KEBA shows more compact and faster packaging robotics

Compact packaging cell

Photo by KEBA AG

More compact & faster – KEBA’s motto for the Fachpack 2013 exhibition. And this is underscored by a unique, space-saving and at the same time remarkably fast robot demonstration.

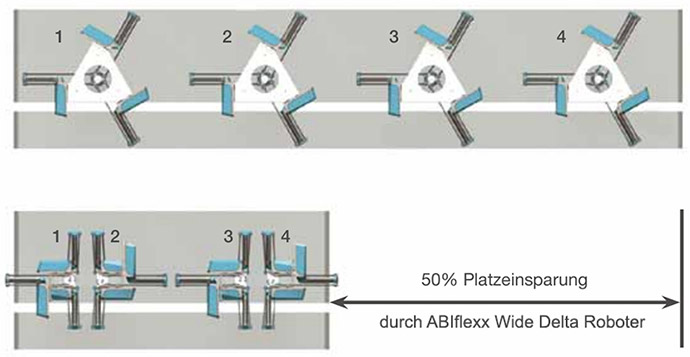

The packaging cell stands out through an up to 50% reduction in footprint compared to conventional cells, despite having impressive pick speeds and productivity.

Packaging cells only half the size

This enormous saving in space is made possible by the new, compact ABIflexx Wide Delta robot. Its asymmetric design means you can line up the individual mechanical units much closer together on packaging lines with several robots. In the case of 4 robots in one line, for example, the result is a roughly 50% saving in space compared to conventional configurations.

Another benefit of this unique design is that the ABIflexx kinematics feature an oval and therefore wider and larger working area than conventional parallel kinematics, which in turn means that products are picked earlier. The result is a notable increase in productivity.

The Hygienic Design of the robots makes them suitable for use in the food sector and other sensitive application fields.

Footprint reduced by 50 %

Photo by KEBA AG

Fast and energy-saving thanks to Intelligent Motion

An intelligent KeMotion control system from KEBA drives the packaging robot to peak performance with a remarkable 220 picks per minute.

Thanks to the integrated look-ahead path planning Intelligent Motion, the control system recognises all moving robots and objects in the workspace. This means that the speeds and movements of the kinematics can be calculated and optimised in advance, taking into account the physical limits. Abrupt start/stop movements are thus avoided effectively. The result is around 10% less energy required but an around 10% boost in productivity.

Robot vibrations are also drastically reduced which not only increases the service life of the mechanical components but also keeps servicing costs low.

Control, Drive and mobile operator panel

Photo by KEBA AG

Thanks to Intelligent Motion there is a noticeable gain in performance and productivity – even with the reduced spaces between the individual ABIflexx robots.

Easy customizing

The system comprising ABIflexx kinematics and KEBA KeMotion control has a modular configuration. This makes it easier for engineers designing packaging cells to implement specific customer requirements quickly.

Additionally, visualization with the software KeStudio ViewEdit can be easily adapted to customer requirements and the corporate design of the respective client. This applies to both mobile and stationary operating panels.

Branch-focused KeMotion solutions for the packaging industry

Besides the robot demonstration KEBA will also be presenting its industry-optimized KeMotion solutions for pick & place and palletizing applications. These solutions stand out through highest possible speeds and fast commissioning within only a few hours. This is made possible by the typical KEBA easy-to-use operating concept.

More than 30 well-known robot types are already preconfigured in the software, Cognex Insight Vision systems can be easily linked, plus the user is assisted by numerous wizards and preconfigured program modules. Parameterizing instead of elaborate programming is not just theory with the KeMotion concept, it is true practice.

for further information, please visit: www.keba.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech