Nikon Metrology announces new metrology CT system

Nikon Metrology combines 50 years’ experience of Coordinate Measuring Machine (CMM) metrology with 25 years’ experience of X-ray Computed Tomography (CT) to develop a new “absolute accuracy” metrology CT system. MCT225 provides Metrology CT for a wide range of sample sizes and material densities with 9+ L/50 µm accuracy in accordance with the VDI/VDE 2630 guideline. All internal and external geometry is measured efficiently in a single non-destructive process. A full 3D visualization of the sample volume additionally provides valuable insights into part deformations and internal structural integrity.

MetrologyCT, the future of dimensional inspection

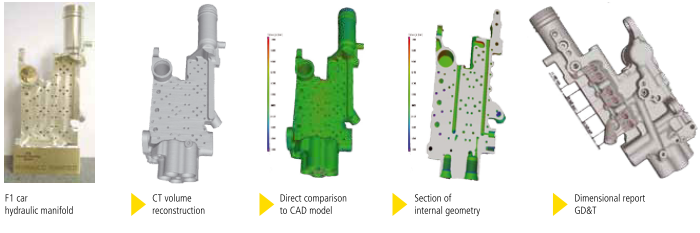

MetrologyCT is the fusion of metrology and X-ray Computed Tomography (CT). X-ray has long been used for industrial applications. WithX-ray CTa number of 2D X-ray images are taken at different angles around the sample. All of the external and internal geometry is captured as the X-rays pass through the sample. CT software constructs a 3D model of the sample using these 2D images. Dimensional characteristics such as size, position and form can be measured directly using the model as well as full part-to-CAD comparison, section reporting and GD&T analysis.

Absolute accuracy for internal geometry

MCT225 is pre-calibrated using accuracy standards traceable to theUK’s national measurement institute (NPL) and verified using VDI/VDE 2630 guidelines for Computed Tomography in Dimensional Measurement. “Absolute accuracy” guarantees measurement accuracy without time consuming comparative scans or reference measurements; samples are simply placed on a rotary table inside the enclosure and measured.

A key component of the MCT225 system is the in-house developed Nikon Metrology 225 kV micro-focus X-ray source. It produces incredibly sharp images with low noise levels, enabling magnification levels up to 150x with 2µm feature detection.

High-precision linear guideways equipped with high-resolution optical encoders are error corrected using the laser interferometer mapping techniques employed for CMMs. For optimal accuracy and long term stability, Finite Element Analysis (FEA) was used during the design phase to optimize the stiffness of the manipulator.

To minimize thermal effects the interior of the MCT225 enclosure is temperature controlled, effectively creating an air conditioned measurement room stable to 20°C ± 1°C.

Flexible efficiency

MCT255 is an invaluable asset for manufacturers seeking to benefit from reduced lead times and inspection cycles. The powerful X-ray source and large capacity manipulator combine with high magnification and detailed feature detection to create a solution suited to a wide variety of applications.

Plastic injection-mold and metal die-cast manufacturers can significantly reduce correction cycles during tool development and production start-up, accelerating time to market for new products. All shrinkage, deformation and dimensional errors are clearly identified in easy to understand inspection reports making it simple to define corrective actions.

Emerging production techniques like additive manufacturing now make it possible to produce small and highly complex components that can’t be inspected using touch probes or optical sensors. Here too, MCT225 makes it possible to measure and analyze these components in a single non-destructive operation.

Further information is available on www.nikonmetrology.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech