Efficient picking

Increase the throughput of your picking process

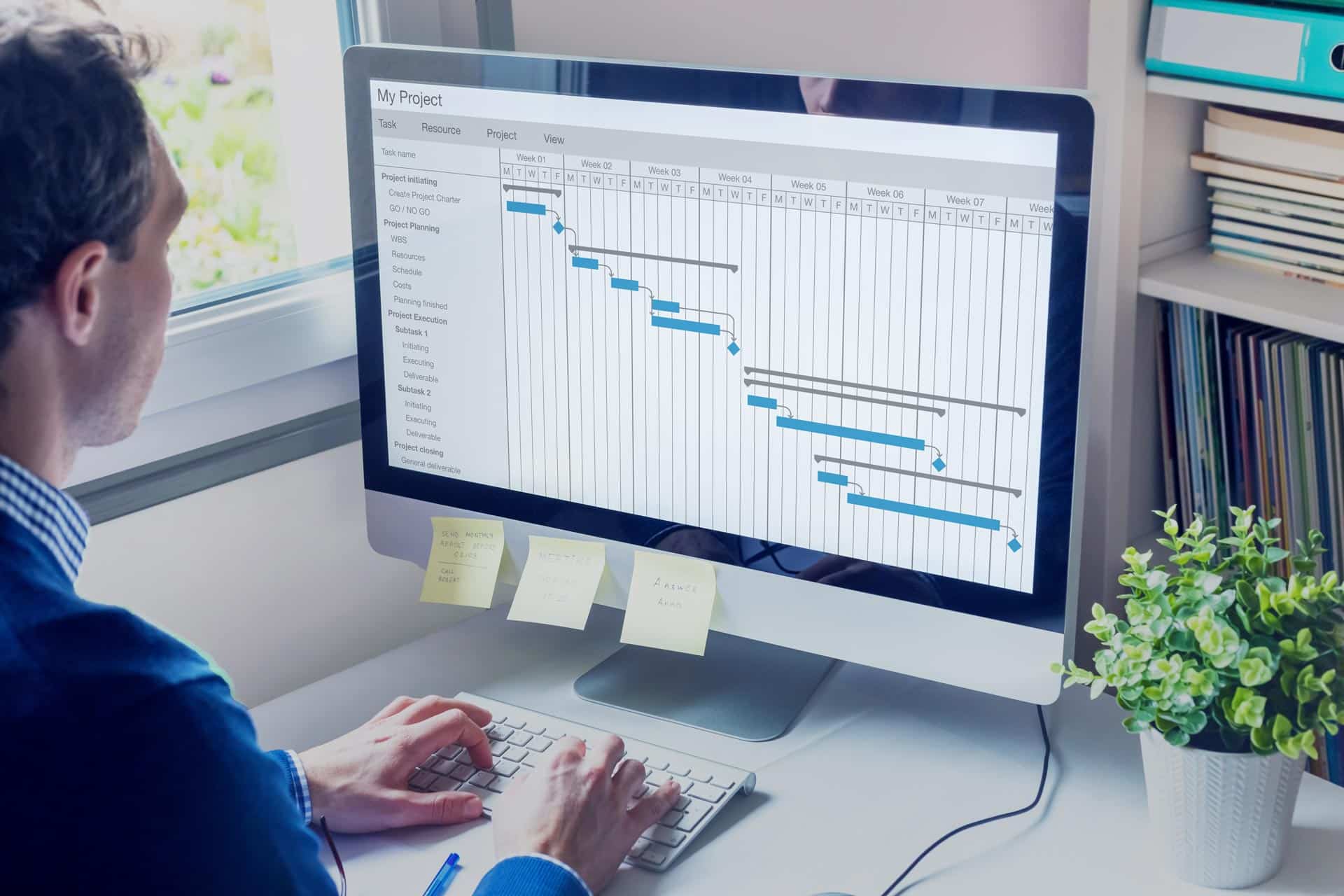

Every intralogistics infrastructure has its individual parameters. Technical, structural, and assortment criteria influence the entire picking process. To transform this process into a competitive pillar of your intralogistics, both stages of the picking process must be taken into account: First the planning, then its implementation. Modern calculation modules, so-called solvers, which are implemented in the warehouse management software, support you in the time and cost-efficient planning of the pick. During the realization, everything revolves around the optimal usability for the user. Therefore, TUP has designed the hybrid picking system.

Optimized working environment

How our hybrid picking system increases your throughput through user-friendliness

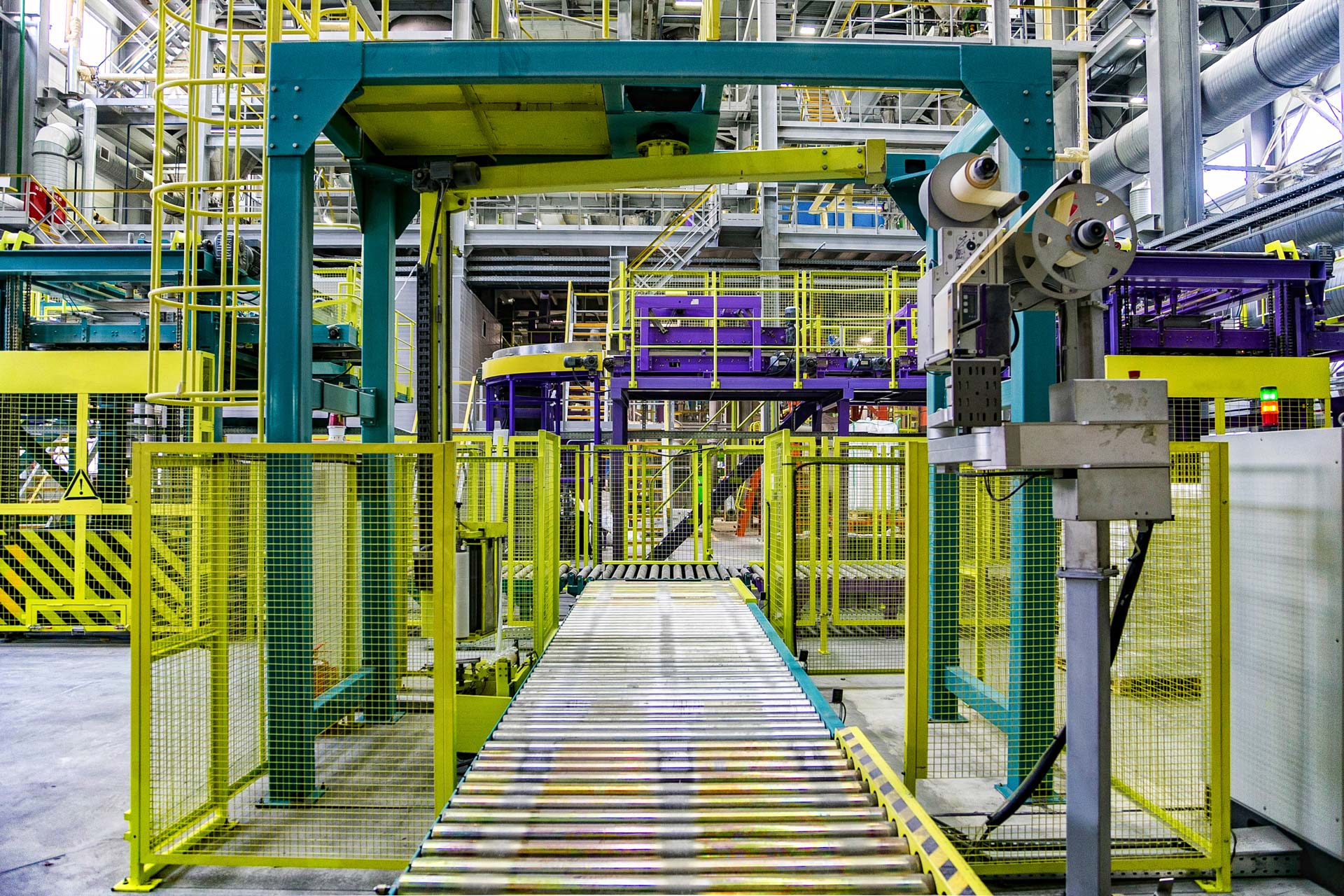

To ensure high flexibility, the hybrid concept relies on manual participation. The user is the central component in the workflow of the hybrid picking form and is supported in the best possible way – at all conceivable levels. Via the conveyor system, the system provides the picker in sequence with the pallets, thus minimizing distances and throughput times. In addition, the pallets are served vertically at an ergonomically correct gripping height to safeguard the personnel. The aim is to provide the assistance needed at any place and at any time. Experienced employees can move freely within the scope of their tasks due to the responsiveness of the workstations, new personnel does not have to be trained in a time-consuming manner, but is guided step by step by the system through the process.

Hybrid follows function

Advantages are appropriated, possible applications expanded

The idea of the hybrid system puts the process first. Instead of using ‘pure’ one of the numerous picking techniques, the integrated system extracts and combines helpful aspects. Pick-to-Light, Pick-by-Light, Pick-by-Scan – the hybrid approach expediently combines elements from different types of picking.

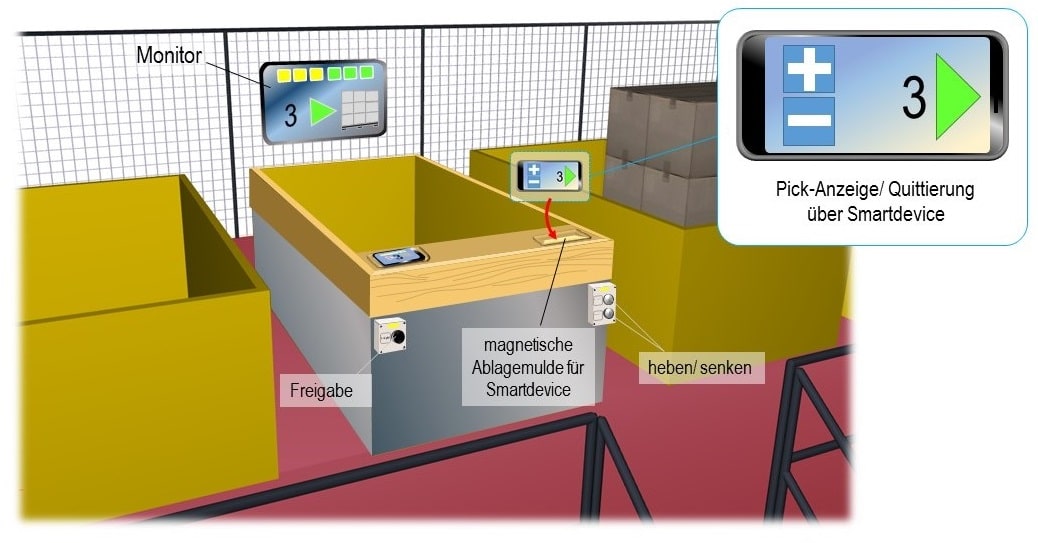

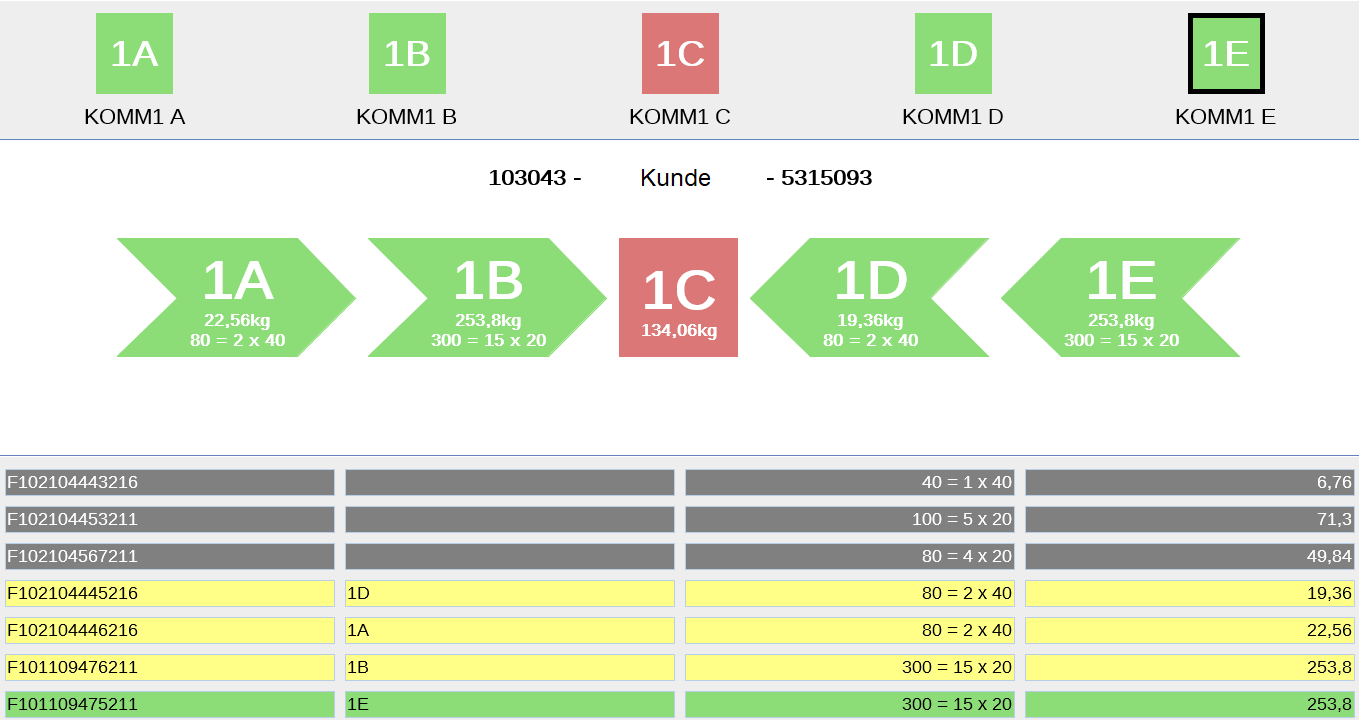

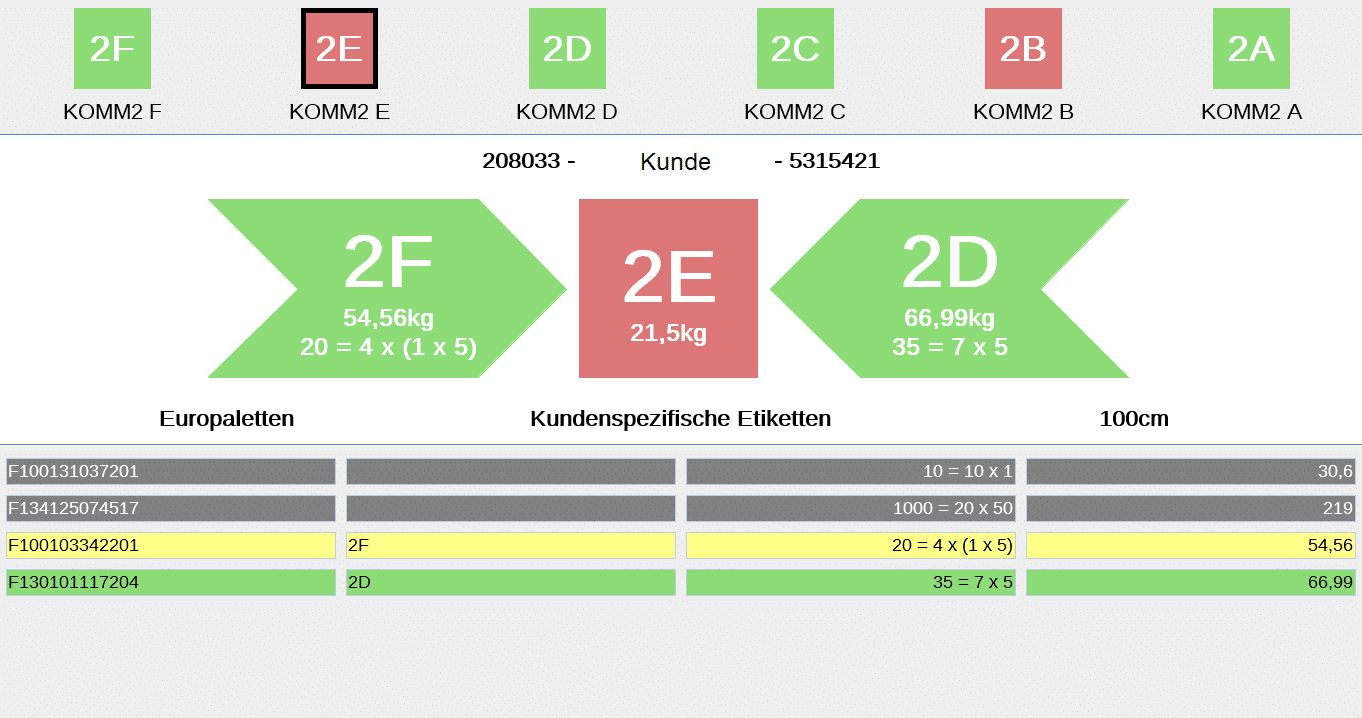

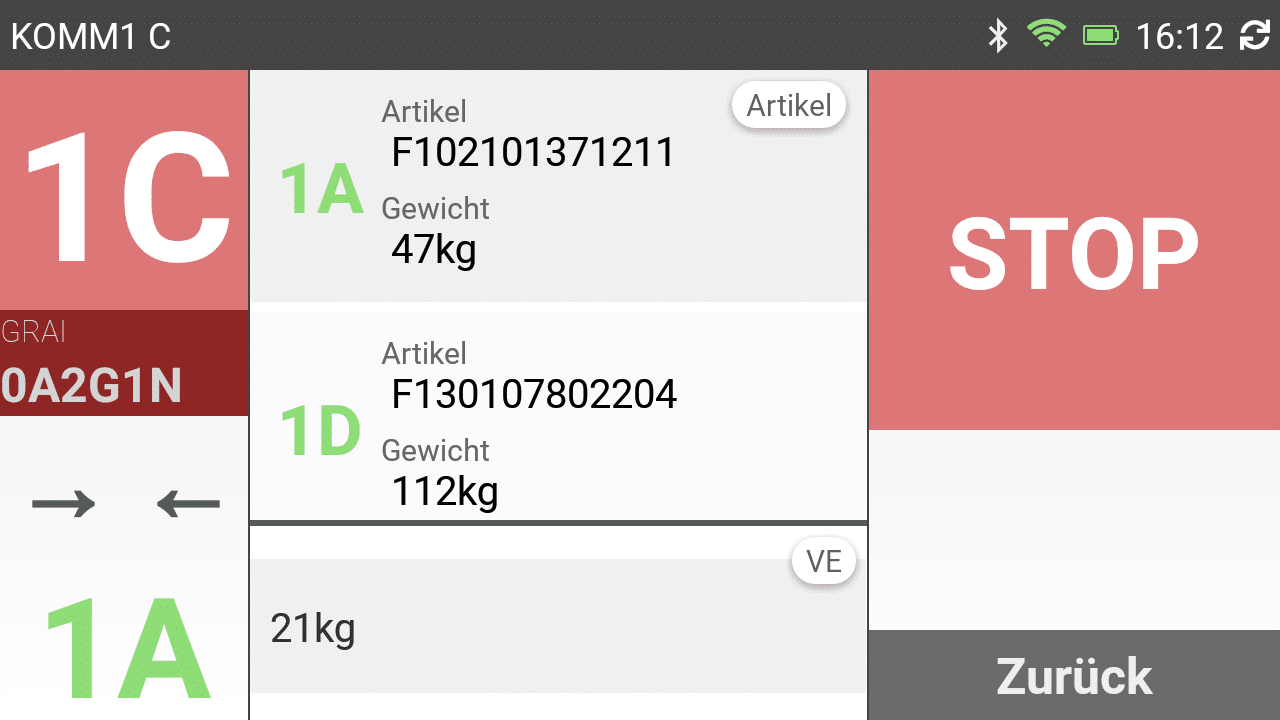

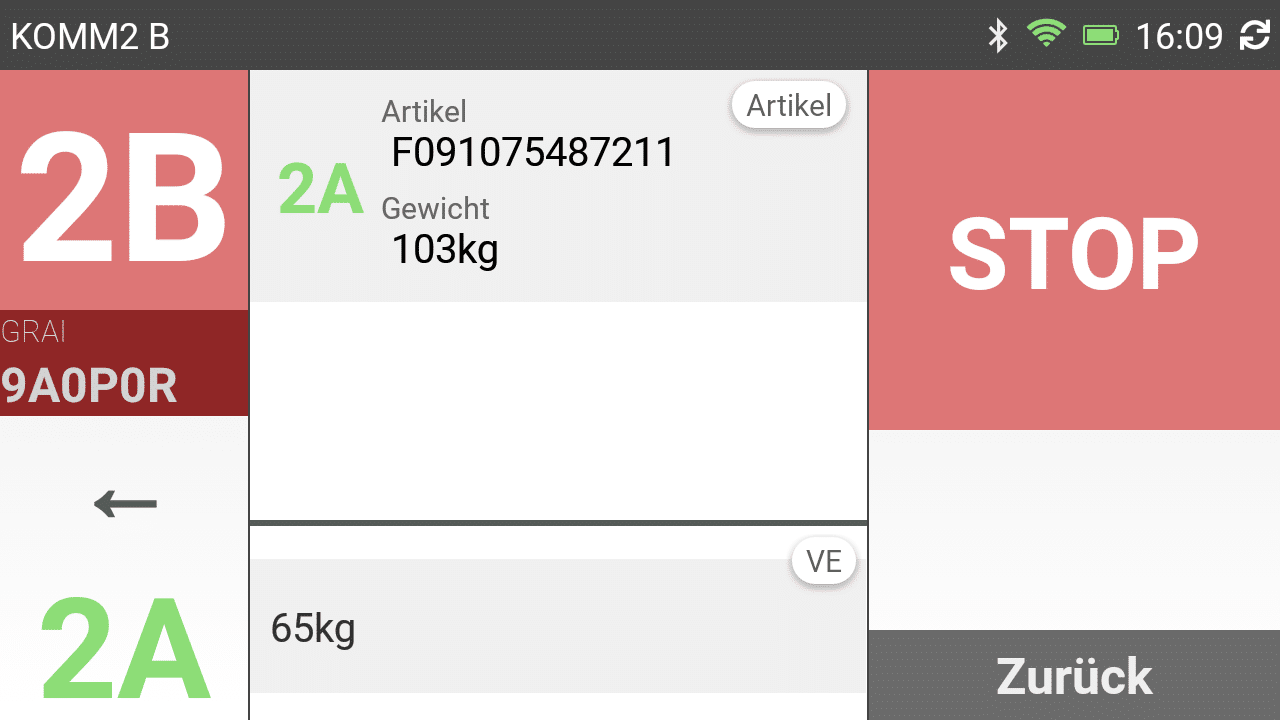

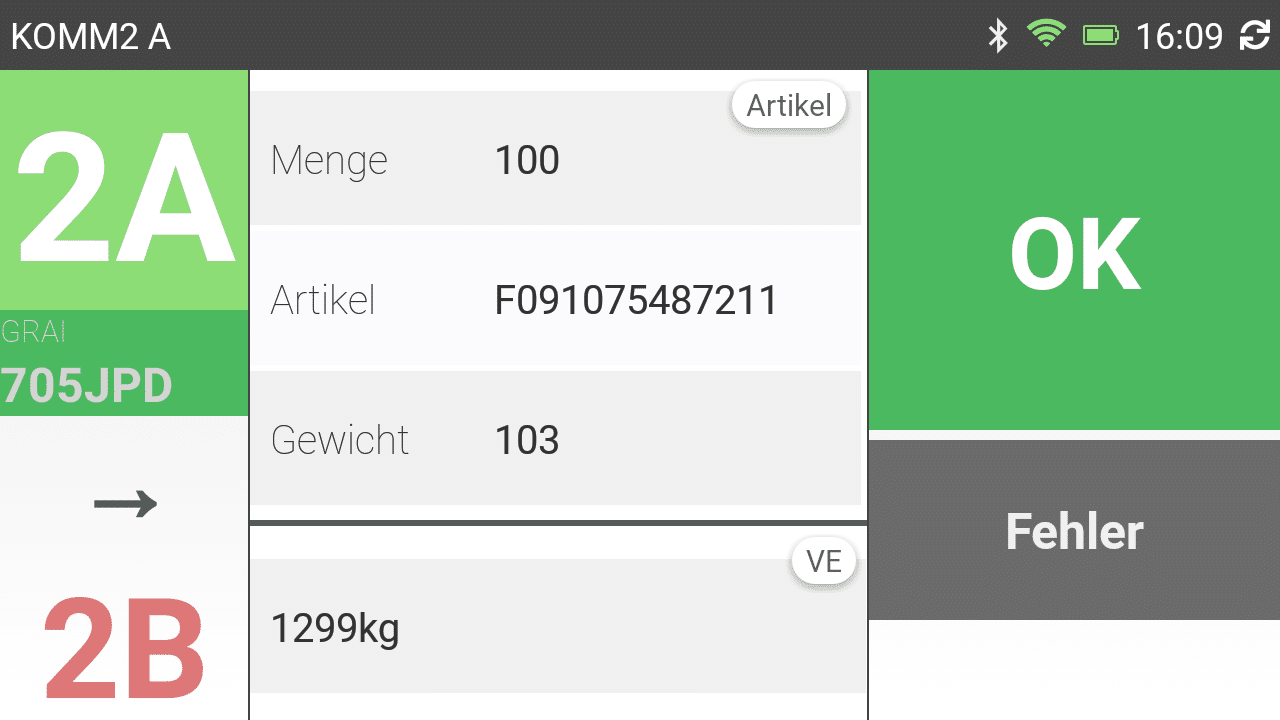

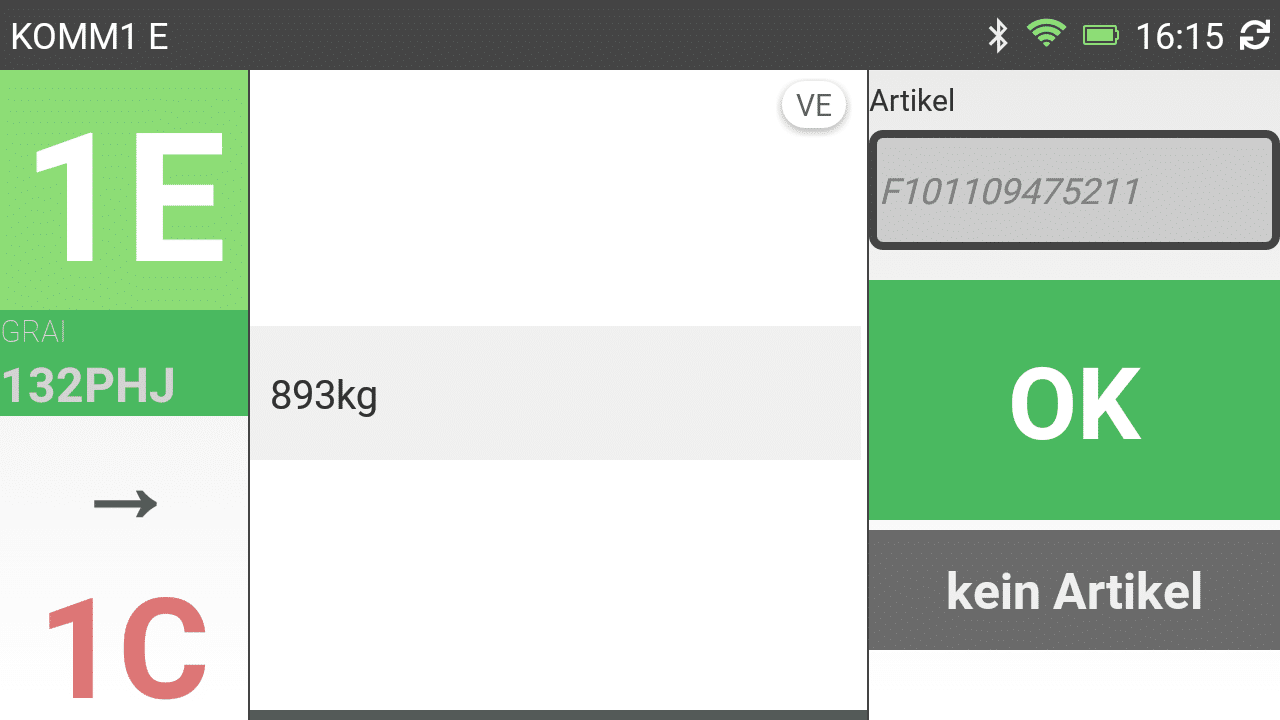

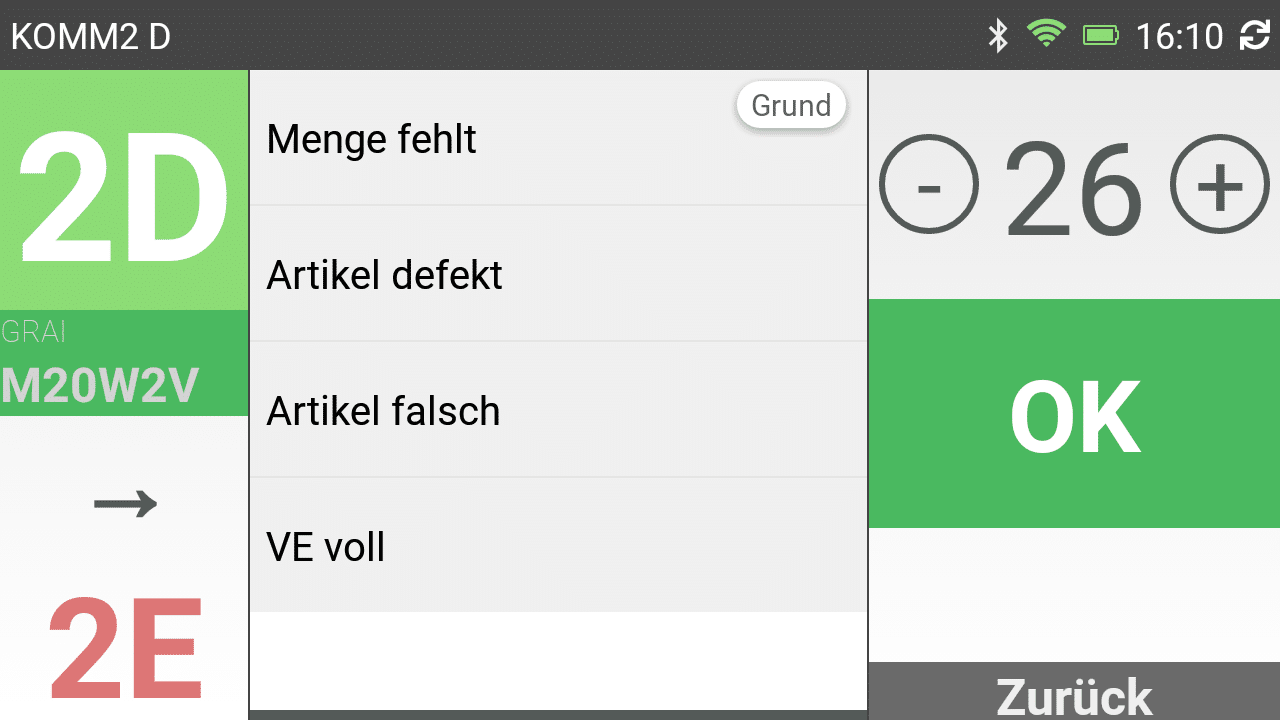

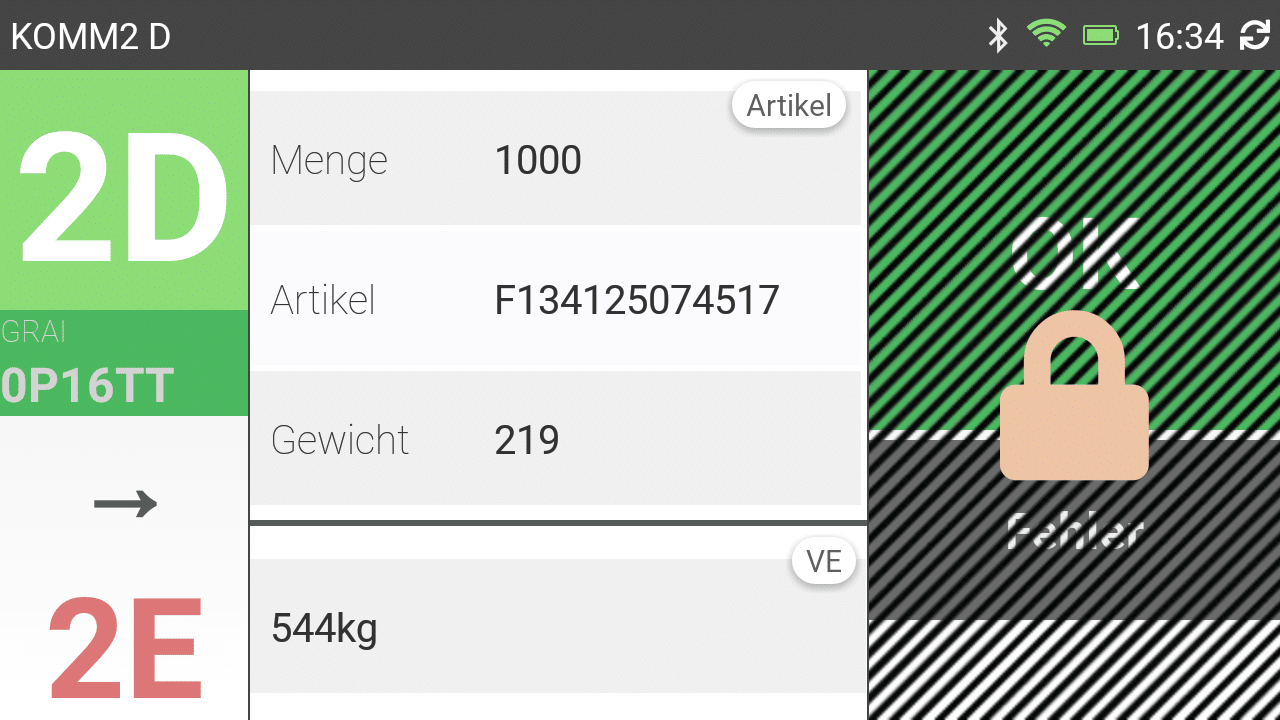

The hybridity also extends to the hardware used. The classic setup of the Pick-by-Light principle is replaced by detailed, mobile device-transmitted dialogs. This allows new use cases to be mapped, for example in the context of palettes. A working group has five synchronized picking stations, each with one pallet location. The process is accompanied by a combination of linked end devices. Each picking station has its own overview screen and two mobile data terminals (MDTs). The workgroup consisting of several stations coordinates itself internally and communicates independently with the pallet conveyor system. Users receive further information and can interact directly with the Warehouse Management System (WMS).

All relevant information

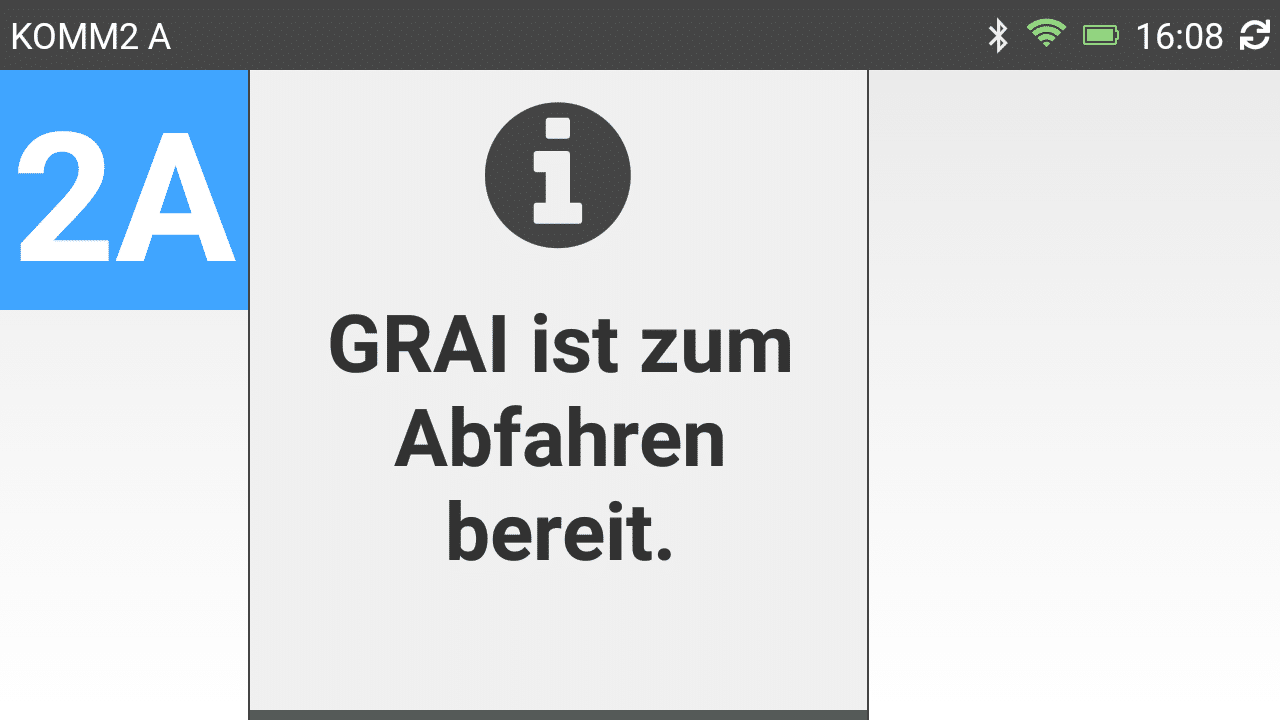

Visual hybridity through end device coupling

In a multimedia overview, real-time information on picking and progress is provided: Guidance screens provide orientation, detailed MDT dialogs convey the relevant information at every position. In this way, supplementary tasks, such as customer-specific requests, can be made directly accessible and implemented during the picking process. The hybrid presentation of information enables the user to carry out picking more efficiently.

Case Calculations for optimal capacity utilization

The ideal complement to the hybrid-optimized picking process is a time- and cost-efficient supply with goods. The basis for ensuring this is the right warehouse management software. Powerful calculation modules, so-called solvers, that can be implemented in the WMS are able to decode complex situations in the shortest possible time. Solvers provide flexible results, whether in the area of batch formation, route planning, or load simulation. We are experts in the parameterization of such calculation modules. This makes it possible to ideally plan the order picking process: shipping units are simulated in advance and calculated at minimum cost, then the pick station is supplied in the correct order.

The advantages of the hybrid system

Picking types used in the hybrid system and resulting added values

According to Pick-to-Light/Pick-by-Light:

- Usability through color-supported guidance system

- Application on e.g. pallets is made possible

According to Pick-by-MDT/PDT, Pick-by-Barcode:

- Mobility and flexibility through removable mobile devices (e.g. when handling special goods)

- Possibility to interact or confirm

Further added values:

- Work protection through ergonomic design of the picking stations

- Sequential delivery

- More efficient pallet construction

Click here to learn more about the advantages of our TUP.MSF manual sorter fulfillment solution, on which the hybrid picking system is based.

Hybrid picking

The dual user interfaces of the hybrid picking system

your-contact

You have a project inquiry or want individual consultation on the hybrid picking system?

Our sales manager Swen Weidenhammer is a specialist in combining automation solutions with modern information technology.