The development of modern plant protection machinery is governed by ever-increasing environmental protection awareness and growing demand for high-quality products. This prompted Agromehanika to develop a new family of mist blowers, AGP 300-500 EN, which comply with the most rigorous standards and at the same time facilitate the entire plant protection process.

The development of modern plant protection machinery is governed by ever-increasing environmental protection awareness and growing demand for high-quality products. This prompted Agromehanika to develop a new family of mist blowers, AGP 300-500 EN, which comply with the most rigorous standards and at the same time facilitate the entire plant protection process.

A robust frame of the sprayer made from high-quality steel ensures a long service life.

Its structural design ensures a short barycentre distance between the tractor and machine, a well-stirred

spraying agent mixture, complete drainage of the tank and easy cleaning process. A modern powder coating method provides an effective protection of the frame.

A robust frame of the sprayer made from high-quality steel ensures a long service life.

Its structural design ensures a short barycentre distance between the tractor and machine, a well-stirred

spraying agent mixture, complete drainage of the tank and easy cleaning process. A modern powder coating method provides an effective protection of the frame.

Tanks with a capacity of 300, 400 and 500 l.

Modern design of the tank with rounded edges, smooth interior walls and

inclined bottom ensures complete drainage and efficient cleaning.

The tank is made from chemically resistant polyethylene. It features a large lid with a strainer mounted at the top of the tank to facilitate filling operations. The tank includes an engraved litre scale for easier reading of the quantity of the chemical agent.

The capacity of the tank is 20-50 l.

It is intended for washing the main tank and other elements when spraying is finished or interrupted.

The capacity of the tank is 12.5 l.

It is designed for washing your hands after handling spraying agents.

The medium-pressure piston diaphragm pump Agromehanika BM 65/30 P is suitable for pumping spraying agents and liquid fertilizers and is designed for spraying and mixing of chemical solutions in the tank.

It is manufactured from factory tested materials. Its 3-year warranty offers an additional quality guarantee.

The medium-pressure piston diaphragm pump Agromehanika BM 65/30 P is suitable for pumping spraying agents and liquid fertilizers and is designed for spraying and mixing of chemical solutions in the tank.

It is manufactured from factory tested materials. Its 3-year warranty offers an additional quality guarantee.

It mixes the spraying agent and prevents the build-up of chemical residues on the bottom of the tank. Mist blowers are equipped with two mixing nozzles.

The nozzle is actuated by a directional control valve mounted on the pump. It is installed in the bottom section of the tank. The mixing nozzle is supplied directly by the pump.

Proper distribution of the spraying agent on the plants is only possible if the air speed and fan capacity are both adjusted according to the size and vegetation period of crops. If the air speed is to high, it causes the spray droplets to drift excessively, which means that the spraying agent is lost. On the other hand, if the fan speed is too low, the crops may not be sufficiently protected.

All Agromehanika mist blowers are fitted with adjustable fans to enable the adjustment of air speed and flow volume.

Proper distribution of the spraying agent on the plants is only possible if the air speed and fan capacity are both adjusted according to the size and vegetation period of crops. If the air speed is to high, it causes the spray droplets to drift excessively, which means that the spraying agent is lost. On the other hand, if the fan speed is too low, the crops may not be sufficiently protected.

All Agromehanika mist blowers are fitted with adjustable fans to enable the adjustment of air speed and flow volume.

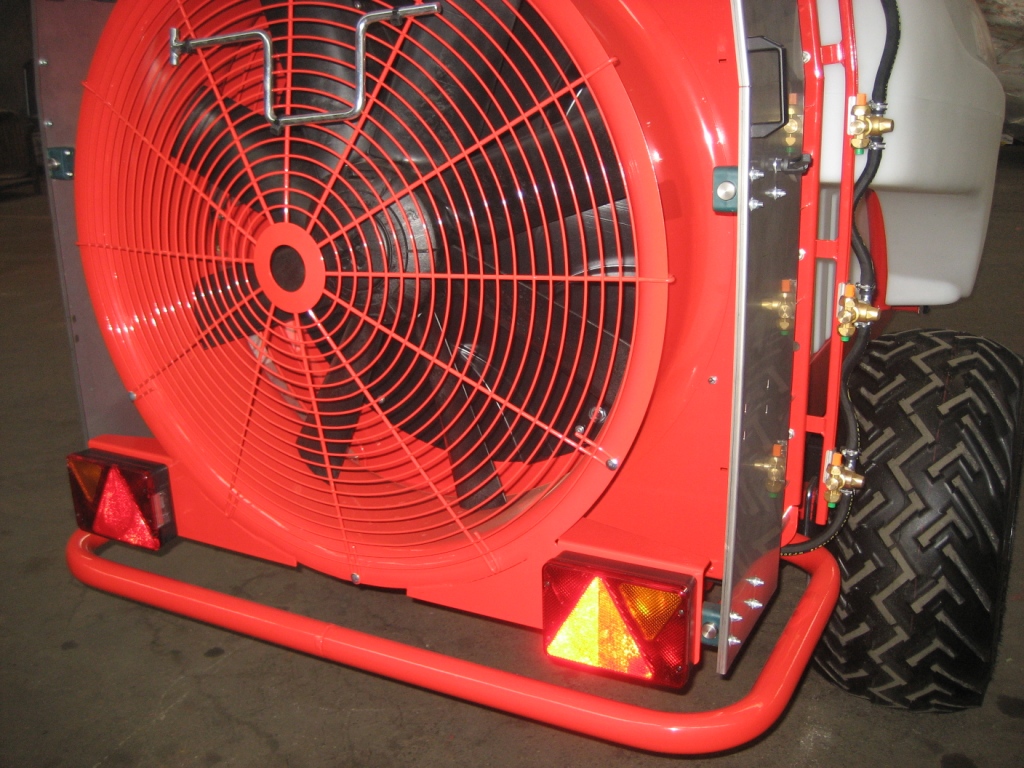

The blower was designed to produce a quality air flow to transport the spray droplets to the plant leaves. Effective spraying depends on the quality of air flow. All blower versions are equipped with a metal casing with a double layer of powder coating.

The main advantage of blowers with an air deflector lies in a more even distribution of air to the left and to the right side of spraying and over the entire height of the orchard.

The use of deflectors increases the quality of spraying and reduces the consumption of spray per hectare.

All deflectors are coated with a double layer of powder coating.

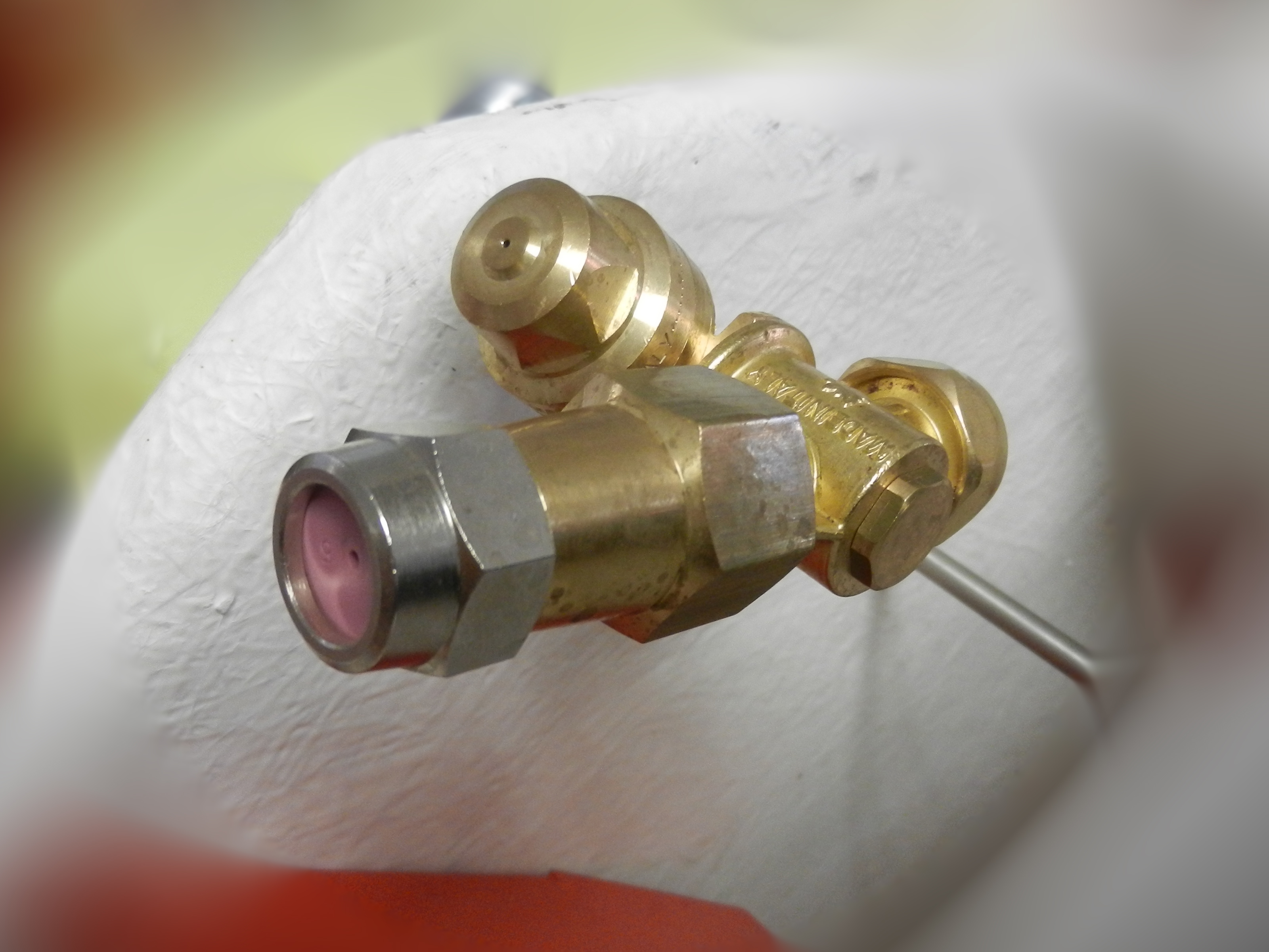

As standard, the mist blowers are fitted with double diaphragm nozzle holders and various ceramic inserts by a renowned manufacturer Lechler. An anti-drip valve is provided to prevent the leakage of liquids.

Double diaphragm nozzle holders provide for a quick selection of nozzles when spraying different crops.

Individual nozzles can be opened or closed with a 90-degree turn.

The M170 regulator is installed next to the operator's seat to ensure easy operation of the sprayer. The regulator allows remote opening and closing of the left and right spraying section as well as pressure adjustment. A manometer is mounted on the regulator to facilitate pressure readings.

Remote control is provided by the robust high-pressure regulator M170. It can be used for an operating pressure range up to 50 bar and pumps with a maximum flow rate of 150 l/min.

The M170 regulator is installed next to the operator's seat to ensure easy operation of the sprayer. The regulator allows remote opening and closing of the left and right spraying section as well as pressure adjustment. A manometer is mounted on the regulator to facilitate pressure readings.

Remote control is provided by the robust high-pressure regulator M170. It can be used for an operating pressure range up to 50 bar and pumps with a maximum flow rate of 150 l/min.

The PR8 high-pressure regulator is a state-of-the-art electric regulator with remote control. It is controlled from the tractor cab using a control panel.

The PR8 regulator is distinguished by:

Agromehanika mist blowers feature two types of electric regulators:

Users with particularly high requirements will be able to seize all the benefits provided by the spraying computer AGtronik M1. Offering state-of-the art features, this advanced spraying computer system for sprayers is based on 25 years of experience in development of spraying computers. AGtronik M1 features a large screen enabling simultaneous view of all important functions. Key features of AGtronik M1:

Partial cleaning of the mist blower does not affect the spray content in the main tank. Such cleaning is very useful if spraying is interrupted for various reasons (lack of time, weather conditions etc.).

Partial cleaning includes cleaning the suction filter, the pump, the pressure regulator and nozzles. The sprayer can be easily adjusted for partial cleaning. Clean water is pumped from the rinsing tank by means of a pump. Cleaning the mist blower after each use prolongs its service life and improves spraying results.

Partial cleaning of the mist blower does not affect the spray content in the main tank. Such cleaning is very useful if spraying is interrupted for various reasons (lack of time, weather conditions etc.).

Partial cleaning includes cleaning the suction filter, the pump, the pressure regulator and nozzles. The sprayer can be easily adjusted for partial cleaning. Clean water is pumped from the rinsing tank by means of a pump. Cleaning the mist blower after each use prolongs its service life and improves spraying results.

The mist blower should be fully cleaned after each spraying. This contributes to cost-effective spraying and environmental protection.

Such cleaning removes all spray residues from the sprayer. Full cleaning includes the cleaning of all interior parts of the mist blower, consisting of the main tank, the suction filter, the pump, the pressure regulator and the nozzles. The mist blower can be easily adjusted for partial cleaning. Cleaning the mist blower after each use prolongs its service life and improves spraying results.

The suction filter is used for spray filtration. In addition, it also removes larger particles from the spray that could cause problems during spraying.

The suction filter is installed between the main tank and the pump. It is recommended to clean the suction filter before each filling of the main tank.

The pressure filter provides additional filtration of the spray before it enters the nozzles and allows uninterrupted spraying.

It is located on the pressure regulator of the mist blower. The pressure filter should be thoroughly cleaned after spraying.

The nozzle is designed for cleaning the interior surface of the main tank after spraying. It further removes any spray residues, thus contributing to cost-effective spraying and environmental protection.

The nozzle is installed inside the main tank. It is actuated by a directional control valve mounted on the regulator. Clean water is pumped from the rinsing tank.

This system consists of four spraying sections (two on the left and two on the right side of the deflector). Each section can be controlled using an electronic or electric regulator.

This system enables spraying fruit trees or shrubs at different levels.

The cleaner contributes to a more efficient use of the spray and helps protect the environment. The chemical residues in the container and the strainer are washed into the main tank using valves.

Both the container and the strainer cleaner can be purchased individually, as per the client’s requirements.

Signal lights increase safety in road transport. They are attached to the rear part of the mist blower.

Long range nozzles are recommended for spraying areas with tall plants.

Normally, two nozzles are installed on the top of the deflector.

The suction basket with a (5m) hose is designed for pumping water from ponds, streams and wells.

Water is pumped into the main tank through the filter, the pump and the regulator.

The suction basket is easily attached using the bayonet fitting under the main tank.

We recommend cleaning the exterior of the machine after each spraying. Removing the residues of the aggressive chemicals ensures proper operation of the machine and prevents corrosion of metal parts.

Cleaning should be performed on a suitable place. The kit includes a spraying lance and a hose with a connection fitting. It is attached to one of the regulator valves.