Ammeraal Beltech to launch uni QNB Ball Belt innovation at LogiMAT 2018

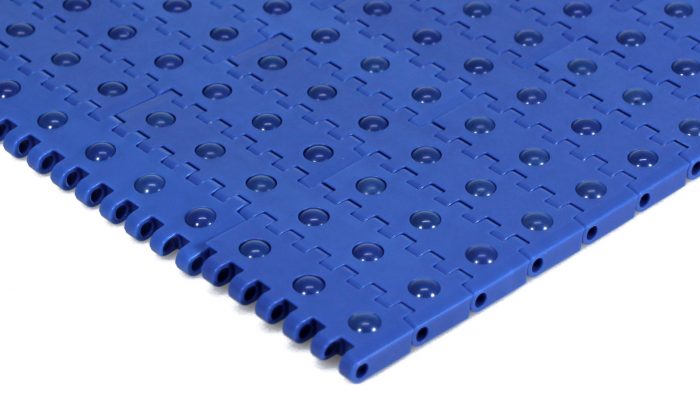

Auxiliary belts may be added to create

additional spheres of product movement – turning them round, or

transferring them from left to right, for example. Photo by Ammeraal Beltech Holding BV

At LogiMAT 2018, global belting specialists Ammeraal Beltech will feature an important innovation for their leading-edge multi-directional uni QNB Ball Belt, which was introduced at last year’s show and is already a huge contributor to improved performance in a variety of tasks in intralogistics, materials handling, packaging and manufacturing.

To fine-tune uni QNB Ball Belt’s efficiency in today’s ever-increasing colorimetry and video sorting applications, the belt’s integrated rotating closed ball construction – at a surface density of 1550 per square meter — is now supplied in one single default standard colour: blue. ‘This’, says Norman Gill, Ammeraal Beltech’s Logistics Industry Segment Manager, ‘is a major simplification and time-saver for today’s logistics businesses, eliminating the need to define different measurements for different colours of balls. Belt speed can be slowed at defined points for such key tasks today as inspection using colour definition sensors for precise location of the products on the belt, or in video sorting systems. Here, the introduction of a standard belt colour adds extra speed and accuracy to process operations. In other words, a single colour of ball across all your production lines means you need just one standard measurement basis.’

In partnership with a number of industry-specific tracking and control systems, the blue balls’ movement can also be precisely activated or deactivated to allow goods to be aligned, rotated, sorted, accumulated, or separated to order, with acceleration and deceleration of conveyor speed appropriately controlled. Auxiliary belts may be added to create additional spheres of product movement – turning them round, or transferring them from left to right, for example.

‘We expect to attract considerable interest in this innovation at LogiMAT 2018’, adds Norman Gill. ‘It’s certainly blue chip!’

Along with Norman Gill, Ammeraal Beltech specialists will be on hand at LogiMAT to demonstrate relevant features of the company’s broader product range that make up its ‘One-Stop belt shop’. These include solutions for specific intralogistics needs such as low-noise, flame-retardant and anti-static materials to minimise fire risk, as well as impact-, abrasion- and temperature-resistant conveying solutions.

For more Information, please visit: www.ammeraalbeltech.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech