The new distribution centre employs fully automated material handling equipment based around a central conveyor designed and installed by Amsort Sp company. The client required a compact, quiet, autonomous and modular solution able to evolve with the growing needs of the company.

Our solution

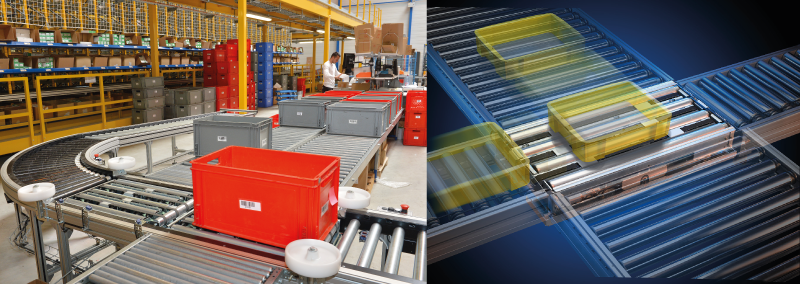

The conveyor solution is driven by runon-demand Power Moller® 24v DC Motorised Drive Rollers (MDR) from Itoh Denki. These drive rollers are incorporated within drive zones which are controlled by Itoh Denki’s HB510 circuit board with unique Zero Pressure Accumulation logic. This technology allows the conveyor to transport cartons and totes, zone-by-zone between the storage areas, order picking and despatch locations. The HB510 is configurable to allow adjustment of roller speed, transfer configuration and error monitoring. The zones automatically start and stop according to the demand for product and allows fast picking and sorting of orders as they are retrieved from stock.

To achieve the required design aesthetic Amsort company manufactured conveyor modules constructed from aluminium profiles which are scalable and very flexible to allow for remodelling and expansion of the system. The drive rollers and zone sensors are fully integrated within the profile along with the cabling. This means that the conveyor has very clean lines without mechanical protrusions usually associated with traditional drives or mechanical support legs.

A special feature of the conveyor system is a series of sortation lines that rely on the unique F-RAT (Flat Right Angle Transfer) also by Itoh Denki. The F-RAT uses only 24v power to transfer products quickly and smoothly in the correct sequence. Another unique characteristic of the system is its compact design – only 15cm in height, the self-contained module, including the drives is fully integrated within the conveyor line. This compact solution is characterized by high performance with very low power consumption and product transfer can be made in any of four directions. Cartons are not raised or lowered during transfer thus ensuring efficient and vibration-free transfer. This also means that the F-RAT can be moved or added to any other position without tedious frame modifications.

Sorted products are transported through the appropriate F-RAT to one of five packing stations, where goods are inspected, packaged, addressed and placed on a pallet ready for shipping.

About Itoh Denki

Founded in 1946 in Japan, Itoh Denki introduced the first 24v DC brushless motor roller technology in 1989. Through ongoing research and development this technology has culminated in the industry standard Power Moller® range of motorised rollers.

From our head office and ISO9001 certified manufacturing plant in Kasai – Japan, Itoh Denki distributes Power Moller® globally via dedicated business operations in America, Asia, Europe and Japan. R&D and Production Engineering functions are exclusively managed in-house to ensure that Itoh Denki remains a brand of reliable quality and innovative technology.

Power Moller® 24v drives and controls can offer up to 60% energy savings compared with traditional industrial conveyor drives. These savings and our ISO14001 certified environmental management policy ensures Power Moller® technology will remain a vital component in future automated material handling projects.

About Euro Negoce

An Independent distributor of electric equipment since 1996, Euro-Négoce sells products from network of European suppliers and is able to offer the best prices on the market. They stock thousands of products & manage daily imports with their own computerized inventory systems to provide immediately delivery to customers all over Europe. Well established transport partnerships ensure orders can be monitored and tracked to guarantee prompt delivery. Their powerful product management system takes care of multi-rate tariff purchases, inventory control and invoicing. This unique in-house software solution helps to drive and coordinate all of the company’s services.

About Amsort

AMSORT is a Polish company established in 1993. They provide complete internal transportation and sorting systems. Amsort has completed several large projects for blue-chip manufacturing and logistic companies throughout Poland and beyond: Portugal, France, Czech Republic and as far as China. They combine their own technology with proven solutions from Europe’s leading manufacturers including ItohDenki, Ammeraal Beltech, Uni-chains, Mink Bürsten czy Anderstorps Transportband. and also provide a full after-sales maintenance service.