SR2010

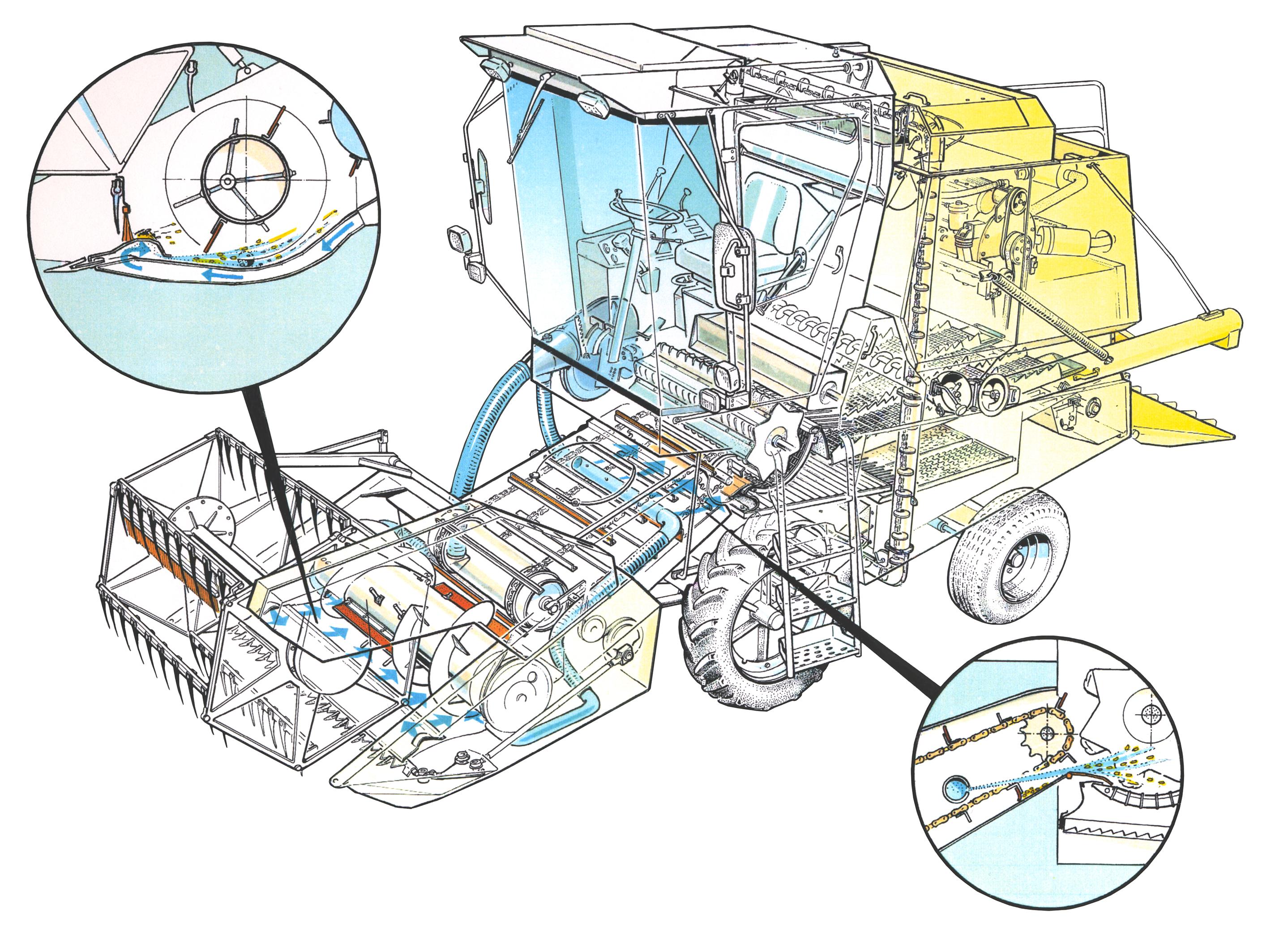

The Sampo Rosenlew 2010 is specially designed for experimental fields and seed breeding.

Watch video

Watch video

The Sampo Rosenlew 2010 is specially designed for experimental fields and seed breeding. With this in mind Sampo Rosenlew’s engineers have perfected every detail in the SR 2010 combine. The single most important factor in plot harvestingis to ensure that all the grains come from the intended plot.

Cutting header

1,5m, 2,0m, 2,3m

Grain tank

1700 l

Engine

73 hp VM Motori engine

Air conditioning

No

Threshing cylinder

7-rasp bar HD sealed

Straw walkers

3 pcs

Straw chopper

available

Front tires

12.4R24

Rear tires

11.5-15

Cab

Practical, wide and basic

The special made cab is wide and provides a convenient working environment for two operators. From the cab you can make all the basic adjustments for harvesting. You have good visibility around the combine the tinted glasses of the cab. Air conditioning is available as an option, but heater is standard.

Cutting table

Special designed header

The header cuts cleanly and evenly. The SR 2010 uses the CHAC System (Constant High Volume Air Stream Cleaning) to provide high cleanliness on the table to ensure clean samples. The electrical and hydraulic adjustments conveniently operated from the cab make threshing versatile and accurate. The special made brushes on the pick-up reel combined with an effective airflow system results in supreme cleanliness throughout the whole threshing mechanism. Every detail has been taken into consideration in the design to provide uniform and reliable grain samples. Header sizes are available, 1,5 m, 2,0 m or 2,3m

Threshing mechanism

Threshing system designed for plot harvesting

The heavy duty closed threshing drum and large wrapping angle. The electrically adjustable threshing drum is designed to outperform itself even in the hardest threshing conditions. This cylinder manage in the thoughts crops and conditions. The special made good grain elevator has a sealed construction throughout the whole elevator area. This prevents grain overflow and ensures clean, uniform samples. The elevator chain has round plastic, paddles which fits perfectly to the “pipeline”.

Sieve and straw walker areas

Double sieve system available

The SR 2010 has three turn over walkers and a single sieve system. For additional efficiency an optional double sieve system can be fitted on the combine. The double sieve system makes the separation area bigger and delivers the combine with a proper return system. A re-threshing system like on the conventional Sampo combines. The double sieve system, includes 5 round hole sieves, 5,8,10,12 and 16 mm.

Grain tank and grain chopper

BIg sizes tank as standard

The SR2010 has a big grain tank with 1700 l. The bottom auger of the tank can be removed for cleaning. The unloading auger has two different unloading heights, 2,75 and 3,0 m The 2010 can be equipped with a straw chopper also. The chopper can be taken out of use, for long straw, by sliding it. The chopper is an optional equipment.

Transmission and engine

Big diameter tires

The standard tires on the SR2010 are big in diameter and the ground clearance is good. 12.4R24 are the standard size, but you can get 360/70R24 as an option. The rear tires are 11.5 15. The final drives and gearbox are robustly built. The have been used in other Sampo conventional combines in the past. Transmission is hydrostatic and can be equipped with a 4WD. The engine is a 4 cylinder 73 hp VM Motori.

Accessories

Many features available

SR2010 can be equipped with maize equipment from the factory. Maize headers are available from different manufacturers. Also rape extension for the cereal header are available. On the 2010 can be fitted weighing systems also. The Coleman system or Harvestmaster Grain Cage.