Navigation : EXPO21XX > MOTION 21XX >

H01: Complete electric drive solutions

> PI Physik Instrumente

PI Physik Instrumente

Videos

Loading the player ...

- Offer Profile

- Since its foundation in 1970, PI (Physik Instrumente) has established itself as a leading manufacturer of precision positioning technology. The key element and motivation of the entrepreneurial behavior have always remained the same: Finding the best possible solution for the customer.

PI is well known for the quality of its products and has been one of the leading players in the global market for precision positioning technology for many years. One of the most important building blocks for this is the team spirit within the international PI family, which is based on mutual understanding and support that goes beyond international borders and functional restrictions.

PI is a privately owned company with healthy growth, more than 1,300 employees worldwide and a flexible, vertically integrated organization, which enables it to fulfill almost any request in the field of innovative precision positioning technology. The foremost priority for PI is to be a reliable and highly qualified partner for the customer.

Product Portfolio

PI is a worldwide leading supplier of solutions in the fields of motion and positioning

- PI does not only develop and produce a broad range of positioning stages and actuators for linear, rotary and vertical motion or combinations of different axes. PI also adapts those solutions to customer-specific applications or supplies finished subsystems for motion and positioning.

The control is an important system component and is also supplied by PI. This not only provides sophisticated control concepts but also the hardware and software interfaces for the application environment.

Whether a standard product or a completely new development, whether OEM drive or an integrated system, the objective is always to provide the optimum solution for every possible application.

Customized Products

- Competitive Edge due to Large Range and Unconventional Solutions

PI is fully at home where unconventional solutions are in demand. This is no longer limited to fields of research. Today, nanotechnology is also present in standardized industrial processes. Whether for industry or research, PI is in a position to offer solutions that far exceed the performance of "standard commercial" technology. Understanding the customers' requirements is essential in finding a creative solution.

The technological range available to PI always permits different approaches to a solution and is not limited to a single technology in advance. This often gives customers a considerable competitive edge.

Nanopositioning Piezo Flexure Stages

- PI's piezo flexure stages combine sub-nanometer resolution and guiding precision with minimum crosstalk. This makes them particularly suitable for applications in metrology, for super resolution microscopy, for interferometry or in inspection systems for semiconductor chip production. Piezo flexure stages are available for millisecond-settling precision positioning and dynamic scanning with up to several 100 Hertz in up to 6 degrees of freedom.

The unique combination of proprietary sensor design, frictionless flexure guides and long-life PICMA® piezo actuators makes for excellent and robust mechanics. Piezo motion controllers support positioning and scanning performance optimization, and are easily integrated over digital or analog interfaces and comfortable programming.

Miniature Stages

- Miniaturized stages and manipulators are essential in applications, where space is limited. This includes mobile applications for measuring and medical devices, in industrial microassembly or use for research, e.g. in UHV and non-magnetic environments.

Proprietary piezo motor technology allows for specific integrated solutions. High resolution even below nanometer can be achieved with all piezomotor solutions as the accuracy is only limited by the integrated sensor. They are self-locking with no energy consumption at rest and therefore ideal for set-and-forget applications. Drivers and motion controllers are available from rack models to the OEM module to the „intelligence on the chip“ to integrate.

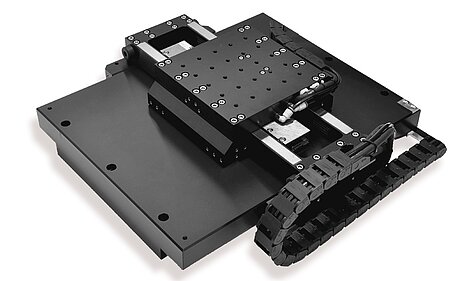

Linear Stages

- PI offers a broad portfolio of motorized linear stages. The huge variety of applications also means a huge variety of technical possibilities for the linear axes. Travel ranges extend from a few millimeters to meters and for precision classes, from nanometers to micrometers: PI adapts the drive, guides or sensor technology to the application conditions.

There are vacuum versions for a large number of different models. Multi-axis combinations can be realized with the help of adapter brackets or be more compact with matching Z stages and rotation stages.

Motion controllers are available as benchtop devices, rack versions or compact OEM devices. The common factor for all of them is commanding via the General Command Set (GCS), which simplifies control and programming, and is independent of the drive type.

Multi-axis systems in multi-axis industrial applications with motion controllers from ACS are available. That ensures easy integration via Fieldbus interfaces for precision and motion-centric industrial applications.

Linear Actuators

- Choose from the widest range of technologies the optimum for your special demands:

Set-and-forget applications benefit from the specific features of piezomotors that provide excellent long-term stability, also for vacuum or nonmagnetic environments. Stepper and DC motor solutions are well-established and reliable for both industrial and research use.

The unique force control option of Voice Coil actuators is essential for touch-sensitive devices. Nanopositioning actuators stand for high dynamics and forces as required in shutters or machining processes.

Rotation Stages

- Requirements for rotary motion show a very broad range of different sizes, load capacity, and positioning accuracy. PI offers stages with all kinds of motorization and guiding options: air-bearing, torque motor driven, motorized worm-gear coupled, tiny piezomotor stages and specialized goniometer stages with orthogonal tip-tilt mounting option. All of them can be mounted to multi-axis combinations with corresponding linear, vertical and XY stages.

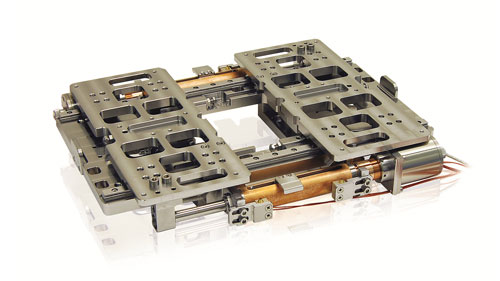

XY Stages

- Stability, precision and dynamics are crucial in the application fields of PI’s XY stages. They are the basis of high throughput rates and reliable operation.

PI makes use of own developments in the fields of PIMag® magnetic linear motors and PIglide air bearings. Industrial production and quality control benefit from PI’s high-load XY stages and planar scanners.

For microscopy applications e.g. in the field of topology measurement, fast, repeatable scanning is combined with best velocity constancy by PIline® driven sample stages. Their low profile is outstanding in this field. Combination with piezo flexure sample stages makes them very versatile.

Hexapods

- Hexapods provide motion in six degrees of freedom in the most compact package. In combination with absolute measuring sensors, software and motion controllers that make the most complicated motion profiles easy to command, PI hexapods answer industrial requirements. All drive types can be matched to meet the conditions of the individual application.

The broadest portfolio of standard hexapods ranges from miniature versions for sample positioning in beamline experiments, high-resolution dynamic positioners for fiber alignment, to equipment for industrial production processes, where hexapods position high loads with sub-micrometer precision.

Motion hexapods provide more dynamic motion and are designed to follow pre-defined trajectories with high precision, for example in camera test stands.

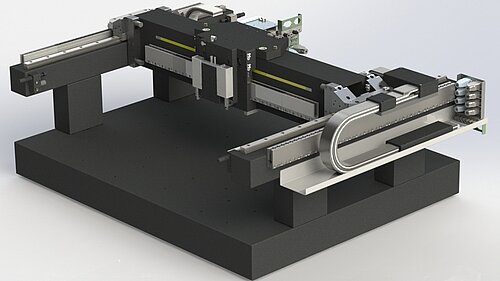

Engineered Subsystems for Automation

- Precision components, stable control and a great deal of experience in engineering are essential for high-precision complex motion and positioning solutions. PI is a supplier of technologically sophisticated motion-centric solutions and therefore makes use of own drive components and high-precision positioners. All levels of integration can be offered up to multi-axis combinations that use different drive technologies including motion control.

Engineering designs of motion subsystems have been a part of PI's core business for many years. Customized solutions, fitting seamlessly into existing processes, advance automation in manufacturing and inspection processes for chip production or photonics packaging as well as major research installations.

Fast Multi-Channel Photonics Alignment Systems

- PI’s Fast Multi-Channel Photonics Alignment (FMPA) systems are based on a highly specialized digital motion controller (E-712) and a hybrid active alignment mechanism to achieve the required long travel ranges without sacrificing stability, resolution or alignment speed. FMPA is implemented in the E-712 controller’s modular firmware to enable fast, simultaneous alignment and tracking of multichannel couplings in multiple degrees of freedom. The efficient algorithms for first light detection, area scanning, and gradient search guarantee highest throughput in 24/7 operation.

Motion Control Software

- All digital controllers made by PI are accompanied by an extensive software package. It includes the user software which is installed on a host PC connected to the controller. PI relies on platform-independent concepts which make it possible for the positioning systems to be integrated into the most common operating systems.

PI software covers all aspects relevant to the application and supports a quick and comprehensible integration into external programs.

Controllers & Drivers

- The decision for a motion controller depends on the specific application situation. Various criteria, such as limited installation space, the number of axes or the drive type, determine which controller is the right one. PI offers a broad spectrum of controllers and regulation concepts.

Piezoelectric Transducers & Actuators

- Piezoelectric ultrasonic transducers are available in a wide range of shapes like disks, plates or tubes, and different performance levels. They can be adapted to application requirements by using different piezoceramic materials, electrodes, and assembling technology. They are present wherever ultrasound is needed, like in flow metering, structural monitoring, and many medical applications.

Piezo actuators are available as stacked and multilayer versions, in different force classes and for displacements up to some hundred micrometers, while piezo bending actuators achieve up to millimeters. Their basic features like millisecond response time and high dynamics combined with virtually unlimited resolution make them indispensable in applications from industrial production or dispensing to ultra-precision positioning.

Air Bearings & Stages

- Air bearing stages are used where vibration-free motion is required, velocity needs to be highly constant, and optimum angular repeatability is requested.

Air bearings avoid friction, wear, and backlash effects. PIglide linear, rotary and spherical bearings are precision components that can be integrated and motorized for applications in OEM, industrial, and research markets.

Sensors, Components & Accessories

- Nanometrology Sensors & Signal Conditioners

PI offers the nanometrology capacitive sensor technology that is used in the superior nanopositioning stages also as a component for integration in OEM applications.

Microscopy Stage Accessories

For microscopy applications, a wide range of useful supplements like QuickLock adapters for objective positioners and various inserts are available.

Adapter Brackets

Adapter brackets and plates are standardized for many stages and can be modified on request.

Adapter Plates Adapter brackets and plates are standardized for many stages and can be modified on request.

Product Series with Vacuum-Ready Items

- PI offers specific catalogue items for selected product series that are already suitable for high vacuum (HV) or ultra-high vacuum (UHV).

Original Equipment Manufacturer (OEM) Solutions

Advanced Technology for Securing Competitive Advantage

PI (Physik Instrumente) is a strong partner in the OEM business, because PI concentrates the broadest technology portfolio for precision positioning worldwide. That gives customers the assurance that the best possible solution is always selected for their application and without any limitations.

All key technologies, the drives, the sensor technology, and the control are developed exclusively by PI. On the one hand, that assures the flexibility to realize adaptations quickly. On the other hand, the in-depth know-how makes solutions possible that are both technologically new and unconventional.

Production and qualification take place exclusively at PI and can therefore be geared to the expectations and needs of the customer.What Distinguishes PI

PI is ideally positioned as a medium-sized enterprise in high-tech Germany. The size of the company allows a quick and flexible response to customer requests and at the same time, offers the reliability and safety of established and tested processes. PI is also well known for both the high quality of its products and total reliability in its customer relationships.- Global account management: Close proximity to the customer thanks to international presence

- Depending on the task: From the drive to the system

- Competitive advantages due to unconventional, technological adept solutions

- Production of series of several 10,000 units in the shortest time

- Manufacturing and testing capacities from functional samples to mass production

- Located in the middle of Europe, quality production in Germany

- The best answer for positioning and motion tasks every time

- Continual improvement due to KAIZEN processes

- More than 40 years of experience in customized solutions

Competencies for Pushing the Boundaries of What Is Possible

Piezo Technology, Nano Positioning, and Performance Automation Are the Basis for Sustainable Solutions

Pushing boundaries together with the customers, making new technologies possible, and shaping market trends – this is PI's ambition and what has shaped the company's history for more than 50 years. Decades of experience in nanopositioning and piezo technology, a constantly developing patent and technology portfolio, and in-depth application knowledge for the automation of precision motion emphasize this ambition.

Today, PI is already working on the solutions of tomorrow in order to support customers in industry and research to master technological leaps and be successful in their markets.Piezo Technology

The Heart of the Customer Application

With longstanding experience and technical know-how, piezo experts from PI produce the perfect functional core piece for customer-specific applications. Piezo actuators perform high-precision movements, piezo elements generate and detect the slightest vibrations. We bring your application to life.Your Advantages with PI as a Partner

- Custom piezo element and transducer manufacturing

- Value-added designs

- Miniaturized piezo components

- Flexible quantities

- Cleanroom environment

- Entire value chain in one hand

Medical Technology Applications - Therapeutic and Surgical Instruments

- Ultrasound for Gentle Medical Interventions

Medical therapeutic options continue to develop steadily and so does also the possibility to develop ever new treatment methods. The modern methods ensure gentle, partly also outpatient, therapeutic procedures. "Minimally invasive therapy" is the buzzword. In the past years, such medical interventions, e.g. with the help of the keyhole technique, have replaced the open surgeries that were common for many diseases in the past. For patients, this means gentler procedures, less risks, and a quicker recovery. The prerequisite for this are modern medical technological devices that make such interventions possible. Ultrasound is a powerful tool for this purpose – ultrasonic scalpels and power ultrasound ensure fast incisions and coagulation of wounds, shorter surgeries, smaller fields for surgery, faster wound healing, and less tissue trauma and therefore less blood loss.

With ultrasound technology, surgeries that are completely incisionless can be realized. Focused ultrasound makes a completely contactless coagulation of tissues possible by bundling the sound waves in a targeted manner. An important field of application is the treatment of tumors or even the targeted release of medication.

In dentistry also, the use of ultrasound is equally popular – a very gentle treatment technique using ultrasound has the advantage of manipulating the bone without a scalpel. The ultrasonic waves interact only with hard tissues such as bones or teeth without damaging soft tissues, nerves, or blood vessels. This treatment techniques are based on ultrasound, which is generated by piezo elements. The piezoceramic elements that are used in medical instruments can be produced in the most diverse shapes and sizes. For example, tiniest piezo elements, smaller than 1 mm, are used in catheters that are applied for cardiovascular procedures close to the heart and perform life-saving procedures as gently as possible. In order to develop and produce suitable piezo elements for the respective application field, PI works closely with its customers right from the start. With its technical know-how and longstanding experience in piezo technology, PI can produce piezo ceramics in a wide range of dimensions, designs, and quantities – entirely according to the wishes of the customers.

Medical Technology Applications - Medical Sensors

- Contactless and Contamination-Free Measuring with Ultrasound

The automatic monitoring of medical processes is essential in numerous situations.

For example, devices for patient monitoring can continuously check and evaluate vital signs of patients in order to make the correct diagnosis and be able to intervene immediately in the event of possible irregularities. It is, however, important that the monitoring is contactless and gentle.

Ultrasonic sensors that are placed on the tubes of the monitoring devices, are ideal for this – ultrasonic sound waves penetrate the tube from the outside and ensure a contactless monitoring.

In addition, with the help of ultrasonic sensors different media can be monitored, for example, the gas flow of ventilators can be measured contactlessly and without contamination, or life threatening air bubbles in tubes such as the heart-lung machines or dialysis machines can be detected.

Piezo components are integrated into the ultrasonic sensors that are responsible for generating the ultrasound.

PI manufactures these piezo elements – especially tailored to the wishes of the customers.

In addition to designing customer-specific piezo components, PI masters extensive technologies for assembling and contacting these sophisticated focus elements. The piezo components, therefore, can be higher refined – be it by contacting with flexible printed circuit boards or gluing into housings.

Medical Technology Applications - Microfluidics

- Dispensing Tiniest Fluid Volumes Quickly and Precisely

Medical technology is developing rapidly and microfluidics contributes to a large part to it – it is seen as a future technology and is the key to many high-tech applications that are used for diagnostics and therapy.

Microfluidic applications can benefit enormously from the properties of piezo technology – thanks to their compact size, high speed, accuracy, and their low energy requirements, piezo ceramics can be used in numerous applications.

High-precision dosing systems, which are operated by piezo ceramics, can generate several thousands of picoliter droplets per seconds. This high throughput, for example, is indispensable for array plotting in manufacturing lab-on-a-chip systems or for consumables for in vitro diagnostic (IVD) tests.

Furthermore, piezo elements are readily used in liquid handling in IVD instruments, e.g. for PCR tests. They can dose, move, and mix tiniest liquid volumes with differing properties with high precision.

Piezo elements are convincing in dosing systems, such as micropumps for insulin or pain medication, thanks to their precision and their small size and low weight. This makes it possible to produce systems that are small, lightweight, and easy to handle; therefore, making it easier for the patient to manage their application.

PI develops and manufactures customer-specific piezoceramic materials and piezo elements for applications in microfluidics with the most varied shapes, dimensions, designs, or higher refinement.

The value chain for these solutions comes from one single source – from the specially developed piezo elements up to the production and assembly of the piezo elements, all manufacturing processes and process steps are carried out directly in one location.

Industry Applications - Fluid Metering

- Contactless and Contamination-Free Measuring with Ultrasound

Ultrasound has been used to realize fluid metering for many years – be it in pipelines, tanks, silos, or even in water meters. Automated process monitoring is one of the most important applications of fluid metering in the industry – measuring must be quick, precise, safe, and maintenance-free therefore ensuring product quality and throughput, e.g., in production lines or industrial plants. In addition to fluids, often air bubbles are detected in tubes of industrial plants.

In order to carry out ultrasonic measurements, sensors are applied to the tube or pipe, mostly on the outside, and sound impulses penetrate into it. Ultrasound can recognize the flow of various media contactlessly and without contamination.

With piezo technology these ultrasonic sensors can work reliably and save energy – piezo-ceramic components offer the best conditions to generate and detect ultrasonic waves.

PI offers customer-specific piezo ultrasonic transducers that can be integrated in ultrasonic sensors. Thanks to its longstanding experience in piezo technology, PI can also offer assembly to its customers, for example, gluing or soldering of the piezo elements as well as a higher refinement, such as contacting with flexible printed circuits.

Industry Applications - Sensor Devices

- Ultrasound as a Precise Measurement Tool

Sensor devices refer to the application of sensors for measuring and monitoring various physical and chemical properties. Sensor devices in industrial production are becoming especially important in conjunction with digitalization and Industry 4.0. Since ultrasound is a versatile instrument in measuring and monitoring various processes and procedures, such sensors are very sought after in the industry.

Ultrasonic sensors are used in smart metering and maintenance of machines and plants, e.g., for predictive maintenance. With ultrasound, machines, plants, pumps, and other equipment can be monitored noninvasively.

Positioning sensors with ultrasound are often applied in level detection and displacement measuring in logistics, in production plants, or filling systems to contactlessly and flexibly determine the presence and position of components, materials, or products with high speed.

Piezo elements generate ultrasonic waves in the sensor. The transducer is placed outside of the medium to be detected, in this way, contactless metering is possible.

The piezo ceramics used in the ultrasonic transducer must fulfill high expectations. As key component, it influences the quality of the transducer; therefore, also the accuracy of the sensors. The piezoceramic material, design, and assembly and connection technology are here the decisive factors because the piezoceramic used must fit the respective application and must be easy to integrate in the sensors.

PI offers various piezo shapes, electrode configurations, and flexible production quantities. If required, the matching assembly and connection technology is available so that the user only has to deal with the installation in the sensor.

Industry Applications - Hydroacoustics

- Ultrasound for Detection and Communication Under Water

Ultrasound has been used for a long time and extensively in hydroacoustics and also occurs naturally in marine animals. This animal navigation function developed millions of years ago – dolphins and wales can orient themselves thanks to ultrasound with their echolocation even in the darkest seas and find their prey.

Submarines also use ultrasound technology for detection; here, ultrasonic sensors can measure the distance under water or locate beacons in airplanes or ships.

Since ultrasound waves can travel over long distances under water, they are used, for example, also for cartography of the seabed.

The wireless underwater communication with ultrasound opens up one more large application area for monitoring climatic and biologic changes, and to explore and observe the oceans and underwater world. For this, underwater sensors use ultrasound for communication and to transfer data in the water. Autonomous underwater vehicles can, for example, recognize and avoid obstacles on their route.

Hydroacoustic applications profit from piezo technology. The low frequencies, generated by piezo components, are perfectly suitable for use in in direction-finding ultrasonic beacons for object detection.

Such demanding applications require special piezoceramic components with special geometries, for example large tubes or hemispheres.

PI develops and manufactures customer-specific piezo elements and supports customers with technical know-how and longstanding experience in piezo technology.

Nano Positioning

The Fast Lane to a Precision Advantage

In almost all industrial manufacturing processes, the correct positioning of individual components and their precise alignment to each other are essential for proper product function and manufacturing efficiency. This is even more important as products and their components get smaller and smaller. This ongoing process of miniaturization makes alignment more challenging and more expensive. With 50 years of experience in nanopositioning, hundreds of patents, and expert staff, PI has helped countless customers successfully master the challenge of nanopositioning and gain a decisive competitive advantage.

Let us guide you to "the fast lane to a precision advantage".Your Advantages with PI as a Partner

- Setting the pace in nanopositioning

- Extensive patent portfolio

- Broad technology pipeline

- Passionate advice

- Lots of testimonials

Industrial Automation

- Positioning, Dosing, and Measuring Solutions for a Precise, Fast, and Economic Production and Process Monitoring

Markets are more dynamic than ever. Together with ever shorter innovation cycles and the growing range of products and new technologies, the expectations of end customers with respect to the availability, performance, and price of the solutions have grown as well. This poses huge challenges for manufacturers: Increased productivity and quality, more efficient and flexible production processes, shorter production times, and lower costs.

These requirements make it necessary to develop more powerful and smarter automation solutions – both in production and also process monitoring. For plant and machine manufacturers, this means that the precision, throughput, reliability, and scalability of production systems are becoming increasing decisive factors. Development and delivery times, operating costs, and optimizing the solutions to meet the requirements of digitalization and industry 4.0 are also important factors when it comes to creating a competitive advantage in a global environment.

Every component and every subsystem must be selected and designed so that they contribute to achieving the desired performance of the application. This also applies to positioning, dosing, or measuring tasks.

Photonics

- Light is an exceptionally versatile and efficient carrier of information. In order to fully use this potential, it is crucial to exactly align the individual elements for producing and detecting light (e.g., lasers and photodiodes) as well as light-carrying and light-modulating elements such as glass fibers, lenses, or prisms. This plays a decisive role both in the quality assurance of individual elements and in the test and packaging of components and (sub)systems. For customers and users in the photonics market segment, PI offers an extensive portfolio of solutions for alignment. The focus is on motion and positioning systems as well as intelligent algorithms with which glass fibers can be coupled to silicon photonic chips, for example, or laser beams for free-space communication can be aligned and stabilized. PI develops solutions for production and quality assurance also for numerous other application areas such as quantum photonics or the design and alignment of optical systems made of lenses, prisms, plates, etc.. PI's strategy defines the algorithm-controlled, active alignment as an enabling technology. The mechanics being used, make active positioning in six degrees of freedom possible. Algorithms such as the search for first light and the parallel gradient search lead to accuracies in the submicrometer range and velocities that are suitable for series production. Both in test and packaging and for use in series control.

Performance Automation

The New Dimension of Precision Automation

Throughput, precision, availability, reliability, and yield – the variety of technologies, the long-term experience in precision positioning, and a modular approach make it possible for PI to react in an application-specific manner to requirements in order to support system integrators and OEMs worldwide in reaching the requested process and machine performances.

For customers in the field of precision automation this combination means that they not only receive an economical high-tech solution quickly and efficiently, giving them a competitive edge in their business sectors, but that they get the assurance of knowing that they are prepared for future requirements.

PI can grow with its customers – both in applications and quantities – and together we can develop new prospects and spaces for solutions in order to push the boundaries of what is possible.Your Advantages with PI as a Partner

- Competent advice – right from the start

- Flexible configuration and application-specific adaptation

- Different integration levels and high integration capability

- High economic profitability

- Always near you

Semiconductor

- Positioning Solutions for Improving Throughput and Enabling the Next Technology Node in Semiconductor Manufacturing

Today, semiconductor technology represents one of the most important industry sectors in the world. It paves the way for progress made in processor technology, data storage, signal processing, and opto-electronics and, therefore, facilitates for the next generation of microprocessors, memory chips, and power semiconductors. These semiconductor components are the prerequisite for essential developments in 6G technology, Internet of Things (IoT), Cloud and Edge Computing, or Electric and Autonomous Vehicles. At the same time, these growing markets are placing high demands on semiconductor manufacturers: Even smaller and more complex integrated circuits (IC) with higher functional density and reduced energy consumption, shorter product and technology innovation cycles, higher volumes, and increasing cost pressure.

Each equipment component and machine used by integrated device manufacturers (IDMs) or foundry companies for the manufacturing of semiconductor chips must follow these requirements. And also each of the demanding and sensitive manufacturing steps – both in the development of process-related technologies and the numerous processing steps a silicon wafer undergoes.

Lithography is one of the most decisive process steps in wafer processing. This is where the foundation for the functionality of the chips is laid, i.e., processor speed, storage capability, space requirements, and power consumption. During the repetitive exposure process, smallest structures for printed circuit boards, transistors, and other components have to be transferred onto the silicon wafer.

Measurement and inspection processes are necessary at all critical points in the manufacturing process to ensure high quality and reliability of the final products and also the yield of the cost-intensive chip production.

In many manufacturing steps, the ability to move components with nanometer and even sub-nanometer precision and with high dynamics, or to hold a position precisely over an extended period of time, plays a crucial role.

Microscopy & Life Sciences

- Innovative Diagnostic and Therapeutic Procedures with Precision Positioning, High-Speed Actuation, and Ultrasonic Solutions

From genome research through the accurate diagnosis of illnesses to innovative solutions in surgery ‒ life sciences entail numerous disciplines in which new biomedical procedures are researched and devices are developed that are meant to improve the therapy for and quality of life of patients.

To improve the diagnosis of illnesses and initiate therapies early on, high-precision and fast methods are necessary. In addition to numerous solutions for microscopy, such as sample positioning and ultrafast focusing, highly modern imaging methods are becoming increasingly important. Precision drives and miniature piezo elements make endoscopic solutions possible that increase the image information and allow deeper insights into tissue structures. Microfluidic systems as, e.g., portable point-of-care systems or for cell sorting, profit from compact and energy-efficient piezo solutions that make the precise manipulation of fluids or tiniest particles possible.

In the surgical devices sector, automated robotics systems with high-precision positioning units allow for gentle minimally invasive procedures. Ultrasound is increasingly being used as a powerful instrument. For both, a gentle targeted treatment of the tissue and also for disruptive treatment methods such as incisionless surgeries that are made without having to cut into the body.

New therapies, e.g., in pain medication or insulin administration, are made possible by tiniest piezo elements within miniaturized micropumps. In addition, contactless ultrasonic sensors ensure a contamination-free monitoring of processes, such as the detection of tiniest fluidic flows or air bubbles.