BEUMER paletpac, a solution that palletises bags carefully and very stable

In the chemicals industry, if polyethylene (PE) bags filled with granulated material are palletised, secured, stored or loaded onto trucks, then high-capacity palletisers must ensure high stack quality and stack stability. Various climatic conditions or a flow behaviour of varying intensity can result in the bags becoming stuck on the conveyor belts and layer stacking tables and undergoing significant deformation during handling. With the ventilated and specially coated layer stacking table integrated in the BEUMER paletpac, the BEUMER Group has developed a solution that palletises bags in a careful and dimensionally stable manner.

If the PE bags are filled with plastic granulated material, they often show an unstable behaviour similar to that of liquids. The process-related, self-generated heat of the granulated material, as well as the ambient temperatures, additionally affect this behaviour. This hampers the handling of these bags considerably, as for example they deform considerably during the palletising process. However, the degree of filling of the bags during handling can also present problems: to prevent any sealing seams splitting during filling, the bags are often larger than they actually need to be. This reduces the pressure, and the bags do not split. However, they deform more easily, which likewise hampers handling. In order to enable transport and palletising of these bags carefully and in a dimensionally stable manner, BEUMER equips its high-capacity palletisers specifically with regard to the customer’s requirements and wishes.

Frequency converters, for example, control the movements of the driven elements so that start-up and braking movements ensue evenly, moderately and gently. This way, the product hardly shifts in the bags and the filled bags are subject to only minimum deformation.

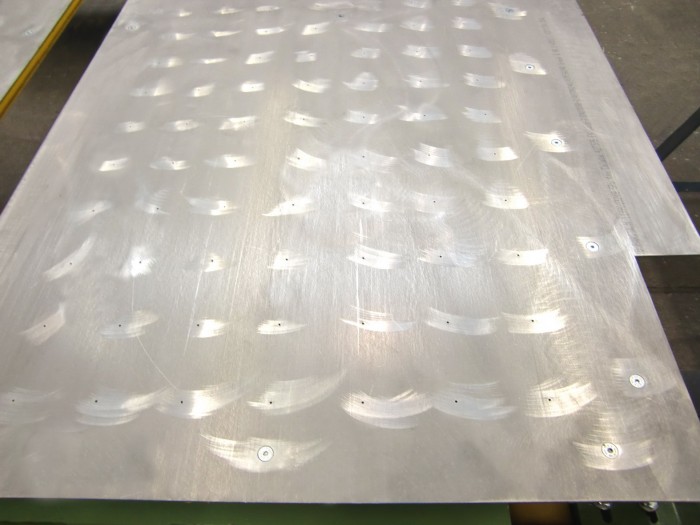

The softer and more unstable the bags, the higher the adhesion forces on the belt or the layer stacking table. This hampers palletising, as high friction arises between the bags and the contact surface. BEUMER has therefore developed special layer stacking tables for the BEUMER paletpac, which are coated with plastic material and can be ventilated.

No adhesion possible

Mild temperatures prevail in Europe, and the systems are not subject to extreme atmospheric influences. The metal surface of the tables is polished smooth, allowing the bags to glide well on them. If this polished stainless steel surface is insufficient to ensure secure handling, then compressed air flows through small apertures in the layer stacking table. This allows the bags to “hover” on an air cushion. This therefore greatly reduces the friction between the bag and the layer stacking table, and the bags do not stick to the contact surface. This way, the bags can be moved and positioned rapidly and in a dimensionally stable manner. This allows geometrically precise stacks, space-saving storage and problem-free conveyance to the packaging system downstream.

For further information visit www.beumergroup.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech