Industrial float glass production

Versatile possible application of digital pyrometers in the float glass industry

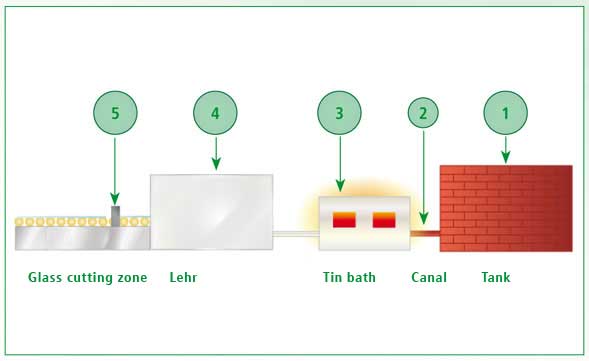

Float glass is produced in the so called float glass process. It is the base for insulation glass, window glass, safety glass, mirror glass or automobile glass. During the process the glass melt is leaded continuously from the melting furnace on to a liquid tin bath where the glass spreads out. By means of DIAS pyrometers PYROSPOT the temperatures in the float glass process can be measured on liquid glass as well as on solid glass and so the quality of the glass can be monitored.

The image on the right side shows the production process of the float glass production:

(1) Tank

(2) Canal

(3) Tin bath

(4) Lehr

(5) Glass cutting zone

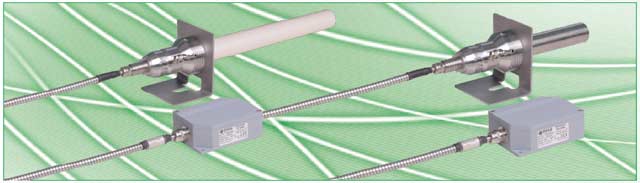

Pyrometer with fiber optic cable for the temperature measurement on liquid glass

In the zones 1 and 2 (tank and canal) special fibre optic pyrometers are used for the measurement of the molten glass as there are very high ambient temperatures up to 200 °C. Here the models PYROSPOT DSF 30NG or DSF 34NG are mounted in combination with a special quick release mounting angle equipped with an air purge and sighting tube. The fibre optic cable and optic head withstand ambient temperatures up to 250 °C without cooling.

Solid float glass requires a special spectral range for a accurate temperature measurement

In the zones 3 and 4 (tin bath and lehr) the pyrometers have to measure solid glass. For this application pyrometers with a spectral range around 5 µm are necessary so that only the glass surface will be detected. At each position 3 pyrometers are placed in a row, left and right edge of the glass plate and the middle. This gives a rough temperature profile of the glass plate.

Digital pyrometers with large temperature measurement ranges

Here the pyrometer models PYROSPOT DT 40G, DT 42G, DA 44G or DA 47G are used. As these pyrometers have very long temperature ranges the same model can be used in the different temperature zones. Caused by the high ambient temperatures in these zones the pyrometers will be mounted with a water cooling jacket and an air purge unit. This guarantees a long maintenance free operation.

Measure solid float glass at lower temperatures

In zone 5 (exit of lehr, cutting zone) the solid glass has to be measured at lower temperatures. For this reason the pyrometer models PYROSPOT DT 40L, DT 42L, DT 44L and DT 47L are used. As also the ambient temperature is lower only a solid adjustable mounting angle for easy alignment and strong mounting of the pyrometers and an air purge unit is required to keep the lens clean of contamination for a long term maintenance free operation.

All information at a glance:

- Temperature monitoring in the industrial float glass production with digital DIAS PYROSPOT pyrometers

- Overview: DIAS PYROSPOT pyrometer series

- DIAS PYROSPOT 3x – Fiber optic pyrometers specifically designed for the temperature measurement on glass surfaces

- DIAS pyrometer series PYROSPOT 40 – Universal USB pyrometers

- DIAS pyrometer series PYROSPOT 42 – Pyrometers for first-time users

- DIAS pyrometer series PYROSPOT 44 – Bus compatible pyrometers using Modbus RTU data protocol

- DIAS pyrometer series PYROSPOT 47 – Compact pyrometers with Ethernet interface