Successful crashtest coverage with PCO’s highspeed camera pco.dimax HD/HD+

Highspeed camera system pco.dimax HD/HD+ as it is used in many car crashtest applications

Photo by PCO AG

To implement successful car safety or crashtest applications one require a powerful highspeed camera system with appropriate performance qualities with a high frame rate. However, it takes futher measures to make a crashtest application a successful one. Since the success is defined by the application, in crashtest it means, how good the deformation can be measured and how good the 2D and 3D evaluation can be processed. This depends on the quality of the image data and their time relationship. In the following it is explained and discussed what it takes to achieve these high quality image sequences.

These performance characteristics in combination with the build quality and all the other features were a major argument, that some of the major German car manufacturers decided to equip their main crashtest facilities with these cameras. As an example in figure 2 a single image from the recording pit is shown, where the different relevant parts below the car were painted in different color for better observation. The sequence was taken at 100 frames/s at a shutter time of 300 μs at 1920 x 1440 pixel resolution and illuminated with synchronized LED lamps (IES).

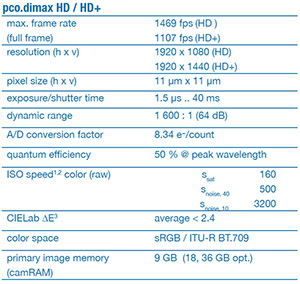

1 highspeed camera pco.dimax HD/HD+

First of all, a good and proven highspeed camera system like the pco.dimax HD/HD+ is required to record images with at a sufficient speed, resolution, dynamic and quality. Some of the key parameters are given in the following table.

Beside the usual performance data, which are compared if a highspeed camera should be applied in crashtests, there are a number of additional features, which might be important for an application.

Key parameters of the highspeed camera pco.dimax HD/HD+

2 free of session referencing

While other highspeed camera manufacturers advise to do a session referencing before a recording is started, and even offer special measures to improve or ease the session referencing, the pco.dimax and pco. dimax HD/HD+ are free of session referencing due to their design. Therefore it doesn’t matter, whether the camera has been started now or hours before, the high image quality will always be achieved.

3 sensitivity and dynamic

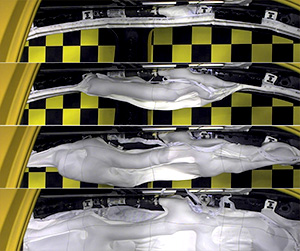

In crashtest applications, as high frame rates and short expsoure or shutter times are required, always a high amount of illumination is demanded. In the past this gave rise to lamp rigs with lots of power which cause a lot of heat, a lot of electronical noise and which are quite expensive. As consequence for example the test car is set up in a climate chamber, which is only left for the real crash itself to prevent all the addditional sensors in the car to be heated up by the lamps more than half a degree °C ( a regulation requirement). Therefore a good sensitivity of the camera system help the reduction of lamp power and associated heat and it reduces the overall costs of the crashtest set-up significantly. Figure 3 shows a difficult to illuminate scene with a side-airbag inflation within the car which was recorded with a pco.dimax HD+ at 1500 frames/s. The images are extracts of the total image in 1192 x 792 pixel resolution. Every detail of the airbag surface can be observed and analyzed.

highspeed sequence taken with a pco.dimax HD+ at 1000 frames/s from the recording pit (taken from a Mercedes presentation at the SafetyUpdate 2012)

Since there are many strongly reflecting surfaces on a car, many crashtest cars are treated with a special less reflecting paint. Nevertheless, this is not always possible, as well not always wished, if a car just is taken from the serial production. Additionally there are parts like the wheel rims which can’t be painted well. The inside of the car is often partially in the shadow.

A high dynamic of the camera system is therefore important to deal with this challenging light situation and achieve images with a sufficient information content, such that structures in the shadows as well as in the bright lights can be successfully resolved. Sometimes if highspeed cameras are compared with respect to their sensitivity, there are myths discussed, like “the camera with the larger pixels is the more sensitive”. The relationship between sensitivity and pixel size is a little bit more complex and for that reason explained in a technical paper4 on our website. Here it is shown, that the most important contribution to sensitivity is given by the quantum efficiency.

4 failsafe synchronisation & trigger

Extracted images of a highspeed sequence of the inflation of a side airbag in a weak illumination setting at various point in the time line

Photo by PCO AG

For 2D and 3D image processing the time relationship between each image recorded by different cameras is very important for a proper and meaningful image processing. Therefore this application has high requirements for the precision and time stability of the synchronisation and triggering units of highspeed camera systems. Usually all cameras which are involved in a crashtest set-up receive the same external synchronisation signal, which either triggers each image or delivers a clock synchronisation for each camera. Since the timing is important, the camera should process the so called sync-signal with minimum delay and jitter. Therefore the nanosecond values for internal delay and even smaller jitter of the pco.dimax HD/ HD+ are very convenient.

5 single cable solution

Due to the requirements defined by the automotive manufacturers the interface signals like trigger, sync, busy and the like have to be able to deal with: TTL voltage levels (high & low), differential signals and passive signals at the same contacts, which can be selected by software.

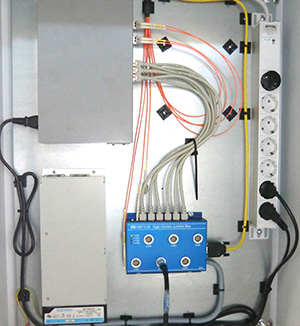

pco.dimax HD/HD+ back panel

Photo by PCO AG

These demanding requirements are realized within the pco.dimax camera family including an adjustable digital lowpass filter. And everything can be controlled with a single plug, which helps to set up larger camera applications like the ones in crashtest facilities. With this single cable approach together with a proper cabling and sync signal structure, where the signals are shaped and sophistically distributed, it is possible to achieve a high level of fail safety. Figure 4 shows the back panel of a pco.dimax HD/HD+ with the high variety of input / output signals and the single cable plugs. Therefore the customer can decide which pathway to pursue. Figure 5 shows a view into a new switch board where an IES switch box, which connects with up to 6 highspeed cameras pco.dimax HD+, is installed. The cameras are connected with a single cable to this box, which handles the trigger and synchronisation signals as well as the image data and transfers everything properly to the control computers. This allows for a simple but powerful connection scheme and a less complex cabling set-up which is less prone to failures.

6 system integration

Switch board for a crashtest facility with an IES control box for 6 pco.dimax HD+ cameras

The influence of the proper cabling solution already shows, that it is the whole application system has to act in concert to achieve the best possible results. Therefore the high performing cameras have to be integrated properly with a clever timing signal generation and a proper cabling system. If this exists new LED light sources can be used, which can be triggered according to synchronisation of the image recording of the cameras. This has the advantage of lower cost lightings with less temperature input into the crashtest scene. The recording pit example in figure 2 was obtained with triggered LED lamps, which have been found ideal for the limited space in the recording pit. Recent LED lamp developments for example by IES showed powerful LED lighting like the single LED block shown in figure 6. This can be combined to create larger lamps, which are powerful enough to illuminate crashtest scenes which are recorded by cameras like the pco.dimax HD/HD+. Having considered the system made of highspeed cameras with proper lenses, clever cabling and good illumination, what remains to achieve a successful crashtest application is the software. The software, which controls the cameras and the image recording and storage, and the software, which does the evaluation or processing of the image data.

Single LED block from IES which is used as core element for creating larger crashtest LED lamp system which are used in trigger mode

The larger manufacturers in Germany use a software bundle that does it all, the Falcon software5, meaning camera control, processing, calibration and archiving. Other manufacturers prefer to use camera control packages like Visart from HS Vision6 and image processing packages like TEMA7 from Image Systems. All of them can be used with the pco.dimax highspeed camera systems.

7 summary

Two different stereo 2D set-ups with pco.dimax highspeed cameras In front there is a mirror set-up, where two images are recorded in the same image sensor side-by-side. While the set-up on a stereo bar behind uses two synchronized pco.dimax highspeed cameras to record stereo images at higher resolutions.

Successful crashtest applications require a well harmonized system of suitable components. At the heart, there is clearly a powerful highspeed camera system, which delivers images with high quality. Nevertheless all the other components like light sources, synchronization and trigger signal generation, software, cabling have an important impact on the results. A good interaction between all of these components enables high quality results.

For further information please visit: www.pco.de

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech