Contrinex presents the smallest self-contained inductive sensors on the market

Photo by Contrinex AG

Reduce size, not performance…subminiature inductive sensors

Machines and systems today are ever smaller and more compact. The demands placed on miniaturized components grow constantly, as they must be both compact and powerful. Miniature sensors are the ideal solution when it comes to applications where space is limited. Maximum reliability is achieved in the minimum space. The sensors are small, compact and functional.

With miniature inductive sensors from Contrinex, robot position can be defined precisely, reliably and in the smallest space. The sensors are compact, have low weight and withstand high stress. Miniature inductive sensors are a cost-effective approach to producing competitive machines, because the sensors are adaptable and reliable. They offer the greatest possible benefit in the least space.

Key advantages:

- Smallest self-contained inductive sensors on the market

- Miniature sensors are ideal for mounting where space is limited

- Outstanding temperature stability from -25°C (-13°F) to +70°C (+158°F)

- High switching frequency up to 5000 Hz

- Light weight of the sensor

- Electronics vacuum potted for optimum long-term reliability under high stress

Typical applications

Robotics

Robots have become indispensable helpers in many everyday areas of industry. They need small, compact, reliable components and demand from them excellent dynamic properties. Miniature sensors detect position and location and will operate reliably for years.

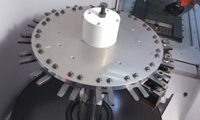

Automation for tool changers

Automation for tool changers

With the help of miniature inductive sensors, automation solutions can be implemented in tool changers. The sensors detect precisely which tool is loaded in the magazine. Effective and robust solutions are therefore possible with just a few sensors.

Micromechanics

Micromechanics

Inductive miniature sensors are used for applications in micromechanics, such as the switching and detection of small actuators and devices. Micromechanical applications require small and efficient sensors which can be built into the smallest spaces.

Linear drive technology

Linear drive technology

Inductive miniature sensors are used in linear drives. This is the simplest approach for the correct detection of end positions in linear drives: a simple, inexpensive solution with a huge impact.

Photo by Contrinex AG

MINIATURE SENSORS FOR EXTREME CONDITIONS

High pressure resistant miniature sensors

The hydraulic industry has been able to develop new application fields as sensors increasingly miniaturize and achieve higher dynamic properties. in addition, the ability to work under even higher prevailing pressures has been achieved for these sensors. controlling piston movement with contrinex high pressure resistant sensors allows fatal piston crashes to be avoided.

Key Advantages

- Miniature sizes m5 and m8

- Resistant to dynamic pressure cycles

- Pressure resistant up to 1000 bar (14,500 psi) peak pressure

- Extended temperature range up to +100°c (+212°f)

Full-metal miniature sensors

Harsh environments do not stop at m8; for this reason contrinex has developed miniature sensors to suit these applications. with a one-piece, full-metal housing not only mechanical robustness is guaranteed, but also optimum chemical resistance.

Key Advantages

- Miniature sizes Ø4 and m5

- Mechanically and chemically extremely robust

- One piece, full-metal, stainless steel housing

- Extended sensing distances and factor 1

Customer benefits

- Long operating distances increase the mechanical resistance

- Robust design ensures extended lifetime

- Extended lifetime reduces downtime

Get more information and visit the online exhibition stand of Contrinex on EXPO21XX.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech