- Offer Profile

-

Since it was established in 1986, elcom has been designing and producing industrial sub-assemblies, belt conveyors and transfer systems.

In order to overcome the economic challenges of our time and respond to new markets requirements, we are developing our processes to satisfy both existing and future customers. This will require us to be innovative, both in terms of our organisation and our products. And encourage common sense, simplicity and the involvement and commitment of all involved.

MODULAR SOLUTIONS

-

Mechano assembled in aluminium profiles

YOU HAVE BEEN ENJOYING THE ELCOM STANDARD FOR 30 YEARS, DISCOVER THE 3 H’ELCOM STANDARDS

Multimodular and intelligent, h’elcom is the brand of aluminium profiles and accessories of the hellomoov’ group.

The h’elcom offer is complete and multimodular. Whatever your project, our range fits perfectly into all your environments. MODULARITY- STANDARDS- PROFILES

MORE THAN MODULAR, MULTIMODULAR, IT’S THE H’ELCOM DIFFERENCE

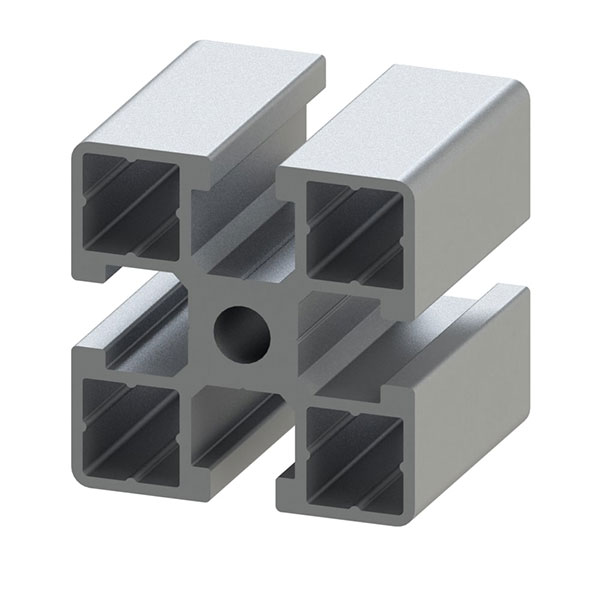

h' 8 40 aluminium profile

- With more than 3000 accessories and aluminium profiles, h’8 40 is the standard of reference for designing and building mechanically assembled solutions in 40×40 sections.

The first profile offered on the French market for over 30 years is available in 5, 6, 8 and 10 h’8 40 grooves, allowing solutions to be created in the following areas

– aesthetics to enhance the investments you make in your workshops, for your men and your machines.

– sustainable to guarantee the durability of the industrial mechanics solutions in which you invest

– does not rust or corrode, it is unalterable.

– sustainable also for the planet because aluminium is an eco-responsible material and hellomoov’ is an ecosystem #greentech

In summary, h’8 40 fits perfectly with all equivalent profiles of the same section that you may already have in your workshops.

The difference is simple: by choosing h’8 40, you have the possibility to welcome the 4.0 transformation in the heart of your workshops by making them perfectly inter-modular and connected to the Moovitique® – you have the security and speed of supply of a partner established worldwide and rigorously covering the French territory – you benefit from the expert support of the team – you have the assurance of robust and durable solutions with certified technical performance.

h' 10 45 aluminium profile

- With more than 2000 accessories and aluminium profiles, h’10 45 is the reference standard for designing and building mechanically assembled solutions in 45×45 sections.

The result of know-how long proven by the experts of our partner transept, the line available in 6 and 10 grooves, are

– aesthetics to enhance the investments you make in your workshops, for your men and your machines.

– durable to guarantee the durability of the industrial mechanics’ solutions in which you invest – does not rust or corrode.

– sustainable also for the planet because aluminium is an eco-responsible material and hellomoov’ is an ecosystem #greentech

In short, h’10 45 fits perfectly with all equivalent profiles of the same cross-section that you may already have in your workshop. The difference is simple: t

– you offer yourself the possibility to welcome the 4.0 transformation in the heart of your workshops by making them perfectly inter-modular and connected to the Moovitique®.

– you have the security and speed of supply of a partner with a worldwide presence and a strict control of the French territory

– you benefit from the expert support of the h’équipe

– you can be sure of robust, durable solutions with certified technical performance.

Discover the many creative solutions offered by the h’elcom range of profiles and accessories. Casing, machine frames, handrails, workstations … let your imagination run wild and assemble, dismantle, reuse, the elements of the h’10 45 standard.

h' 8 45 aluminium profile

- With more than 1500 accessories and aluminium profiles, h’8 45 is another standard in line 8 of section 45X45mm.

Resulting from a know-how long proven by the experts of our partner transept, the standard available in 8 groove allows to realize industrial sub-assemblies.

– aesthetics to enhance the investments you make in your workshops, for your men and your machines.

– durable to guarantee the durability of the industrial mechanics solutions in which you invest – does not rust or corrode.

– sustainable also for the planet because aluminium is an eco-responsible material and hellomoov’ is a #greentech’ ecosystem.

In short, h’8 45 fits perfectly with all equivalent profiles of the same cross-section that you may already have in your workshops. The difference is simple: by choosing NOstress

– you offer yourself the possibility to welcome the 4.0 transformation in the heart of your workshops by making them perfectly inter-modular and connected to the Moovitique®.

– you have the security and speed of supply of a partner with a worldwide presence and a strict control of the French territory

– you benefit from the expert support of the h’équipe

– you can be sure of robust, durable solutions with certified technical performance.

The special shape of the h’8 45 grooves allows you to use standard hexagon nuts.

Discover the many creative solutions offered by the h’8 45 range of profiles and accessories.

Enclosures, machine frames, service desks, workstations … let your imagination run wild and assemble, dismantle, reuse, the elements of the h’8 45 standard.

OUR AREAS OF EXPERTISE

Modular solutions

-

MODULAR ASSEMBLY

Frame, enclosure, workstations are available in kits or assembled. Our profiles and accessories can be delivered in packs, in bars or cut on request.

Moovitics

-

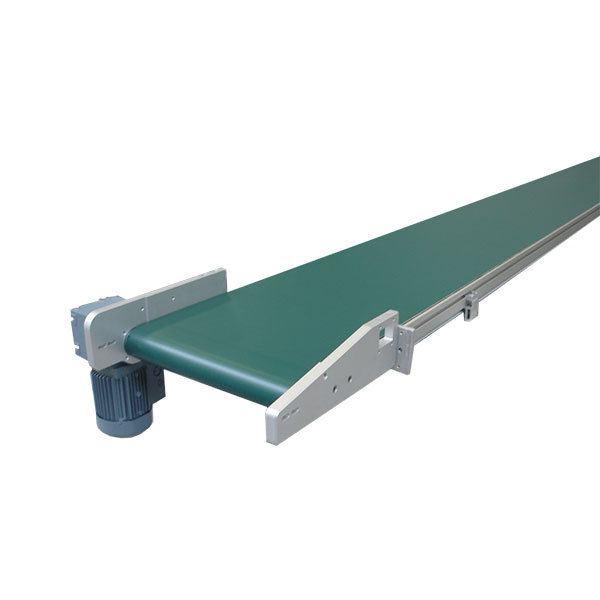

BELT CONVEYORS AND ASSEMBLY TRANSFERS

Conveyors and transfers are designed to provide the best price, performance, ergonomy, and liability ratio.

Modules and solutions

-

TAILORED ONE MOVE AHEAD

Manage flows thanks to pallet transfer lines and conveyors integrating automatic stations or manual workstations.

ERGONOMIC WORKSTATIONS

-

OUR ERGONOMIC WORKSTATIONS

Standard or customizable, we offer a wide range of ergonomic workstations to reduce the risk of MSDs and optimize your productivity.

H’ELCOM’S ERGONOMIC WORKSTATIONS WILL ENABLE YOU TO IMPROVE THE PRODUCTIVITY OF YOUR EMPLOYEES WHILE REDUCING THE RISK OF MUSCULOSKELETAL DISORDERS (MSDS).

ERGONOMICS, FOR WHAT PURPOSE??

There are – at least – 3 good reasons to take into account the ergonomic constraints for your workstations:- The human aspect: To create working conditions without adverse effects and without bad consequences on health.

- Productivity: Improving quality and performance

- Motivation and satisfaction: Taking into account the difficulty that work represents for the staff and aiming for mental well-being. The fundamental principle is to adapt work to people by designing an adapted and comprehensive work system.

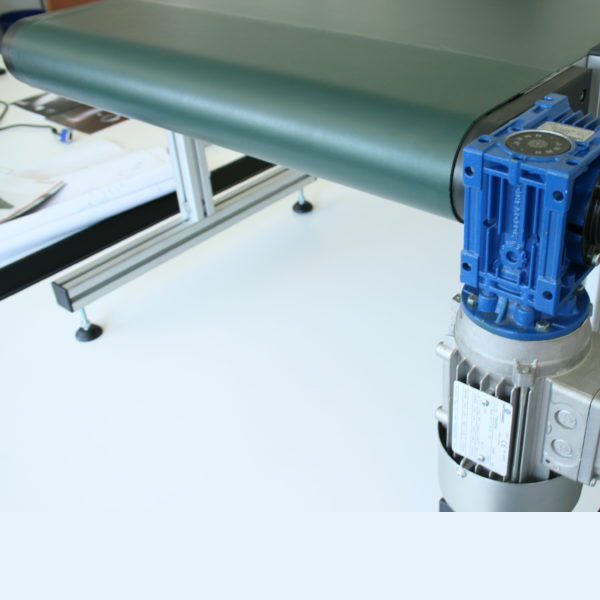

CONVEYORS

-

We ensure the best combination in terms of cost, performance, ergonomics, and reliability.

The conveyors designed by elcom provide the best combination in terms of cost, performance, ergonomics and reliability.

Since its inception, elcom has developed a worlwide network in order to meet its customers’ need abroad.

FLAT BELT CONVEYORS

-

Our standard flat belt conveyors are a classic in a majority of conveyor technology applications. Individual workpieces and packaging units, and in many cases also bulk goods, are transported via a conveyor belt stretched over a frame using pulleys. We cover standard segment belt widths from 20 to 1000 mm and axle distances from 300 to 6000 mm.

With elcom , the belt conveyors are divided into 4 classes according to the diameter of the pulleys on the belt heads; these are the elcom 20, 40, 80 and 90 series belt conveyors. All systems use flat belts as the conveyor belts; the belt type is adapted to your requirements.

- CONVEYOR 20 : Compact conveyor on a 20 mm profile 5 base, for very small, lightweight parts.

- CONVEYOR 40 : Compact conveyor on a 40 mm profile 8 base, for all types of part

- CONVEYOR 80 : Compact conveyor manufactured from h’elcom‘s profile range, dedicated to the conveying of light and bulky loads.

- CONVEYOR 90 : Conveyor for heavier, high-volume components.

TIMING BELT CONVEYOR

- Timing Belt Conveyor are mostly used for heavier workpiece weights or stricter requirements on precision. In addition, they are frequently used in multi-track conveyors that place strict requirements on the synchronicity of the conveyor strands. In contrast to belt conveyors, workpiece-specific attachments can be added very easily. A common use is for supplying workpiece carriers to robot cells or gantry loaders.

ROLLER CONVEYORS

- Besides belt conveyors, roller conveyors are standard conveyor technology. They are used frequently, especially for plastic containers or packages with heavy weights. As with all our standard modules, the support is based on h’elcom-profile. Therefore, it is easy to incorporate these modules into your production environment. Besides standard roller conveyors, curved roller conveyor are available. Furthermore, the systems can be designed as driven roller conveyor or gravity roller conveyor.

MODULAR BELT CONVEYOR

-

Modular belt conveyor are a middle ground between belt conveyors and chain conveyors. A modular belt consists of individual plastic modules usually linked together with joint rods. This modular belt is driven by chain spockets; the base frame of the conveyor is constructed on standard profile supports.

The modular belt makes it possible to accept hot workpieces or workpieces with sharp edges. Furthermore, large conveyor widths can be implemented without high pre-tensioning of the belts. However, in contrast to chain conveyors, this design is less maintenance-intensive and is a technically simpler solution. These systems are frequently used as cooling lines, since the chain modules can be designed to be permeable to air.

INCLINED CONVEYORS

- Level differences are often bridged with inclined conveyors, for instance in the plastic injection moulding machines sector. Both modular belt conveyors and conveyors with timing belts, but also belt conveyors, are available for this. The lengths of the individual segments of the conveyor or the distances between the cleats can be adapted to the customer’s needs.

INFLATABLE BELT CONVEYORS

- This conveyor is suitable for workpiece pallets or boxes with flat bottoms.

The line can be motor-driven or operated by hand.

Load transfer of the weight of the product is implemented via ball bearings mounted on the aluminium profiles. The profiles simultaneously serve to guide the workpiece pallets or boxes.

These are moved forwards by a continuously-running conveyor belt whose pressure against the bottom of the workpiece pallets is controlled pneumatically. The pressure of the conveyor belt moves the workpiece pallets, which can also easily be running in accumulation mode using stoppers. Indexing units are also possible.

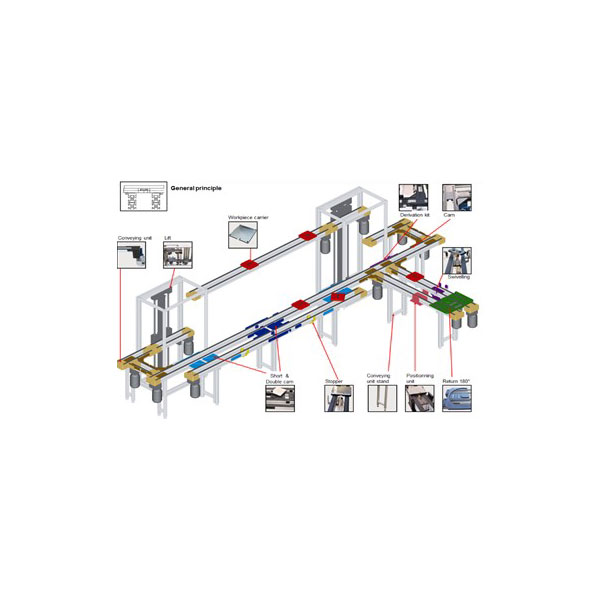

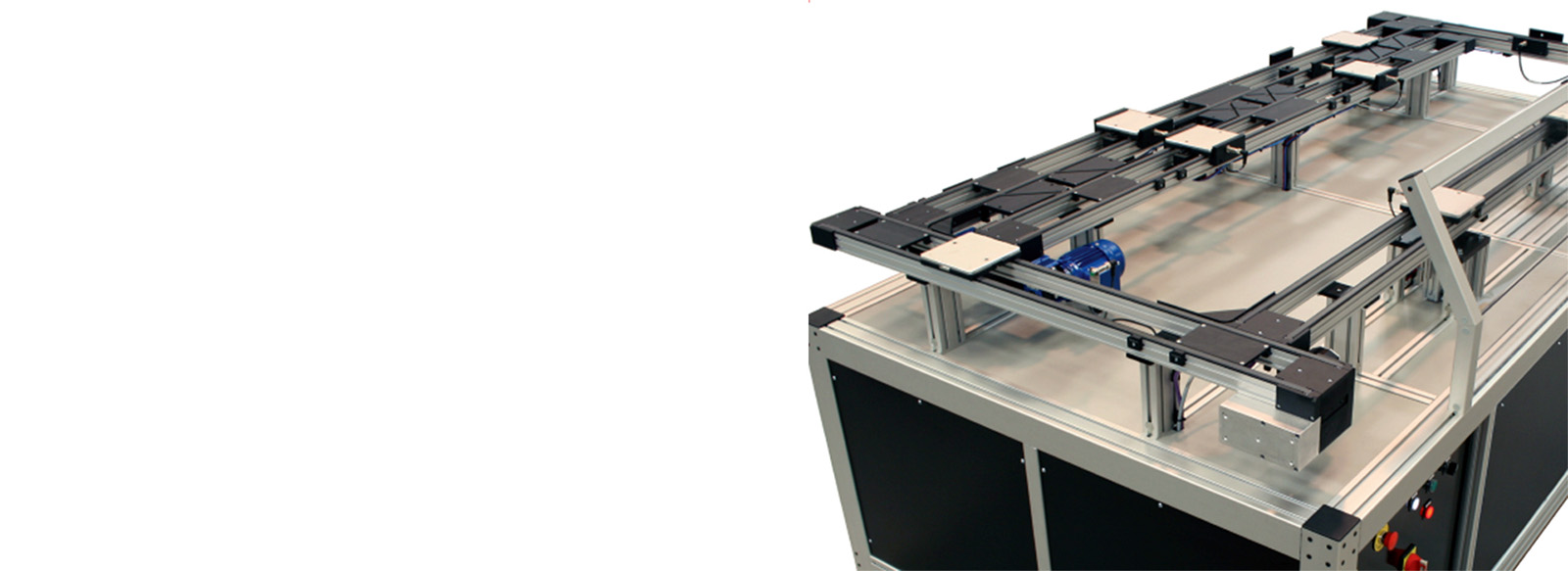

MODULAR LINEAR TRANSFERS

-

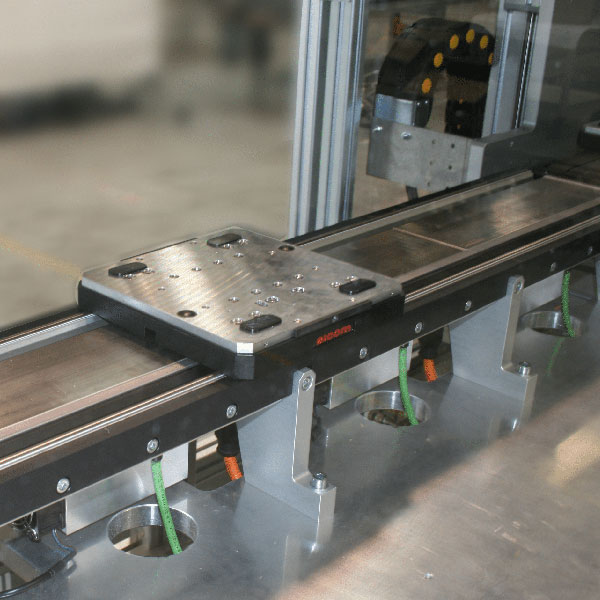

The modular linear transfer of elcom is the simple and reliable connection tool for the realization of your assembly lines

The elcom modular linear transfers systems is the simple and reliable linking tool to build your assembly lines.

Since its inception, elcom has developed a worlwide network in order to meet its customers’ need abroad.

MODULAR LINEAR TRANSFER 1000

- The TLM 1000 transfer system is particularly suitable in a standard system for loads with total weight up to 2 kg per pallet (workpiece carrier + product holder + product). The maximum traction in accumulation mode is 50 kg or 25 kg, depending on the configuration (with reference to a transfer unit length of 3 m).s

MODULAR LINEAR TRANSFER 1500

- The new TLM 1500 transfer system features a 150×150 mm width workpiece carrier and uses elcom’s patent with retractable pins, guides and derivation sets.

This new system benefits from the advantages of our TLM 2000‘s range (workpiece carriers with dimensions from 200×200 to 400×400) with a straightforward management and a very affordable short cam derivation system.

Workpiece carriers of a total weight of 4 kg can be conveyed thanks to a timing belt drive.

MODULAR LINEAR TRANSFER 2000

-

The TLM 2000 transfer system is particularly suitable in a standard system for loads with total weight up to 10 kg per pallet (workpiece carrier + product holder + product).

The maximum traction in accumulation mode is 60–150 kg, depending on the configuration (with reference to a transfer unit’s length of 6 m).

TLM 5000

-

The modular construction of the TLM 5000 allows large architectures of workpiece carriers. The workpiece carriers are transported using multi-directional rollers attached to the four corners of the workpiece carrier and clipped into the line’s support structure on stainless steel rails. The workpiece carrier is transported via both the corner blocks and the central blocks (one, two or three depending on the dimensions of the workpiece carrier). The central blocks make it possible to quickly drive the workpiece carriers into corners and to stop the workpiece carriers on the stoppers. Two centering bushes handle the positioning on the positioning units. Numerous workpiece carrier variants are possible:

- 40×40 aluminium profile or others

- Aluminium plate, thickness 8, 10, 12 or 16 mm

- Steel plate

- Beechwood plate, multilayer

- Laminate plate, compact