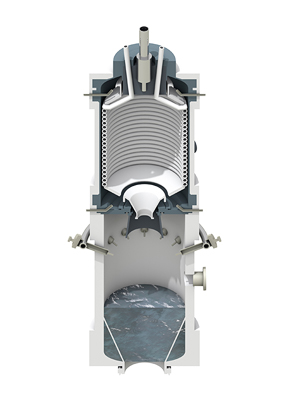

Siemens Energy introduces its new SFG-850 entrained-flow gasifiers

An SFG-850 gasifier can convert around 3,000 metric tons of coal per day into more than 5 million standard cubic meters (Nm3) of high-quality synthesis gas.

Photo by Siemens AG Energy Sector

Siemens Energy is adding a new high-performance model, the SFG-850, to its range of entrained-flow gasifiers. The SFG-850 is designed to enhance the profitability of future gasification plants by reducing specific plant costs, along with the associated production costs of synthesis gas. An SFG-850 gasifier can convert around 3,000 metric tons of coal per day into more than 5 million standard cubic meters (Nm3) of high-quality synthesis gas. The SFG-850 was introduced to the market at the end of March 2014.

With a length of 22 meters, an outer diameter of 4.8 meters and weighing in at 380 metric tons, the SFG-850 gasifier is among the world’s largest and most economic entrained flow gasifiers. The new model can be completely fabricated and tested at the factory. Despite its size and weight, the unit can be transported to its installation location in one piece eliminating the time and expense of field fabrication.

The SFG-850 gasifier is based on the same technical design as Siemens’ current gasifier models, the SFG-200 and SFG-500, which are operating at plants around the world. The proven central burner design, and dry feed system have now been optimized further in the SFG-850. As with its predecessor models the new model stands out because of its high degree of fuel flexibility. All of the proven advantages of Siemens gasifier technology, including its short startup and shutdown times, and the tried-and-tested serviceability of its water-cooled design contribute to its ability to maintain the high levels of availability of today’s Siemens fleet.

The synthesis gas produced using the SFG-850 can be used in large-scale chemicals projects, such as for producing CTL, SNG, methanol or polypropylene, or for the production of clean transportation fuels. In addition, Siemens can offer an optimized configuration of gasifiers and latest-generation Siemens gas turbines with the new SFG-850 gasifier. This will make power generation in IGCC (Integrated Gasification Combined Cycle) plants more economically appealing and, hence, more competitive than current solutions.

For more information, please visit http://www.energy.siemens.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech