. Alternatively, it can be equipped with a swivel traverse fork.

Mayesto series characteristics:- Transfer heights: up to 11 m

- Load: up to 1.5 tons

- Speed: up to 2.7 m/s

- Navigation: free magnet navigation

- Energy supply: Pb battery 80 V/930 Ah, charge manually in vehicle or change battery

Specialized vehicles

AGV special vehicles

- Our strength is the development of custom special solutions for special and custom vehicles. This includes AGVs with scanning, weighing, or dosing functions, outdoor vehicles, and fourway or double forklifts, for example. In addition to the classic three-wheel vehicles, we offer a vehicle chassis with four- or six-wheel construction. Multi-link suspension is also possible. All wheels can be purposefully steered depending on the wheel arrangement. This technology allows both transverse and diagonal travel (crab move) and is the best choice for conditions with less space. Special requirements for hygiene and safety are predominant in food manufacturing, as well as clinics and hospitals. We can also produce driverless transport vehicles in stainless steel by request, and seal all panels and lifting equipment in accordance with protection class IP54. This allows vehicles to be disinfected on all sides with hot steam.

AGV special vehicles characteristics:- Optional extras: RFID- / barcode readers, weighing equipment, dosing equipment, roller conveyor, belt conveyor, chain conveyor, flexible lifting equipment, cover lift, dual operation

- Stainless steel vehicles: IP54, dust-tight, spray-proof, jet-proof

- Cleanroom approval: emissions-free, GMP approval

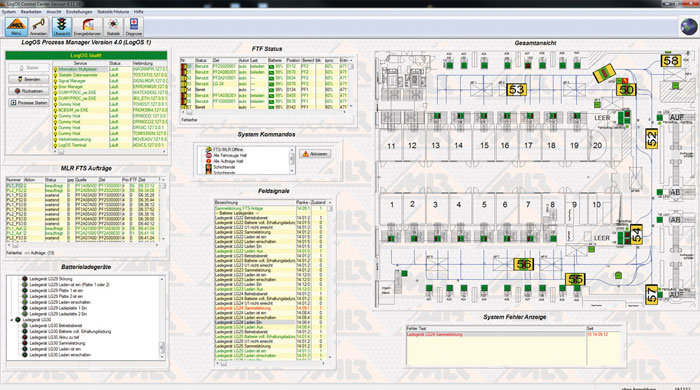

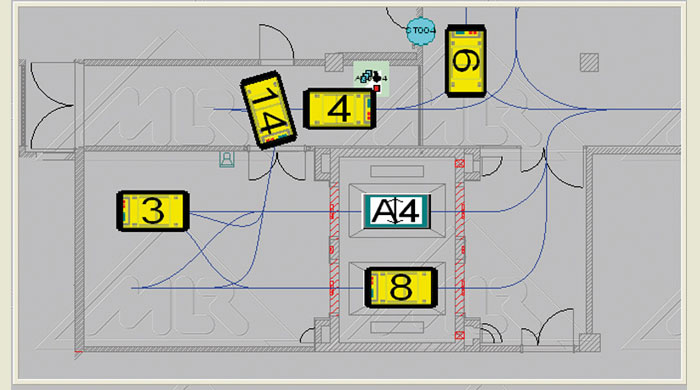

Management and control software (LogOS)

LogOS | Logistic Operating System

- With the multi-functional Logistics Operating System LogOS, we have developed our own control and management software for our AGVs to control your in-plant transport systems, monitor machines, coordinate and track material and goods flows, and organize and manage all common types of warehouse. External vehicles, such as forklifts and cranes, as well as materials handling technology and high-bay warehouses, can also be integrated into the full system, in addition to elevators, fire safety doors, and safety equipment. LogOS has standard interfaces for the common ERP and merchandise management systems, which allows it to be quickly and cost-effectively integrated into already existing IT structures. The ongoing further development of LogOS guarantees our customers a safe investment for the future.

MLR INDUSTRY FOCUS

Automotive & Commercial Vehicles

- The ROFA Group grew with the automotive and commercial vehicle industry. This area is still an important focus throughout the whole group of companies today. We are one of the top suppliers of materials-handling technology, more than 5,000 reference projects worldwide and 50 years of industry experience speak for themselves. All the manufacturers we work with are well-known, and we keep setting new standards on the market with numerous patents and innovative product developments. The increasing electrification of course also affects the production lines. In these times of change, we accompany our customers to successfully master this fundamental change in mobility.

The high process reliability and availability of our systems, our well-developed supplier network across the globe, and precise knowledge of manufacturer-specific requirements makes us stand out. Here, where production processes run in 3 shifts, and so in 24 hours, the principle of zero error tolerance applies. With our solutions we cover all production areas from body in white construction to final assembly, including suitable transport solutions from a single source. In our strong group there is a suitable expert for every task and every technology. We also live by the motto “one face to the customer”.

Chemical & Pharmaceutical

- There are strict regulations in chemistry and pharmacy, and the requirements for efficient processes are high. As a full-service provider for intralogistic transport solutions, we have the right answers to these challenges. Our driverless transport systems are constructed exactly to the required cleanliness levels or are designed so that they meet the GMP and FDA regulations. But not only is the hardware tailored to customer needs, integration into the overall system is also one of our strengths. The control software solutions developed by us are compatible with all common storage systems and fit seamlessly into the existing IT landscape. Third-party vehicles and external conveyor elements can be easily integrated. Besides individual transport solutions, the ROFA Group also offers holistic intralogistics concepts for production, storage, and order picking in the chemical and pharmaceutical industries. The requirements are especially high in the pharmaceutical industry. With the boom in online pharmacies, efficient, secure solutions are more in demand than ever. Sensitivity to light and temperature play a role in the storage of sensitive products, as does the complete traceability of every batch within the entire supply chain. Because patient safety comes first! We provide you with convincing answers for this through our company BSS.

Thanks to the strength of the ROFA Group, we can offer even more: We always keep an eye on the optimization of the entire materials-handling technology so that your system is safe, reliable, and efficient.

Healthcare

- In healthcare, strict regulations regarding hygiene, process safety, documentation and system availability apply. The medical staff is in high demand and must be able to rely on smooth processes in order to handle everyday clinical work. With our flexible, secure solutions in the transport sector, we have significantly improved processes in many medical facilities around the world. Whether transporting dishes, bedding, sterile goods or medication: Our goods transport systems contribute to optimal hygienic supply and disposal and improve workflow across the departments. The intelligent vehicles use existing elevators and move independently on different floors. In this way, everyday clinical practice is organized even more efficiently, and staff have more time for what’s important: the patient.

Thanks to the strength of the ROFA Group, we can offer more than excellent AGV solutions.

Trade & E-Commerce

- In times of digitization and omni-channel business, online trade is constantly growing. Today’s customers want to be able to do almost all purchasing immediately online. They expect the desired goods to be available and to be delivered promptly. This places high demands on logistics. Demands have also changed in traditional retail. For reasons of cost and space, stores and markets increasingly use just-in-time delivery, often several times a day. For this very reason, in view of the increasing variety of products and capacity constraints, many companies must now completely realign important sub-areas of their intralogistics. Shortened process times, increased flexibility and the need to be able to react quickly to seasonal fluctuations are increasing.

In this fundamental change we are on the side of our customers. As a full-service provider, we plan and implement the optimal material flow for existing and new warehouses and develop the appropriate, turnkey solution, on request from construction in the countryside. We are experienced automation experts and stand for scalable solutions that are future-proof – even where the space on offer is limited. We have already proven our maxim “What does not exist, we invent” many times and welcome every new challenge.

Food Industry & Beverages

- The food industry is characterized by a constant price war and changing customer requirements. The challenges are particularly enormous in terms of freshness: The quickly perishable and sensitive products must be delivered to the markets in defined requested quantities just in time. Cold storage solutions are also important because the sensitive goods sometimes need to be stored in defined temperature zones. The pet food sector has very similar requirements and is equally growing rapidly. Standards are increasing, the variety of products is continuously developing. This leads to a need for more storage capacity and optimized intralogistics. When it comes to beverages, special topics such as protection against leaks, fall protection and easy maintenance of the system always play a role in the projects – we always take this into account when planning and flexibly adapt the delivery solution to the respective requirements.

For a large amount of different articles, which only need to be temporarily stored, the ROFA Group, with the participation of the companies BSS, DLS and ROFA AG, has developed a unique solution on the market: the Flowpicker®. This fully automatic, high-performance order picking system enables efficient handling of a wide variety of packaging types, from plastic containers through cardboard boxes to vegetable crates or retail trays. The smart flow storage system warehouse sorts the incoming products in such a way that they are put together just in time for the mixed pallets requested by the customer. The system also sets new standards in ergonomics. Depalletizing and palletizing is done by simply moving. The difficult process of picking up, carrying, and resetting the goods is a thing of the past. A health-friendly solution that is also interesting in terms of staff recruitment.

Find out more about our customized solutions! Upon request, we accompany you from construction of your warehouse or distribution center to adequate shipping or production logistics. And always have the right conveyor system ready.

Machinery & Plant Construction

- Mechanical engineering is one of the strongest industries in Germany and is a leading driver of innovation. “German engineering” is an export hit of the German economy, and even topics such as Industry 4.0 and Smart Factory would be inconceivable without the engineering skills of mechanical and plant engineering.

We support this key industry in achieving its goals. Whether materials-handling systems for in-house material transport, systems for automated processes, or the necessary intralogistics systems: The ROFA Group is your reliable partner on the way to more efficient productivity. The group company MOLL deserves special mention here. With its excellently equipped machinery, the company can manufacture high-precision components of all types, functions, and sizes – we can even respond to special requests.

Even if you don’t need any design know-how from us, but are only seeking a manufacturing partner with whom you can produce, MOLL is the right place to go. With the job order production model, you have access to our machinery and save high investment costs; we in turn can fully utilize our machines to capacity. Both sides benefit from this.

Paper, Printing & Packaging

- The intralogistic transport of paper, printing materials or packaging requires sensitivity and frequently special vehicles in order to be able to pick up and unload the material undamaged. These challenges can often not be mastered with standard vehicles. Here we play to our strength in the individual construction of special vehicles that are precisely tailored to customer needs and the goods to be transported (e.g. large paper roll transports). Whether indoor or outdoor storage: We find the right transport system for every context, e.g. in the form of four-way or double forklifts. The integration of driverless transport systems in the existing storage environment and link to other components used complement our profile. We use LogOS, a control and guidance system that we developed ourselves.

Thanks to the strength of the ROFA Group, we can offer even more than excellent AGV solutions. We always have the optimization of your entire materials-handling technology in mind.

More Industries

- As a special machine and plant manufacturer, our motto is: “Nothing is impossible.” Our procedural know-how, our quality standards, and our flexibility in implementation are transferable to all industries. Whether it is a question of modernizing an aging plant, increasing the degree of automation, putting up a new plant or optimizing the workflow through smart intralogistics: A discussion with the ROFA Group is always worthwhile. We are good at uncovering optimization potential in the value chain and making companies of different types and sizes fit for the challenges of the future and Industry 4.0. To do this, we combine a solution-oriented mentality with in-depth technological knowledge. We bundle the exact skills you need for your project from all the companies in the group!