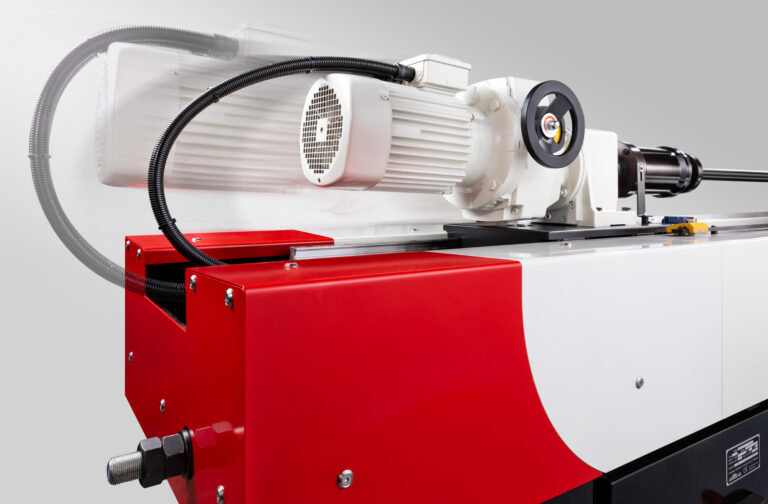

HTB Series

Small Production Tube Hone

The HTB-S series is the ideal system when flexibility for repair work and small production is required. The job shop system with the 3.5 kW spindle drive ensures maximum power up to diameter (ID) 550 mm with 400 cm³/h stock removal.

Details

Specifications and advantages

- Spindle motor

3.5 kW - Diameter range

25 – 550 mm - Stroke length

2’000 – 10‘000 mm

- Automatic bore geometry correction

- Fast setup

- Simple operation

- Excellent for repair & job-shop production

Tube Hones

Solutions for a large diameter range.

Performance & Benefits

HTC-x121

- Short setup and changeover time

- Automatic bore geometry correction

- Program memory for over 900 setups

- 100% process control with tool overload protection

- Operator-friendly Windows®-based monitoring system

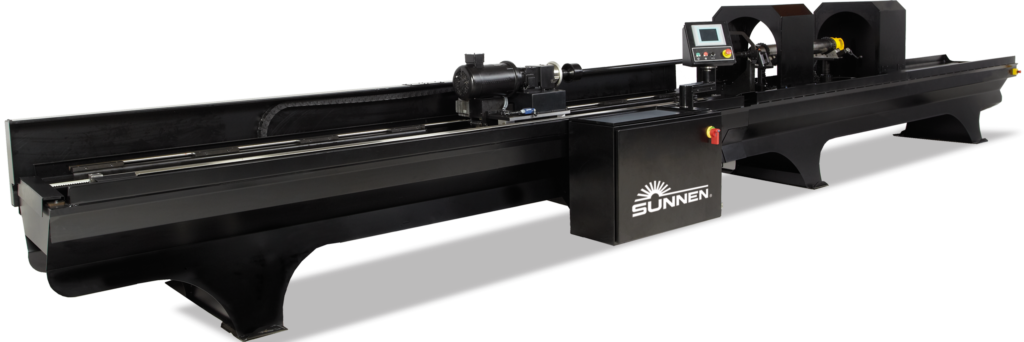

HTB Series

- Automatic bore geometry correction

- Fast setup

- Simple operation

- Excellent for repair & job-shop production

HTH Series

- Automatic bore geometry correction

- Fast setup

- Simple operation

- Excellent for production

HTC Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Fast setup

- Excellent for production

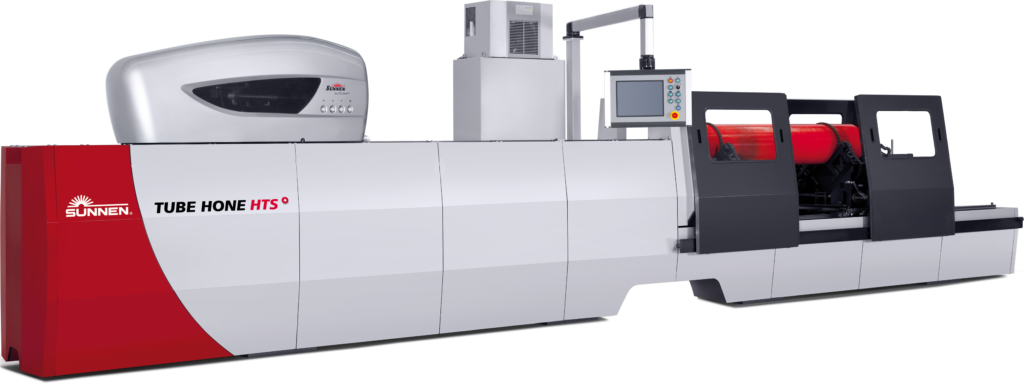

HTS Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

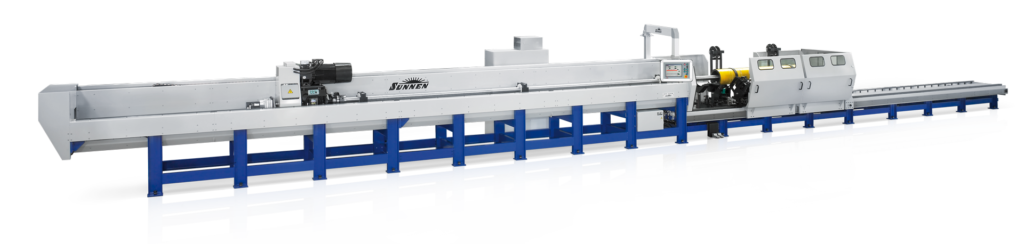

HTD Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

- High stock removal up to 2’500 cm3/h

HES Serie

- Large diameter range

- Automatic correction of roundness and parallelity

- Operator-friendly, Windows ®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

|

|

|

|

|

|

|