All-printed Flexible Pressure Sensor Array Made with Polyamino Acid Developed

An affordable and mass-producible printed large-area sensor

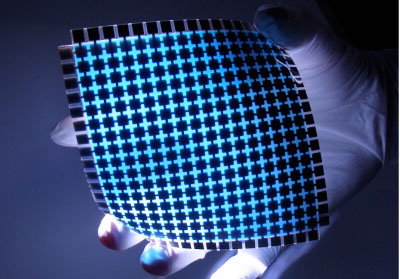

- A piezoelectric ink has been developed to enable sensors to be arrayed on a flexible substrate.

- A large-area sensor array has been achieved by joining sensor array sheets together.

- This technology will contribute to the development of safe and secure sensor network devices, such as watch sensors.

Sei Uemura (Researcher), Printed Electronics Device Team, the Flexible Electronics Research Center (Director: Toshihide Kamata) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), has developed an all-printed flexible pressure sensor in collaboration with Ajinomoto Co., Inc. (Ajinomoto; President: Masatoshi Ito).

Sei Uemura (Researcher), Printed Electronics Device Team, the Flexible Electronics Research Center (Director: Toshihide Kamata) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Tamotsu Nomakuchi), has developed an all-printed flexible pressure sensor in collaboration with Ajinomoto Co., Inc. (Ajinomoto; President: Masatoshi Ito).

AIST and Ajinomoto have developed a polyamino acid material that exhibits piezoelectricity and have fabricated a sensor array printed on a flexible substrate by forming the material into an ink and adopting a structure that reduces current leakage. This fabrication technology by printing for the sensor array, as well as the increased sensor array size, will allow affordable sensors to be supplied in large quantities. This technology is expected to contribute to the widespread use of sensor network devices such as watch sensors.

Social Background of Research

In recent years, sensor networks through which people can communicate with electronic devices from anywhere and at any time have been attracting attention to create a safe and secure society. There is an expectation that a system will be developed in which unobtrusive sensors will provide the necessary information, such as movement of people, to the network. These sensors need to be applicable to a wide variety of uses, affordable, and mass-producible. Existing pressure sensors are very expensive and often not suitable for array fabrication. Also, the structures of these sensors make it difficult to increase the sensor array size, preventing their widespread use in society.

History of Research

AIST has been conducting research and development of flexible electronic devices. Particularly, it aims to develop a technology to perform all fabrication processes by printing and has developed an all-printed memory array, an RF tag, an evapotranspiration sensor, etc. Ajinomoto has years of experience in research and development of functional organic materials, such as amino acids and polyamino acids, and in the production technology of them.

The all-printed memory arrays developed by AIST are ferroelectric memory arrays that use ferroelectric polyamino acids as the ferroelectric layer of the transistor. The polyamino acids exhibit high ferroelectricity as well as high piezoelectricity when the large dipole moment of the main chain is efficiently used. AIST and Ajinomoto have developed a polyamino acid material suitable for piezoelectric devices and have fabricated a pressure sensor array by forming the material into an ink and adopting a device structure suitable for printing processes.

Details of Research

Please visit the website of the National Institute of Advanced Industrial Science and Technology to get detailed information about this research project.

Future Plans

The researchers intend to enhance the performance of the piezoelectric sensor, including the improvement in its sensitivity and the miniaturization of it. They will also propose new applications of piezoelectric sensor devices by developing combinations with other devices and network interfaces. Because the developed piezoelectric sensor array can be used for vibration power generation, they aim to develop self-power-generating sensors by combining the array with a battery.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech