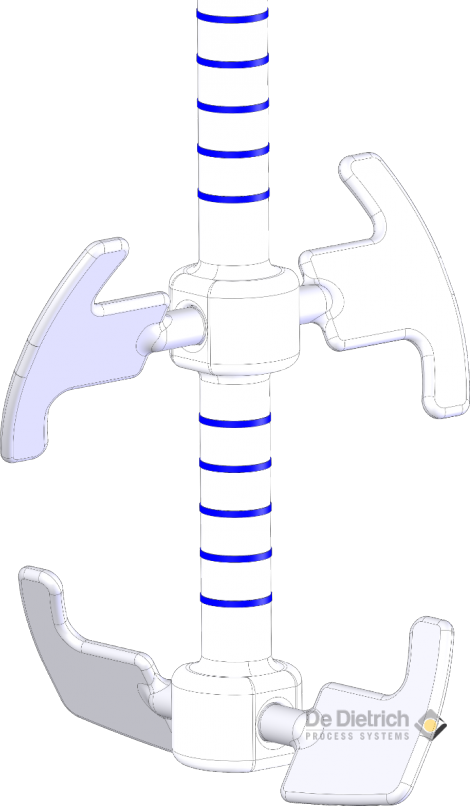

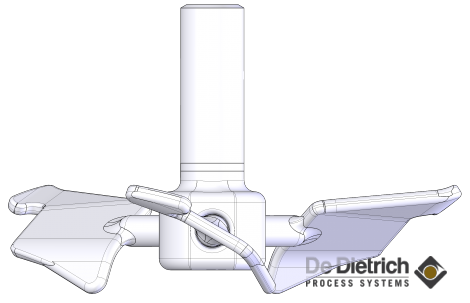

The GlasLock® System

This system has been especially designed for BE reactors where the main opening is the manhole, but is usable for all kinds of reactors.

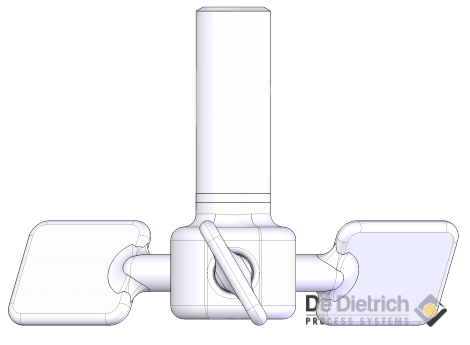

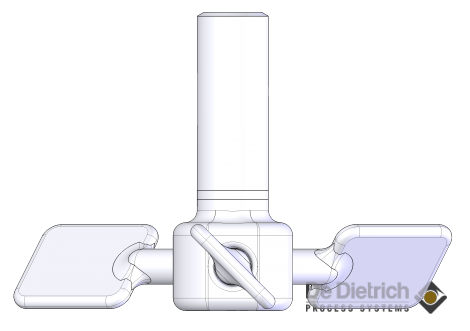

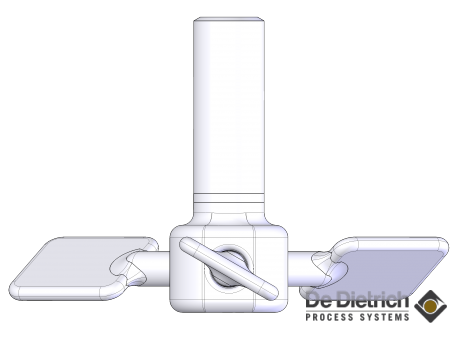

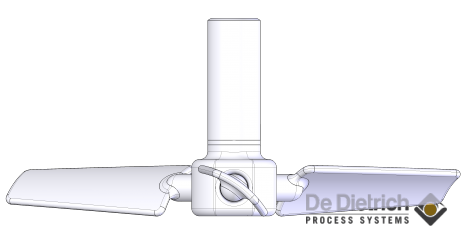

Fitting and dismantling are carried out laterally, making it possible to work on the scraping agitators without completely dismantling them. With multi-tiered agitators, it is possible to modify just one stage independently of the others by leaving the agitator in place.

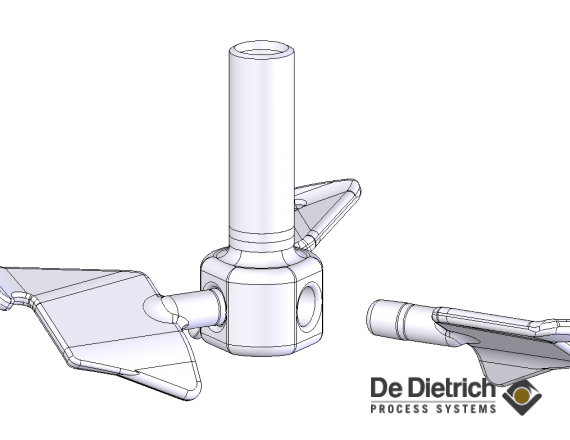

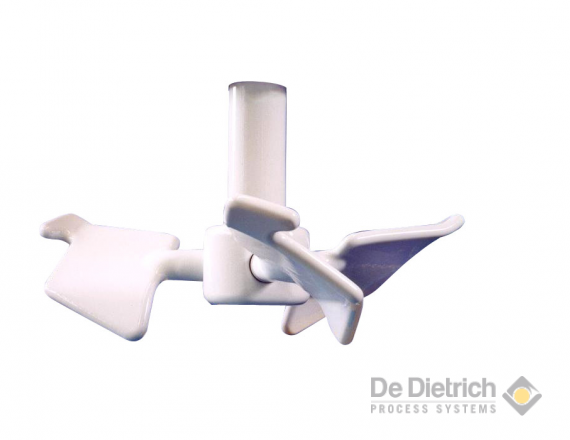

The assembly of a blade in its conical emplacement, both fully enamelled, is done using a manual tool according to a simple procedure. GlasLock uses a single hub offering greater flexibility by allowing all types of blade profiles to be fitted. This technology reduces the time needed to dismantle the drive, when this is required.

Our teams can define and install a blade profile according to your process and your agitation parameters. This technology makes it possible to fit several flights of blades to better suit the reaction.

Characteristics

GlasLock blades are lined with DD3009 glass for superior corrosion resistance. They are available in a variety of blade designs to meet various process requirements.

Advantages

- Multi process-system

- Individual dismantling of the blades

- Small agitated volume

- Easy maintenance

- Limited stock of blades

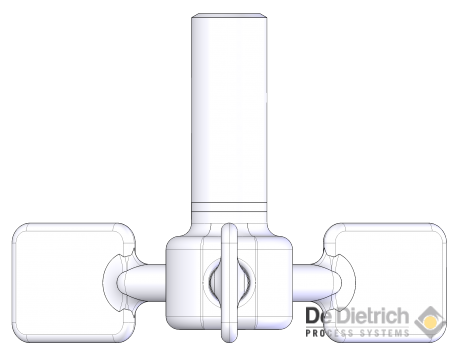

The agitation characteristics are different in function of the blades' angle and their design

Blade angle at 90°

- 100% radial flow

- Very important shear

- Applications: all dispersion process

Blade angle at 60°

(the most common used position)

- 2/3 radial - 1/3 axial flow

- Important shear

- Applications: homogenization, heat transfer, suspension

Blade angle at 45°

- 50% radial flow - 50% axial flow

- Medium shear

- Moderate agitation

- Pumping effect

- Applications: homogenization, suspension

Blade angle at 30°

- 1/3 radial - 2/3 axial flow

- Low shear

- Moderate agitation

- Pumping effect

- Applications: crystallization (fragile crystals)

The Hydrofoil blades

Improvement of the pumping effect, low power consumption

- Major axial flow

- Medium shear

- Moderate agitation

- Applications: suspension of particles

- Dissolution, crystallization (fragile crystals)

- Heat transfer

The Optifoil blades

- Run low volumes with high axial flow

- Facilitates the emptying of the reactor

- Do not damage fragile crystals

- Improved combination of Hydrofoil / Trapezoidal blades

- Improved suspension

- Strong flow close to the bottom

- Non agitated volume for 40m3 reactor: ±300 l

The Viscofoil blades

- Viscosity up to 120,000 cP

- Two kinds of blades Viscofoil (Bottom & Shell) designed to follow the profile of there actor angled at 45° to generate axial flow.