SICK introduces new EuroFID3010 hydrocarbon analyzer

Reliable UEG monitoring in processes with EuroFID3010.

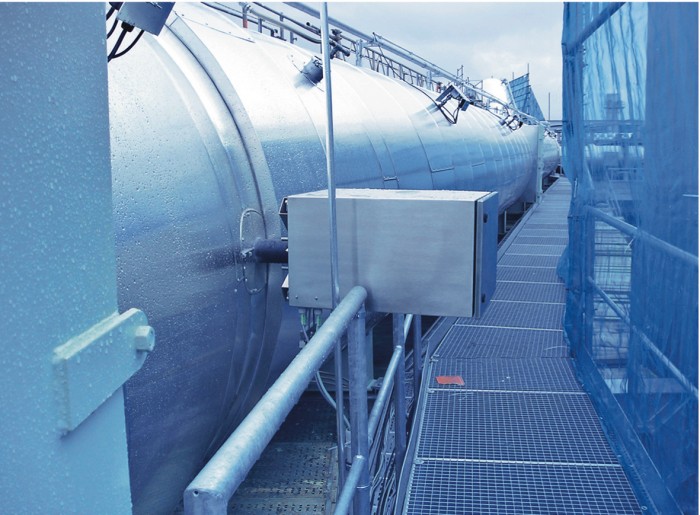

Photo by Sick AG

The EuroFID3010 total hydrocarbon analyzer from SICK is a heated flame ionization detector for determining the volatile organic compounds (VOC) in exhaust air and exhaust gas. It is currently the only FID gas detector on the market to be approved in accordance with the most recent European standard, EN 50271:2010.

The EuroFID3010 is the specialist equipment of choice for continuously monitoring the lower explosive limit (LEL) of hydrocarbon mixtures. It is typically used for monitoring the LEL in drying plants and for leakage monitoring in solvent tanks. The inline analyzer features a modular structure and can be combined with an analyzer unit, control unit, and terminal box to form a system. Other options, such as the Ex 1 industrial housing, allow the system to be adapted to demanding tasks.

Winning technology

The analyzer is connected to the system via a flange. The sampling tube is therefore located directly in the process area. Its tried-and-tested flame ionization detector allows the organic components of the gas sample to be continually transformed into a hydrogen flame. During this chemical and physical process, ionization of the molecules takes place, resulting in the creation of an electrical current. This signal is proportional to the hydrocarbon concentration, and is analyzed electronically.

The EuroFID3010 continually takes measurements without moving parts. An ejector pump is used for taking samples of the gas to be measured instead of a mechanical pump. Wear and mechanical failures are therefore not an issue – leading to lower maintenance costs. All of the device components which carry gas, right up to the analysis chamber, are continuously heated in order to prevent condensation forming inside the analyzer unit. Integrated dilution of the gas to be measured, a short response time, and a design with no moving parts ensure excellent availability and, more importantly, quick and reliable information about the process.

For more information, please visit http://www.sick.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech