STOREPICK

Automate your operations for store-friendly deliveries

Many ingredients must come together to complete efficient, store-friendly deliveries. When dealing with growing volumes of diversified stock and multiple store formats, logistics needs to be agile and predictable at the same time to avoid empty shelves.

Your goal is to ensure that both full case and single item deliveries run seamlessly. In addition, the expanding number of SKUs means you need to be smart with space. And the icing on the cake? Finding a solution to labour scarcities.

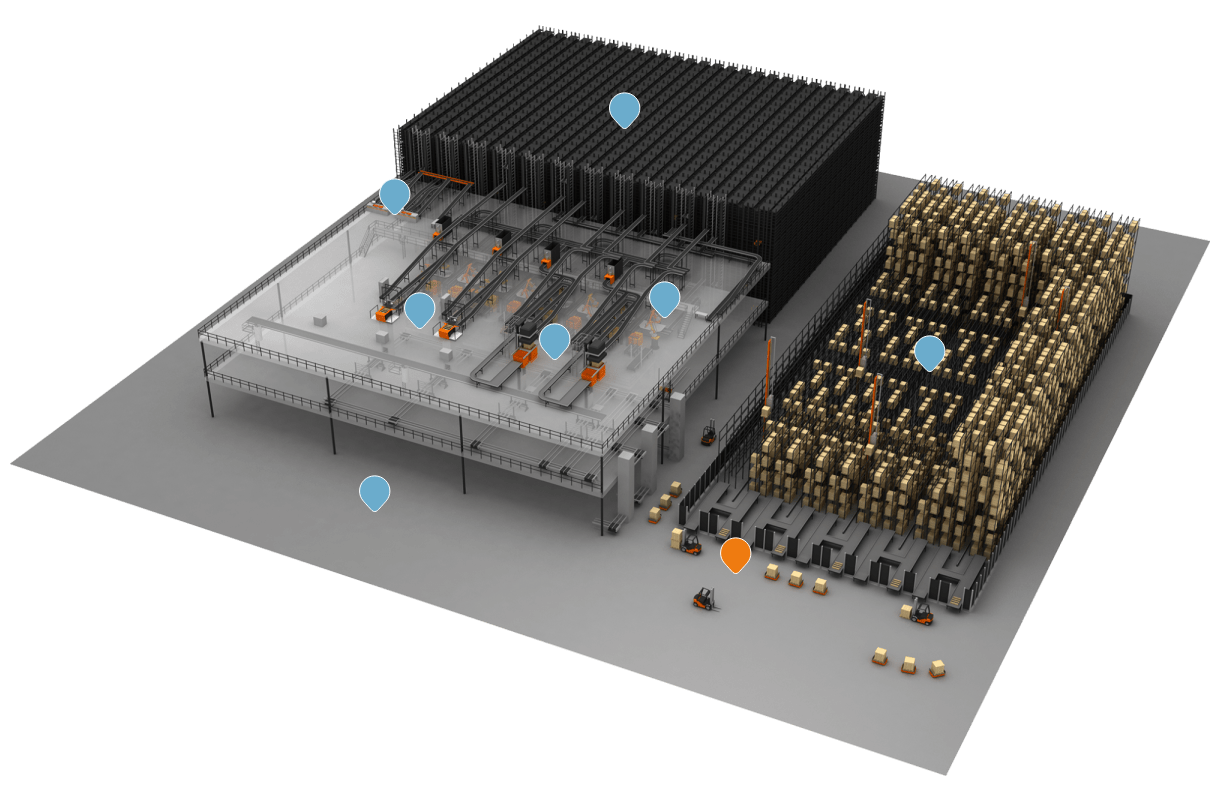

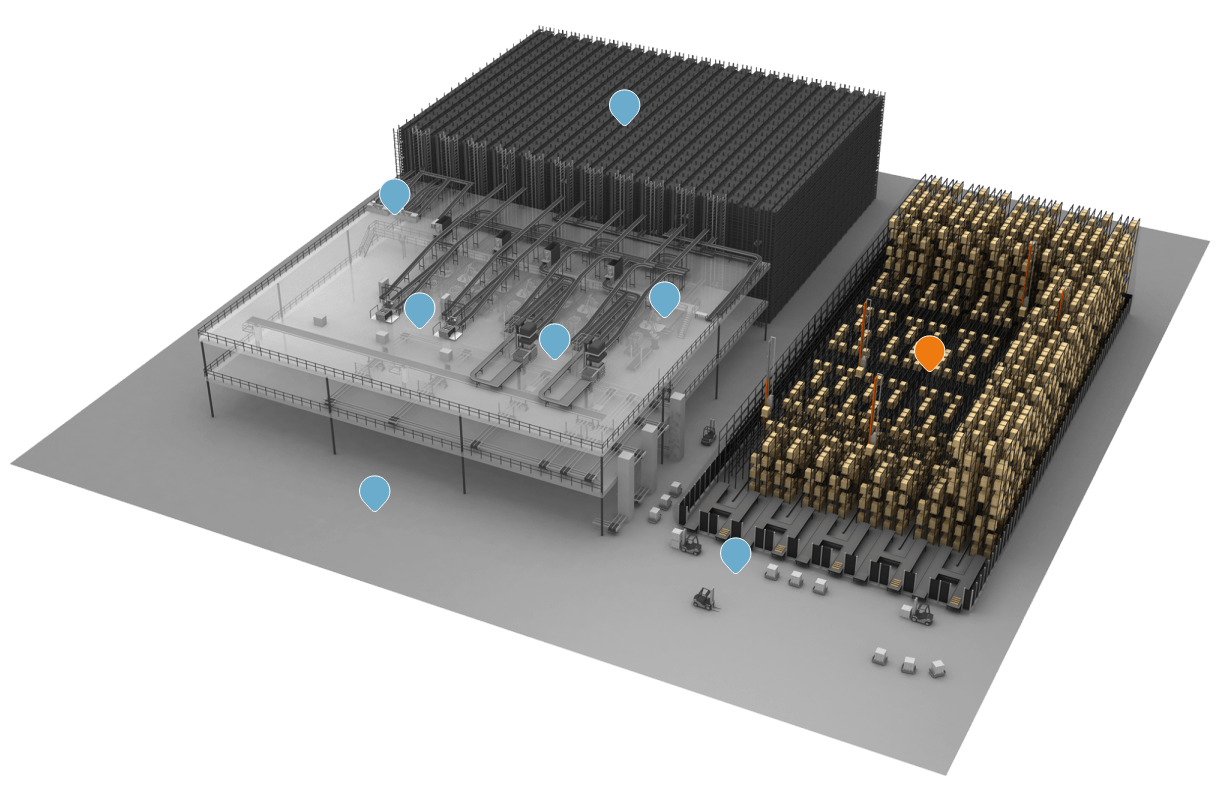

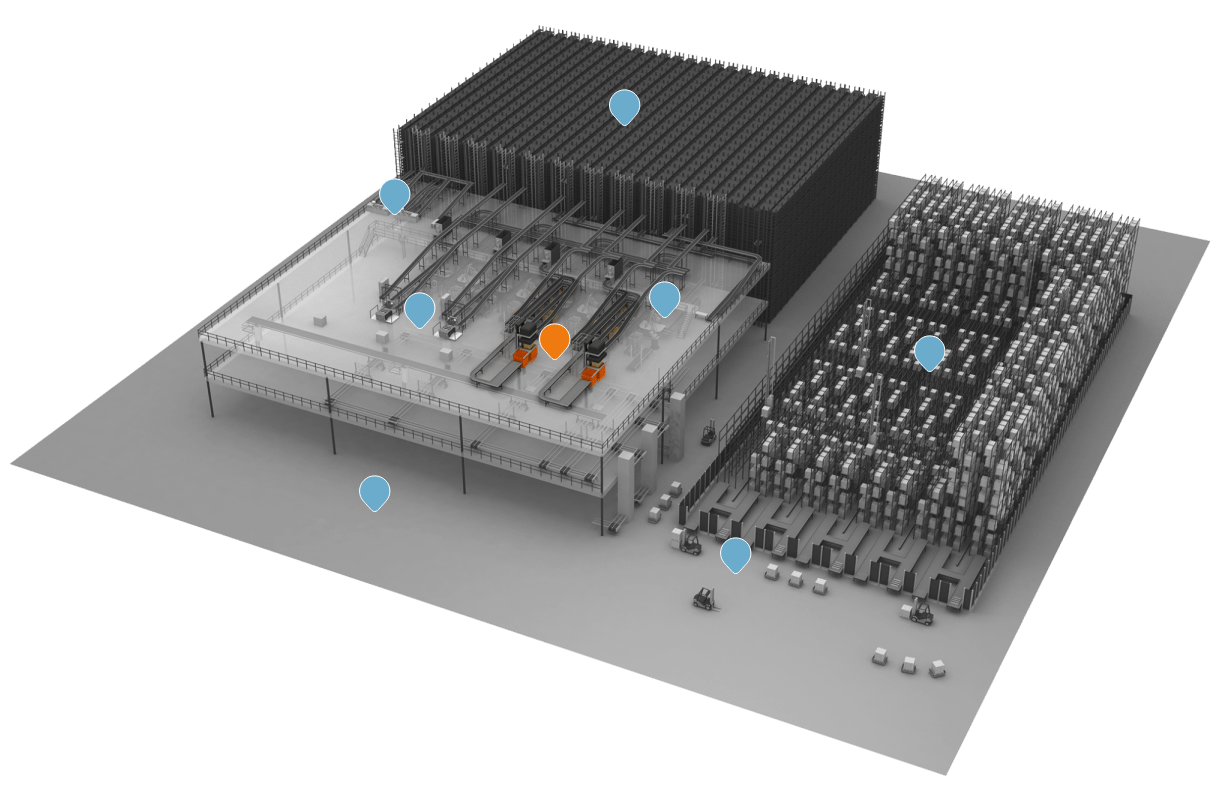

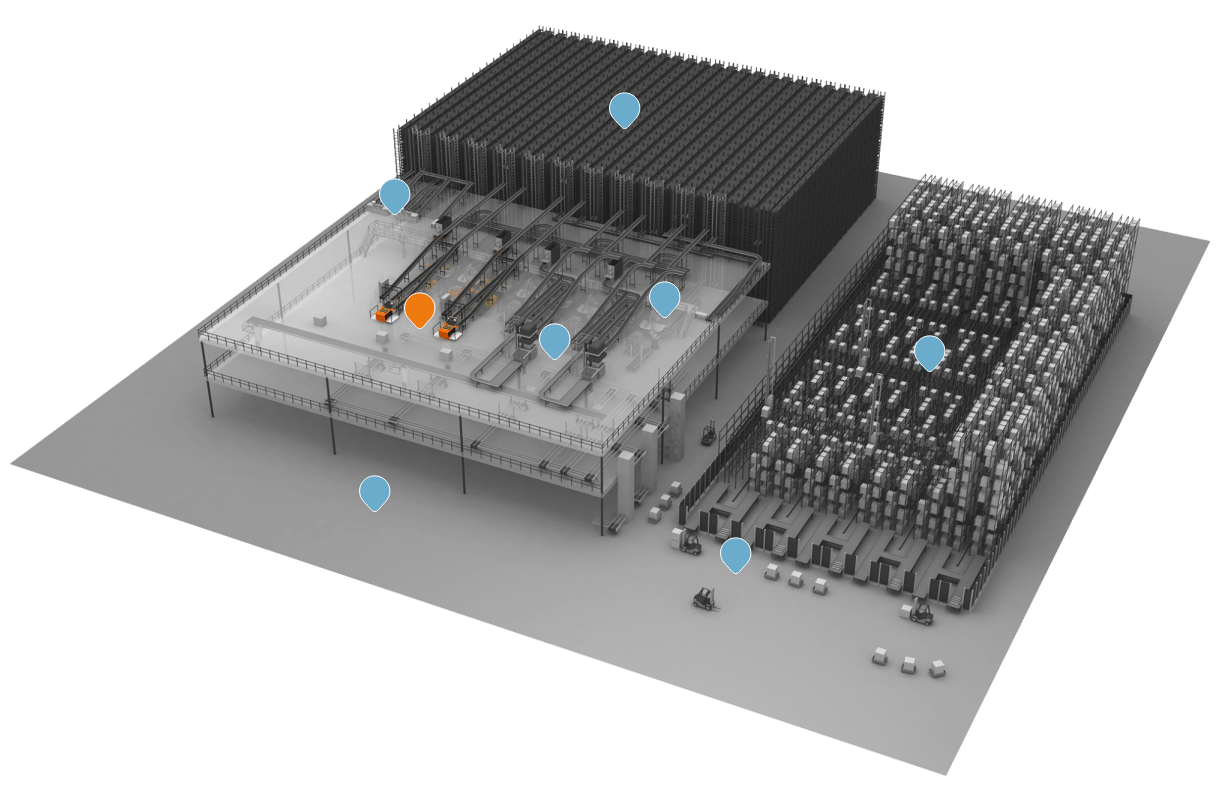

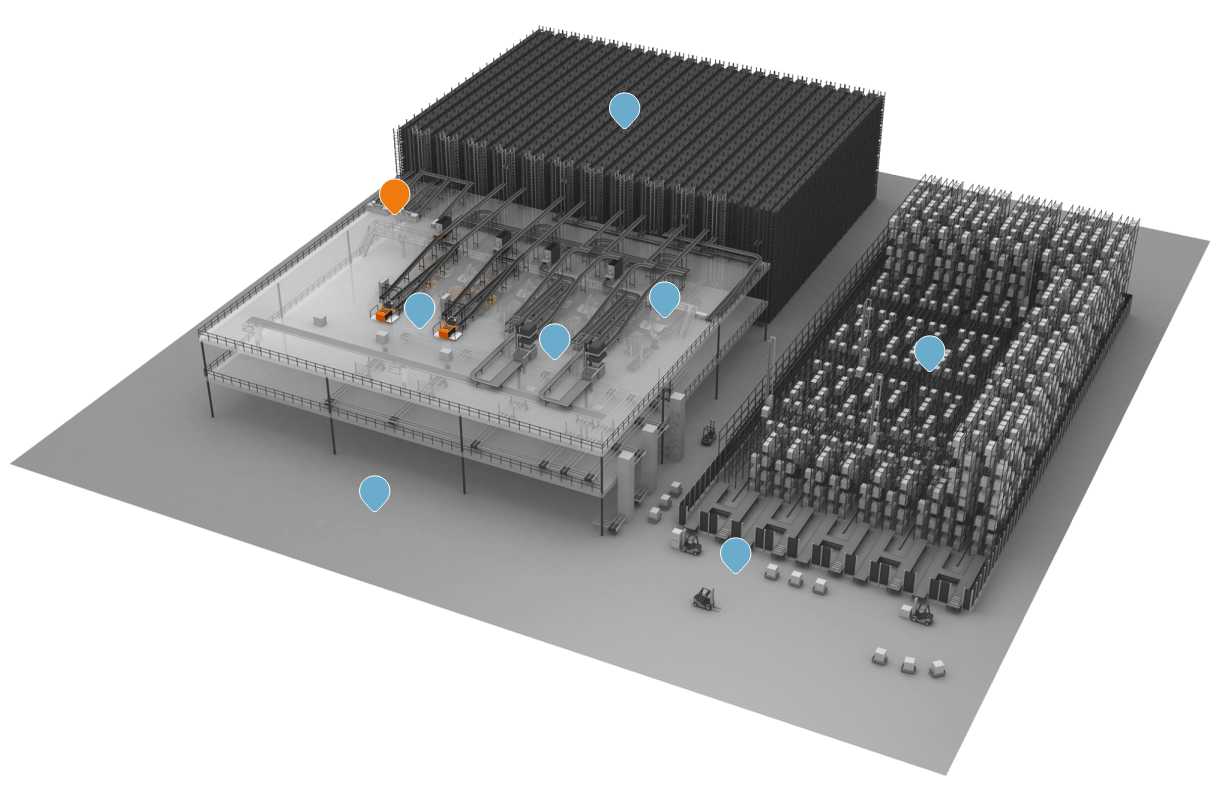

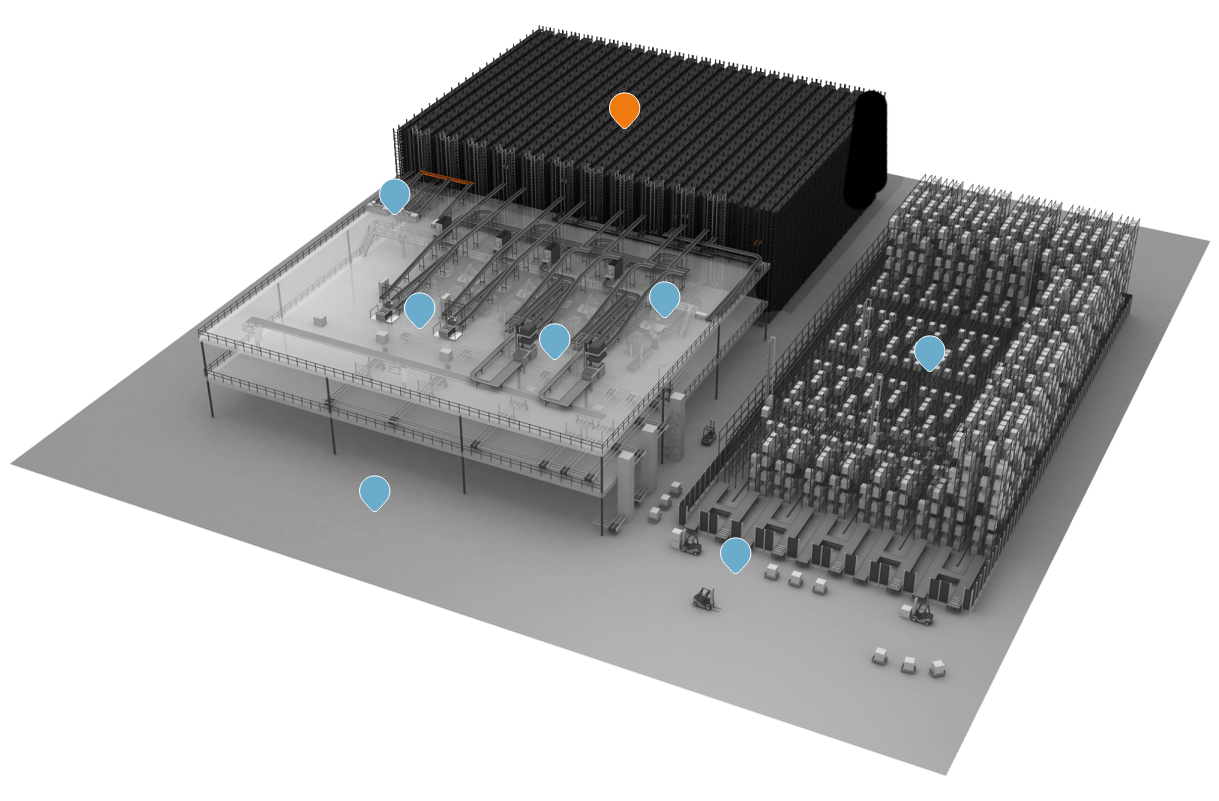

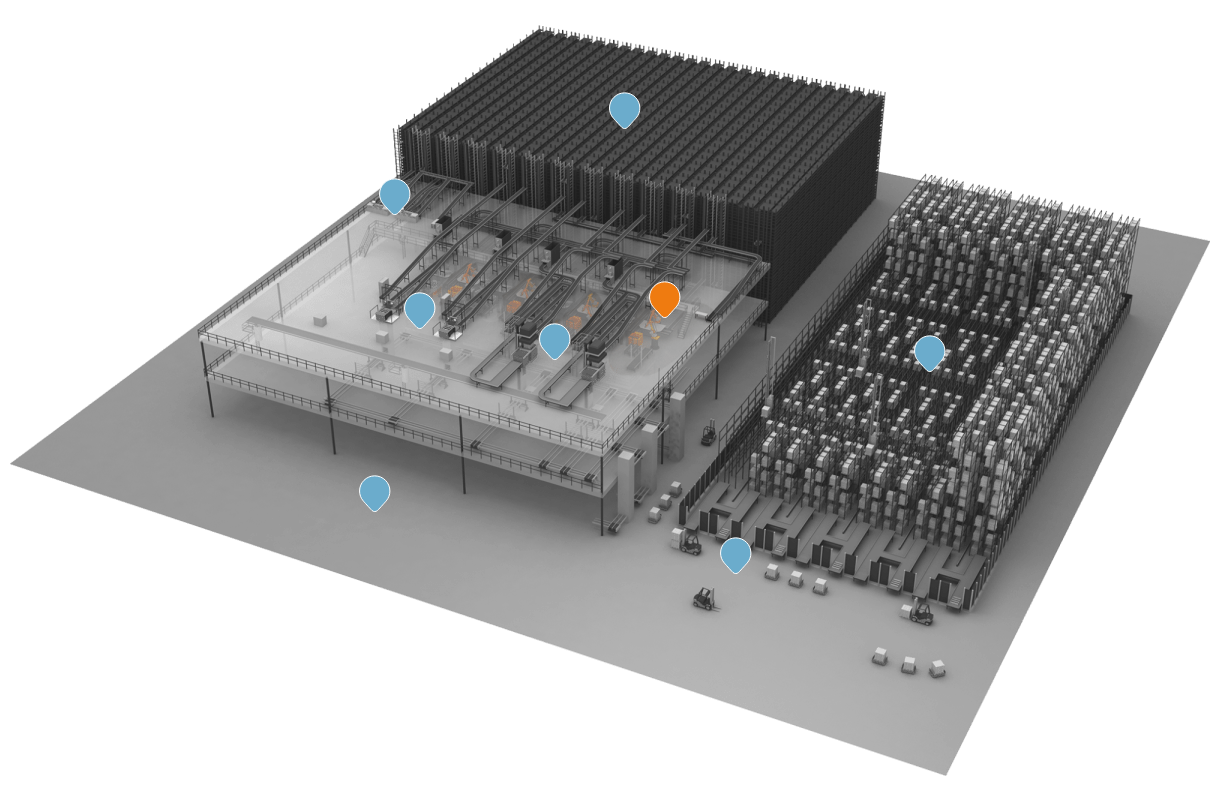

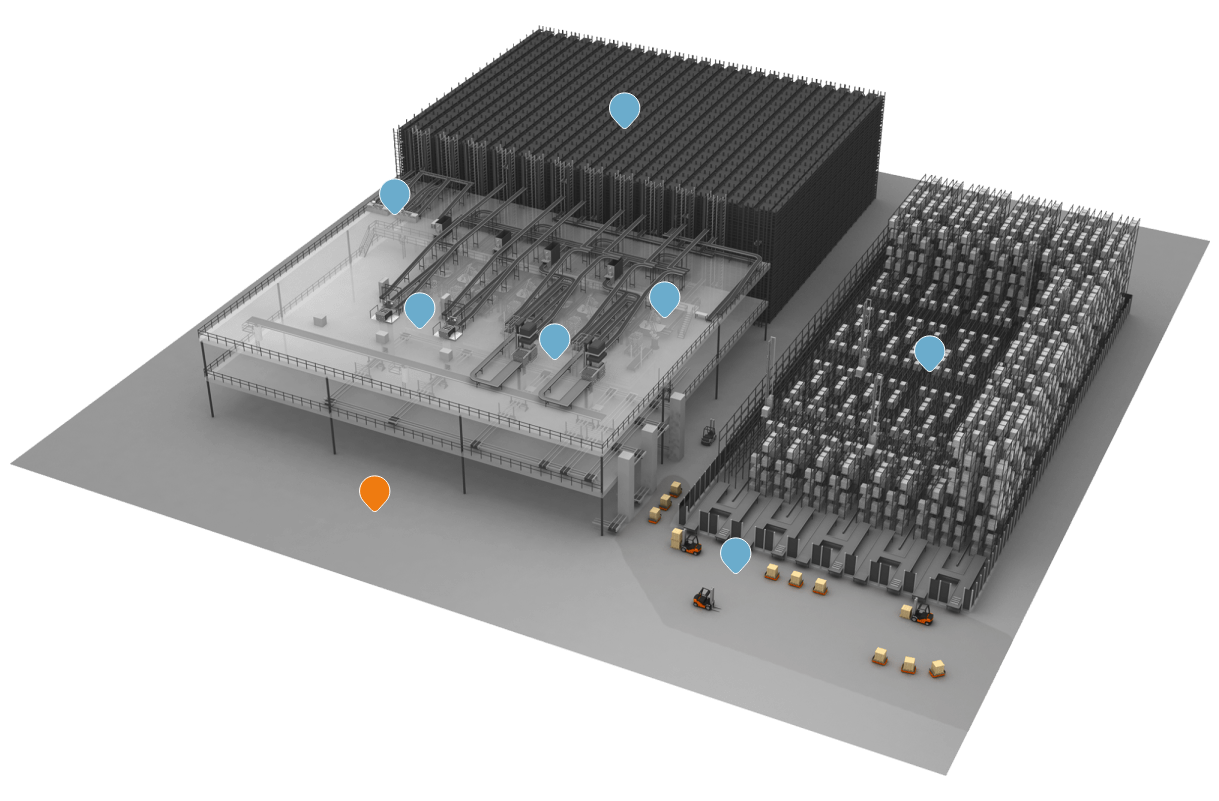

We offer a robotised, end-to-end automated case picking (ACP) system – STOREPICK – one of our next generation of scalable solutions. STOREPICK tackles today’s challenges with tomorrow’s technology to:

- handle both incoming and outgoing goods

- guarantee store-friendly deliveries across store formats

- significantly reduce labour dependency

- cope with ambient, fresh and chilled warehouse processes

- offer a redundant design

- and scalability to handle a strongly growing market.

This is the warehouse solution on the market that delivers highly-predictable performance against healthy operational cost. So it’s the perfect choice, helping you take on store supply with confidence.