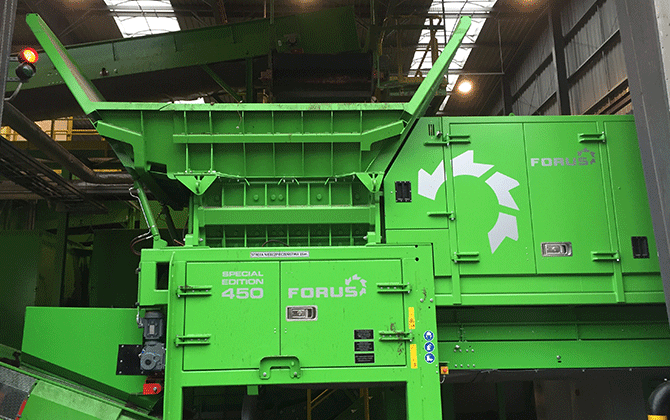

Eggersmann’s FORUS Special Edition SE 450 provides reliable shredding solution for Marszów Waste Management Plant

With more than 1,000 machines sold, FORUS is quite rightly considered to be a specialist in the sector of shredder technology.

Photo by Eggersmann GmbH

Since November of last year, the SE 450 – a pre-shredder of the Eggersmann Group’s FORUS brand – has been found in use in a mechanical-biological treatment plant in Marszów. The MBT realized by the Eggersmann group of companies has been in operation since January 2015 and was to a large degree provided using their own product portfolio.

Waren. The large diversity of types of the input materials delivered to Marszów (household waste, green waste and bulk waste etc.) requires, as well as a high throughput, a great application flexibility of the machines used. The one shaft pre-shredder which has been running since commissioning – a machine from a competitor – could meet these requirements less and less in recent months. The machine was quickly over-burdened and reversed on high material throughput or on the introduction of bulk materials. Furthermore, the opposing teeth loosened several times and fell out. This in turn disturbed the overall process of the MBT so that a replacement of the shredder was unavoidable in the end.

The FORUS Special Edition SE 450, a slow running pre-shredder with two shafts and an electrical operational performance of 250 kW took over the shredding of various materials – from plastic sheet mixes to bulk waste. The throughput performance of the shredder – dependent of the input material – is thereby up to 65 tons per hour.

The loading of the machine occurs according to material by wheel loader (green waste, bulk waste and plastic sheet mix) or by conveyor belt from the sorting cabin (residual material). The material discharge is similarly flexible by using a reversible discharge belt. Thus, depending on the load, the shredded green waste is transported directly using a conveyor belt into the decomposing unit, the pre-shredded plastic sheet mix in the direction of refuse-derived fuel (RDF) production or bulk waste directly into the loading station.

“Since the installation of the FORUS Special Edition SE 450, the plant has been running much better. In recent years, we have already installed a number of machines of the Eggersmann group of companies – for instance, BACKHUS compost converters, BRT HARTNER bag openers and Eggersmann materials handling technology and sieve drums – which is why we have been confident with regard to this pleasing result”, states Jacek Poomka, President of the Administrative Council of the Marszów Waste Management Plant. “The FORUS SE 450 is an outstanding all-rounder which conforms reliably to our requirements.”

For more information, please visit http://www.eggersmann-group.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech