SERVUS

Videos

Loading the player ...

- Offer Profile

- Servus Intralogistics is a

subsidiary of the Austrian technology company Heron.

Our passion is the development and production of customized Intralogistics systems with the intelligent ARC (autonomous robotic carrier). Servus helps customers to combine all in-house logistics in one optimal flow process – from goods receipt to the automated spall-parts warehouse, production, assembly or order picking to goods issue. Your logistics solution becomes as individual as your processes, with Servus system components.

Servus – serves you more

Product Portfolio

Efficient and innovative shuttle technology

-

The SERVUS transport robots manage the complete internal transportation from goods receipt to goods issue, via the automated small-parts warehouse, production, parts-picking, assembly and office. One system for all areas.

In comparison to other shuttles, this means:

- more efficiency

- more flexibility

- more security

Servus Solutions

-

Intelligent solutions for each application

Whether highly dynamic storage for the retail sector or just-in-time material provisioning in production. Efficient and innovative shuttle technology by SERVUS makes same-day delivery possible in e-commerce. A system for your entire intralogistics. By Function

Warehouse and Production Logistics

- SERVUS merges warehouse and production into a single unit. Autonomous transport robots by SERVUS convey your goods through the entire value chain. This makes seamless automation of your entire value chain from a single source a reality. Production and logistics are perfectly matched. Instead of isolated solutions, customers can keep track of the bigger picture at-a-glance. Industry 4.0 is no longer just a buzzword, but plays a key role in your company's success. With SERVUS, you can benefit from 15 years’ experience in merging warehousing and production.

Warehouse and Picking

- Automated small parts stores (ASRS) by SERVUS are always tuned to the customer’s needs. Whether for slow movers or highly dynamic storage and removal, whether single or double-depth storage. In addition, the SERVUS ASRS is fully integrated into the flow process, as the SERVUS transport robots simply leave the warehouse and supply the picking stations directly.

Production

-

Lean Logistics for your production

We don’t want to automate wastefulness, we want to eliminate waste. Lean production needs equally efficient logistics. SERVUS improves the material flow, reduces intermediate storage and on-site stock, thus freeing up space on the production lines. SERVUS ensures automated material transport along the entire value chain.

By Industry

Commerce / Retail

-

Customers are ordering more and more online, but do not want to lose the

benefits of stationary retail outlets. Click and have, or click and wait. Today,

fast delivery times and uncomplicated returns drive customer satisfaction. In

addition, the sales channel boundaries are blurred; new channels are being added

everyday. This requires logistics solutions that are at the same time individual

and flexibly adaptable. With its highly dynamic warehouses and tailor-made order

picking cells, Servus has the answer to requirements in wholesale trade and

e-commerce.

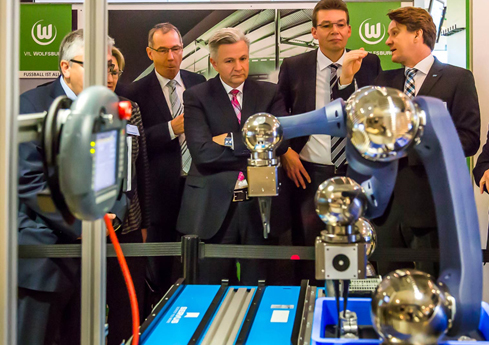

Automotive

- Especially in the automotive and supply industry, in which all process steps in production are precisely controlled and intralogistics of the highest efficiency are required, the SERVUS system can fully leverage its intelligence. SERVUS does not just take care of the individual process step, but also the upstream and downstream processes. Logistics and production become a single unit and the partition line between the two areas disappears. SERVUS has over 15 years of experience in linking entire value chains and integrating warehousing and production.

Plastics

- Autonomous transport robots by SERVUS can also transport bulk goods in addition to cartons, boxes, trays and workpieces. This means that SERVUS can connect injection moulding machines with packing stations, supply the right material to assembly machines at the right time, and also keep finished or semi-finished parts in intermediate storage until the next production step. In the plastics industry, injection moulding and assembly cycles are often not well synchronised. SERVUS decouples the processes, thus increasing their flexibility. This requires logistics solutions that are at the same time individual and flexibly adaptable. SERVUS has the answer to the demands of the plastics industry.

Medicine and Healthcare

-

Almost silent, cleanroom-capable, adaptable to any environment. These are the

ingredients that help SERVUS find the ideal recipe for your intralogistics.

Autonomous transport robots by SERVUS can also be used to transport material in

the cleanroom as well as in the high-concentration area. The flexible modular

assembly kit by SERVUS lets you fully automate your laboratory.

Technology

-

Effective. Flexible. Universal.

Design your individual intralogistics solution to suit your needs and ensure your success in the long term. Thanks to the SERVUS logistics modular assembly kit, Industry 4.0 is no longer just a buzzword. SERVUS combines the principles of “lean culture” with the benefits of Industry 4.0 in your company. The system ensures a high level of process assurance, is easily scalable and allows for optimum cooperation between logistics and production. An optimised material flow reduces unnecessary interim storage and thus frees up your “working capital”.

Servus ARC3 transport robot

-

The key element of the SERVUS system is the intelligent and autonomous SERVUS ARC3 (Autonomous Robotic Carrier Generation 3) transport robot, which can transport anything weighing up to 50kg. The ARC3 is not just an ordinary shuttle that runs back and forth in the warehouse. As a self-sufficient swarm robot, it travels out of the warehouse and always supplies its stored goods to the desired location in the company via the shortest route, at the right time (just-in-time).

And your SERVUS transport robots are individually adapted to your customer needs, in terms of length, width and performance. Depending on the equipment level, size or load handling device, everything from simple cartons or boxes, to bulk goods, or customer-specific parts can be transported.

Automated Storage and Retrieval System (AS/RS)

-

Since the SERVUS transport robots travel out of the warehouse, the Servus AS/RS is fully integrated with the flow process. Depending on the requirements, a SERVUS AS/RS is suitable for slow movers or highly dynamic storage and removal, for single or double-depth storage, and for central or localised storage.

The combination of exceptional storage density and the highest storage capacity utilisation with direct access ensures maximum flexibility with low space requirements. Capacity and performance can be increased and adjusted at any time by adding more swarm robots.

Track System and assistants systems

-

The guide elements are simple carrier sections without wiring and sliding contacts. The allows for a flexible route guidance and ideal adaptation to the current or a new infrastructure. The SERVUS track is predominantly overhead. This frees up valuable space for production purposes.

Assistance systems such as lifts or switches, are integrated into the route system and enable easy integration of local storage locations, assembly or picking stations on different floors and in different buildings. Lifts and switches help SERVUS during its journey. This is why we call them assistance systems. The SERVUS ARC communicates directly with the lifts and switches without a central control. This keeps the system scalable, fast and flexible.

Load Handling Device

- Depending on the requirements, different load handling devices are integrated into SERVUS ARC3 for automatic loading and unloading of individual goods. The various load handling devcies guarantee gentle and efficient handling of boxes, cartons, trays, bulk materials, or customer-specific workpieces at top speeds.

Software & Communication

- The SERVUS system does not require a central control and works in a similar way to a taxi company. The ARC3 (taxi) receives its orders via various options. One of these options is the taxi centre. The taxi centre is directly connected to the Warehouse Management System (WMS), either to WMS by SERVUS or to any storage management system (Microsoft, SAP, etc.). However, with the WMS from SERVUS, the processes can be synchronised and efficiency increased in a superior way.

Connections and Stations

-

Individual system components, such as storage and removal stations, stations, assembly and picking stations or breathing buffers make the delivery and collection of goods possible at any location in the company. Due to Just-in-Time delivery, work-in-progress stock can be reduced and unnecessary storage between processes avoided.

Whether fully automated or manual workstations – you can connect all value-adding processes directly to your logistics.

Services

- Our passion to collaborate with you on defining the ideal state for your intralogistics and eliminating waste. Our services and our system are tuned to your needs as a customer.

Consulting

- At the start of each project there is the workshop. Together with your part or project owners, our lean logistics experts discover the ideal state in logistics and production in the course of a two or three-day workshop – regardless of the product. In cooperation with your specialists, we analyse the current status of the material and goods flow along the entire value chain, check the general conditions and define the ideal solution for your logistics and production. You will be surprised with the efficiency improvements when SERVUS merges logistics and production into a single unit.

Project implementation

- SERVUS Intralogistics provides turnkey, automated intralogistics systems. For you as a customer, this means a single point of contact from solution finding, through design and project management, to production and assembly. Everything from a single source.

Support

- With support and maintenance services by SERVUS, we offer a bespoke service for your logistics system. In order to meet your requirements, after commissioning your SERVUS system, we also seek to optimise the efficiency of your logistics. From support through spare parts management to preventive maintenance, we provide customer-oriented support to ensure maximum system availability. In addition, innovative service products, such as 3D system visualisation or SERVUS data goggles, support the operation of your SERVUS system.

Software

-

The software for your needs

The Servus software portfolio is just as flexible as the system itself. SERVUS supplies you with exactly the software package that you need. SERVUS can handled your entire warehouse management, if so desired, thus optimising your material flow. However, SERVUS can also interface with existing warehouse management systems. The latest features of the SERVUS software give you real time access to all your data; an overview of the system status is also available at any time, and the entire system is visualised in 3D.

Warehouse Management System (WMS)

- Using SERVUS WMS helps you get even more out of your warehouse. SERVUS WMS means that the transport robots work even more efficiently and run far more double cycles than other warehouse management systems. In addition to the SERVUS warehouse, other conventional warehouses can also be easily managed, whether manually or automatically. The SERVUS Software also offers extensive analysis opportunities as well as 3D indicators in real time. The SERVUS WMS can be connected to any ERP system, e.g. SAP, Microsoft, proAlpha, ABACUS, AP+, BIOS 2000 and many more.

SERVUS Efficient Agents System (SEAS)

- SEAS is the communication hub between the Warehouse Management System, the transport robots and their assistance systems. Smart coordination of the individual tasks improves both the efficiency and the performance of the system. Material flow, system status and historical performance indicators are all graphically displayed in the SERVUS web portal. 3D system visualisation gives feedback in real time, thus providing a full overview of the system at any time.