Horizontal Gear Hobbing Machines

K 300

- Module range: 0.5 / 4

- Workpiece dia., max.: 200 mm | 8 in

- Workpiece length, max.: 800 mm | 31.5 in

Gear hobbing how it should be

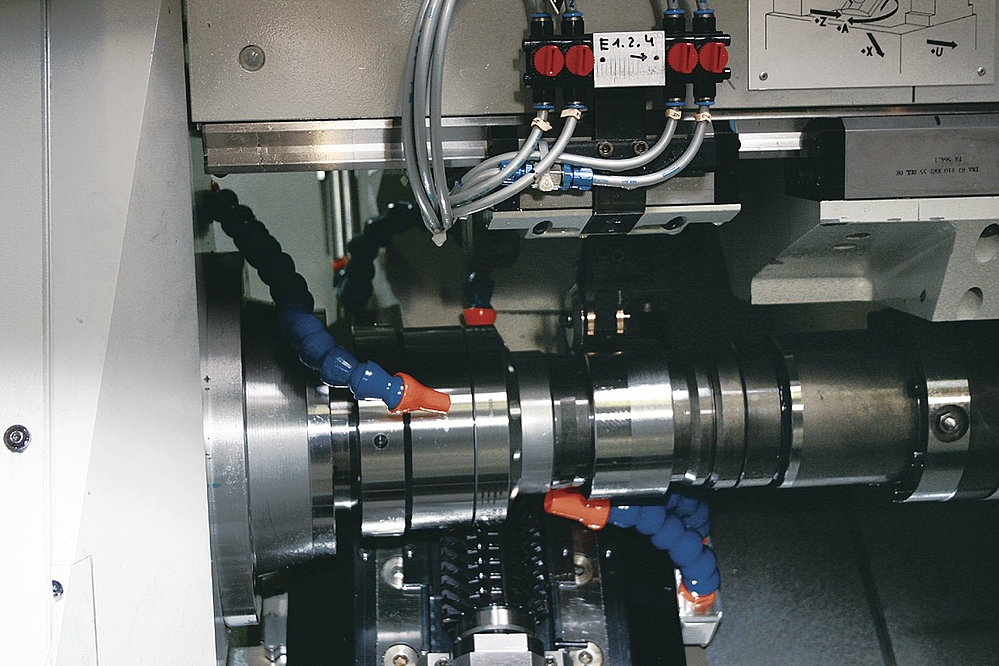

The high degree of precision achieved on the K 300 Gear Hobbing Machine, with its nine activated CNC axes is the result of a machine base in wet-mix aggregate, featuring motion guideways in all linear axes. The closed-loop frame construction of the CNC-Machine ensures highest possible rigidity of tailstock and work spindle, even under the greatest possible clamping and machining forces while gear hobbing.

Furthermore, the diagonal positioning of the milling head offers ideal chip flow conditions for both dry and wet machining.

Horizontal K 300 CNC-Machine for precise gear hobbing

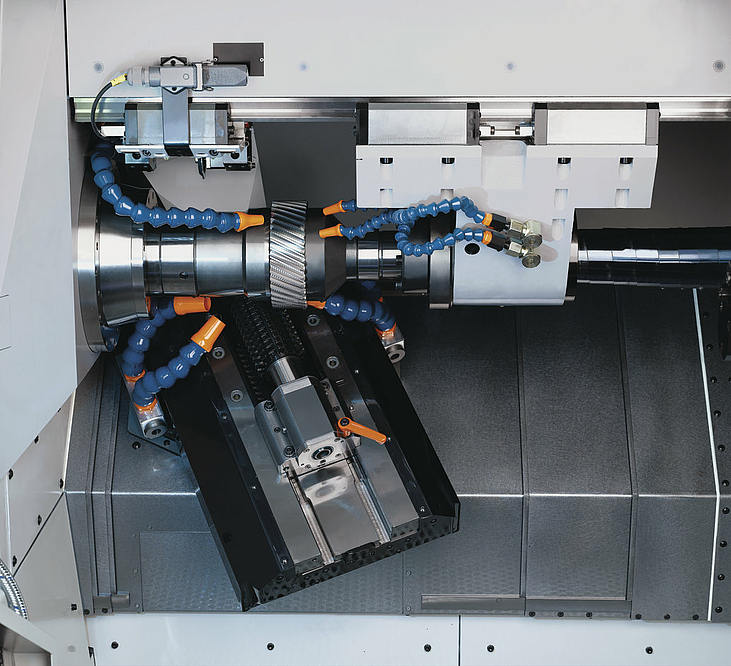

The EMAG Koepfer K 300 CNC-Machine employs a variety of gear cutting technologies: gear hobbing, soft and hard machining, skiving, high speed hobbing, radial hobbing, tangential hobbing, etc. This makes it possible to configure the machine to suit individual manufacturing requirements. And the ability to combine these technologies offers further rationalization potential. The main advantage is that the use of finish-hobbing technologies eliminates complete processes.

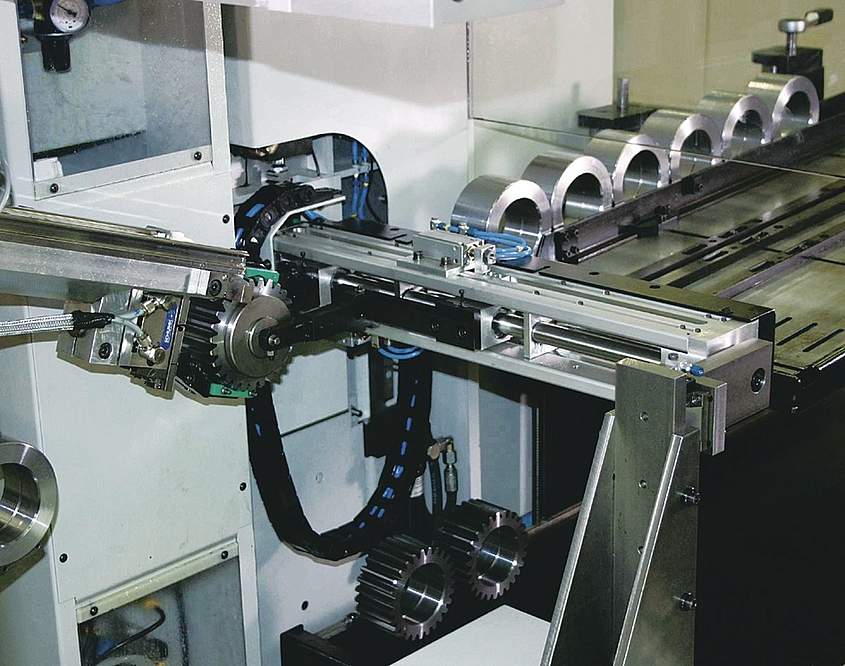

The question of automation solved

The KOEPFER CNC-Machine loading system, equipped with V-grippers, can hold workpieces up to 5 kg in weight, and forms the basis of the automation system. A number of blank and finished component magazines – such as chain magazines, oscillating conveyors, and workpiece storage systems – are available to cover a variety of components. A gravity-type loading rail with a conveyor belt for the unloading of components is the standard solution for this CNC-Machine.

The capacity of a universal, gravity-based magazine – and the autonomy of the CNC-Machine – can be increased with the use of multiple feeding rails. The triple distributor system can also be used as a twin or even a single feeder. The grippers are adjustable and can accommodate a multitude of workpiece lengths.

Advantages K 300

- Hob arbor

- Hydraulic precision collet to clamp shank hobs

- Deburring device (dampening device, sensor) available in single or double head configuration

- Oil mist suction system

- Suction system for dry hobbing

- Automatic orientation for skiving

- Software for special programs such as skip shifting of a damaged area on the hob, for positioning tasks, etc.

- Magazine loading systems for blanks or semi finished parts

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Industry 4.0

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

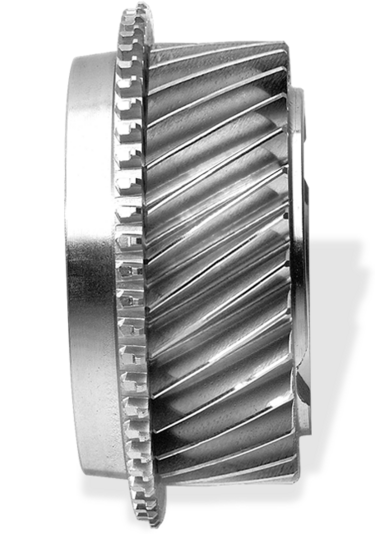

Flexible, highly productive, highly accurate - as a continuous gear production process, hobbing is indispensable in many industries, as it allows any…

Technical Data

Module range

0.5 / 4

Workpiece dia., max.

200 mm

8 in

Workpiece length, max.

800 mm

31.5 in

| Module range | 0.5 / 4 | |

| Workpiece dia., max. | mm in | 200 8 |

| Workpiece length, max. | mm in | 800 31.5 |

| Hobbing length, max. | mm in | 300 12 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact