- Offer Profile

- Our company is specialized on

the development and production, the service and distributing of intelligent,

flexible milling and boring centers as well as vertical turning and milling

centers.

Complete Solutions are our daily business

With innovative and highly sophisticated machines, Bimatec Soraluce has developed into a specialist for complete turn-key solutions in numerous industrial sectors. As a result of our clear concepts, high flexibility and short decision making processes we are able to guarantee individual solutions for ambitious challenges.

Machines

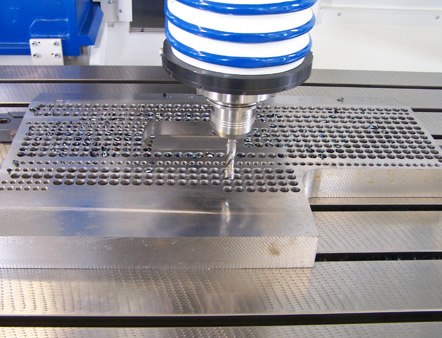

Bed Type Milling Centre T

Bed Type Milling Centre TA-A

Longitudinal traverse 2.000 / 2.500 / 3.500 mm Vertical traverse 1.250 mm Cross traverse 1.200 mm - A stable and vibrating-reducing cast construction of the whole machine causes a high accuracy over a long time.

- Compact design for installation without a separate foundation. Normal hall floor with reinforcement is sufficient.

- Wear-free INA - linear roller guides in all axes.

- Machine table INA - linear roller guided over the entire travel for high stability and precision of alignment.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing of the ram.

- All-round grounded ram for an optimal heat emission.

- 3D-Thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- Complete 4-sided splash guard with 2 front doors and a rear door to operate at the front and the rear.

Bed Type Milling Centre TA-D

Longitudinal traverse 2.000 / 2.500 mm Vertical traverse 1.250 mm Cross traverse 1.200 mm - A stable and vibrating-reducing cast construction of the whole machine causes a high accuracy over a long time.

- Compact design for installation without a separate foundation. Normal hall floor with reinforcement is sufficient.

- Wear-free INA - linear roller guides in all axes.

- Machine table INA - linear roller guided over the entire travel for high stability and precision alignment.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing of the ram.

- All-round grounded ram for an optimal heat emission.

- 3D-Thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- Complete 4-sided splash guard with 2 front doors and a rear door.

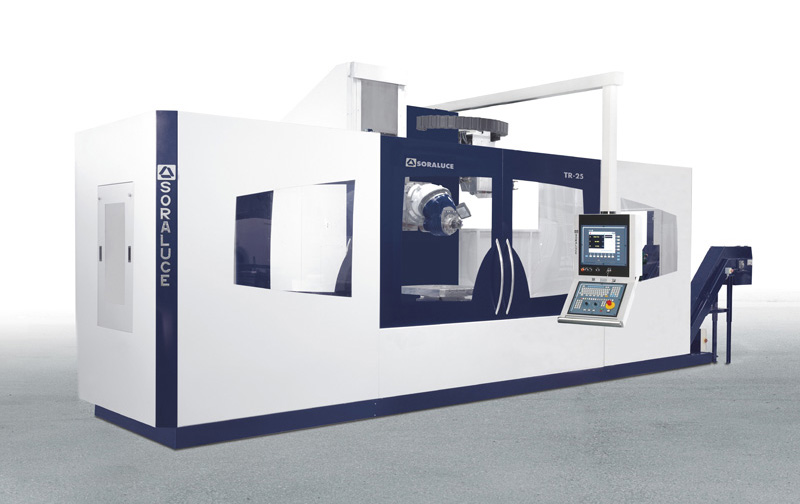

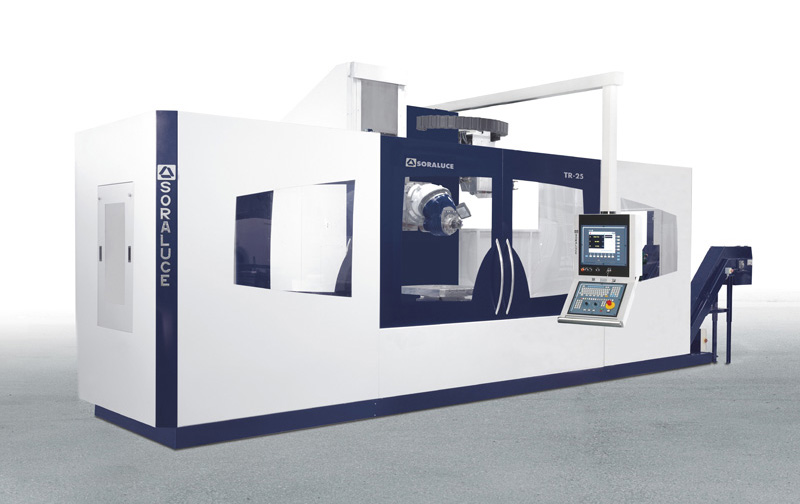

Bed Type Milling Centre TR

Longitudinal traverse 2.500 / 3.500 / 4.500 mm Vertical traverse 1.600 mm Cross traverse 1.300 mm - Extreme heavy, stable and vibration-reducing cast construction of the whole machine and therefore high accuracy over a long time.

- Very large guide distances for high leverage forces by heavy machining and interrupted cuts.

- Very wide machine table with 1.200 mm for ideal clamping of extensive and heavy workpieces.

- Integrated, water-cooled main spindle motor for absolutely smoothly and quietly machining even with speeds up to 6.000 rpm.

- Wear-free INA - linear roller guides in all axes.

- Machine table guided over INA - linear roller guides for a maximum of stability and accuracy.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing of the ram.

- All-round grounded ram for an optimal heat emission.

- 3D-Thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- Complete 4-sided splash guard with 2 front doors and one rear door to operate at the front and the rear.

Fixed Table Travelling Column Milling Centre S

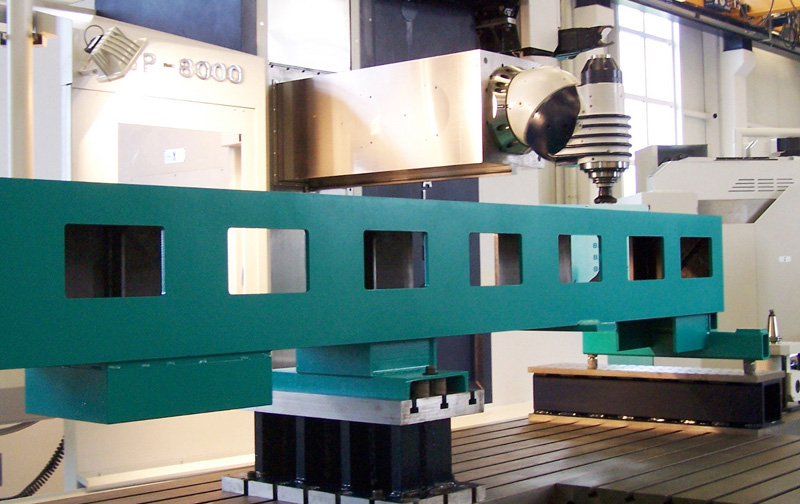

Fixed Table Travelling Column Milling Centre SLP

Longitudinal traverse 4.500 - 8.500 mm Vertical traverse 1.800 mm Cross traverse 1.300/ 1500 mm - Traditional fixed table travelling column concept, table attached column supported by separate. rear guide. Your benefits: Highest accuracy through Frame guiding at the machine table, low foundation costs through block foundation.

- Rigid, stable and vibration-reducing cast construction of the whole machine for highest precision.

- Very large guide distances to absorb large leverage forces during heavy machining and interrupted cuts.

- Extendable machine table for mounting of angle plates and for optimal clamping of extensive and heavy work pieces.

- Integrated, water cooled direct drive spindle motor, which also guarantees low heat, reduced noise and no maintenance.

- Wear-free INA-linear roller guided in all axes.

- Hydrostatic damping carriages for optimal shock absorption.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing.

- All-round grounded ram for the optimal heat emission.

- 3D-thermal Expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling heat exchangeability within one hour through a locating hole in the ram.

- Possibility to complete 3-sided splash guard with 2/4 front doors.

- Travelling operator platform and control panel to operate at the front and the back of the machine.

Floor Type Milling-Boring Centre F

Floor Type Milling-Boring Centre FL

Longitudinal traverse 3.000 - 39.500 mm Vertical traverse 1.800 / 2.200 mm Cross traverse 1.300 mm - Traveling-column concept guided on a very stable machine bed and constructed in a compact design. Your benefits: Milling spindle travels so far over floor that a foundation as such for hydrostatic- or flat-guided machines, isn't necessary.

- Very flexible machine concept with the possibility of using universal-, compact orthogonal-, stable vertical-, small angle - milling heads of any kind for narrow passages and spindle extensions.

- NC turning table, floor plates, machine tables, angle plates in all sizes and NC rotary-travelling tables up to 2.000 x 2.000 mm with a load capacity up to 40t for flexible clamping and machining possibilities.

- Carousel- and interpolation function for turning operations from 10 to 2.500mm.

- Individual clamping systems and customized devices for machining and clamping in horizontal positions.

- Extreme heavy, stable and vibration-reducing cast construction of the whole machine and therefore high accuracy over a long time.

- Very large guide distances for high leverage forces by heavy machining and interrupted cuts.

- Water-cooled inline main spindle motor for absolutely smoothly and quietly machining.

- Wear-free INA - linear roller guided in all axes.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing of the ram.

- All-round grounded ram for optimal heat emission.

- 3D-thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- User-friendly customized splash guard.

- Extensive, practice-oriented traveling operator platform.

Floor Type Milling-Boring Centre FP

Longitudinal traverse 4.000 - 40.000 mm Vertical traverse 2.600 / 3.200 / 3.600 mm Cross traverse 1.300 / 1.500 mm - Traveling-column concept guided on a very stable machine bed and very short guide distances of the aces. Your benefits: Milling spindle travels so far over floor that a foundation as such for hydrostatic- or flat-guided machines, isn't necessary.

- Very flexible machine concept with the possibilities of using universal-, compact orthogonal-, stable vertical-, small angle - milling heads of any kind for narrow passages and spindle extensions.

- NC turning tables floor plates, machine tables, angle plates in all sizes and NC rotary-travelling tables up to 3.000 x 2.500 mm with a load capacity up to 60 t and tilt functions +/- 5° or 10° for flexible clamping and machining possibilities.

- Crousel- and interpolation function for turning operations from 10 to 3.000mm.

- Individual clamping systems and customized devices for machining and clamping in horizontal and vertical positions.

- Extreme heavy, stable and vibration-reducing cast construction of the whole machine and therefore high accuracy over a long time.

- Very large guide distances for high leverage forces by heavy machining and interrupted cuts.

- Water-cooled inline main spindle motor for absolutely smoothly and quietly machining.

- Wear-free INA- roller guided in all axes.

- Hydrostatic damping carriages for optimal shock absorption.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing of the ram.

- All-round grounded ram for optimal heat emission.

- 3D-thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking in consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- User-friendly customized splash guard.

- Extensive, practice-oriented travelling operator platform.

Floor Type Milling-Boring Centre FS

Longitudinal traverse 4.000 - 40.000 mm Vertical traverse 3.200 / 3.600 mm Cross traverse 1.600 mm - Traveling-column concept guided on a very stable machine bed and with very short guide distances of the axes. Your benefits: Milling spindle travels so far over floor that a foundation as such for hydrostatic- or flat-guided machines, isn't necessary.

- Very flexible machine concept with the possibility of using universal-, compact orthogonal-, stable vertical milling heads, Quills up to 180 mm, small angle milling heads and spindle extensions.

- Clamping plates and angles in every size, NC rotary-traveling tables up to 3.500 x 3.500 mm with a load capacity up to 150 t and tilt functions +/- 5° or 10°.

- Carousel- and interpolation function for turning operations for turning diameters from 10 to 3.500 mm.

- Individual clamping systems and customized devices for machining and clamping in horizontal and vertical positions.

- Extreme heavy, stable and vibration-reducing cast construction of the whole machine and therefore high accuracy over a long time.

- Very large guide distances for high leverage forces by heavy machining and interrupted cuts.

- Water-cooled inline main spindle motor for absolutely smoothly and quietly machining, elective with ZF-drive for extreme high torque.

- Wear-free INA - linear roller guided in all axes.

- Hydrostatic damping carriages for optimal shock absorption.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing.

- All-round grounded ram for optimal heat emission.

- 3D-thermalexpansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- User-friendly customized splash guard.

- Extensive, practice-oriented traveling operator platform, additional unattached height- and cross- adjustable.

Floor Type Milling-Boring Centre FR

Longitudinal traverse 4.000 - 40.000 mm Vertical traverse 3.600 / 4.000 / 4.500 mm Cross traverse 1.600 / 1.900 mm - Traveling-column concept guided on a very stable machine bed with very short guide distances of the axes. Your benefits: Milling spindle travels so far over floor that a foundation as such for hydrostatic- or flat-guided machines, isn't necessary.

- Very flexible machine concept with the possibility of using universal-, compact orthogonal-, stable vertical milling heads, quills up to 180 mm, small angle milling heads of every kind for narrow passages and spindle extensions.

- Clamping plates and angles in every size, NC rotary-traveling tables up to 5.000 x 5.000 mm with a load capacity up to 150 t and tilt functions +/- 5° or 10°.

- Carousel- and interpolation function for turning operations for turning diameters from 10 to 6.000 mm

- Individual clamping systems and customized devices for machining and clamping in horizontal and vertical positions.

- Extreme heavy, stable and vibration-reducing cast construction of the whole machine and therefore high accuracy over a long time.

- Very large guide distances for high leverage forces be heavy machining and interrupted cuts.

- Two- or three-stage, oil-cooled drives with reducible torque up to 8.736 Nm

- Wear-free INA - linear roller guided in all axes.

- Hydrostatic damping carriages for optimal shock absorption.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing.

- All-round grounded ram for optimal heat emission.

- 3D-thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- User-friendly customized splash guard.

- Extensive, practice-oriented travelling operator platform, additional unattached height- and cross- adjustable.

Floor Type Milling-Boring Centre FX

Longitudinal traverse 6.000 - 40.000 mm Vertical traverse 4.300 / 4.800 / 5.300 mm Cross traverse 1.600 / 1.900 mm - Traveling-column concept on a very stable machine bed with very short guide distances of the axes. Your benefits: Milling spindle travels so far over floor that a foundation as such for hydrostatic- or flat- guided machines, isn't necessary.

- Very flexible machine concept with the possibility of using universal-, compact orthogonal-, stable vertical milling heads, quills up to 180 mm, small angle milling heads of every kind for narrow passages and spindle extensions.

- Clamping plates and angle in every size, NC rotary-traveling tables up to 5.000 x 5.000 mm with a load capacity up to 150 t and tilt function +/- 5° or 10°.

- Carousel- and interpolation function for turning operations for turning diameters from 10 to 6.000 mm.

- Individual clamping systems and customized devices for the machining and clamping in horizontal and vertical positions.

- Extreme heavy, stable and vibration-reducing cast construction of the whole machine and therefore high accuracy over a long time.

- Very large guide distances for high leverage forces by heavy machining and interrupted cuts.

- Two- or three-stage, oil-cooled drives with reducible torque up to 8.736 Nm.

- Wear-free INA - liner roller guided in all axes.

- Hydrostatic damping carriages for optimal shock absorption.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing.

- All-round grounded ram for optimal heat emission.

- 3D-thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- User-friendly customized splash guard.

- Extensive, practice-oriented travelling operator platform, additional unattached height- and cross - adjustable.

Floor Type Milling-Boring Centre FXR

Longitudinal traverse 6.000 - 40.000 mm Vertical traverse 6.000 / 6.500 / 7.000 / 8.000 mm Cross traverse 1.600 / 1.900 mm - Traveling-column concept guided on a very stable machine bed with very short guide distances of the axes. Your benefits: Milling spindle travels so far over floor that a foundation as such for hydrostatic- or flat-guided machines, isn't necessary.

- Very flexible machine concept with the possibility of using universal-, compact orthogonal-, stable vertical milling heads, quills up to 180 mm, small angle milling heads of every kind for narrow passages and spindle extensions.

- Clamping plates and angles in every size, NC rotary-traveling tables up

to 5.000 x 5.000 mm with a load capacity up to 150 t and tilt function

+/- 5° or 10°. - Carousel- and interpolation function for turning operations for turning diameters from 10 to 6.000 mm.

- Individual clamping systems and customized devices for machining and clamping in horizontal and vertical positions.

- Extreme heavy, stable and vibration-reducing cast construction of the whole machine and therefore high accuracy over a long time.

- Very large guide distances for high leverage forces by heavy machining and interrupted cuts.

- Two- or three-stage, oil-cooled drives with reducible torque up to 8.736 Nm.

- Wear-free INA - linear roller guided in all axes.

- Hydrostatic damping carriages for optimal shock absorption.

- Specially developed mechanical sag compensation for highest accuracy during the cross traversing.

- All-round grounded ram for optimal heat emission

- 3D-thermal expansion compensation for measurement and correction of the effects of thermal influences to the machine, also taking into consideration the ambient temperature.

- Milling head exchangeability within one hour through a locating hole in the ram.

- User-friendly customized splash guard.

- Extensive, practice-oriented traveling operator platform, additional unattached height- and cross-adjustable.

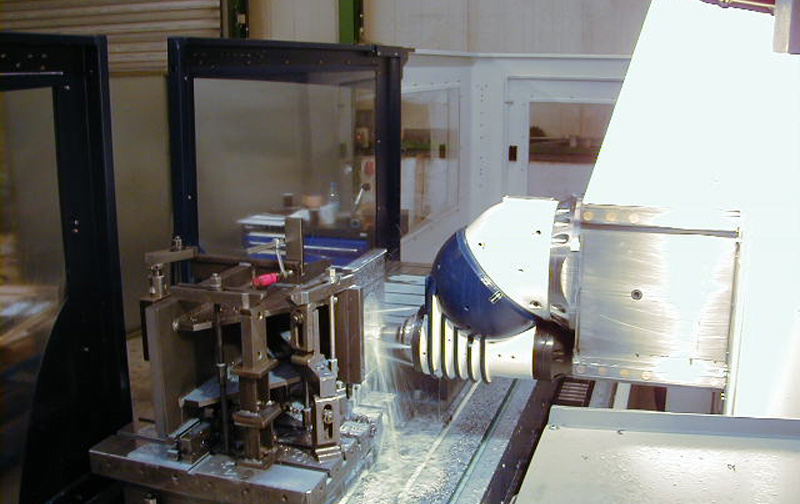

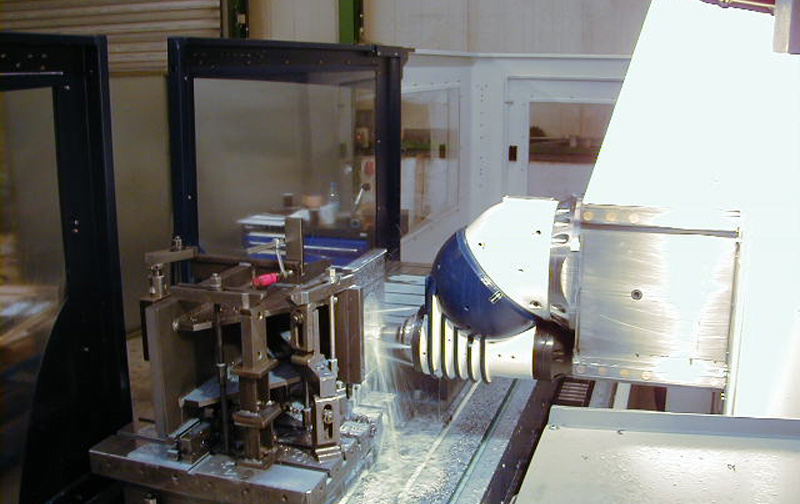

Multitasking Milling-Turning Machine F-MT

Multitasking Milling-Turning Machine F-MT

Longitudinal traverse 4.000 mm Vertical traverse 1.600 mm Cross traverse 1.000 / 1.300 mm

With that unique solution, SORALUCE opened new dimensions in the 5-sided machining sector and integrated several processes in one machine.

Previously you had to machine heavy and bulky workpieces an several tooling machines like boring mills, vertical turning- and grinding machines. With the help of the F-MT you can machine this workpieces 5-sided, cost- and time-saving with one machine.

The directly into the machine bed integrated turning table can be used for vertical turning as well as the precise positioning. The multitasking milling and turning center is able to handle all these operations in one setting. The automatically swiveling milling heads allows to machine in every sloping position without renewed clamping. The machine is particularly suitable for the machining of complex workpieces, for example for he energy-, aviation-, railway- or valve sector.

The longitudinal traverse of 4.000 mm allows the machining of long and bulky welding components. By the means of a palletization system the workpieces can be clamped outside of the machine and changed time-saving.

Vertical Turning Centre VTC

Vertical Turning Centre VTC 2500 / 2800 / 3200 / 4000

Turning-table diameter 2.100 / 2.400 / 2.800 / 3.500 mm Turning diameter 2.500 / 2.800 / 3.200 / 4.000 mm Turning-table speed 260 / 200 / 175 / 100 rpm

The VTC-series has been developed to offer our customers a machine with the highest standards. Our customers can be found in all fields of technology. Proven performance in conjunction with turning-, milling- and grinding operations with excellent precision has established the VTC-series a permanent position in many industrial sectors. Nowadays you can find our machines in the aviation-, railway-, wind power-, energy generation-, precision bearings-, mining- and contract processing sector.

The key elements of the VTC vertical turning center are engineered out of strongly ripped cast constructions that guarantee a maximum level of stability. Before the machine is finally mounted, all cast constructions are completely stressless annealed. Therefore, the machine is constructed to absorb strong mechanical load and reduce vibrations during the milling process. The ram is made out of annealed steel as well as induction hardened and precision grounded.

The main drive is equipped with a 2-step gear. The drive of the spindle is effected by a reduction gear. The pressure-regulated oil-lubricant system assures the adequate lubrication of the main drive and the turning table. In addition to that, the machine is equipped with an oil-cooling unit to keep the temperature stable and the heat gain as low as possible.

The C-axis guarantees highest positioning accuracy and allows milling- and boring- operations with a high cutting capacity. The positioning of the tool holders and the milling heads at the ram, is performed via a Hirth face gear. This system assures highest precision during the tool change.

The rotating tools can optionally used in the axial or radial way. Vertical- and angle milling heads offer a maximum of flexibility and stability during the milling process.

Vertical Turning Centre VTC-H 5000 / 6000 / 8000

Turning-table diameter 4.000 / 5.000 / 7.000 mm Turning diameter 5.000 / 6.000 / 8.000 mm Turning-table speed 60 / 35 rpm

The VTC-series has been developed to offer our customers a machine with the highest standards. Our customers can be found in all fields of technology. Proven performance in conjunction with turning-, milling- and grinding operations with excellent precision has established the VTC-series a permanent position in many industrial sectors. Nowadays you can find our machines in the aviation-, railway-, wind power-, energy generation-, precision bearings-, mining- and contract processing sector.

The key elements of the VTC vertical turning center are engineered out of strongly ripped cast constructions that guarantee a maximum level of stability. Before the machine is finally mounted, all cast constructions are completely stressless annealed. Therefore, the machine is constructed to absorb strong mechanical load and reduce vibrations during the milling process. The ram is made out of annealed steel as well as induction hardened and precision grounded.

The main drive is equipped with a 2-step gear. The drive of the spindle is effected by a reduction gear. The pressure-regulated oil-lubricant system assures the adequate lubrication of the main drive and the turning table. In addition to that, the machine is equipped with an oil-cooling unit to keep the temperature stable and the heat gain as low as possible.

The C-axis guarantees highest positioning accuracy and allows milling- and boring- operations with a high cutting capacity. The positioning of the tool holders and the milling heads at the ram, is performed via a Hirth face gear. This system assures highest precision during the tool change.

The rotating tools can optionally used in the axial or radial way. Vertical- and angle milling heads offer a maximum of flexibility and stability during the milling process.

Milling Heads

Milling Heads

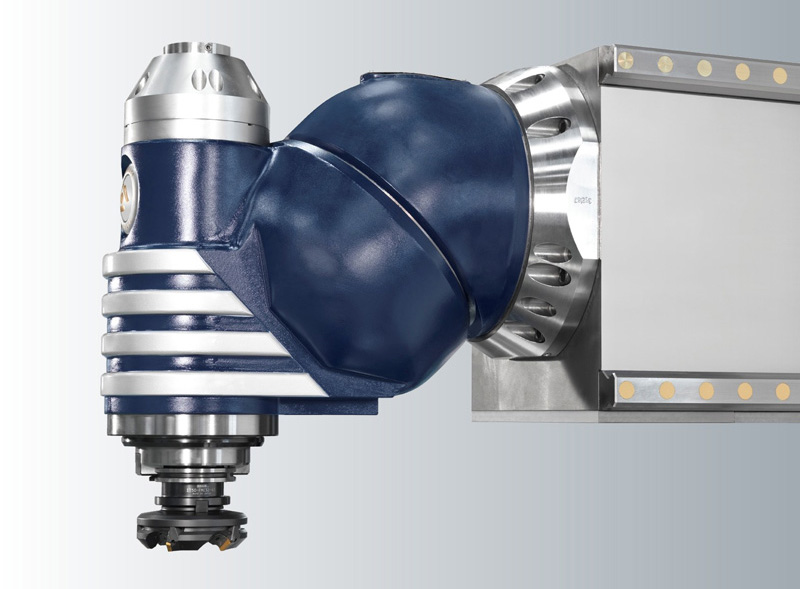

Automatic indexing milling head

Drive power 32 / 46 kW Division 2,5° x 2,5°, 1° x 2,5° or stepless Speed range 4.000 - 5.000 - 6.000 - 7000 rpm Tool holder SK 50 / HSK 100

Orthogonal milling head

Drive power 32 / 46 kW Division 1° or 1° x 0,001° Speed range 4.000 - 5.000 - 6.000 - 7000 rpm Tool holder SK 50 / HSK 100

2-axes NC-orthogonal-milling head

Drive power 34 kW Division 0,001° x 0,001° Speed range 18.000 rpm Tool holder HSK 63

Stepless vertical milling head

Drive power 25 / 40 kW Swivel range/division ± 92° / 0,001° / simultaneous axis Speed range 12.000 - 15.000 rpm Tool holder HSK 63

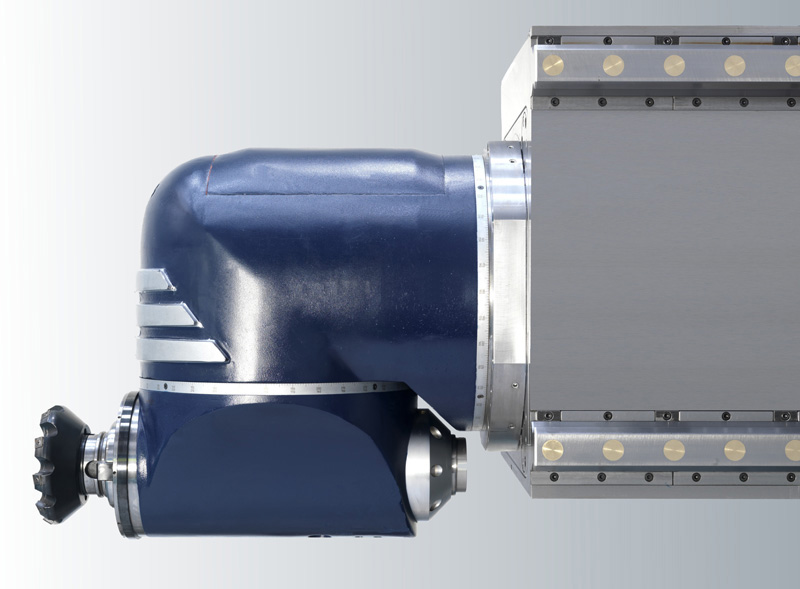

Horizontal milling head

Drive power up to 60 kW Front diameter 130/150/170/195 mm Tool holder SK 40/SK50/HSK63/HSK100 Length 230/480/600/1.000 mm Speed range 2.500 - 5.000 rpm

Quill

Drive power 46 / 71 kw Diameter 130 / 150 / 180 mm Speed range 3.000 rpm Torque 3.955 / 8.736 Nm

Special Milling Heads

Right-angled milling head

- Very stable, right-angled milling head with slim front case for machining of complex work pieces.

D’Andrea CNC boring and facing head

- D`Andrea face cutting milling heads with a diameter up to 1.200 mm can be integrated as wholesome axis in the machine control and ensure a high-precision leveling of precision and bearing bores. The milling head can be fully automatic exchanged by the milling head changing system.

Gyroscopic milling head

Drive power 34 kW Division two simultaneous axes Drive type linear motors Speed range 18.000 rpm Torque 102 Nm Tool holder HSK 63

Angular milling head

- Small, manual, infinitely adjustable fork-type milling head for machining in narrow passages.

Spindle extension milling head

- Extension of the spindle for 450 mm for machining of inboard surfaces and bores.

Angular milling head

Drive power 12 kW Swivel range 360 x 1° Teilung Speed range 1.500 rpm Tool holder SK 50

Accessories

Angle plate

- Stable angle plates made out of cast iron for the vertical machining in every desired size.

Operator platform

- Extensive and practice-oriented operator platform which travels, depending on the machine size, in the longitudinal direction and is additional height - adjustable as well as transversally.

Hand wheel

- Depending on the selection of the CNC - control, we install the latest versions of handwheels from Heidenhain ad Siemens. In addition to that we can offer our customers wireless handwheels.

High frequency spindle

- Attached and integrated high frequency spindles with a speed range of 12.000 rpm to 40.000 rpm.

Cooling lubricants

- Our coolant lubricant systems are developed on the basis of the long-term experience of our suppliers. All coolant lubricant systems are equipped with paper belt filters, magnetic separators, oil skimmers and micro aerators. A high standard cause high process stability. On the basis of adjustable coolant pumps with pressures up to 70 bar, it is possible to use the latest, internally cooled tools.

Magnetic clamping systems

- Optimal clamping without interfering clamping claws in every desired size and with an extremely high holding force for the horizontal and vertical clamping.

Workpiece and tool measurement

- Fully automatic measurement of work pieces and tools after and during the production process. It is possible to create measurement reports with comments after the measuring of a work piece.

Dry machining

- Many customers of Soraluce are already using our machines without any coolant lubricant. By the use of internal or external air supply in conjunction with a minimum quantity lubrication unit, it is possible to achieve best production results without any coolant lubricant. Your benefits: Work pieces don't have to be cleaned before painting. A clean working place is guaranteed.

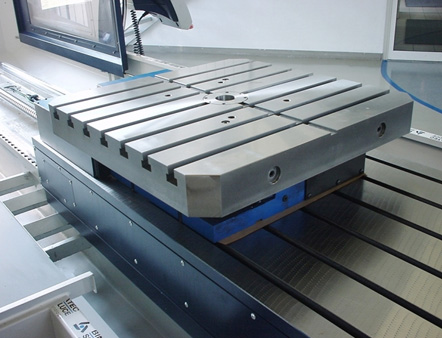

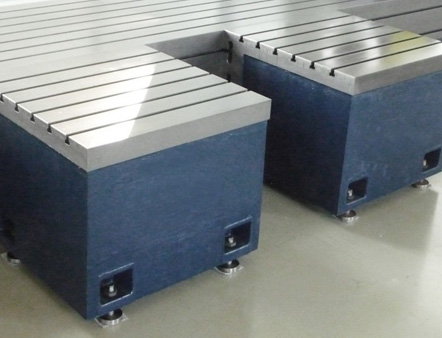

NC-rotary table

Floor plate

Chip conveyor systems

Splash guard systems according to CE norm

Visiport

Tool changer