FARO EUROPE

Videos

Loading the player ...

- Offer Profile

- sssss

Product Portfolio

FACTORY METROLOGY

FAROARM®

-

The Global Standard for Arm Technology

For more than 35 years, FARO® has designed, developed and delivered the leading and most trusted arm technology in the market and is recognized as the world’s most innovative portable 3D measurement solution provider for factory metrology.

The FaroArm is the preeminent portable coordinate measuring machine (PCMM) that allows manufacturers easy verification of product quality by performing 3D inspections, tool certifications, CAD comparison, dimensional analysis, reverse engineering, and more.

The FaroArm has become the global standard for arm technology and has been specifically designed to meet the diverse and ever-increasing requirements of both large and small-to-medium manufacturing customers. The FaroArm is built from nearly three decades of manufacturing innovation and experience to enable highly-precise and reliable 3D measurements of both large and small parts during production and quality assurance processes.

FARO® SCANARM®

-

The ideal contact/non-contact portable measurement system.

FARO QUANTUM SCANARM® HD

Through simple Plug and Play, users can attach the FAROBlu Laser Line Probe HD to the Quantum measuring arm, creating an all-in-one measurement solution.

The hard probe and the Laser Line Probe can digitize interchangeably without having to remove either component. Users can digitize simple features with the Arm’s hard probe and seamlessly scan across diverse surface materials regardless of contrast, reflectivity or part complexity without any special coatings or target placement.

The Quantum ScanArm® HD is ideal for inspection and quality control, offering capabilities such as point cloud comparison with CAD, rapid prototyping, reverse engineering, and 3D modeling of free-form surfaces.

The FAROBlu Laser Line Probe HD leverages an optically-superior blue laser technology, for improved scanning and higher resolution. The FAROBlu also has an advanced sensor and custom optics for faster capture and more accurate data.

With the Quantum ScanArm HD, you now get unparalleled non-contact 3D scanning capabilities for detailed measurement of surface form, making it the perfect combination of a contact and non-contact portable CMM.

FARO® LASER TRACKER

-

A Breakthrough in Productivity and Portability.

VantageS: Short-to-long range measurement applications up to 80 m.

VantageE: Short-to-medium range measurements up to 25 m

The VantageS is intended for short-to-long range measurement applications of up to 80 meters, while the VantageE supports short-to-medium range applications of up to 25 meters. Both compact models offer:

RemoteControls™ workflow (patent-pending) which streamlines Laser Tracker operations, allowing a single user to control functions such as live video feed and tracker movements from a mobile phone or tablet. A single operator is able to easily control the tracker from anywhere in the measurement area.

Industry-leading portability with an integrated master control unit (MCU). These Laser Trackers are easily transported between job sites or locations within the factory in a single carrying case.

Hot swappable batteries that eliminate the need for AC power and cabling.

Industrial grade Wi-Fi® for reliable, wireless communications.

Easy integration with FARO’s patented Super 6DoF (Degrees of Freedom) TrackArm solution to completely eliminate line-of-sight challenges.

FARO® COBALT ARRAY IMAGER

-

FARO® Cobalt Array Imager enables custom configurations to improve productivity.

UNLIMITED MULTI-IMAGER SCANNING CONFIGURATIONS

The FARO Cobalt Array Imager is a metrology-grade non-contact scanner which captures millions of high resolution 3D coordinate measurements in seconds. The Cobalt Array Imager is equipped with dedicated on-board processors – an industry first. The smart sensor allows unique multi-imager array configurations which expand the scan area to deliver rapid, automated and comprehensive inspection; dramatically improving cycle time. The actionable data is then displayed as simple go/no-go result or an easy-to-read dimensional deviation color map.

The Cobalt Array Imager is designed for the factory floor so it can be used anywhere inspection is needed, thereby aligning to lean manufacturing principles of eliminating unnecessary movements and time. Cobalt delivers fast and consistent measurements for dimensional inspection and reverse engineering applications on parts, assemblies, and tooling. Cobalt’s versatility supports a variety of deployment options including tripod, rotary table, robot, industrial inspection cells and multiple imager arrays.

Cobalt, which is available in two resolution models, both offering interchangeable fields of view, combines speed, accuracy, flexibility and portability making it an ideal solution for your demanding metrology needs. At an affordable price point providing unparalleled value, the Cobalt is a simple-to-use solution ideal for maximizing productivity and automating workflows for near-line and in-line inspection applications, anywhere in the factory.

FARO® LASER PROJECTOR

-

FARO TracerM: 3D Laser Projection System for Efficient, Accurate, Laser-Guided Assembly and Production.

ELIMINATE PHYSICAL TEMPLATES WITH VIRTUAL TEMPLATING AND POSITIONING SOLUTION.

The FARO® TracerM Laser Projector accurately projects a laser onto a surface or object, providing a virtual template which operators and assemblers use to quickly and accurately position components with absolute confidence. The laser template is created using a 3D CAD model which enables the system to visually project a laser outline of parts, artifacts, or areas of interest. The result is a virtual and collaborative 3D template to streamline a wide range of assembly and production applications.

FARO® FACTORY ROBO-IMAGER MOBILE

-

Automated Inspection Station for the Shop Floor.

ROBOT-MOUNTED 3D IMAGER ON TURNKEY MOBILE STATION

The FARO® Factory Robo-Imager Mobile combines the latest advancements in optical 3D measurement and robot technology. The solution pairs a metrology-grade 3D sensor with a human-collaborative robot integrated on a mobile cart that can be quickly moved to wherever measurement tasks are required. This turnkey mobile station provides a highly adaptable, safe and automated near-line inspection solution.

The system utilizes the FARO Cobalt Array Imager, a metrology-grade 3D sensor with blue light technology, capable of quickly capturing high-resolution measurement data for dimensional inspection on parts, assemblies and tools.

The Robo-Imager Mobile provides a simple solution for automating the inspection and verification of parts, at any location in the production environment, to significantly reduce cycle times for inspection and eliminate scrap and costly rework. The system’s unmatched mobility enables the inspection processes to be moved out of the quality lab and onto the shop floor, so parts can be automatically checked without delay.

FARO® GAGE

-

3D measurement and gauging tool; the ideal portable CMM for any production environment.

FAST, EASY AND ACCURATE PORTABLE CMM

The FARO® Gage measuring arm is an accurate 3D gauge for smaller parts and is an industry leader in portable CMMs. Ending the reliance on expensive and hard-to-use fixed CMMs, the FARO Gage offers high accuracy levels, improves measurement consistency, reduces inspection time, and generates automatic reports. Made specifically for shop floor personnel, the FARO Gage sets up in seconds and allows anyone to measure parts and assemblies easily, quickly, and accurately.

Save time and money by replacing cluttered inspection areas with the one tool that can do it all – the FARO Gage. Built with temperature and overload sensors that allow the FARO Gage to detect and react to change, and with internal counterbalancing that limits user fatigue, the FARO Gage maximizes accuracy, allowing your team to maintain their focus and come away with quality results.

1.2m (4 ft.) spherical working volume

Accuracy of 0.018mm (0.0007 in.)

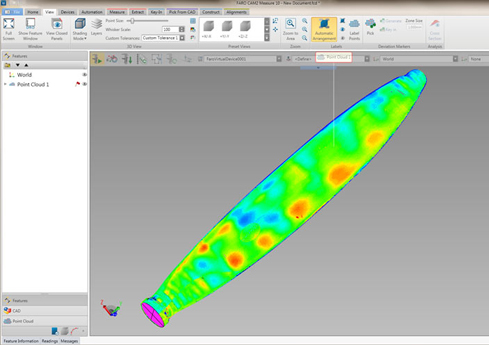

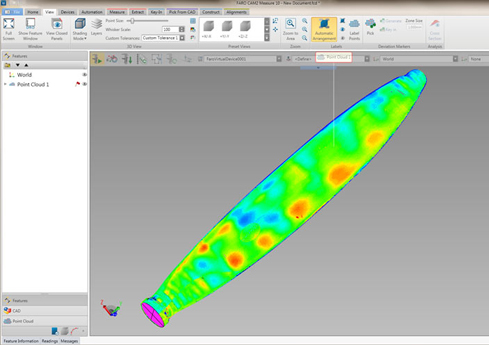

CAM2 MEASURE 10

-

Your Complete 3D Measurement Software.

YOUR COMPLETE 3D MEASUREMENT SOFTWARE

FARO® CAM2 Measure 10 is an all-in-one metrology software for users that are looking for a single, complete solution for all tactile measurement and non-contact 3D scanning applications. The software is ideal for CAD and non-CAD inspection and Geometric Dimensioning and Tolerancing (GD&T).

CAM2 Measure 10 features an intuitive user interface with image-guided measurement, automatic nominal association to nominal features and QuickTools. The software include a reliable CAD import tool which increases the ability to load a large amount of CAD data.

CAM2 Measure 10 leads the market with the ability to connect multiple 3D measurements devices within the same coordinate system, and simultaneously scan into a single seat of software on one computer. This capability allows users to seamlessly scan large objects with rapid speed and precise accuracy and complete 3D scanning jobs faster than ever before.

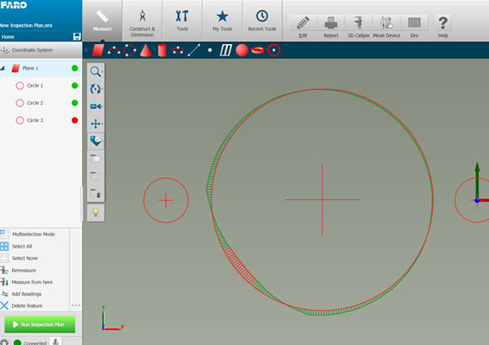

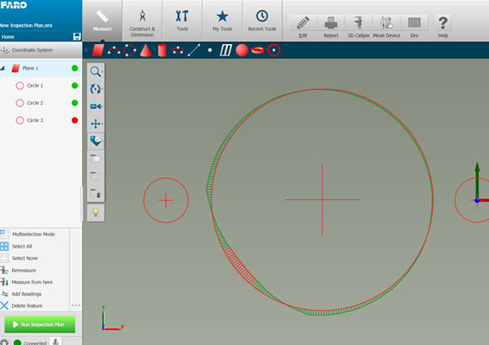

CAM2 SMARTINSPECT

-

The first portable metrology software for Laser Tracker, Arm and Gage.

Engineered for simplicity, FARO’s CAM2 SmartInspect is the perfect software for any FARO® Laser Tracker, Arm and Gage users who are looking for non-CAD based inspection.

CAM2 SmartInspect 1.2 has been optimized to run on all Microsoft Windows™ based Touch PCs or Touchpads, providing users a new way to interact with inspection data and measurement devices. The addition of touch capability makes the software ideal for fully mobile measurement applications and establishes it as the first portable metrology software for FARO Laser Trackers and FaroArms on the market.

The software interface is designed to be simple and intuitive, so that users without any 3D metrology background can be easily trained.

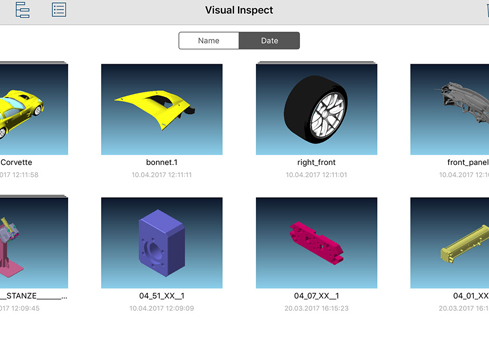

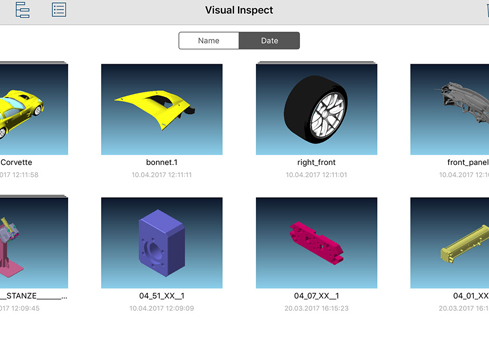

VISUAL INSPECT

-

FARO inspection solutions for streamlining manufacturing processes

FARO Visual Inspect is a powerful mobile solution to control production processes. It allows for intuitive viewing as well as the use of complex 3D data of parts and assemblies and additional information such as process and workflow details on an iPad. Visual Inspect AR expands the functionality of Visual Inspect and provides innovative Augmented Reality to the base package.

FARO® LASER PROJECTOR

-

ARO TracerM: 3D Laser Projection System for Efficient, Accurate, Laser-Guided Assembly and Production.

FARO TRACER™ SOFTWARE – RAYTRACER™

The FARO RayTracer™ Software Suite – containing the RayTracer™ Operator and RayTracer™ Administrator programs operate the TracerM projector. Customers may also choose to use additional software packages that can directly create projection files for the TracerM.

RAYTRACER ADMINISTRATOR

RayTracer™ Administrator organizes and streamlines processes for factory operators. It is intended for use by manufacturing process engineers who prepare laser projection jobs by selecting, organizing, and storing necessary data into one or more RayTracer™ databases. RayTracer™ Administrator is used to set up a RayTracer™ database, manipulate its components, configure jobs and control parameters, edit projection data and reference tool data, create user names and passwords, and more. Its easy-to-use interface allows multiple document handling, copying and pasting, layered tree structure viewing, and other options.

RAYTRACER OPERATOR

RayTracer™ Operator is an intuitive and user-friendly program that enables the projection of 3D templates. It is designed for use in manufacturing environments. Specified user access levels as well as predetermined sequences of operating steps help impose strict production rules on the work process. Projection data and control parameters are stored in a RayTracer™ Database. Personnel running RayTracer™ Operator can retrieve and execute pre-configured jobs from a RayTracer™ database, but cannot change the content.

FARO® IMAGING LASER RADAR

-

VectorRI: A New Class of LIDAR with High Speed Imaging (HSI) Technology.

An ultra-high speed, large-volume, non-contact 3D measurement solution with high-resolution 3D imaging and projection guidance for manual and automated manufacturing processes.

WORLD’S ONLY LIDAR WITH HIGH SPEED IMAGING (HSI) TECHNOLOGY

The FARO VectorRI Imaging Laser Radar introduces a new class of LIDAR with High Speed Imaging (HSI) technology. HSI technology combines ultra-high speed 3D scanning and ranging with high-resolution 3D imaging and projection. The solution is a groundbreaking advancement in large-volume, non-contact metrology and guidance – and promises to provide industrial manufacturers with significant inspection cycle time reduction and exceptional throughput.

The VectorRI delivers a continuous stream of high-resolution surface data with scanning speed that is thousands of times faster than any currently-available technology. Not only does the solution provide unmatched speed, the VectorRI has proprietary 3D imaging capabilities to provide qualitative and quantitative inspection data. Extreme resolution and very dense point spacing allow the system to scan massive areas of up to 15.2 x 15.2 meters (50 x 50 feet) without sacrificing fine details that would be missed by any other device.

Engineered to streamline measurement workflows, the VectorRI has built-in functionality that allows users to easily program fully-robotic, automated measurement routines that can run without any operator interaction. Until now, this degree of automation was impossible without the use of large, costly and complex robot integration.

CONSTRUCTION BIM-CIM

FARO® FOCUS

-

Focus Laser Scanner Series – the perfect instruments for 3D reality capture for AEC, Public Safety-Forensics and Product Design Applications

LASER SCANNER FOR FAST AND EXACT INDOOR AND OUTDOOR MEASUREMENTS IN THREE DIMENSIONS: SIMPLY AT YOUR FINGERTIPS

FARO®‘s latest ultra-portable FocusS Laser Scanner series enable to capture fast, straightforward and highly accurate measurements of complex objects and buildings.

The intuitive touch-screen of the FocusS models has been increased in size and clarity to deliver an extraordinary user experience. A built-in 8 mega-pixel, HDR-camera captures detailed imagery easily while providing a natural color overlay to the scan data in extreme lighting conditions. Familiar traits such as light weight, small size and a 4.5-hour battery runtime per charge makes the FocusS Laser Scanner truly mobile for fast, secure and reliable scanning.

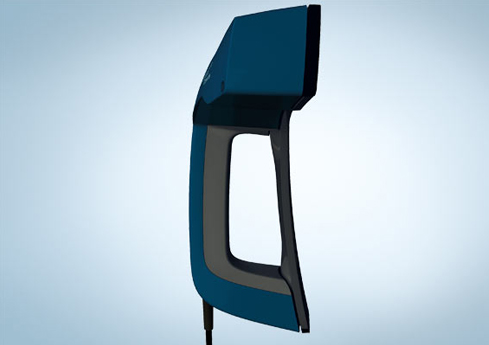

FARO® SCANNER FREESTYLE3D X

-

Innovative, User-Friendly Handheld 3D Laser Scanner

FARO® FREESTYLE3D SCANNER – EFFICIENT HANDHELD 3D LASER SCANNING

The FARO Freestyle3D is a top-quality, high-precision, handheld scanner for professionals. It quickly and reliably documents rooms, structures and objects in 3D and creates high-definition point clouds. With unbeatable precision, it is suitable for all uses in which installations, properties or environments must be quickly measured from various perspectives. The applications of the FARO Freestyle3D include construction, industrial engineering, and forensics.

Freestyle Benefits:- Ability to measure and scan in tight and hard-to-reach areas

- Scan around corners where there is limited visibility

- Memory-scan technology allows users to pause and resume scanning at any time

- Auto leveling

- Flexibility to work with or without artificial targets

- Seamless integration with Focus3D laser scanner data

- Precision handheld scanning

- Easy-to-use scanning software

- Worldwide service and support from local FARO facilities

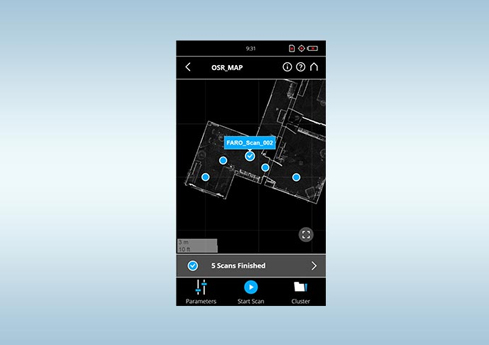

FARO® SCAN LOCALIZER

-

On-Site registration & processing made easy.

COMPLETE MAPPING AND REGISTRATION SOLUTION

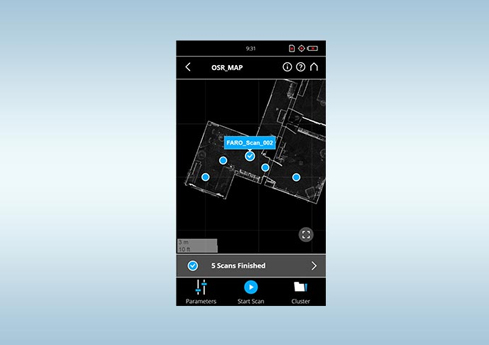

The FARO® Scan Localizer is a state-of-the-art scanning accessory that streamlines the registration process, substantially increasing productivity.

The FARO Scan Localizer combines information from multiple sensors and software algorithms to determine the exact position of the scanner inside buildings. It allows the as-built capturing for BIM(Building Information Modelling) related applications with unmatched speed, confidence and quality.

While moving a FARO Focus3D Laser Scanner through a large site, the FARO Scan Localizer captures the exact position of the laser scanner, thus enabling greater automation of registration.

The FARO Scan Localizer simultaneously maps the scan space in real-time while giving individual scans initial placement information.

With this new workflow, users are able to immediately utilize cloud-to-cloud registration with high confidence, substantially reducing office work.

FARO® SCENE

-

FARO’s 3D Documentation Software for Laser Scanner.

SCENE software is specifically designed for all Focus, Freestyle and third-party laser scanners. Users can process and manage scan data efficiently and easily by using real time, on-site registration, automatic object recognition, scan registration, and positioning.

The new SCENE 7.0 provides users with a new on-site registration functionality which enables 3D scan data to be wirelessly transmitted, processed, aligned and registered directly to an on-site mobile device or PC in real time. Generating an entire overview map of the completed project is part of the new on-site registration workflow.

Once the project is complete, scan data can be published in the highest quality on a web server with the touch of a button. With SCENE WebShare Cloud, laser scans can be easily accessed and viewed with a standard Internet browser. SCENE 7.0 allows users to upload scans, sections, and complete project point clouds directly to WebShare Cloud with all applied filters resulting in exceptional visual 3D quality data.

SCENE is extremely user-friendly, from simple measuring to 3D visualization to 3D meshing and exporting scan project data into various point cloud and CAD formats.

SCENE WEBSHARE CLOUD

-

SCENE WebShare Cloud – a secure cloud-based solution for storing and sharing scanning data with different project partners.

SHARE WITHOUT LIMITS

SCENE WebShare Cloud is cloud-based hosting solution from FARO® for easy and secure sharing of scan data worldwide via the internet.

With SCENE WebShare Cloud, FARO offers a comprehensive service to provide users with simple access to 3D documentation. Neither technical training nor specialist skills in 3D laser scanning are necessary to work with the intuitive user interface. Digital data, such as 3D documentation, often has to be available to many different project partners. Previously, users having their own internet server, could use SCENE WebShare to present their laser scan projects to clients an project partners. Now FARO goes considerably further, offering the SCENE WebShare Cloud solution, a hosting service with various packages at different prices.

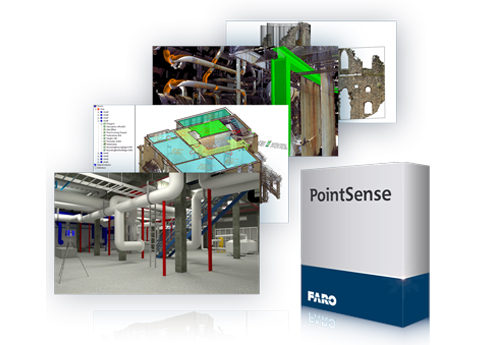

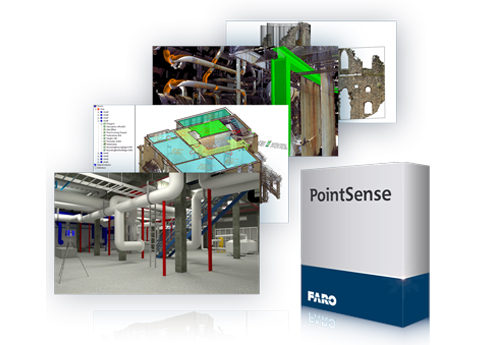

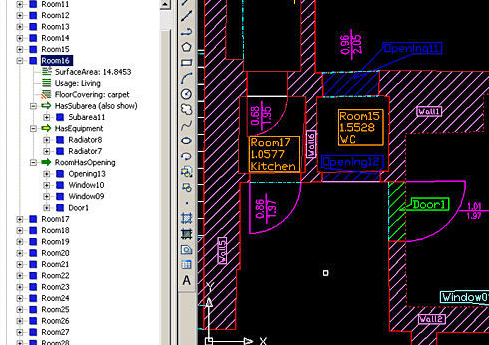

FARO® POINTSENSE

-

The FARO PointSense industry solutions provide several intuitive tools for the management and processing of laser scan data within AutoCAD® and Revit®.

EFFECTIVE AND INDUSTRY SPECIFIC MODELLING, EVALUATION AND ANALYSIS OF 3D LASER SCAN DATA.

FARO PointSense products provide enhanced functionality for processing point cloud data allowing you a reliable and effective evaluation of hardware independent scanning and photogrammetry data within Autodesk’s CAD construction and planning tools such as AutoCAD® or Revit®.

PointSense programs support the data formats from all of the major laser scanner manufacturers and offer specific solutions for industries such as architecture, plant construction and heritage preservation. Because these powerful tools are used for a large number of different applications, FARO bundles all of the PointSense programs in one solution: the PointSense Suite.

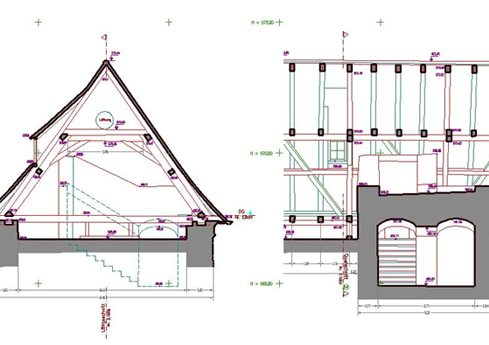

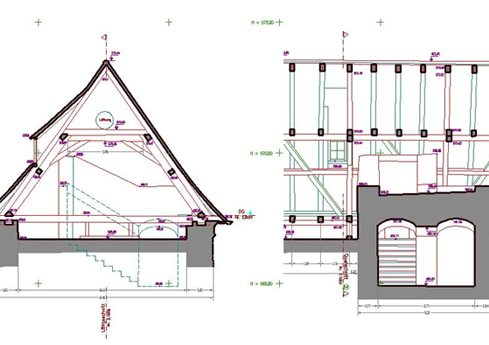

FARO® TACHYCAD

-

FARO TachyCAD industry solutions can connect nearly all of the commonly used total stations to AutoCAD®. The user leaves the site with a completed AutoCAD® drawing.

LEAVE THE EXCAVATION OR CONSTRUCTION SITE WITH A FINISHED PLAN

TachyCAD is an AutoCAD® application that connects a total station or hand-held laser to mobile computer via cable or Bluetooth. TachyCAD supports most of the tachymeters on the market from all of the major manufacturers.

When the measuring device is connected and a measurement is triggered, TachyCAD transfers the data automatically into AutoCAD® and is used for the active AutoCAD® command. You are able to take the measurements directly from your total station or simply control them using your notebook. The transmitted measurements are available for drawing and construction commands from AutoCAD® just as if the user had clicked with the mouse or entered the coordinates manually.

In addition, TachyCAD extends AutoCAD® with many industry-specific functionality and commands that enable the effective drawing of complete AutoCAD® plans on-site.

FARO® PHOTOPLAN

-

The add-on FARO PhoToPlan enhances AutoCAD® and AutoCAD® LT with real photogrammetric functions.

THE FARO PHOTOPLAN SOFTWARE FAMILY

The PhoToPlan family of AutoCAD® based applications allow for the evaluation of photos and plans directly within AutoCAD®. PhoToPlan basic, PhoToPlan, PhoToPlan Pro and PhoToPlan Ultimate are built on top of each other, the range of functions is increasing.

PHOTOPLAN BASIC AND PHOTOPLAN: PHOTOGRAMMETRY INSIDE AUTOCAD®

PhoToPlan is an AutoCAD® or AutoCAD® LT add-on for true-to-scale digital image rectification of plane objects.

The result is a versatile image plan, which allows for easy measurement of areas and distances. The image plan connects photographic documentation of existing conditions with precise geometrical information. Rectified images can be used to draw plans of façades or acquire geometrical data of ceilings and wall frescos. Using traditional CAD commands and/or PhoToPlan tools, accurate dimensions are instantly taken from the photo and digitizing is a snap.

FARO® OTHER SOFTWARE

-

VirtuSurv, DistToPlan, MonuMap and hylasFM

The FARO products DistToPlan, MonuMap and hylasFM are plugins, that extend AutoCAD® with special functions. FARO VirtuSurv is a stand-alone Windows program.

ROAD-SCANNER C

-

The most compact and affordable road scanner available in the market. (A Siteco mobile mapping system).

ROAD-SCANNER C “COMPACT EDITION“ – THE BEST AMONG MOBILE MAPPING SYSTEMS

FARO® and Siteco Informatica have partnered together to bring the most compact and affordable mobile mapping system for AEC and law enforcement customers. The Road-Scanner C is a state-of-the-art system that is more flexible than competitive systems and priced to appeal to a broad market of users who need to capture existing infrastructure for applications such as utility pole location, electric transmission and distribution lines, etc.

This partnership pairs FARO‘s worldwide sales network with Siteco‘s technical expertise in mobile mapping systems to launch the new Road-Scanner C. Under this agreement FARO will provide a global sales network to market the Road-Scanner C while Siteco will execute sales, installations and support of the mobile mapping systems.

PRODUCT DESIGN

FARO® DESIGN SCANARM

-

Turnkey 3D Scan-to-CAD Solution for Product Development.

HIGH-RESOLUTION SCANARM FOR REVERSE ENGINEERING AND CAD-BASED DESIGN

FARO® Design ScanArm is a portable 3D scanning solution tailored for 3D modeling, reverse engineering, and CAD-based design applications across the product lifecycle management (PLM) process.

The FARO Design ScanArm features optically-superior blue laser technology with fast scanning speed to deliver high-resolution point cloud data and the ability to seamlessly scan challenging materials without the need for spray or targets. The device is lightweight and maneuverable for convenient desktop mounting in the design studio or engineering lab and features a simplified user interface that makes it easy to operate regardless of skill level or 3D scanning experience.

The FARO Design ScanArm is the ideal 3D scanning solution for any organization that may have the need to manufacture parts without existing CAD models, develop aftermarket products that need to fit tightly with existing products, reverse engineer legacy parts for design changes or replacement, create digital libraries to decrease inventory and warehouse costs, design aesthetically pleasing, freeform surfaces, or leverage the power of rapid prototyping.

FARO® FREESTYLE3D OBJECTS

-

Best solution for medium volume scanning

With the new powerful Laser Scanner Freestyle3D Objects FARO expands the successful product concept of its construction BIM/CIM Freestyle3DScanner Series to the growing and fast moving product design and public safety forensics markets.

Featuring a midrange measurement volume, the Freestyle3D Objects is easier to use than narrow field of view scanners that have high detail but are difficult to handle as the tracking is easily lost, yet provides more detail and precision than large volume hand held scanners.

The balanced approach of detail and ease of use makes the Freestyle3D Objects ideally suited for a number of challenging measurement applications like reverse engineering for product design and crime/crash scene investigation in public safety forensics.

With a scan range of 0.3 to 0.8 meter, FARO Freestyle3D Objects is optimized for scanning mid-sized components and items in almost every industry. Whether the goal is to capture industrial pump and wind generation components, molded plastic items or documenting the inside of a vehicle as part of an investigation, FARO Freestyle3D Objects scans the needed geometry into a high resolution color point cloud. Once the object has been measured, the user gets data prepared in SCENE Process 6.1, offering a large scale meshing tool or can export the data into many end user applications.

FARO® COBALT ARRAY IMAGER

-

FARO® Cobalt Array Imager enables custom configurations to improve productivity.

UNLIMITED MULTI-IMAGER SCANNING CONFIGURATIONS

The FARO Cobalt Array Imager is a metrology-grade non-contact scanner which captures millions of high resolution 3D coordinate measurements in seconds. The Cobalt Array Imager is equipped with dedicated on-board processors – an industry first. The smart sensor allows unique multi-imager array configurations which expand the scan area to deliver rapid, automated and comprehensive inspection; dramatically improving cycle time. The actionable data is then displayed as simple go/no-go result or an easy-to-read dimensional deviation color map.

The Cobalt Array Imager is designed for the factory floor so it can be used anywhere inspection is needed, thereby aligning to lean manufacturing principles of eliminating unnecessary movements and time. Cobalt delivers fast and consistent measurements for dimensional inspection and reverse engineering applications on parts, assemblies, and tooling. Cobalt’s versatility supports a variety of deployment options including tripod, rotary table, robot, industrial inspection cells and multiple imager arrays.

Cobalt, which is available in two resolution models, both offering interchangeable fields of view, combines speed, accuracy, flexibility and portability making it an ideal solution for your demanding metrology needs. At an affordable price point providing unparalleled value, the Cobalt is a simple-to-use solution ideal for maximizing productivity and automating workflows for near-line and in-line inspection applications, anywhere in the factory.

FARO® FOCUS

-

Focus Laser Scanner Series – the perfect instruments for 3D reality capture for AEC, Public Safety-Forensics and Product Design Applications

LASER SCANNER FOR FAST AND EXACT INDOOR AND OUTDOOR MEASUREMENTS IN THREE DIMENSIONS: SIMPLY AT YOUR FINGERTIPS

FARO®‘s latest ultra-portable FocusS Laser Scanner series enable to capture fast, straightforward and highly accurate measurements of complex objects and buildings.

The intuitive touch-screen of the FocusS models has been increased in size and clarity to deliver an extraordinary user experience. A built-in 8 mega-pixel, HDR-camera captures detailed imagery easily while providing a natural color overlay to the scan data in extreme lighting conditions. Familiar traits such as light weight, small size and a 4.5-hour battery runtime per charge makes the FocusS Laser Scanner truly mobile for fast, secure and reliable scanning.

FARO® SCENE

-

FARO’s 3D Documentation Software for Laser Scanner.

SCENE software is specifically designed for all Focus, Freestyle and third-party laser scanners. Users can process and manage scan data efficiently and easily by using real time, on-site registration, automatic object recognition, scan registration, and positioning.

The new SCENE 7.0 provides users with a new on-site registration functionality which enables 3D scan data to be wirelessly transmitted, processed, aligned and registered directly to an on-site mobile device or PC in real time. Generating an entire overview map of the completed project is part of the new on-site registration workflow.

Once the project is complete, scan data can be published in the highest quality on a web server with the touch of a button. With SCENE WebShare Cloud, laser scans can be easily accessed and viewed with a standard Internet browser. SCENE 7.0 allows users to upload scans, sections, and complete project point clouds directly to WebShare Cloud with all applied filters resulting in exceptional visual 3D quality data.

SCENE is extremely user-friendly, from simple measuring to 3D visualization to 3D meshing and exporting scan project data into various point cloud and CAD formats.

GEOMAGIC® DESIGN X

-

Ultimate Scan-to-CAD Solution

Geomagic® Design X, the industry’s most comprehensive reverse engineering software, combines history-based CAD with 3D scan data processing so you can create feature-based, editable solid models compatible with your existing CAD software.

GEOMAGIC® WRAP

-

Scan it, Mesh it, Surface it…in minutes

Geomagic Wrap® delivers the industry’s most powerful toolbox to transform 3D scan data and imported files into 3D models for immediate use downstream. From engineering to entertainment, art to archeology and manufacturing to museums, people from every walk of life are effortlessly reverse engineering perfect 3D models from scan data and 3D files using Geomagic Wrap.

GEOMAGIC® FOR SOLIDWORKS®

-

The fastest path from 3D Scan to SOLIDWORKS

Imagine being able to capture anything in the physical world and have a solid model of it in minutes. Geomagic for SOLIDWORKS is the industry’s most comprehensive Scan-to-SOLIDWORKS solution. Reduce the time required to build complex 3D models of real world objects by directly scanning or importing scan data into SOLIDWORKS. The advanced, automated wizards quickly and easily create accurate feature-based editable solid parts inside SOLIDWORKS.

SCENE WEBSHARE CLOUD

-

SCENE WebShare Cloud – a secure cloud-based solution for storing and sharing scanning data with different project partners.

SCENE WebShare Cloud is cloud-based hosting solution from FARO® for easy and secure sharing of scan data worldwide via the internet.

With SCENE WebShare Cloud, FARO offers a comprehensive service to provide users with simple access to 3D documentation. Neither technical training nor specialist skills in 3D laser scanning are necessary to work with the intuitive user interface. Digital data, such as 3D documentation, often has to be available to many different project partners. Previously, users having their own internet server, could use SCENE WebShare to present their laser scan projects to clients an project partners. Now FARO goes considerably further, offering the SCENE WebShare Cloud solution, a hosting service with various packages at different prices.

PUBLIC SAFETY-FORENSICS

FARO® FOCUS

-

Focus Laser Scanner Series – the perfect instruments for 3D reality capture for AEC, Public Safety-Forensics and Product Design Applications

LASER SCANNER FOR FAST AND EXACT INDOOR AND OUTDOOR MEASUREMENTS IN THREE DIMENSIONS: SIMPLY AT YOUR FINGERTIPS

FARO®‘s latest ultra-portable FocusS Laser Scanner series enable to capture fast, straightforward and highly accurate measurements of complex objects and buildings.

The intuitive touch-screen of the FocusS models has been increased in size and clarity to deliver an extraordinary user experience. A built-in 8 mega-pixel, HDR-camera captures detailed imagery easily while providing a natural color overlay to the scan data in extreme lighting conditions. Familiar traits such as light weight, small size and a 4.5-hour battery runtime per charge makes the FocusS Laser Scanner truly mobile for fast, secure and reliable scanning.

FARO® SCAN LOCALIZER

-

On-Site registration & processing made easy.

COMPLETE MAPPING AND REGISTRATION SOLUTION

The FARO® Scan Localizer is a state-of-the-art scanning accessory that streamlines the registration process, substantially increasing productivity.

The FARO Scan Localizer combines information from multiple sensors and software algorithms to determine the exact position of the scanner inside buildings. It allows the as-built capturing for BIM(Building Information Modelling) related applications with unmatched speed, confidence and quality.

While moving a FARO Focus3D Laser Scanner through a large site, the FARO Scan Localizer captures the exact position of the laser scanner, thus enabling greater automation of registration.

The FARO Scan Localizer simultaneously maps the scan space in real-time while giving individual scans initial placement information.

With this new workflow, users are able to immediately utilize cloud-to-cloud registration with high confidence, substantially reducing office work.

FARO® FORENSIC SCANARM SOLUTION

-

High-Resolution, Non-Contact 3D Scanning for Forensic Anthropology and Crime Labs.

3D SCANNING OF EVIDENCE AND ARTIFACTS FOR FORENSIC APPLICATIONS

FARO® Forensic ScanArm is a portable 3D scanning solution tailored for forensic anthropology, crime lab, and medical examination applications.

The FARO Forensic ScanArm features optically-superior blue laser technology with fast scanning speed to deliver high-resolution point cloud data and the ability to seamlessly scan challenging forensic evidence and artifacts without the need for spray or targets.

The solution is portable and maneuverable for mounting in the anthropology lab, crime lab, and at the desktop. Tripod mounting options are also available for when the Forensic ScanArm needs to be used in different locations.

The FARO Forensic ScanArm is an ideal solution for providing permanent 3D digital documentation of forensic evidence and allows subsequent measurements to be taken at any time. Non-contact scanning capability ensures that data can be collected without the risk of damaging often fragile evidence. Full 3D data can be gathered and documented up to ten times faster than using conventional measurement and photographic methods.

The scan data can be used to help identify the victim, document traumatic injuries to bones, and help solve the crime.

The scan data can ultimately be meshed into a 3D model which can be printed using a 3D printer for the purpose of developing accurate and visually compelling evidence for courtroom presentations.

FARO® SCANNER FREESTYLE3D X

-

Innovative, User-Friendly Handheld 3D Laser Scanner

FARO® FREESTYLE3D SCANNER – EFFICIENT HANDHELD 3D LASER SCANNING

The FARO Freestyle3D is a top-quality, high-precision, handheld scanner for professionals. It quickly and reliably documents rooms, structures and objects in 3D and creates high-definition point clouds. With unbeatable precision, it is suitable for all uses in which installations, properties or environments must be quickly measured from various perspectives. The applications of the FARO Freestyle3D include construction, industrial engineering, and forensics.

Freestyle Benefits:- Ability to measure and scan in tight and hard-to-reach areas

- Scan around corners where there is limited visibility

- Memory-scan technology allows users to pause and resume scanning at any time

- Auto leveling

- Flexibility to work with or without artificial targets

- Seamless integration with Focus3D laser scanner data

- Precision handheld scanning

- Easy-to-use scanning software

- Worldwide service and support from local FARO facilities

FARO® SCENE

-

FARO’s 3D Documentation Software for Laser Scanner.

SCENE software is specifically designed for all Focus, Freestyle and third-party laser scanners. Users can process and manage scan data efficiently and easily by using real time, on-site registration, automatic object recognition, scan registration, and positioning.

The new SCENE 7.0 provides users with a new on-site registration functionality which enables 3D scan data to be wirelessly transmitted, processed, aligned and registered directly to an on-site mobile device or PC in real time. Generating an entire overview map of the completed project is part of the new on-site registration workflow.

Once the project is complete, scan data can be published in the highest quality on a web server with the touch of a button. With SCENE WebShare Cloud, laser scans can be easily accessed and viewed with a standard Internet browser. SCENE 7.0 allows users to upload scans, sections, and complete project point clouds directly to WebShare Cloud with all applied filters resulting in exceptional visual 3D quality data.

SCENE is extremely user-friendly, from simple measuring to 3D visualization to 3D meshing and exporting scan project data into various point cloud and CAD formats.

FARO® ZONE 2D

-

Accurately create diagrams for crash reports, crime and fire investigations, and pre-incident planning.

FARO® ZONE 2D PUBLIC SAFETY DIAGRAMMING SOFTWARE

Use FARO Zone 2D to quickly create all your 2D diagrams for law enforcement, the fire service, and insurance. This innovative software application is ideal for creating diagrams for state crash reports, 2D crime and fire scene diagrams, fire service pre-incident plans, fire-protection site plans, and much more.

Developed by the world leader in crash, crime, and fire scene diagramming, FARO Zone 2D is the next generation of public safety diagramming software. FARO’s development team has more than a 25 year history of producing public safety’s best diagramming software and FARO Zone 2D continues that tradition.

With FARO Zone 2D, it’s fast and easy to create detailed, accurate diagrams. Start with a perfectly sized satellite map, bring in a top-down view of a point cloud from your laser scanner, import total station data, or enter hand measurements in baseline or triangulation format. You can even merge data from all of these sources and import drawings from other CAD applications.

Add text, dimensions, and any of the thousands of pre-drawn symbols to diagram exterior and interior scenes. Browse the symbol pallets or use the Symbol Search tool to find exactly the symbol you want. Change the position, size, rotation and color of symbols with just a couple clicks.

Unique Power Tools automate much of your work when drawing streets, intersections, and buildings with windows, doors, and stairs. Just point and click to diagram the intersection in your scene, add or remove lanes, change centerlines, add crosswalks, turn lanes, and stop bars.

FARO Zone 2D can open diagrams created in other FARO Public Safety software, including CrashZone, CrimeZone, FireZone, Quick Scene, Easy Plan, and Blitz.

FARO® ZONE 3D

-

FARO® Zone 3D is the first of its kind to enable investigators to move fluidly between 2D and 3D environments and enhance the quality of incident reconstruction analysis or presentations.

FARO® ZONE 3D FOR PUBLIC SAFETY PROFESSIONALS

FARO Zone 3D is a revolutionary software application for public safety professionals. Through its advanced smart tools, it is the first of its kind to enable investigators to move fluidly between 2D and 3D environments and enhance the quality of incident reconstruction analysis.

Take the pain out of scene documentation: Leverage FARO Zone 3D’s Smart Tools for crash, crime, and fire investigators

Bring all your data together: Use measurements from many different sources to analyze the scene, including manual measurements, drones, total stations, and laser scanners

Make an impact in court: Create accurate, 2D and 3D diagrams, 3D scene walk-throughs, and stunning animations

Plan and be prepared: Enhance your ability to plan for, and respond more effectively to emergencies, by creating accurate representations of critical locations within your community

3D MACHINE VISION

-

Configurable integrated solutions – without compromise

3D Machine Vision is the right partner for all your 3D tasks that require a new interaction and further development of FARO hardware and software components. We analyze actual situations, develop individual overall concepts for all measurement tasks and optimize your process flows. 3D SERVICES

-

Excellence through Quality Training, Support, Repair, and Measurement Services

FARO’s committed to excellence in product training, support, repair, and measurement services.