- Offer Profile

-

PRODUCTION AND PUMPS

An annual production of more than 16 million pump units makes Grundfos one of the world’s leading pump manufacturers. Circulator pumps for heating and air-conditioning as well as other centrifugal pumps for the industry, water supply, sewage and dosing are the main products. Today Grundfos is the world’s largest manufacturer of circulators, covering app. 50% of the world market of these pumps.In addition to pumps Grundfos produces standard and submersible motors as well as state-of-the-art electronics for monitoring and controlling pumps. Additional products are produced in the BioBooster and Lifelink divisions, which are part of the company’s new business activities. Grundfos has also introduced Grundfos Blueflux, which is a new technology-label, which insures that the equipment is among the absolute best in the market.

Efficient pump solutions for all purposes

- Grundfos supplies a broad range of pump systems and solutions for industrial processes, industrial utilities and system builders and OEMs. Grundfos combines competencies within customisation and engineering with system integration and built-in intelligence, ensuring the perfect solution for specific industrial applications.

Pumps

-

Efficient pump solutions for all purposes

With over 16 000 employees and annual production of more than 16 million pump units a year, Grundfos is one of the world's leading pump manufacturers.

No matter for which purpose an efficient and energy saving pump solution is required, Grundfos offers a high-quality solution. Multistage pumps

CR, CRE, CRN, CRNE, CRI, CRIE, CRT, CRTE

-

Multistage pumps for pressure boosting in a wide range of applications

The Grundfos CR vertical, multistage, centrifugal in-line pump family works for water supply, water treatment and almost any industrial solution – including those for high-pressure, hot, dangerous, flammable and aggressive liquids.

The CR is available in millions of different configurations through four modules:- Motors

- Shaft seals

- Pump modules

- Connections.

The Grundfos CR is suitable for:

- Industrial processing systems

- Washing and cleaning systems

- Pumping of acids and alkalis

- Filtration systems

- Water pressure boosting

- Water Treatment

- HVAC

- Irrigation

CM, CME end-suction centrifugal pumps

-

The Grundfos CM and CME pumps are non-self-priming, horizontal, multistage, end-suction centrifugal pumps.

Applications:

The CM or CME pump is a multi purpose pump for both industry and water boosting in general.

It is compact, noiseless, reliable and flexible, and this make it an optimal solution for installation and interaction with other components in small and large systems or as a stand-alone pump.Features and benefits:

- Compact design

- Modular construction/customised solutions

- Worldwide usage

- High reliability

- Service-friendly

- Wide performance range

- Low noise level

- High-performance hydraulics

- Electro-coated cast-iron parts

- Customised solutions

- Grundfos motor

- E-solutions

- High efficiency.

NB, NBE, NBE centrifugal volute pumps

-

A complete range of non-self-priming, single-stage, centrifugal volute pumps.

Applications:

Grundfos offers a virtually limitless range of close coupled (NB) end-suction pumps. Their sturdiness and reliability make them ideal for use in demanding environments such as the following:

- District heating plants

- Heating systems for blocks of flats

- Air-conditioning systems

- Cooling systems

- Wash down systems

- Other industrial systems.

Features and benefits:

- Optimised hydraulics in housing and impeller = unimpeded liquid flow

- O-ring seal between pump housing and cover = no risk of leakage

- Housing, impeller and wear ring in different materials = improved corrosion resistance, no sticking elements

- Pump is CED coated to increase corrosion resistance

- Available with IE1, IE2 and IE3 motors

- Available in a number of shaft seal and material variants

- PN 10,16 and 25 bar

- For temperatures up to 140 °C.

NK, NKE, NKE end-suction pumps

-

Grundfos offers a virtually limitless range of long-coupled (NK) end-suction pumps

Applications:

Grundfos offers a virtually limitless range of long-coupled (NK) end-suction pumps. Their sturdiness and reliability make them ideal for use in demanding environments such as the following:

- District heating plants

- Heating systems for blocks of flats

- Air-conditioning systems

- Cooling systems

- Wash down systems

- Other industrial systems.

Features and benefits

- Optimised hydraulics in housing and impeller = unimpeded liquid flow

- O-ring seal between pump housing and cover = no risk of leakage

- Housing, impeller and wear ring in different materials = improved corrosion resistance, no sticking elements

- Back pull-out design for easy dismantling for service

- Pump is electro-coated to increase corrosion resistance

- Available with IE1, IE2 and IE3 motors

- PN 10/16 and 25 bar

- Temperatures up to 180 °C

- Available in a number of shaft seal and material variants.

TP, TPE for air-conditioning and heating

-

For air-conditioning and heating applications in commercial buildings

Applications:- These vertical in-line volute pumps are used in commercial buildings for air conditioning and heating applications.

- The pumps are all single-stage, in-line centrifugal volute pumps with standard motors and mechanical shaft seals. The pumps are of the close-coupled type, i.e. pump and motor are separate units. Consequently, the pumps are less sensitive to impurities in the pumped liquid than similar pumps of the canned rotor type.

Features and benefits:

- Optimised hydraulics for high efficiency

- Reduced power consumption

- High-efficiency motors

- TP pumps are fitted with high-efficiency motors

- High-efficiency motors provide reduced energy consumption

- 2-pole and 4-pole TP pumps from 0.75 kW to 375 kW have IE3 motors (By March 2012)

- Top-pull-out design

- Easy dismantling for service

- In-line design

- Unlike end-suction pumps, in-line pumps allow the use of straight pipework, which often results in reductions in installation cost and amount of space occupied

- Hydraulically and mechanically balanced impeller (Series 300 and 400)

- The impeller is hydraulically and mechanically balanced to increase the life of motor bearings and shaft seals

- Pump housing and pump head/motor stool are electro-coated

- Improved corrosion resistance

- TPE, TPED – pumps with built-in frequency converter

- Reduced power consumption

- TPE and TPED motors are based on IE3 motors (except 18.5, 4-pole).

Dosing Pumps

SMART Digital, DDA, DDC, DDE, dosing pumps

-

Intelligent dosing pumps with new drive and adjustment mechanisms represent the ideal solution for increasingly complex dosing.

Features and benefits:

- Simplicity – simple handling and perfect overview and control even from the distance

- Modularity – flexible and suitable for any environment or situation

- Flow Intelligence – highest process reliability

Processes:

- Disinfection

- pH regulation

- CIP

- Dosing of chemicals and biocides

- Precipitation and flocculation

- Filtration

- Reverse osmosis

Applications:

- Drinking water treatment

- Waste water treatment

- Pulp and paper industry

- Textile industry

- Cleaning water treatment

- Food & Beverage industry, dairies

- Cooling tower water treatment

- Low-pressure boiler feed water treatment

Digital dosing, DDI

-

Grundfos DDI pumps provide Digital Dosing from 75 ml/h up to 150 l/h with real setting of the flow rate.

Areas of application:

- Paper production

- Food and beverages industry

- Industrial process water and sewage treatment

- Drinking water treatment

Benefits:

- High precision and ease of use

- Flexibility Adaptability

- Able to handle highly viscous media

- High turndown ratio and functionalities allow large range of applications

- Flow Control

- Double PTFE diaphragm

- Diaphragm leak detection

Digital dosing, DME

-

Grundfos DME Digital Dosing pumps combine perfect precision with user-friendliness, covering large dosing quantities in the range from 60 l/h to 940 l/h with few variants.

Applications:- Pulp and paper industry

- Textile industry

- Food and beverage industry

- Industrial process water and waste water treatment

- Drinking water treatment

Features and benefits:

- Digital Dosing

- Ratio 1:800

- High precision – unique technology

- Dosing of high viscosity media

- Robustness and reliability

Booster pumps

BMS

-

The BMS range is a completely new range of booster modules mainly used for reverse osmosis and (ultra-) filtration applications that improve efficiency compared to earlier ranges. It features a directly coupled pump powered by a permanent magnet motor and VFD.

The BMS range comes in 3 different combinations:

- BMS hs: High pressure booster system

- BMST: High pressure booster system with energy recovery via turbine

- BMSX: High pressure booster system with energy recovery via pressure exchanger

Technical data:

- All critical components are super duplex stainless steel suitable for use in seawater and brackish water applications

- The shaft seal is made from carbon/silicon carbide, especially designed for high pressure

- The thrust bearing material is ceramic and carbon

- Pump bearings and seal rings are made of NBR rubber

- Built-in thrust bearing absorbing the axial thrust from the pump

Applications:

- Reverse Osmosis systems

- Ultra filtration system

- Filtration systems

- Pressure boosting systems and water supply

Features & Benefits:

- Energy savings due to high efficiency

- Easy maintenance and alignment due to improved design

- Easy integration in any water treatment system

- Extreme durability and reliability

- Very small footprint

- Designed for high flows and pressure

- All critical components in contact with water are made of super duplex stainless steel

- Speed ramp up and down are included

- VFD pre-set at duty point

Hydro MPC

-

The Grundfos Hydro MPC booster systems are made to the very highest standards. Thanks to the CU 352 controller, they handle even the most difficult boosting jobs with ease and accuracy.

Applications:

- Schools

- Hotels

- Blocks of flats

- Irrigation systems

- Industry

- Municipal supply systems.

Features and benefits:

- Reliable highly efficient

- Highly efficient

- Service-friendly

- Space-saving

- Easy to commission

- Perfectly adapting to the flow

- Low-flow detection

- Application-optimised software

- BUS and Ethernet communication option

- Large, clear display

- Menus in plain text

- Log function.

CM, CME Booster

-

Modern technologies have brought a high degree of comfort to people within their homes by providing a strong water supply. Grundfos offers complete tailored pressure boosting systems for domestic water supply that ensure optimal water pressure for household applications.

Applications:

- in private homes

- in summer houses and weekend cottages

- on farms

- in market gardens and other large gardens.

- Blocks of flats

- Schools

- Small hotels or guest houses

- Small office buildings

Disinfection

Selcoperm for disinfection

-

Safe and simple electrolytic production of hypochlorite solution for disinfection applications

Applications:

The systems are a good alternative to chlorine-gas based systems. Typical disinfection applications for electrolytic chlorination systems are above all:- Drinking water treatment

- Swimming pool water treatment

- Wastewater treatment.

Features and benefits

- Only water, common salt and electricity is needed for the electrolysis

- Low operating costs

- Common salt is non-toxic and easy to store

- Fresh hypochlorite is always on hand

- Disinfectant solution does not dissociate like commercial hypochlorite solutions

- Approved disinfection method complying with drinking water regulations

- Alternative with less safety requirements to chlorine-gas based systems

- Robust and elementary components – low-maintenance and a long service life.

Vaccuperm VGA and VGB regulators

-

Chlorine gas vacuum regulators and dosing regulators for safe and accurate dosing of chlorine gas

Applications:

Ideal fields of application for Vaccuperm include the following applications:- Drinking water treatment in municipal waterworks

- Shock chlorination

- Municipal wastewater treatment

- Industrial wastewater treatment

- Pool water disinfection.

Features and benefits:

- Safe operation due to the vacuum principle and easy handling

- Precise regulation and dosing of gaseous chlorine

- All the parts in contact with the media are made of corrosion-proof materials

- Large variety of models and extensive possibilities of combination

- Easy installation

- Low operating costs

- Approved disinfection method complying with most drinking water regulations.

Oxiperm

-

An ideal means of ensuring the cleanliness of drinking water is to use chlorine dioxide (ClO2) as a disinfectant. Chlorine dioxide is highly effective against all types of germs and has a long residual time in the system, meaning that it disinfects even without extracting water. The big advantage of chlorine dioxide over other disinfectants is its effectiveness against biofilms.

The chlorine dioxide production system, Oxiperm 164/166, is the perfect solution for fighting Legionella and other germs in drinking water.Applications:

Ideal fields of application for Oxiperm 164/166 discrete disinfection of drinking water installations, such as:- Combating Legionella in building installations of hospitals, nursing homes, hotels, sports facilities and schools

- Drinking water treatment in municipal waterworks

- Irrigation water treatment, e.g. in plant nurseries

- Process water treatment in food & beverage industry

- Cooling water treatment.

Features and benefits:

- On-site preparation of chlorine dioxide

- Easy installation

- Low operating costs

- High operational reliability due to integrated control system

- Adaptable for various water disinfection tasks

- Robust design

Submersible pumps

DWK Submersible Pumps

-

DWK and DPK are submersible pumps designed for dewatering and drainage applications. The cast-iron construction and the hydraulic design contribute durability and high efficiency. The differences between the DWK and DPK pump ranges lie in the discharge arrangement and the installation type. The DWK is designed with a top discharge pipe and suction strainer, and is thus more suitable for temporary installation, whereas the DPK has a side discharge and a ring-stand or auto coupling (as accessories), and is suitable for permanent installations.

Applications:

DWK/DPK are excellent pumps for dewatering and draining applications. The combination of compact design with high-pressure capability makes the pumps suitable for use in pits, whether for temporary or fixed installation. The installation design options provide the flexibility needed to cover many needs. Applications include:

- Construction sites

- Excavations

- Tunnels

- Fish ponds

- Drainage pits.

Features and benefits:

- Durability

- High efficiency

- Installation flexibility

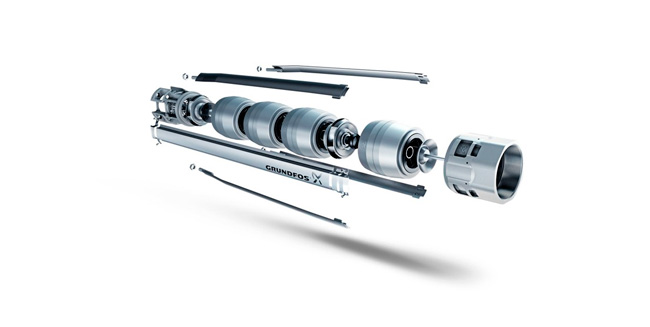

SP Submersible pumps

-

Submersible pumps for irrigation, water supply, pressure boosting and dewatering.

Applications:

- Groundwater supply to waterworks

- Irrigation in horticulture and agriculture

- Groundwater lowering

- Pressure boosting

- Industrial applications.

Features and benefits:

- State-of-the-art hydraulics provide high efficiency and low operating costs

- 100 % stainless steel inside and outside

- Sand resistant

- Resistant to aggressive water

- Motor burnout protection

- Dry-running protection

- Monitoring, protection and communication via the MP 204 protection unit and the R100 remote control.

Unilift AP submersible centrifugal pumps

-

Vertical, single-stage, submersible centrifugal pumps

The Unilift AP and Unilift AP Basic are submersible drainage pumps designed for both temporary/portable installation and permanent free-standing installation. These single-stage pumps are made mostly of stainless steel. All types are available in either single phase or three phase versions and for 50 or 60 Hz power supply.Applications:

- Water and rainwater in horticulture

- Water from rivers and lakes

- Rainwater, drainage water and water from flooding

- Water for filling/emptying containers, ponds, tanks, etc.

- Effluents from showers, washing machines and sinks below sewer level

- Pool water

- Ditch drainage water

- Groundwater (lowering applications)

- Domestic effluents from septic and sludge-treating systems

- Liquids containing fibres from light industry, laundries, etc.

- Effluents from viaducts, underpasses, etc.

- Drainage water from garage sprinkler systems

Features and benefits:

- Unilift AP is for permanent or temporary free-standing installations.

- Most components are made of stainless steel.

- Cable fitted by means of a plug.

- Available in both automatic and manual versions.

- Single-phase versions have an integrated thermal switch.

Unilift CC single-stage submersible drainage pump

-

The Unilift CC is a single-stage submersible drainage pump, designed for the pumping of drain water and grey wastewater. The Unilift CC has now the dual outlet option which makes installation more flexible and replacement even easier than before. Connect vertically or horizontally – as you like.

Applications:

The pumps are designed for pumping rainwater or grey wastewater from:

- Washing machines, bath tubs, showers, sinks, etc.

- Cellars or buildings prone to flooding

- Draining wells

- Collecting wells for surface water with inlets from roof gutters, tunnels, etc.

- Swimming pools, ponds or fountains

- The Unilift CC pumps are suitable for the following liquids:

Clean, non-aggressive water

Slightly dirty (grey) wastewater

EN 1.4401 version available for slightly aggressive liquids

Features and benefits:

- Horizontal or vertical outlet for easy installation or replacement

- Suitable for low suction levels down to 3mm

- Light-weight

- EN 1.4401 version available for slightly aggressive liquids

- Stainless steel strainer

- Composite materials

Unilift KP submersible drainage pumps

-

Unilift KP pumps are submersible drainage pumps for pumping drain water or grey wastewater. The KP is suitable for both temporary and permanent free-standing installation or installation in collecting tanks.

Applications:

The Unilift KP pumps are designed for the pumping of:

- Water from rivers and lakes

- Rainwater, drainage water and water from flooding

- Water for filling/emptying containers, ponds, tanks, etc.

- Effluents from showers, washing machines and sinks below sewer level

- Pool water

- Ditch drainage water

- Lowering groundwater

- Domestic effluents from septic and sludge-treating systems

- Effluents from viaducts, underpasses, etc.

Wastewater

SRG

-

Grundfos SRG recirculation pumps provide enegery-efficient pumping.

Applications

The recirculation pumps are designed for distribution of liquids in:- Sludge treatment systems

- Wastewater treatment plants

- Industrial processes

- Agriculture

- Biogas plants.

- The recirculation pumps are fitted with stainless steel impellers with diameters between 300 and 800 mm and rotation speeds up to 1000 min-1.

Features and benefits:

- Highly energy-efficient products, driven by IE3 motor components

- Wide range of flexible installation accessories

- Simple maintenance and service

- Electronic leak sensor and moisture switch

- Shaft seal protected against abrasive materials

- Self-cleaning stainless steel

- Hydraulically efficient and robust propellers

- cast-iron motor housing.

SOLOLIFT2 compact lifting stations

-

A unique range of compact lifting stations

Applications:- SOLOLIFT2 collect wastewater of domestic sanitary appliances and pump the wastewater through a thin pressure pipe to the next pipe with downward slope, – up to a height of 6 meters or 100 meters in distance.

- The product line includes five models of compact lifting stations,

covering all the needs of a family household.

Features and benefits:

- Highest reliability, thanks to a high performance cutter and motor

- Able to handle accidently flushed female articles

- Very compact design

- Fast, easy and clean maintenance – no need to remove the unit from installation

- All relevant service parts dry and clean accessible – not submerged in tank

- Pressure proof, welded tank system, leakage free in case of backwater

- Odour-free by venting valve with charcoal filter

- Hot water resistant up to 90 °C for 30 min.

- Low start levels enable modern, flat shower trays

- Height adjustable inlet connectors ease installation and replacement

- Ready to install solution

- all units are LGA, VDE, EMC and EAC approved

SMD, SMG, SFG mixers and flowmakers

-

Grundfos mixers and flowmakers provide engergy efficient mixing. The drive unit is equipped with IE3 motor components, and combined with the large variety of gear steps, this enables Grundfos to provide a suitable mixer or flowmaker within the overall range.

Applications:

The mixers and flowmakers are designed for mixing, i.e. homogenization and suspension, of liquids in:

- municipal wastewater treatment systems

- sludge treatment systems

- sewage pumping stations

- wastewater treatment plants

- industrial processes

- agriculture

- biogas plants.

- The mixers and flowmakers are fitted with stainless steel or polyurethane propellers with diameters between 160 and 2660 mm and rotation speeds between 25 min-1 and 1500 min-1 (50 Hz).

Features and benefits:

- Highly energy-efficient products, driven by IE3 motor components

- wide range of flexible installation accessories

- simple maintenance and service

- electronic leak sensor and moisture switch

- shaft seal protected against abrasive materials

- self-cleaning stainless steel or polyurethane propellers

- hydraulically efficient and robust propellers

- stainless steel or cast-iron motor housing.

SE

-

Drainage, effluent and sewage pumps

Applications:- The SE range of pumps handles wastewater, process water and unscreened raw sewage in heavy-duty municipal, utility and industrial applications and is ideal for large flows.

Features and benefits:

- High motor efficiency for substantial energy and cost savings.

- Intelligent adaptive controls ensure reliable operation with low energy consumption.

- Integrated analogue sensors offer complete monitoring of pump condition.

- Lifting handle designed for optimum point-of-balance and correct lifting.

- Smooth, easy-to-clean surface is extremely robust and impact-resistant.

- One cable to the pump, simplifying pump installation, commissioning and maintenance.

- Moisture-proof connector plug ensures that liquid cannot penetrate into the motor.

- Patented SmartSeal auto-coupling gasket provides a completely leak-proof connection.

- Easy-to-open clamp for the quick and easy disassembly of pump from motor unit.

- Double mechanical shaft seal ensures longer operation time with less downtime.

- Short rotor shaft reduces vibrations to protect shaft seals and bearings.

- Liquidless motor cooling for continuous operation, even in dry installations.

- Choice of SuperVortex or S-tube impeller.

- Replaceable wear ring to return the pump to full efficiency.

- The SE range of pumps handles wastewater, process water and unscreened raw sewage in heavy-duty municipal, utility and industrial applications and is ideal for large flows.

Power & Control

CIM/CIU

-

The CIM and CIU enable the connection of Grundfos electronic products to standard fieldbus networks.

Applications:- CIM/CIU 100/110 LON is mainly used for HVAC applications

- CIM/CIU 150 Profibus DP is mainly used for factory and process automation

- CIM/CIU 200 Modbus RTU is used for versatile automation e.g. HVAC and wastewater applications

- CIM/CIU 250/251 GSM is mainly used for water supply and wastewater applications

- CIM/CIU 270/271 GRM is used together with Grundfos Remote Management

- CIM/CIU 300 BACnet is used for building automation

- CIM/CIU 500 Ethernet can be used for Modbus TCP, PROFINET IO, BACnet IP and GRM IP

Features and benefits:

- Based on standard functional profiles

- Prepared for future communications standards

- Supports a wide range of Grundfos products

- Easy to install and commission

- Flexible power supply

Control MPC

-

Grundfos Control MPC is a control cabinet with a CU 352 controller that permits monitoring and control of up to six identical pumps connected in parallel. It comes with everything needed to get started, and contains software optimised for your particular application. Control MPC will minimise energy consumption and cut energy costs straight out of the box. With application-optimised software, you have complete control over the pumps in your system. Features such as automatic cascade control ensure the highest possible system energy efficiency.

Applications:- Pressure boosting

- Heating

- Cooling

- Air-conditioning.

Features:

- Efficient cascade control

- Lager color screen

- Setpoint influence

- Individual pump control

- Alternative setpoints

- Clock program

- Proportional pressure regulation

- Alternation

- Standby pumps

- Pump test run

- Pilot pumps

- Stop at low flow function

- Soft pressure build-up function (minimises risk of water hammer)

- Emergency run

- Flow estimation

- Dry running protection

- Ethernet

- Log function.

CUE Frequency converter for pumps

-

The CUE series are frequency converters for the speed control of a wide range of Grundfos pumps.

Applications:

The CUE is a frequency converter for Grundfos pumps, providing a series of predefined functions which make the converters easy to use in almost all application areas. A series of predefined control modes, such as constant pressure, proportional pressure, constant level or constant flow, makes it very easy to set up a system in only a few steps. A special start-up guide will lead you through the set-up of the CUE.Features and benefits:

- Speed control of Grundfos pumps

- Simple set-up

- Predefined control modes

- Predefined range of sensors

- Predefined pump family data

- Shares interface with control equipment

- Additional functions available

- Automatic setting of direction of rotation

- 16 steps to get a system up and running.

MP204 electronic motor protector

-

The MP 204 is an electronic motor protector, designed for the protection of an asynchronous motor or a pump.

The motor protector consists of:- A cabinet incorporating instrument transformers and electronics

- A control panel with operating buttons and display for reading data.

The MP 204 operates with two sets of limits:

- A set of warning limits

- A set of trip limits.

The MP 204 motor protection unit was developed to bring you pump protection that is as simple to use as it is efficient. Pump specialists crammed it full of all the protection features you need – but kept it easy to install, set up, and use.

The MP 204 monitors the following parameters:

- Insulation resistance before start-up

- Temperature (Tempcon, Pt sensor and PTC/thermal switch)

- Overload/underload

- Overvoltage/undervoltage

- Phase sequence

- Phase missing

- Power factor

- Power consumption

- Harmonic distortion

- Run and start capacitor (single-phase)

- Operating hours and number of starts.

Measurement & Control

DIP Dosing Instrumentation Pool

-

The DIP (Dosing Instrumentation Pool) was originally designed for swimming pool applications but is used today in water treatment applications as well. It measures up to three parameters and can control two parameters at the same time thus providing perfect control of the water quality. The DIP speaks five languages making it easy for users without previous knowledge to carry out all operations.

Applications:

- Commercial buildings

- Pool water control

- Water treatment – Commercial buildings

- Drinking water treatment

- pH control for dosing acids and alkalis, monitoring and control of residual chlorine

- Swimming pool and bathing water treatment

- pH control for dosing acids and alkalis, monitoring and control of residual chlorine

- Industrial process water treatment

- pH control for dosing acids and alkalis, monitoring and control of chlorine and-, chlorine dioxide

or ozone

Conex DIA-G Dosing Instrumentation Advanced-Gas

-

Features:

- Monitoring of two separate gas storage rooms or two different gases at the same time

- Simultaneous display of both measured values

- Optimum safety due to permanent sensor monitoring, alarm relay and optional backup operation by connection of an external buffer battery

- Very short response time in the event of a sudden change in the gas concentration

- Long and maintenance-free sensor service life

- Sensor recognition and auto-calibration as well as monitoring of sensor life

- Separate sensor interface for one potentiostatic sensor. When using the separate sensor interface, the Conex® DIA-G can be installed in a control room at a distance of up to 500 m from the sensor interface

- Optional audible and visual alarm device

- Display languages: German, English, French, Spanish, Polish and Russian

- Monitoring parameters

Chlorine

Chlorine dioxide

Ozone

Ammonia

Hydrochloric acid

Applications:

- Drinking water treatment monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

- Swimming pool and bathing water treatment monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

- Industrial process water treatment monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

- Food and beverages industry monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

Conex DIS-C Dosing Instrumentation Standard

-

Features:

- Conductivity measuring with conductive measuring cells in fresh water

- Conductivity measuring with inductive measuring cells for harsh environments. DIS-C models with inductive measuring cells are ideal for aggressive media because the measuring coils do not come into contact with the sample water.

- Display languages: German, English and French.

Applications:

- Drinking water treatment

- monitoring of conductivity in water-works

- Industrial process water treatment

- conductivity as indicator to protect against corrosion in the installation

- monitoring of conductivity in industrial process applications for production

- monitor desalination in cooling systems to protect the environment when draining

can be used within harsh environments in metal plating processes or galvanic - Food and beverages industry

- monitoring of conductivity in bottle washing machines in breweries

- monitoring of conductivity during the cleaning of process tanks in fruit juice production or brewery CIP (cleaning in place)

Conex DIS-G Dosing Instrumentation Standard-Gas

-

Features:

- Monitoring of two gases at the same time

- Simultaneous display of both measured values

- Optimum safety thanks to the automatic sensor test function

- Very short response time in the event of a sudden change in the gas concentration

- Long and maintenance-free sensor service life

- Optional audible and visual alarm device

- Display languages: English, French and German

- Monitoring parameters:

Chlorine

Chlorine dioxide

Ozone

Applications:

- Drinking water treatment monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

- Swimming pool and bathing water treatment monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

- Industrial process water treatment monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

- Food and beverages industry monitoring of ambient air for admissible gas concentrations in gas storage rooms or near chlorine dioxide generators

Circulator Pumps

MAGNA

-

Small, medium and large circulator pumps fitted with communication equipment and electronically speed-controlled motor

Applications

- GRUNDFOS MAGNA/UPE pumps are designed for circulating liquids in heating systems in blocks of flats, schools, hospitals, hotels, industry, etc.

- These pumps, which have stainless steel pump housings, can also be used in domestic hot-water systems. GRUNDFOS MAGNA pumps are suitable for the following:

- Systems with constant or varying flows where it is desirable to optimise the pump duty point

- Systems with varying flow-pipe temperatures

- Systems where night setback is required.

Features and benefits:

- Highly efficient,with communication facilities

- AUTOADAPT control mode as default setting, suitable for most applications

- Integrated differential pressure control (proportional and constant pressure control)

- Low noise

- High starting torque

- Automatic night setback

- Motor based on permanent-magnet/compact-stator technology

- Integrated frequency converter

- Self-venting pump housing

- Stainless steel pump housing

- Twin-head versions

- Wireless remote control, R100

- Communication via GENIbus or LON.

MAGNA3

-

The MAGNA3/UPE pumps make up a broad range of small, medium and large circulator

pumps – all fitted with communication equipment and state-of-the-art motors

Applications

The Grundfos MAGNA3 circulator pumps are designed for circulating liquids in the following systems:- Heating systems

- Air-conditioning and cooling systems

- Domestic hot-water systems.

- The pump range can also be used in the following systems:

- Ground source heat pump systems

- Solar-heating systems.

Features:

- AUTOADAPT

- FLOWADAPT and FLOWLIMIT

- Proportional-pressure control

- Constant-pressure control

- Constant-temperature control

- Constant-curve duty

- Max. or min. curve duty

- Automatic Night Setback

- No external motor protection required

- Insulating shells supplied with single-head pumps for heating systems

- Large temperature range where the liquid temperature and the ambient temperature are independent of each

ALPHA1

-

GRUNDFOS ALPHA1 is a complete range of circulator pumps with integrated differential-pressure control enabling adjustment of pump performance to the actual system requirement.

The pumps are energy-optimised and comply with the requirements of the EuP directive EuP 2015.

Installing an ALPHA1 pump will reduce power consumption considerably, lower noise from thermostatic valves and similar fittings and improve the control of the system.

Advantages:

- High-efficient motors EuP 2015 ready.

- Suitable for installation in existing systems.

- Low-noise operation.

- Built-in electrical and thermal protection of the pump.

- Simple setting and operation in a very compact design.

- Plug and play with patented cable plug for safe and easy connection.

ALPHA2

-

ALPHA2 is the best pump to withstand the tough conditions in a heating system, and with four newly added features, it just got even tougher:

Robust start-up:

Shakes free any impurities before the pump starts at the beginning of the heating season.Summer mode:

Adjustment of the pump’s performance in the summer to the warmer temperature outside – giving customers extra energy efficiencyMagnetite resistance:

Ensures that no small pieces of metal get stuck in the pump’s vital parts when they are magnetisedDry-running protection:

Makes sure the pump never runs without liquid in the systemAdd to that unrivalled energy efficiency, easy installation and the fact that ALPHA2 covers both your heating demands and up to 90 % of your air-conditioning and cooling demands.

The GRUNDFOS ALPHA2 is suitable for:

- Systems with constant or varying flow

- One pipe systems

- Two pipe systems

- Underfloor-heating

- Domestic hot-water recirculation

- Systems where night setback is required.

Features and benefits

- Better performance with market leading efficiency (EEI≤0.15) in a more compact design

- New flow meter for trouble-shooting and balancing

- AUTOADAPT selects best performance curve for efficiency and comfort

- Innovative plug simplifies pump connection

- Insulation shells included.

ALPHA2 L

-

ALPHA2 is a complete range of standalone* circulators. More than 3 million ALPHA2s have rolled off our production lines since its introduction in 2007.

The ALPHA2 L variant features integrated differential-pressure control, enabling adjustment of pump performance to the actual system requirements. The installation of a GRUNDFOS ALPHA2 L pump will reduce the power consumption considerably, reduce noise from thermostatic valves and similar fittings, and improve the control of the system.Characteristic Features

- High Efficiency circulator for standalone applications based on a permanent-magnet motor/compact-rotor technology

- According Ecodesign requirement January, 2013; EEI ≤ 0.23

- Internally self-controlled circulator

- Integrated differential-pressure control enabling adjustment of pump performance to the actual system requirements.

- 5 Configuration Options:

highest proportional pressure curve (default),

lowest proportional pressure curve

lowest constant pressure curve

highest constant pressure curve

constant curve speed I, II and III - ALPHA2 L can run on as little as 5 W

ALPHA3 - easy hydronic balancing

-

The ALPHA3 is our newest circulator for domestic buildings. It is of the renowned Grundfos quality and guarantees easy installation, world-class energy efficiency and reliable operation in the toughest conditions. For the ultimate benefits of the ALPHA3, however, installers need two other components – the ALPHA Reader and the Grundfos GO Balance app. Together, the state-of-the-art ALPHA3 system helps installers complete a hydronic balancing incredibly fast and accurately.

Features and benefits

- Hydronic Balancing

- No blockage

- Best in class efficiency

Benefits of hydronic Balancing:

- Savings on heating bill between 7-20 %*

- Lower return temperature in the system

- Lower noise in the heating system

COMFORT

-

A brand new, low noise permanent magnet motor allows the energy

consumption of the COMFORT PM range to be reduced to as little as 5-8.5 W.

Combined with the intelligent AUTOADAPT function this sets new standards for energy-efficient hot water recirculation in private homes.Thanks to the new high efficiency permanent magnet motor the COMFORT range now features two new variants for hot water recirculation. With an energy usage of only 5-8.5 W both the COMFORT pump with AUTOADAPT and the fixed speed COMFORT B pump can significantly reduce the power consumption. In fact, the electricity costs of operating in AUTOADAPT mode requires a mere 1-2 €* per year. Compared to conventional pumps that run continuously this equals a cost reduction of up to 96 %. Moreover, heat energy savings amount to as much as 48 %.

The AUTOADAPT principle The principle of the AUTOADAPT function is really very simple.

In the course of only a couple of weeks the COMFORT pump learns the hot water consumption pattern of the household and adapts to it. The stored data ensures that the pump runs only when required – which significantly cuts back on both water and power waste. Should the consumption pattern change, e.g. during holidays, the COMFORT pump with recognises the standstill after 24 hours and automatically adapts to holiday mode. On the return of the occupants, the intelligent pump will automatically resume the same consumption pattern as before the holiday. Consequently, the access to instantly hot water is never jeopardised.Minimise water waste

All COMFORT pumps – with or without the AUTOADAPT function – combined with a return pipe deliver instantly hot water all over the house. This eliminates the expensive – and annoying – wait for the water to get warm and reduces the annual consumption of domestic water. The results are lower costs while still ensuring the comfort of instantly hot water.Easy installation

The COMFORT BA pump with autoadapt and the continuously

running COMFORT B pump are equally compact and designed to greatly facilitate installation – even in confined spaces. Both featuring the renowned ALPHA plug all that is really required is to connect the plug and start pumping.

UPM3 AUTO OEM

-

UPM3 AUTO is for all applications in which an internally controlled pump is needed. It is designed to be used in appliances or cabinets with increased ambient temperatures and limited space options; either in standalone applications or in kit systems without PWM controller.

- Standalone OEM high efficiency circulator

- For standalone applications

- Optimal for floorheating with a high valve authority

- Flexibility of settings benefits the OEM production and the installation in the field

Internally controlled circulators

- 3 control modes

- 10 Curves

- PLUS AUTOADAPT proportional and constant pressure

- Substitutes ALPHA2 pumps

Characteristic Features- Glandless High Efficiency circulator for integration in HVAC systems; EEI ≤ 0.20 EN16297/3

- Smallest design ever for a circulator; smaller than the well-known UPS circulator

- Internally controlled circulator

- Available with many standard and customized housings

- Active or passive inrush current limitation

- Ambient temperatures of up to 70° Celsius.

UPM3 Hybrid OEM

-

By combining external controlling through signal entry with internal self-controlling, the UPM3 HYBRID covers all your circulator needs in one product, providing you with access to a full range of settings. For all kind of applications with flexible settings in OEM production or in the installation field.

Characteristic Features

- Glandless High Efficiency circulator for integration in HVAC systems; EEI ≤ 0.20 EN16297/3

- Smallest design ever for a circulator; smaller than the well-known UPS circulator

- Externally and internally controlled circulator

- Substitutes UPM2 and ALPHA2 pumps

- Available with many standard and customized housings

- Active or passive inrush current limitation

- Ambient temperatures of up to 70° Celsius.

Special Pumps

Fire systems

-

Horizontal single-stage fire pumps – NKF and NBF

Applications:

The Grundfos fire pump units are typically used in fire-fighting applications for supplying water to fire-hose reels, fire hydrants or sprinkler systems.

Features and benefits:- Pumps are made according to EN12845 and PrEN12259-12

- Electric or diesel powered

- Designed for superior functionality and performance reliability

- Simple installation and easy maintenance

- Compact design

- Customised and reliable solutions

- Widest range from one supplier.

SQFlex

-

The SQFlex family is an environmentally-friendly water supply solution. SQFlex pumps are fitted with a permanent magnet motor which enables the efficient use of energy from nature. The pump system offers the perfect water supply solution in remote areas where water is scarce and the power supply is non-existent or unreliable.

The SQFlex solar panels and wind turbines adapt to the characteristic weather profile of any given area. A battery backup system can store the extra energy generated and take over when the energy from nature is not available.

SQFlex is more than just a pump – it's a complete intelligent system. Thanks to its built-in electronics, the pump is compatible with both DC and AC power supply without requiring an external inverter.

The complete range consists of ten different pump sizes: Four helical rotor pumps for applications where a high head is required, and six centrifugal pumps for applications where a greater flow rate is necessary.

Applications

The SQFlex systems are suitable for applications in remote locations:

- Villages, schools, hospitals, small houses

- Farms and irrigation of greenhouses

- Game parks and game farms

- Conservation areas.

Features and benefits

- Renewable energy supply: solar panels or wind turbines

- Built-in electronics, easy installation

- Reliable water supply

- Low operating costs

- Dry-running protection.

Applications

- Choose an application to see how Grundfos can help you design and optimise your pump system..