Higher pressure range of hydrostatic drives enables higher power density

02 series from Linde Hydraulics achieves more tractive effort & speed: 20% higher pressures

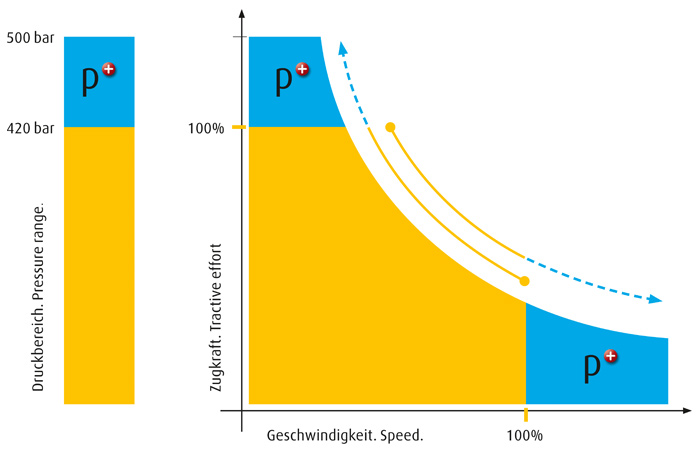

Variable displacement pumps and motors in the 02 series from Linde Hydraulics are the core components of many hydrostatic drives applied e.g. in construction and agricultural machinery as well as in industrial trucks. With a nominal pressure of 420 bar, these pumps and motors allow to design very compact, powerful and flexible drive systems.

Photo by Linde Material Handling GmbH, Linde Hydraulics

The power density of these drives is currently being increased to greater levels. Based on comprehensive tests and the evaluation of experiences in the field, Linde Hydraulics has increased the permissible pressure range of the units. If defined application conditions are adhered to, the motors and pumps in the 02 series can be operated with an effective pressure range of 500 bar — without limiting safety and availability and while still maintaining a reliable service life.

There are numerous ways in which manufacturers of mobile machinery with hydrostatic drive units can use the increased torque the hydraulics provide. Firstly, given the same nominal sizes and identical space requirements, they can increase the capacity of their machine’s performance and offer the user more tractive effort – in other words: enhanced gradability and additional power reserves.

Secondly, machine manufacturers can convert the additional pressure into higher driving speed by providing a longer gear transmission ratio. If, however, and this is the third option, the machine’s power and speed are already adequate, manufacturers can profit from the benefits of downsizing and, without limiting driving performance, use units that require less installation space, thereby achieving a more compact design and increasing efficiency.

Photo by Linde Hydraulics

The potential for downsizing applies to both pumps and motors. By choosing a smaller pump with higher pressure and simultaneously adjusting the gear transmission ratio, less fuel is consumed since efficiency is increased while the hydraulic motor speed is reduced. Use of a smaller motor permits the design of a more compact drive with identical driving performance and increased efficiency because, although the hydraulic motor is operating at the same speed, windage losses are lower.

These benefits are directly in line with the LinDrive® concept, which provides manufacturers and users with hydrostatic drives that are a byword in the industry for impressive dynamics and high precision as well as supreme energy efficiency and excellent reliability. It is further confirmation of Linde Hydraulics’ strategy of offering OEM customers low-speed drives that are supremely adaptable and adjustable.

Design engineers can choose how to use the higher pressure to the benefit of the machine user, and can give their machinery a “facelift” with higher driving performance and enhanced efficiency. Each of these benefits can be implemented in practice without any additional components. It only remains for the application engineers at Linde Hydraulics to check whether the conditions are given in individual cases for using the higher pressure range.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech