CERATIZIT to showcased its latest carbide and cermet rods technologies

Photo by CERATIZIT S.A.

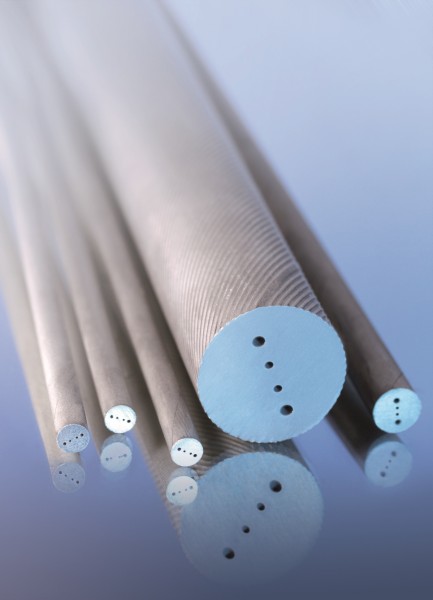

At GrindTec 2014 in Augsburg, CERATIZIT will be presenting its latest developments in the field of carbide rods – rods with four coolant holes, milling cutter blanks combining two different grades of carbide and a new generation of cermet rods. And for wood machining, CERATIZIT will also be introducing self-sharpening saw teeth that can be soldered quickly.

CERATIZIT is expanding its product range with the launch of CTS20D – DualBlank, a milling cutter blank for universal use made of two different carbide grades. In the cutting zone, where performance is key, the blank consists of the high-performance grade CTS20D, while the shaft is made of TMG30, a resource-efficient recycled material. “We care a great deal about handling tungsten resources responsibly and sustainably,” says CERATIZIT product manager Christian Buschneg. “This is why our DualBlank technology is now available in conjunction with our CTS20D premium grade.”

New four-hole system delivers improved cooling

CERATIZIT has also boosted the efficiency of solid carbide drills by developing a range of rods offering four helical coolant holes. The two added holes allow more coolant to flow through the tool without any increase in pressure. And because the lubricant is distributed more evenly, the heat gradient at the cutting edge remains extremely low. So the material comes under significantly less stress, and is therefore much less likely to break.

Cermet: high resistance to heat, thermal shock and oxidation

CERATIZIT has now reintroduced cermet rods – and is the only rod manufacturer to do so. These are used primarily for reamers, but can also be found in milling applications. The reaming process generates high temperatures at the cutting edges. Our CTF28T grade is highly resistant to heat, thermal shock and oxidation. Cermet is exceptionally well suited to machining steel and cast iron. Here the tools, unlike those made of carbide, do not need to be coated. As a result, users enjoy extremely sharp cutting edges and a high level of surface quality.

Saw teeth: self-sharpening, quickly soldered and lightweight

CERATIZIT presents two innovative new products for wood machining:

Thanks to a groundbreaking layer structure, saw teeth made with CTDIA02 are self-sharpening. The result is a tool life of up to 250 kilometers, and tools that deliver an extremely high-quality finish throughout their useful life.

The main feature of the new 60000 series of saw teeth is a tooth radius that optimizes heat conduction. This makes the teeth quick to solder, thereby creating a uniform structure between the carbide and the main body. And the redesigned shape also makes the tooth more lightweight.

For more information, please visit http://www.ceratizit.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech