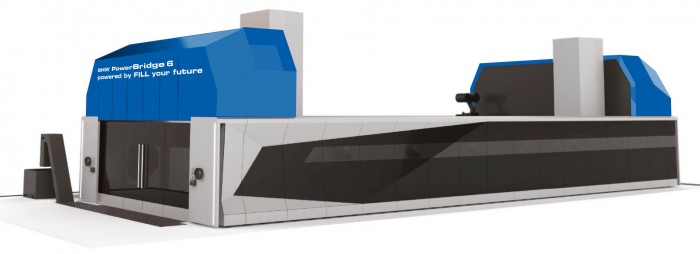

First gantry milling machine with dynamic toolchanger

SHW Werkzeugmaschinen exhibited at the EMO, the modular portal milling machine with driven gantry and a completely new, dynamic toolchanger that exchanges tools while machining is going on

Photo by SHW Werkzeugmaschinen GmbH

SHW Werkzeugmaschinen – EMO world premiere of its modular gantry milling machine

SHW Werkzeugmaschinen exhibited at the EMO for the first time its portal milling machine with gantry drive. PowerBridge has a completely new, dynamic toolchanger that exchanges tools while machining is going on and an operating platform that can travel in the work area. The innovative development and innovative modular design was sponsored by the German Ministry of Economics. But that is not the end of the story.

“Sometimes you don’t only have to think laterally but put things laterally too,” says Martin Rathgeb. Thus the technical manager of the SHW Werkzeug-maschinen GmbH laid the vertical column of an SHW UniForce machine on its side to create a portal milling machine. The completely new portal milling machine, developed jointly by the Aalen machine tool manufacturer together with the Austrian company Fill, also features two world firsts: a toolchanger which brings the tool to the spindle while machining is going on and an operating cabin which travels in the work area.

SHW Werkzeugmaschinen has laid the vertical column of an SHW UniForce machine on its side to create an ingenious portal milling machine

Photo by Jan Walford

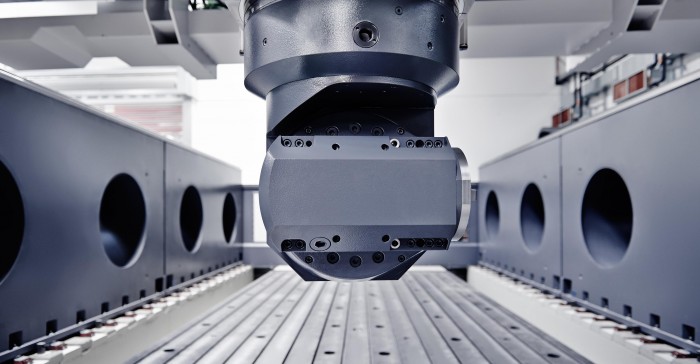

Tool delivered during machining

The toolchanger is as astonishing as it is ingenious. The tool required is not picked up by the spindle from the magazine but brought directly to the spindle by a robot no matter where it is. The robot is dynamically synchronised with the bridge and the tool is transferred synchronously to the toolchanger fork. The toolchanger can even supply two separate bridges with tools. Through this synchronised tool changing during machining, the user gains valuable production time.

From his travelling control console, the operator is always at the same height as the spindle and has a good view of everything. If he does not want this, perhaps because there is a risk of collision, he can park the operating console at any position he wants along the longitudinal axis in the work area.

The innovative approach to developing a new, cost-effective portal gantry machining centre was supported by the German Ministry of Economics

Photo by Jan Walford

Innovative concept worthy of support

In addition, the gantry machine convinces through its modular design with cross-over concept. Through this, SHW Werkzeugmaschinen can use similar components both for travelling column machines and for portal milling machines. What is particularly clever here, however, is that the bridge is able to use the modular concept of the travelling column machine. Thus three different machines with traversing distances between the driving heads of 3100, 4100 and 5100 mm respectively can be realised. The German Ministry of Economics recognised this innovative approach as worthy of funding. The first PowerBridge machine with these ground-breaking innovations and two bridges will be exhibited by SHW Werkzeugmaschinen at the EMO.

And a further innovation is already in the pipeline. A laser tracking system that continuously measures and compensates for any set/actual value deviations of the main axes of the PowerBridge during machining. But that’s another matter.

Visit www.shw-wm.de for further information

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech