Nikon Metrology CMM chosen by RapidFit for its high accuracy

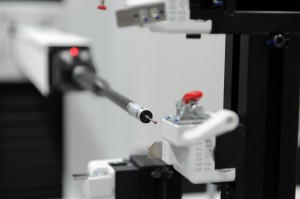

A 3D printed locator is inspected with a TP200 touch probe

Photo by Nikon Metrology Europe NV

Based in Leuven, Belgium, RapidFit has reduced costs and lead-times by making use of additive manufacture (AM), also known as 3D printing, to produce workpiece locators that are added to standard fixture components. The technology enables vehicle production to be streamlined, as innovative fixtures can be constructed with enhanced functionality and better repeatability.

Often, this is achieved by incorporating complex clamping elements with freeform contours that are traditionally produced by conventional machining, which is expensive, time consuming and creates a lot of waste material. Integration of intelligent quick-release mechanisms that do not damage the component being retained is another possibility. Even moving elements like hinges can be printed, as well as features such as clips, pins and holes.

High-wear plastics are used to manufacture the components, sometimes with steel inserts or bushings. Alternatively, parts can be produced from aluminium-filled nylon powder, allowing robust elements to be printed that may be subsequently milled and drilled to an accuracy of ± 0.05 mm.

Users of the fixtures are mainly manufacturers of plastic and composite components for vehicles, from relatively simple, light housings or small sheet metal parts to full body panels, dashboards and bumpers for sports cars. Customers include automotive OEMs such as Audi, Bentley, Lamborghini and Volvo as well as leading players in their supply chains, for example Mecaplast and Valeo.

Shorter lead-time from receipt of order to delivery of the fixture, especially when complex geometries are involved, is a result of not having to program a milling machine to remove typically 90 per cent of material from an aluminium billet, or expending time and expense having a casting made and then machining it. Users are given more time and flexibility to fine-tune their product designs and still meet deadlines. An added advantage is that the locators and contours are typically half the weight of their conventionally machined equivalents and therefore the fixture is lighter and less tiring for operators to use.

A high degree of modularity is provided using standard holding elements, such as the Aluquick range from German firm, Horst Witte, to support the bespoke 3D printed locators. The system allows easy modification by simply replacing them, so fixtures can be reconfigured inexpensively to accommodate design changes.

The patented, customised products supplied by RapidFit are of two types. Gauge fixtures are for inspecting automotive components after manufacture to verify their accuracy, while holding fixtures support components as they are built into a vehicle and measured using CMMs or other metrology equipment. Both types provide comprehensive management of dimensional accuracy, which is vital to the overall quality of the final vehicle.

Accuracy is critical for RapidFit customers

The RapidFit fixture locks a car bumper as it was built into a car.

Photo by Nikon Metrology Europe NV

This in turn means that quality control of the fixtures is crucial. There was a need at the Leuven facility for higher accuracy when checking fixture calibration and to achieve this, an LK H 40.16.16 premium performance, horizontal arm CMM was supplied in early 2013 by Nikon Metrology, together with the manufacturer’s CAMIO8 multi-sensor programming and analysis software. The machine provides almost unrestricted access to the 4m x 1.6 m x 1.6 m measuring envelope and features ceramic guideways and air bearings for stability at high velocity and acceleration.

A Renishaw PH10-MQ motorised indexing head with in-quill head mount and autojoint probe mount together with a TP200 touch trigger probe and various extension bars formed part of the package. The facility is housed in a climate controlled metrology room and is currently operated over a single shift.Stefan Roeding, Marketing Manager at RapidFit, commented, “Customers will only accept measurement results if they trust the equipment that generates them.”The accuracy and repeatability of the LK CMM is very high for its large size. It can measure two of our fixtures at a time, resulting in high productivity in the inspection department.

Installation of the machine has been a big step forward in assuring the quality of our products before delivery and avoiding costly reworking. It is fulfilling all of our customers’ requirements.”

Filip Dehing, RapidFit’s CEO, added “With a worldwide sales and support network, our company is in an ideal position to grow by becoming a preferred partner for large automotive companies on a global scale and by fully exploiting new opportunities.”Underpinning all of this is our commitment to high quality. Our inspection department with the Nikon Metrology CMM breathes accuracy, making it an important marketing tool when customers and prospects visit us.”

Offline programming maximizes use of CMM equipment

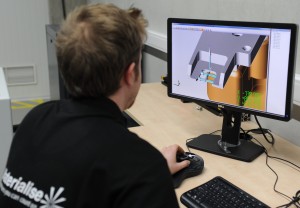

The CAMIO8 inspection programs are offline generated to maximize the use of the CMM.

Photo by Nikon Metrology Europe NV

A typical project at RapidFit starts with the customer sending a CAD drawing of the component to be fixtured and instructions on how it should be clamped for the required application. The fixture is virtually constructed in CATIA by one of RapidFit’s nine design engineers and the 3D locator elements are output as STL files so that they can be produced in one of the company’s powder laser-sintering AM machines.

After 3D printing, the locators are assembled with standard holding elements and a measuring program is created in CAMIO8, in this case offline in RapidFit’s Kiev subsidiary. The offline programming allows maximum use of the CMM in the facility. As each fixture is different, ease of programming based on the original CAD file is a critical advantage.

The program is transferred to the control of the LK H 40.16.16 and the inspection cycle is run to verify that all fixture dimensions are in tolerance. If changes are needed, engineers modify the fixture and run the cycle again, which can be adjusted in teach mode if necessary.

Turn-around for a fixture of average complexity is three to four weeks, although a very complex fixture can take up to six weeks. The customer is invited to the RapidFit measurement room for acceptance and sign-off.Investigations are now being carried out into checking contours more quickly by laser scanning. The heads available from Nikon Metrology are interchangeable with touch probes and both are supported by CAMIO8 software. The technology offers twice the resolution of camera-based optical systems, so is suitable for quality control of RapidFit’s automotive fixtures. It could therefore replace relatively slow touch probing routines in parts of the cycle that involve collection of freeform data.

For more information, please visit http://www.nikonmetrology.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech