Start-up-, Directional and Throttle Valves

TAV, TWV, TDV

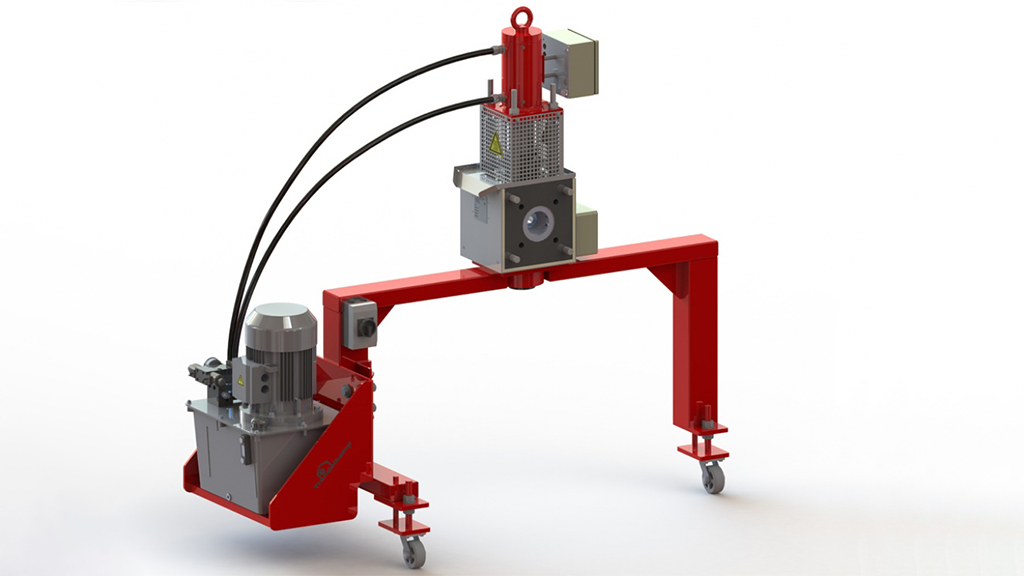

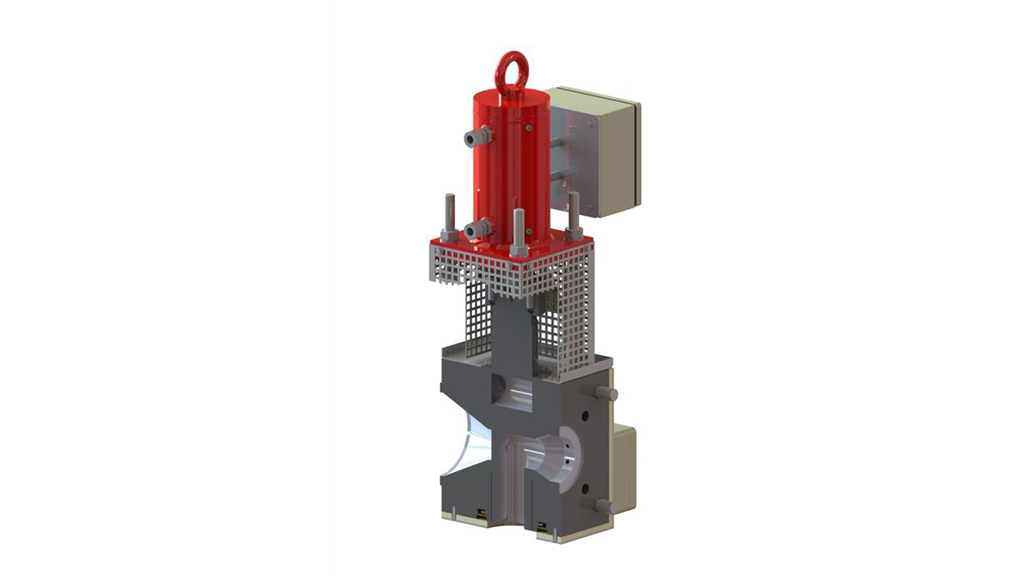

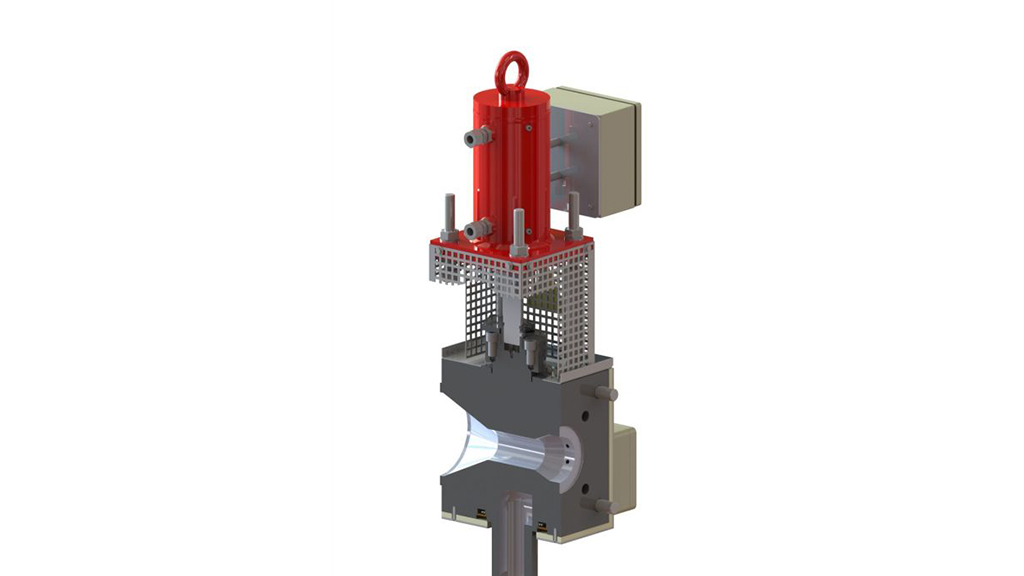

Trendelkamp start-up, directional and throttle valves are used wherever melt has to be diverted, separated, combined or throttled. The valve bolt is moved to the right valve position by a hydraulic cylinder, an electric drive or manually.

With Valves from Trendelkamp you ensure clean processes, for example. This is because the valves prevent downstream equipment from being contaminated with the start-up material, after a shutdown or a product change.

The valves are also ideally suited for processes that require a start-up period of the production line. For example, underwater pelletizing systems can be started without any problems to downstream equipment.

- For applications where melt needs to be diverted, bypassed or throttled

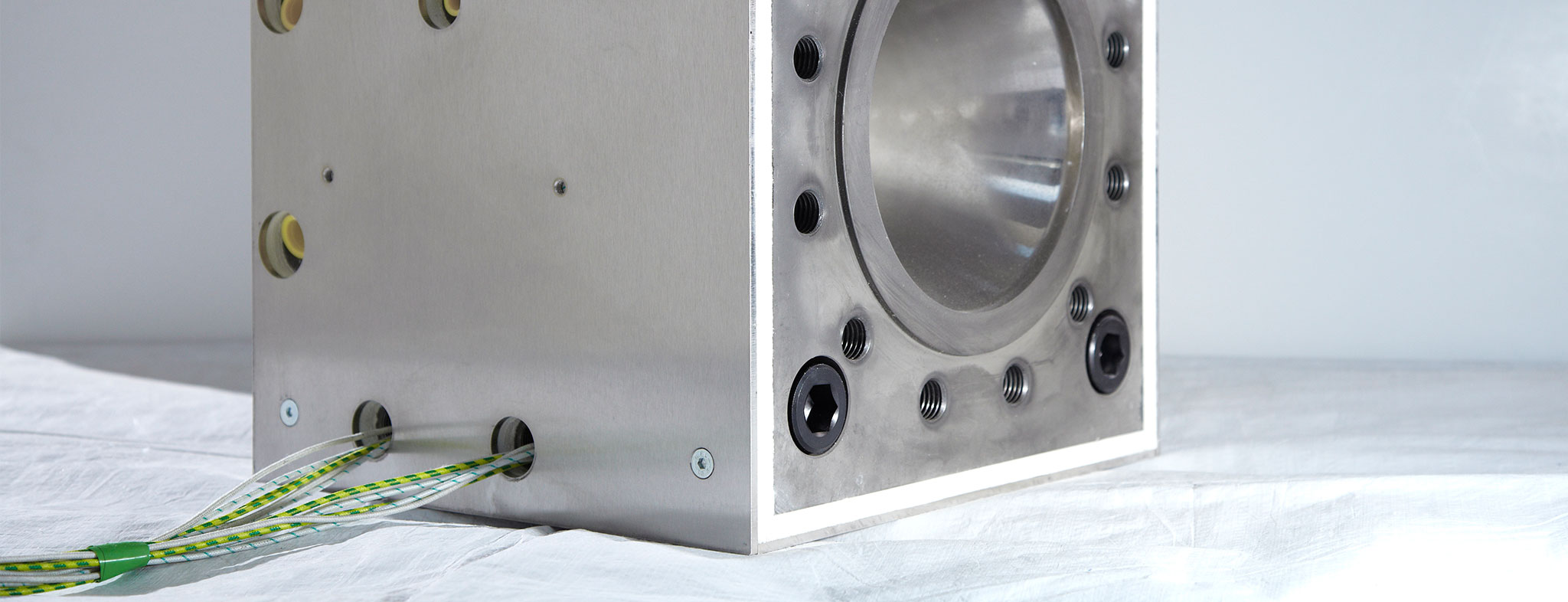

- Proven single bolt system design

- Energy efficient

Advantages:

- Durable and low maintenance design

- Optimized flow channel geometry

- Short actuation time

Features:

- Flow channel geometry adjusted to Up- and Downstream

- Process pressure up to 350 bar

- Process temperature up to 350 °C

Application examples:

- Extrusion

- Compounding

- Masterbatch

- Recycling

- Hot melt / Adhesive

- Food application

Options:

- Oil, fluid or steam heated

- Protection against corrosive or abrasive materials

- Adjustable flow channel restrictors

- Stainless steel design

- High temperature designs up to 450 °C

- ATEX-design for hazard areas

Your Contact persons

Marius Gerdes

Sales Manager

Todd Reed

Trendelkamp L.P. (USA)