COMEXI

Videos

Loading the player ...

- Offer Profile

- Comexi, founded in 1954 by the Xifra family, has wide experience in manufacturing capital goods for the flexible packaging conversion industry. Comexi is made up of five product lines, each one specialising in a different conversion process: flexography print, offset print, rotogravure print, laminating, slitting and logistics complements.

Product Portfolio

Printing FLEXO

- With more than 60 years' experience in the sector, we offer the market a high level of technological innovation and a specialised and localised technical service. Flexographic printing is our core business, and with the passage of time, we have become one of the world's leading manufacturers of flexographic presses with a central drum for short, medium and long runs, and which adapt to the market's most demanding requirements.

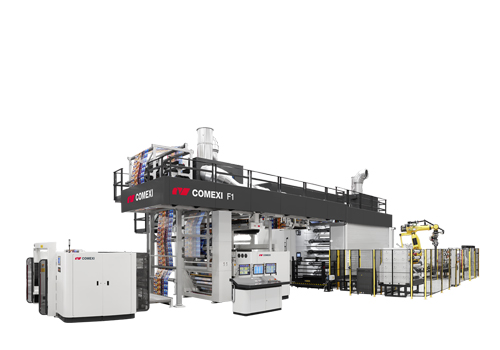

COMEXI F1

-

The F1 machines are defined as excellence in the world of flexography printing with a central drum

With advanced technical solutions, they allow printing at high speeds, thanks to their robustness and drying capacity. The F1 is particularly designed for working with long runs and large repeats.

Main benefits for you- Register and printing unit pressure setpoint

- Inking control

- Stability

- Easy sleeve extraction

- Robustness and quality

- Ergonomic control panel

COMEXI F2 MB

-

The perfect press for your market needs

The Comexi F2MB flexographic press has been designed to satisfy the print needs of medium runs in the flexible packaging sector for the retail and wholesale channel.

The Comexi F2MB shares the patented FLEXOEfficiency concepts of ergonomics and accessibility, as well as the performance and robustness of the rest of the F2 range. All combined with a simplified drying system design.

Technical characteristics

Type Gearless

Colours 8

Print width (mm- in) 870 / 1270

34.2 / 50

Minimum repeat (mm - in) 300

11.8

Maximum repeat (mm - in) 800

31.5

Main benefits for you- Easy job adjustment

- Inking control

- Easy access to the printing units

- High performance doctor blades

- Fast sleeve changeover

- Drying: Power and accessibility

- Access to the top area

- Easy maintenance

- Electronics and perfectly adapted interfaces

- Energy efficiency

COMEXI F2 MC

-

Pure versatility

The Comexi F2 MC press has been designed to satisfy the print needs of medium and long runs in the flexible packaging sector for the retail and wholesale channel.

The Comexi F2 shares the patented FLEXOEfficiency concepts of ergonomics and accessibility, as well as the performance and robustness of the rest of the F2 range.

Technical characteristics

Type Gearless

Colours 8 /10

Print width (mm - in) 870 / 1270

34.2 / 50

Minimum repeat (mm - in) 300

11.8

Maximum repeat (mm - in) 800

31.5

Main benefits for you- Register and printing unit pressure setpoint

- Inking control

- Easy access to the printing units

- High performance doctor blades

- Fast sleeve changeover

- Drying: Power and accessibility

- Easy working on the platform

- Easy maintenance

- Electronics and perfectly adapted interfaces

- Energy efficiency

COMEXI F2 MP

-

The F2 with better perfomance

The Comexi F2 MP press has been designed to satisfy the print needs of the longest runs in the flexible packaging sector for the retail and wholesale channel.

The Comexi F2 shares the patented FLEXOEfficiency concepts of ergonomics and accessibility, as well as the performance and robustness of the rest of the F2 range. All combined with a drying system design for the best drying performance and a reinforced design for the printing units at a maximum speed of up to 500 m/min for runs where the print speed is the differentiating factor.

Technical characteristics

Type Gearless

Colours 8

Print width (mm - in) 1270 / 1470

50 / 57.8

Minimum repeat (mm - in) 350 / 380

13.7 / 14.9

Maximum repeat (mm - in) 850

33.4

Main benefits for you- Register and printing unit pressure setpoint

- Inking control

- Robustness

- Easy access to the printing units

- High performance doctor blades

- Fast sleeve changeover

- Drying: Power and accessibility

- Easy maintenance

- Electronics and perfectly adapted interfaces

- Energy efficiency

COMEXI F2 WB

-

The ideal solution for water-based printing

The Comexi F2 WB machine is the perfect solution for sustainable printing, in medium and long runs, using water-based inks without having to compromise the speed and/or quality.

The press is available in widths of 1270 mm to 1470 mm, in 8 colours and with print repeats of up to 850 mm.

With drying designed especially for water-based inks, the model allows you to obtain a greater printing quality at speeds of up to 500 m/min and to print on different substrates, in forward and reverse printing for lamination.

Technical characteristics

Type Gearless

Colours 8

Print width (mm) 1270 /1470

50 / 57.8

Minimum repeat (mm) 350

13.7

Maximum repeat (mm) 850

33.4

Main benefits for you- Register and printing unit pressure setpoint

- Inking control

- Ideal water-base drying

- Exclusive inking circuit

- Corona treatments

- High performance doctor blades

- Fast sleeve changeover

- Easy working on the platform

- Easy maintenance

- Electronics and perfectly adapted interfaces

- Energy efficiency

COMEXI F2 ML

-

Think big

The Comexi F2 ML printer is the ideal solution for the demanding polyethylene market. An excellent machine from the point of view of profitability, designed to get the best quality at high speeds with large repeats.

An impeccable flexographic printing press that stands out for its high degree of versatility maintaining the ergonomics and usability features of the F2 range.

Technical characteristics

Type Gearless

Colours 8

Print width (mm - in) 870 / 1070/ 1270/ 1470

34.2 / 42.1 / 50 / 57.8

Minimum repeat (mm - in) 350 / 380

13.7 / 14.9

Maximum repeat (mm - in) 850

33.4

Main benefits for you- Register and printing unit pressure setpoint

- Inking control

- Robustness

- Easy access to the printing units

- High performance doctor blades

- Fast sleeve changeover

- Drying: Power and accessibility

- Easy maintenance

- Electronics and perfectly adapted interfaces

- Energy efficiency

COMEXI F4

-

The most effective solution for flexographic printing in short and medium runs

The Comexi F4 machine is the reference in this market segment. After its market launch in 2010, sales have been successful and it is currently being reproduced by various players within the sector.

The Comexi F4 has been the first to embody the patented FLEXOEfficiency concepts of ergonomics and accessibility, as well as performance and robustness, which are also characteristics of the whole Comexi F2 machine range. It is the perfect solution thanks to its dimensions that facilitate any form of handling during the printing process.

Technical characteristics

Type Gearless

Colours 8

Print width (mm - in) 670 / 870

26.3 / 34.2

Web width (mm - in) 720 / 920

28.3 / 36.2

Minimum repeat (mm - in) 240 / 260

9.4 / 10.2

Maximum repeat (mm - in) 600

23.6

Main benefits for you- Register and printing unit pressure setpoint

- Inking control

- Easy access to printing units

- Lighter doctor blades

- Faster sleeve changeover

- Easy working on the platform

- Drying: Power and accessibility

- Easy maintenance

- Electronics and perfectly adapted interfaces

- Energy efficiency

COMEXI FPLUS

-

FPLUS guaranteed efficiency

At Comexi we have built the best presses in recent years. The Comexi FPLUS is a reference in the compact press segment, including features comparable with the top range machines and achieving higher band width printing.

It has been created to obtain high precision presses at high speeds of up to 500 mpm, in widths up to 1520 mm and repeats of up to 1100 mm.

Technical characteristics

Type Gearless

Colours 10

Drum diameter (mm - in) 2500

98.4

Print width (mm - in) 870 / 1070 / 1270 / 1470

34.2 / 42.1 / 50 / 57.8

Web width (mm - in) 920 / 1120 / 1320 / 1520

36.2 / 44.1 / 51.9 / 59.8

Maximum repeat (mm - in) 1100

43.3

Main benefits for you- Register and printing unit pressure setpoint

- Inking control

- Robustness

- Easy access to the printing units

- High perfomance doctor blades

- Agile sleeve Changeover

- Drying: Power anda accessibility

- Easy working on the platform

- Easy maintenance

- Electronics and perfectly adapted interfaces

- Energy efficiency

COMEXI F3

-

The Comexi F3 is a robust printing press incorporating technology developed by Comexi to obtain high quality printing and highly competitive production costs

The Comexi F3 flexographic printing press has been designed to satisfy the standard printing needs in the package and flexible packaging sector. It is available in printing widths of 1270 mm, 8 colours and with printing repeats up to 800 mm. It includes state-of-the-art electronic systems for high quality printing on different substrates, from plastic film to paper or laminates.

Technical characteristics

Type Gearless

Colours 8

Print width (mm - in) 1270

50

Minimum repeat (mm – in) 380

14.9

Maximum repeat (mm – in) 800

31.5

Main benefits for you- Fitted with top brand components

- Quality setpoint

- Comfort

- Drying

Printing OFFSET

- At Comexi we have developed the most revolutionary solution for the most demanding clients: offset printing with Central Impression Cylinder. This innovative solution adapts to the demanding time to market concept, offering reduced costs per print and reducing the environmental impact thanks to the solventless EB offset inks. The Comexi CI8 is the ideal solution for the increasingly more popular short runs in flexible packagings that clients have been asking for.

COMEXI CI8

-

A new horizon in flexible packaging

Our offset technology offers maximum levels of quality, and also dispels the traditional doubts over the possibilities of offset print in non-absorbent and elongable supports.

The offset solutions is more competitive than the flexographic and rotogravure printing regarding time to market and production flexibility, as offset plates can be imaged on the site within minutes.

The offset plates are up to 20 times more economical than the photopolymer plates or the cost to engrave a cylinder. The printer can offer more competitive prices in short and medium runs, improving the total production volumes in comparison with rival companies that use traditional processes.

Environmental aspects carry increasingly more weight in certain areas within the sector, and are even considered a key factor. From the point of view of sustainability, our offset presses use EB inks, which are paving the way towards sustainable printing, and they also fit in perfectly with our environment commitment.

Our EB Flexo coatings for whites, lacquers and varnishes will be one more part of this system.

Technical characteristics

Type Gearless

Colours 8

Print width (mm - in) 850 /1050

33.4 / 41.3

Web width (mm - in) 900 / 1100

35.4 / 43.3

Minimum repeat (mm - in) 455

17.9

Maximum repeat (mm - in) 930

36.6

Main benefits for you- Reduced time to market

- Greater customisation

- Less cost, greater profitability

- Sustainable process

- High quality printing

Printing GRAVURE

-

Thanks to our extensive knowledge of the flexible packaging industry, together with the experience of the prestigious Italian firm, Acom, we can offer cutting-edge solutions in rotogravure printing industry.

Rotogravure presses offer clients a wide range of applications for the food sector, labels, safety and pharmaceutical products. A perfect solution for markets looking for high quality printing, reliability and efficiency.

COMEXI R2

-

The Comexi R2 is our latest development in the rotogravure industry

It has been designed to respond to the broadest needs of the market, maintaining high levels of quality.

The press is available with the main equipment: web video, corona treater or viscosity control, and others. All the main auxiliary equipment controls are integrated in the HMI.

Comexi has buit-in the latest technology in machine control, i.e. Direct Drive, increasing efficiency, as well as Regenerative Drive System which reduces energy consumption.

Technical characteristics

Max. Web width (in) 41.3 / 53.5

Max. Printing cylinder repeat (in) 36.7

Length of drying chamber (ft/min) 5.9 / 15.4

Web tension (N) 35 / 400

Maximum speed (ft/min) 1312.3

Main benefits for you- Exellent register control

- Adjustable doctor blade system

- New inking system

- Pneumatic opening of the drying chambers

- Easy maintenance

COMEXI EXCEL

-

A high perfomance product with multiple setups

In view of the new market demands, calling for equipment suitable to increasingly shorter order lengths and higher quality, at Comexi we can offer a response: our new and revolutionary rotogravure press, Comexi RG EXCEL.

The personalisation of the machine, together with its numerous technical innovations, make it a high performance product, capable of multiplying its benefits, particularly in highly competitive environments. Comexi RG Excel allows you to deal with short and long runs.

Technical characteristics

Max. Web width (in) 25.5 / 33.5 / 41.3 / 53.5

Max. Printing cylinder repeat (in) 40.5

Length of drying chamber (ft) 7.2 / 11.5 / 15.4 / 24.6

Web tension (N) 900

Maximum speed (ft/min) 1640.4

Heating system Oil, gas, steam, electricity

Main benefits for you- Ergonomics

- Adjustable doctor blade system

- The ideal solution for wall paper

COMEXI PLATINUM

-

A technology jewel

With the Comexi RG Platinum model, we offer the most advanced technological solution in the rotogravure field for flexible packaging, and the best guarantee of top results: high printing quality at high speeds (up to 600 m/min), reduced waste and maximum productivity.

Comexi RG Platinum can be tailored according to customers' needs. Using specific solutions, thanks to the knowledge and flexibility of Comexi, it is possible to improve the performance and efficiency of the most complicated applications, thereby obtaining excellent results in online processes like solvent-based or solventless laminating, cold seal and lacquering.

Technical characteristics

Max. Web width (in) 25.5 / 33.5 / 41.3 / 53.5 / 61 / 72.5

Max. Printing cylinder repeat (in) 40.5

Length of drying chamber (ft) 7.2 / 11.5 / 15.4 / 24.6

Web tension (N) 900

Maximum speed (ft/min) 1968.5

Heating system Oil, gas, steam, electricity

Main benefits for you- Fast job changeover

- Top quality components

- Ergonomics and accessibility

- Pneumatic opening of the drying chambers

- High quality printing

LAMINATING

-

Following the strategy of being the main global supplier for the flexible packaging industry, we have positioned ourselves as one of the leading and cutting-edge companies in the development of solutions for laminating and coating.

We offer unique solutions by reducing the environmental impact with solventless and water-based tape applications, as well as the usual solvent-based laminating. The holographic application is the most recent innovation that gives the converter an additional benefit with attractive and stunning designs along supermarket lines.

COMEXI SL3

-

The Comexi SL3 laminating machine, thanks to its high reliability and easy handling, is the ideal machine for every converter who wants to enter the laminating market

The Comexi SL3 is fitted with a fully motorised application head in each calender, with a sleeve metering system and a laminating set with 3 rollers, all essential for obtaining high quality laminating.

With shaftless unwinders and rewinders, together with an optimised web path, changeovers are fast, comfortable and simple.

Technical characteristics

Maximum web width (in) 52.3

Maximum laminate width (in) 51.7

Maximum speed (ft/min) 1148.3

Maximum unwinder diameter (in) 33.5

Main benefits for you- Metering system with sleeves

- Shaftless unwinders and rewinder

- Perfect control tension

- Solventless coating head fully motorized

- 3-Rollers lamination nip

- Fully integrated coating weigth control

COMEXI SL2

-

A compact solvent less machine designed under 3 concepts: simplicity, reliability and productivity

Its machine design, its facility to use and its state-of-the-art controls makes it the ideal laminator for short and medium runs and for a wide variety of materials.

Technical characteristics

Maximum speed (ft/min) 1476.3

Maximum web width (in) 52.3 / 60.2

Maximum laminate width (in) 51.7 / 59.6

Minimum laminate width (in) 19.7 / 13.7 (with extensions) by 52.3

27.5 / 21.6 (with extensions) by 60.2

Main benefits for you- Solventless coating head fully motorized

- Sleeved transfer roller

- Web guide sensor fully motorized

- 3-Rollers lamination nip

- Aluminium prepared

- Prodat data system

- Fully integrated coating weigth control

COMEXI DUAL

-

Versatility is the key word to properly define this machine

Versatility to cover all kind of applications in the flexible packaging, providing the perfect answer for all those converters that want to expand their business, offering different high added value solutions for their customers, from 3-ply structures to Heat Seal applications, from Coldseal for chocolate bars to Solventless lamination for snacks.

Versatility for the capacity to use different technologies in just one machine: solvent and water based adhesives and lacquers, solventless adhesives, coldseals and one colour printing jobs. To this, Comexi offers a full range of different trolleys for this purpose: gravure (open and enclosed doctor blade chamber), solventless (with a full motorization of the coating head), flexo GearLess (with the outstanding technology of Comexi) and semiflexo (for high grammages and perfect evenness).

Technical characteristics

Speed (ft/min) 1476.3

Width (in) 36.6 / 40.5 / 52.4 / 60.2

Maximum laminate width (in) 51.7

Minimum laminate width (in) 9.8 / 27.5

Main benefits for you- High technological trolleys

- Register control

- Drying tunnel

- 3-Rollers lamination nip

- Aluminium prepared

- Prodat data system

- Fully integrated coating weigth control

COMEXI ML1

-

A world-class machine for the most stringent customers

Comexi ML1 is an state-of-the-art laminator which provides the best performance on lamination and coatings, and at the same time, presents an unbeatable proposal in terms of usability and facility to operate with.

With an outstanding drying capacity, totally modular and adaptable to customer’s requirements, and a full set of different high-technological trolleys that will answer to all their coating requirements, ML1 is a laminator of next generation.

Technical characteristics

Maximum speed (ft/min) 1476.3

Maximum web width (in) 52.3 / 60.2

Maximum laminate width (in) 51.7 / 59.6

Main benefits for you- High technological trolleys

- Automatic coupling of the trolleys

- Register control

- Shell-type opening drying tunnel

- 3-Rollers lamination nip

- Aluminium prepared

- Turret winders for a non-stop production

- Prodat data system

- Fully integrated coating weigth control

COMEXI FUTURA

-

The Comexi FUTURA is a versatile machine designed to offer a greater added value to the product, thanks to all its finishing options

It guarantees a holographic finish thanks to a technology known as Cast & Cure, creating a highly attractive visual register effect using a UV lacquer, without the need for laminating and completely free of VOC. It also offers copy protection to guarantee the genuineness of the packaging.

It allows applying cold-foil, UV laminating, different coatings to give an attractive finish to the product, and the possibility of solventless laminating.

Technical characteristics

Maximum speed (ft/min) 1476.3

Maximum web width (in) 52.3

Maximum laminate width (in) 51.7

Main benefits for you- Shaftless unwinders and rewinder

- Perfect control tension

- Gearless flexo technology

- Holograph finishes thanks to the Cast & Cure technology

- UV lamps for perfect curing

- Infinite finishing options

COMEXI L20000

-

The Comexi L20000 is a laminating machine designed especially for working with water-based adhesive and it complements the Digital Printing HP Indigo to offer an unbeatable combination in delivery times, and it also minimises waste reduction and favours environmental sustainability

This highly technological machine responds to the growing demand of short runs and the reduced product delivery times.

Its special application system for water-based tapes, together with its high energy efficiency and very precise web tension control, make the Comexi L20000 the perfect option for your digital print.

Technical characteristics

Speed (ft/min) 492.1

Maximum web width (in) 36.2

Minimum web width (in) 11.8

Maximum rewinder and unwinder diameter (in) 39.3

Main benefits for you- Shaftless unwinders and rewinder

- Perfect control tension

- Closed chamber doctor blade technology

- Automatic washing

- Fully integrated software system

- High efficiency drying

- Very compact machine

SLITTING

-

Following the strategy of being the main global supplier for the flexible packaging industry, at Comexi we provide the most sophisticated slitting and rewinding machines, researching and innovating constantly until we satisfy the most demanding needs of our clients and end consumers.

We offer high value solutions, like the innovating and recent Cingular Laser system, which gives converters the added benefit of making life easier for the packaging end users. The micro-perforating, the QR codes, the "easy-opening" or quality systems are usually applied to the flexible packaging sector, thanks to the loyal orientation of the Comexi client.

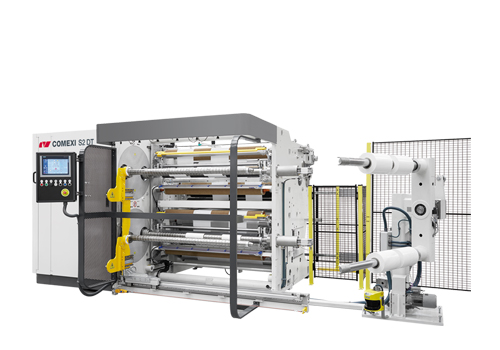

COMEXI S2DT

-

The double-turret S2 DT slitter is our best-seller

It is an all-purpose machine that will slit most of the webs used in the flexible packaging market without problems, at a very high production rate thanks to its double turret exit.

The equipment and accessories included in the S2DT assist you in your search for maximum quality within the range, and provide you with high productivity and excellent balance in your investment return.

Technical characteristics

Speed (ft/min) 1640.4

Acceleration and deceleration 60'

Max web Widths (in) 55.1

(Others to be studied by request)

Range of materials Limited

Minimum standard cut (in) 1.5

(Smaller sizes to be studied by request)

Main benefits for you- Ergonomics and resource optimisation

- Maximum quality and productivity

- Flexibility and easy use

COMEXI S1DT

-

The Comexi S1 DT slitter is a top range machine with a turret

You will obtain excellent results in both quality and productivity, even in the most demanding jobs.

With the turret, you will obtain high production rates in jobs with many output reels, such as those intended for the labels market.

Thanks to its regulating and control elements, it will produce jobs with handling difficulties, without any problem. The Comexi S1DT works with thicker structures in the flexible market, even with aluminium, wax or non-woven webs.

Technical characteristics

Speed (ft/min) 2624.6

Acceleration and deceleration 20'

Max web Widths (in) 55.1

(others to be studied by request)

Range of materials Greater Flexibility

Minimum standard cut (in) 0.8

Main benefits for you- Success with the most difficult jobs

- Maximum quality and productivity

- Easy use and maximum personalisation

COMEXI S-TURRET

-

The Comexi S-TURRET slitter is a single-turret machine designed to obtain excellent results in those rigid materials that require working with high tensions and large reels at the exit.

Technical characteristics

Speed (ft/min) 1968.5

Acceleration and deceleration 60'

Max web Widths (in) 55.1

(others to be studied by request)

Range of materials Limited to rigid ones

Minimum standard cut (in) 1.9

Main benefits for you- For all the heavy weights

- Control and Productivity

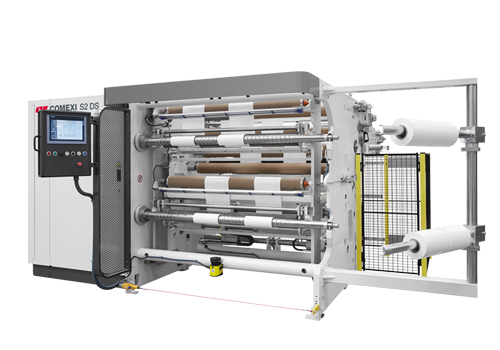

COMEXI S2DS

-

The Comexi S2 DS slitter is a versatile machine that will cover the immense majority of slitting needs in any market that needs supply

The equipment and accessories included in the Comexi S2 DS assist you in your search for maximum quality within the range, and provide you with high productivity and economic performance.

Technical characteristics

Speed (ft/min) 1640.4

Acceleration and deceleration 60'

Max web Widths (in) 55.1

(others to be studied by request)

Range of materials Limited

Minimum standard cut (in) 1.5

Main benefits for you- Ergonomics and easy use

- Search for maximum quality and productivity

COMEXI S1DS

-

Versatility and maximum speed

The Comexi S1 DS slitter is a multi-purpose machine that will allow you to cover a large variety of repeats, up to large diameter reels.

It is a fast machine with a quality-price ratio that is difficult to beat.

Technical characteristics

Speed (ft/min) 1968.5

Acceleration and deceleration 30'

Max web Widths (in) 55.1

(others to be studied by request)

Range of materials Limited

Minimum standard cut (in) 1.5

Main benefits for you- Versatility

- Search for maximum quality and productivity

- Flexibility and easy use

COMEXI DUO2

-

The Comexi DUO2 slitter is a top range machine, which will provide you with excellent results in both quality and productivity, even in the most demanding jobs

Due to its robustness and design, it will generate large diameter reels at the exit at a very high working speed.

Thanks to its regulating and control elements it will produce jobs with handling difficulties, without any problem. With the Comexi DUO2 you will not have any problems working with thicker structures in the flexible packagings sector or even with aluminium, wax or non-woven packagings.

Main benefits for you- Success with the most difficult jobs

- Maximum quality and productivity

- Easy use and maximum personalisation

Comexi Cingular Laser

-

The integrated solution to differentiate

Comexi Cingular Laser is the revolution of the flexible packaging industry. A laser-in-line processing system that can be integrated into any of our slitters. The key technology to make a difference and optimize production, following the latest technology requirements and market trends.

Control, precision and speed are some of the words that best define this innovative tool which permits customize, differentiate and, at the same time, perform a wide gamma of applications and finishing. From microperforation, macro perforations, design windows, precut adhesive labels to alpha numeric codes, bar codes, security systems or easy open applications. All in one single equipment.

The Cingular Laser is based on the high quality of the laser, able to work in the most demanding environments. It has a complex software designed to coordinate all tasks and also allows greater control of the tension of the web and an extraordinary adaptability. The best-integrated manner that gives added value to the products instantly.Technical Data

Cingular Laser 100

Laser Heads 2 a 10

Rated power (per head) 100W

Wavelenght 10,25 μm

Laser Processing Hole Tech, Scribing Tech, Hallmark Tech, Cutting Tech, SelectCut Tech, 3DTreatment Tech

Laser micro ø 50 μm - 500 μm

Laser source Sealed CO2 excited by RF

Beam quality M2<1.2

Cooling system Water

Main benefits for you- Total versatility

- Velocity

- Integration

- Time to market

ENVIRONMENT & LOGISTICS

- In Comexi we believe that productivity improvements are the most profitable investments, that is why we decided a few years ago to work on developing solutions for the printing industry and conversion.

COMEXI RUL

-

The solution to automating reel unloading

Working non-stop is a synonym for productivity, and this is exactly what the automatic Comexi unloader does, a set of systems that allow the reels to be changed over automatically (for rewinder with shafts) without needing manual handling and minimising the reel changeover time. Machine productivity is increased thanks to reel changeover cycles of approximately 3 minutes, which allows increasing the print speed.

The reel unloader has been designed to adapt to any type of machine: printers, laminating machines, extruders or others.

The system is fully automatic and controls the machine parameters using a built-in PLC. Its intuitive menu manages all the procedures simply and comfortably, fully in line with the Comexi philosophy: efficiency, productivity and safety.

Technical characteristics

Web tension 400 / 480 V

Frequency 50 /60 Hz

Power 12 KW

Working pressure 6 bar

Maximum pressure 8 bar

Main benefits for you- Eliminating shaft handling

- Easy reel handling

- Do not waste time managing the cores

- Easy and intuitive control

COMEXi LCR

-

Anilox cleaning system with laser technology

The Anilox and cylinder cleaning system using laser technology, provides in-depth, high performance cleaning, obtaining the best result to be found in the market.

The LCR is a product that differs from all the others because of its faster washing speed, offering excellent cell cleaning as opposed to using any ink, resin, varnish or tapes. With the possibility of working with a large variety of diameters and lengths and with a large washing capacity, this guarantees the cleaning in any kind of alignment and surface without damaging the roller/sleeve surface.

Supply voltage: 230 / 400 / 415 / 440 / 480 Vac

Frequency: 50 Hz / 60 Hz

Maximum power: 4 kWa

Hardware: Colour, touch screen 5.7" (high resolution)

Pneumatic consumption: 100 l/min 2 bar

PLC control

Water consumption: No consumption

Hydraulic consumption: No consumption

Gas consumption: No consumption

Dust atmosphere: Not generated

Explosive atmosphere: Not generated

Toxic atmosphere: Not generated

Main benefits for you- Different programs according to the degree of dirt

- Under maintenance

- Perfect cylinder control

- Easy access and handling

COMEXI ECODISTIL

-

Professional solvent recovery

pigments and other solvent components through distillation. The process achieves a recovery rate over 85% (*), which allows it to be reused for cleaning applications and minimises the waste to be removed.

The recovery unit is made up of a distiller fitted with an autonomous vacuum unit, a heat exchanger for the vapour condensation, a cylinder for collecting the condensation and two tanks with a capacity of 2000 litres and made of stainless steel, for regenerated and contaminated solvent.

(*) Percentage dependent on the degree of pigment concentration.

Main benefits for you- Low consumption and maintenance

- Automatic washing machine

- Safety

- High recovery and profitability capacity

COMEXI ST3

-

Space optimisation

The sleeve store is an automatic warehouse system designed to obtain maximum capacity in minimum space. As it is a modular structure, it can be adapted to any space and can even be raised several meters above the floor, fully optimising the space in your production plant.

The sleeves are kept in a vertical position to prevent deformations, and thanks to the store's organisational efficiency, it occupies a minimum space in production, leaving the space free for other tasks.

Its automatic operating gives the operators considerable time, and its precise handling avoids deterioration and prolongs the useful life of the sleeves.

Our experience is endorsed by the various pieces of equipment we have installed in leading factories.

Technical characteristics

Maximum sleeve weight 40 kg

Noise level

Standard width dimensions 6 / 9 / 12 m

Sleeves Capacity To be defined 900

Main benefits for you- Easy adaptation to the space in your plant

- Automatic stock order

- Sleeves preserved well

- Agility in preparing jobs

COMEXI MIXER

-

The Comexi Mixer is a piece of equipment with 2 components for mixing and supplying solvent-less tape in laminating machines

It has a tank with component A (Resin) and another with component B (Catalyst). Both are heated and metered autonomously. Heating is obtained by means of a plate fitted with resistors, and the process is managed by PLC taking the temperature readings provided by the probes on the heating plates and inside the tanks, as the reference. The metering is done using gear pumps according to the desired mix proportion. Finally, the components are mixed at the point of application using a metering nozzle arranged at the end of the heated hose.

Technical characteristics

Dimensions Width: 1200 mm, Depth: 970 mm, Height: 1145 mm

Mix ratio From 100/0, To 100/100

Maximum supply (with 100/50 rate) 2.2 litres/minute

Maximum pressure 70 bar

Tank capacity 2 x 50 litres

Main benefits for you- Fully automatic system

- Energy efficiency

- Ergonomics and maintenance

CLOUD

Own your data

-

This revolutionary software is the fastest and easiest way to analyze production and help clients understand their data and processes. This consistent data transparency will ensure optimal decision-making.

Monitoring plan

Real-time information

Production control

Historic and process set up parameters

Performance indicators

Machine– Production order – Time

Main advantages- Plant Monitoring. Monitor machines, know how they work

- Process data analysis: OEE, downtimes, scrap, etc.

- Improve productivity

- Better process reliability

- Downtime and scrap monitor

- Process constrains detection

- Paperless Workflow Activities

- Integration of all value chain (Printing/Laminating/Slitting)

- Anytime & Anywhere