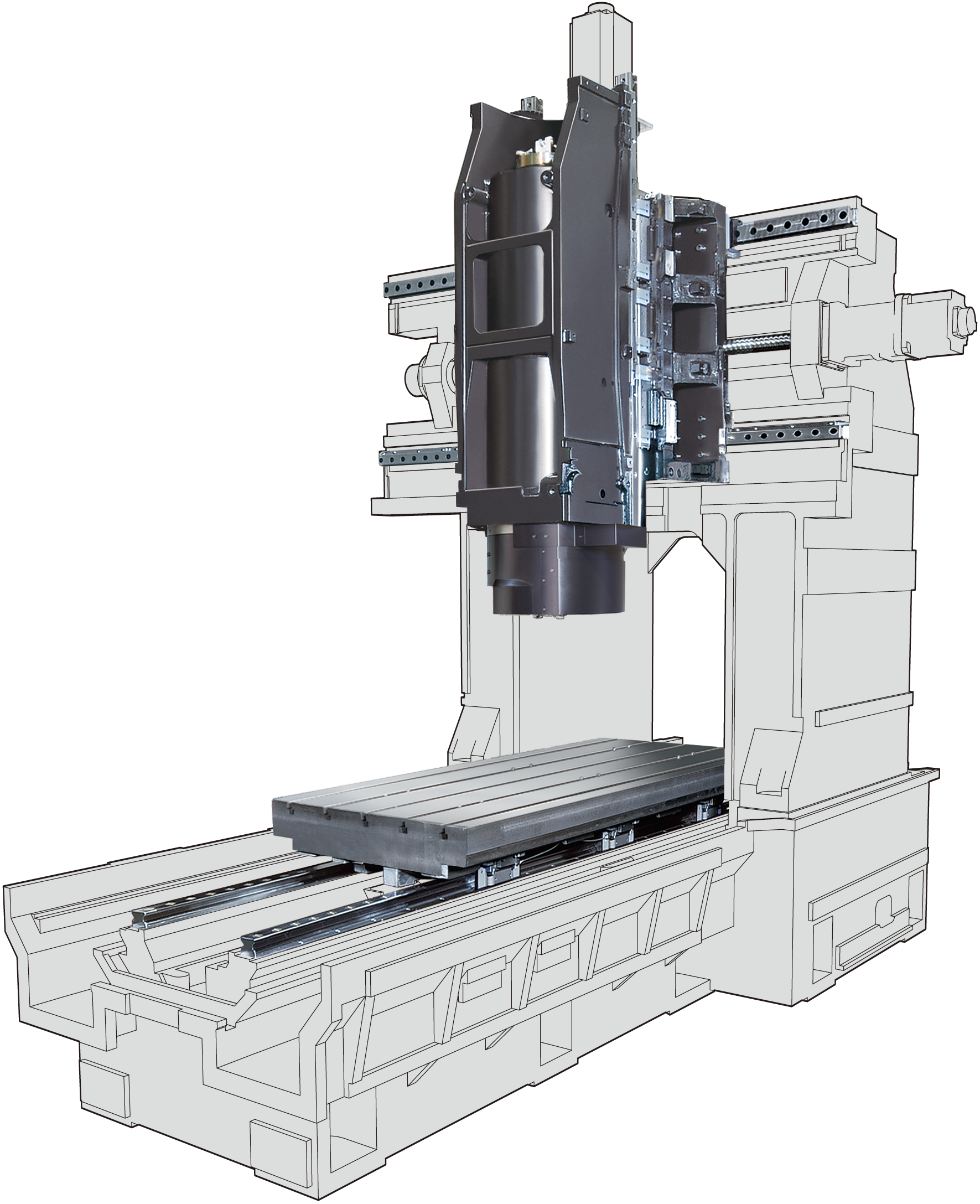

Double column vertical machining centers use a bridge-type construction which can be well suited to the machining of components where extended axes travels are required. Mazak’s range of double column machining centers provide high levels of rigidity and precision over extended periods of operation to deliver superior heavy-duty cutting performance for a wide variety of industries.

Example series: FJV

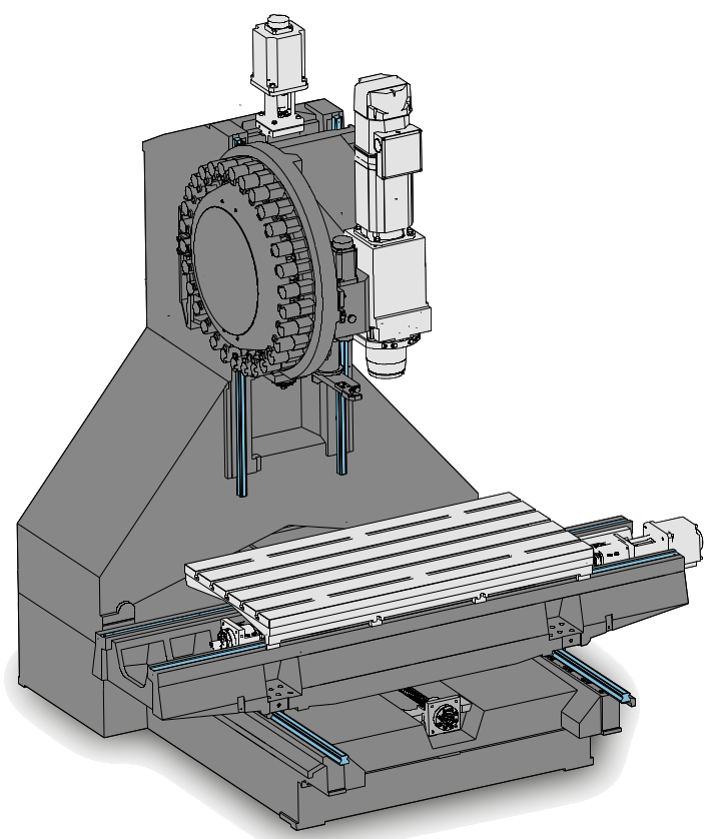

Vertical Machining Centers with C-frame construction offer 3 & 4 axes machining capability using a travelling table and vertical spindle. Mazak’s range of C-frame vertical machining centers are designed with cast iron construction and an A-frame supported column to offer superior accuracy and rigidity. Available in a range of generous table sizes, Mazak’s

Vertical Machining Centers with C-frame construction offer 3 & 4 axes machining capability using a travelling table and vertical spindle. Mazak’s range of C-frame vertical machining centers are designed with cast iron construction and an A-frame supported column to offer superior accuracy and rigidity. Available in a range of generous table sizes, Mazak’s