Egemin Automation installed fully automated warehouse system at Alcon

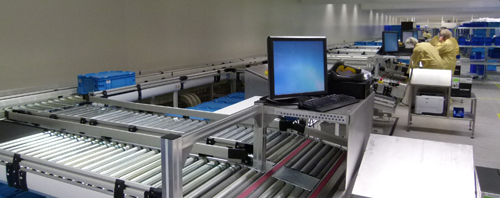

Photo by Egemin Automation GmbH

Egemin Automation has installed a fully automated warehouse system and order picking system with WMS software at Alcon. Production at the site in Puurs of CUSTOM-PAK®’s, personal operation kits for ophthalmic surgeons, now runs automatically and efficiently.

Surgeons receive an eye operation kit comprising instruments and equipment, such as surgical drapes and gowns, masks, scalpels, but also smaller accessories, such as cottonwool, eye-pieces, bandages, etc. As each surgeon has an individual process for carrying out operations, all the materials in a surgeon’s particular kit are packed in a specific order (i.e. customised).The small accessories are first kitted in a sub-kit. Consequently, an operation kit is prepared in a number of stages, and therefore, the coordination of the selection process with the making up of the kit is very important. Egemin made sure that the supply in the CUSTOM-PAK® process is fully automated.

EXPERTISE, PERFORMANCE AND SUPPORT

Alcon chose Egemin because of its expertise and positive approach during the concept phase and the performance and quality of the installation and its management. Egemin’s solution integrates the following installations:

- Fully automated tote storage system with 2 miniload stacker cranes providing space for 3500 totes for storing small goods

- 4 replenishment stations for replenishment of the tote storage system with new goods

- 6 picking stations

- 3 stations for the picking of goods and the preparation of sub-kits

- 1 conveyor loop for transporting goods in and out between the tote storage system and the work stations

- 1 conveyor for transporting empty totes to the work stations

The miniload stacker cranes are responsible for feeding full totes in and out the warehouse. The conveyor loop transports the totes from the store to the work stations in the clean room, where operators pick the right products from the totes to custom-fill each CUSTOM-PAK®.

Goods are delivered to the warehouse via an air lock from an adjacent warehouse. E’wms®, Egemin’s warehouse management system, manages the stock, allocates orders and is also responsible for tracking and tracing. Alcon will also use E’wms® for password management and signatures at work stations, reports, extra control scans and action logging.

INSTALLATION IN CLEANROOM

A large part of the installation is in a cleanroom. “A cleanroom must comply with the statutory international regulations in the pharmaceutical industry,” says Peggy Reyntens, Project Manager at Egemin. “To meet this requirement, we used powder-coated supports for the conveyors instead of galvanised and special conveyor belts. We also made the control cabinet of stainless steel material and placed the electrical wiring in fully enclosed plastic cable ducts. The part of the installation where the operators are located is situated in the cleanroom. The storage area is outside this zone. There is a pressure difference between the two zones. In order to minimise pressure drop, we have built in sliding doors to close off the conveyor passages to the totes.”

In cooperation with Alcon, Egemin also arranged for the validation of the software. “We managed to deliver that because of the expertise of the colleagues from the Life Sciences Division. They have years of experience in the validation of all kinds of systems in the pharmaceutical industry. The project went very smoothly thanks to the pragmatic approach of both parties and the constructive cooperation,” concludes Peggy Reyntens.

For more information, please visit http://www.egemin.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech