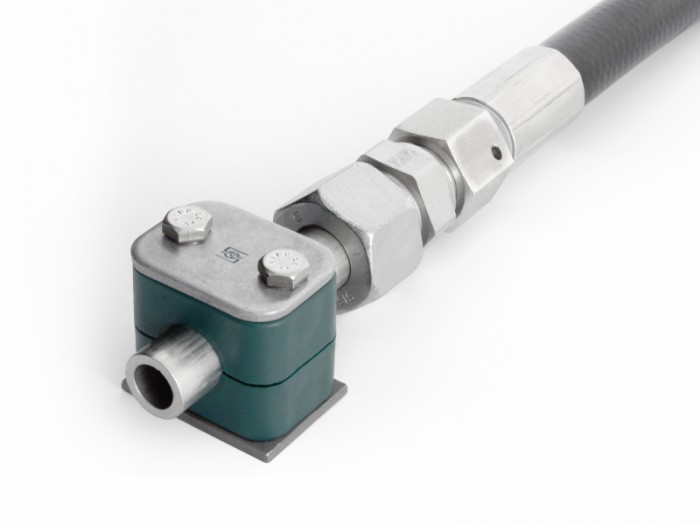

Stauff’s new cutting ring fittings offer space-saving and leak-proof connections

Hydraulic tubing should be fixed directly next to the tube fittings with suitable Stauff clamps to protect it against vibrations.

Photo by Walter Stauffenberg GmbH & Co. KG

Tube connectors with 60° conical bores on the male stud ends can serve as hose adaptors allowing the direct, compact and thus space-saving connection of tubes and hydraulic hoses

Stauff is one of the leading manufacturers and suppliers of pipework components and hydraulic accessories with headquarters in Werdohl, Germany. As part of its new Stauff Connect steel tube connector system, the manufacturer offers cutting ring fittings in line with ISO 8434-1 with BSPP threaded studs and turned sealing surface for use with sealing rings in line with DIN 7603. The undercut of the thread tapering below the hexagon ensures correct alignment and centring of the sealing element which is usually made of copper or aluminium.

Stauff supplies this type of fitting as a straight version for metric tube diameters from 6 to 42 mm and threads from G ¼” to G 1 ¼” from stock. Thanks to the design with 60° conical bore on the threaded stud, these fittings allow simple, space-saving and leak-proof connection of tubes and hydraulic hoses which are fitted with suitable DKR crimp nipples in line with BS 5200/ISO 8434-6. The actual thread connection of the fitting body serves as the counterpart to the BSPP nut thread of the hose fitting.

As no soft seal is used, the components can even be used under extreme temperature conditions or with aggressive media. The zinc/nickel surface used for all Stauff components as a standard guarantees over 1,200 hours resistance against red rust/base metal corrosion in standardised salt spray tests, ensuring the durability of the connection. It can be used with all common hydraulic media. When planning machines and systems it should be considered early on that a suitable Stauff clamp in line with DIN 3015 is ideally placed directly next to the tube fitting to ensure secure fixing of the tube by protecting it against the negative effects of vibrations in the long term. In this case, no individual special designs (e.g. partition plates) and special valves are required for the permanent connection of tubes and hoses. For larger hose diameters up to nominal diameter 51, the company furthermore offers single-part SAE flange connectors with 60° conical bore and external threads up to G 2″.

For more information, please visit http://www.stauff.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech