Application

Solutions for a wide scope of industries

Let our micro-machining expertise inspire your future applications in the electronics, automotive, medtech, watchmaking and further industries.

Electronics

Automotive

SEMICON

MedTech

.webp)

Industries

Watchmaking

Thank you! Your submission has been received!

Oops! Something went wrong while submitting the form.

Test fixture guide plates micro-drilling for IC substrates and bare boards testing industry

Micromachining and drilling test fixture guide plates for IC substrates and bare boards testing present a complex challenge. Precision is paramount, ensuring that every guide plate aligns perfectly with the intricate designs of modern ICs. Minor errors risk unreliable test results or potential IC damage. As IC designs rapidly evolve, micromachining processes must remain adaptive and state-of-the-art to consistently meet the industry's high-tech demands.

Electronics

SEMICON

Testing

Test socket guide plates micro machining (drilling, milling cutting) for semiconductors testing industry

Micromachining test socket guide plates for the semiconductor testing industry faces the challenge of delivering ultra-precision amid rapidly evolving chip designs. Any minor inaccuracies can disrupt testing or damage chips. As semiconductor complexities increase, adaptability in micromachining processes, ensuring speed and consistency, becomes crucial.

Electronics

SEMICON

Testing

Probe card guide plates micro-drilling for semiconductors wafer testing industry

Guide plates for semiconductor devices require impeccably drilled holes for flawless alignment with chip test points. Precision and repeatability are essential, as discrepancies risk test errors or device damage. As semiconductors evolve in complexity, micro-machining must refine its techniques, ensuring guide plate integrity throughout numerous test cycles.

Electronics

Testing

SEMICON

Vertical and MEMS probes micro-cutting for semiconductors testing industry

To achieve balance contact force, high current carrying capability and ultra-fine pitch to optimize wafer probe requirements, a high quality of the treated surfaces and the machined geometries of the vertical and MEMS probes is required.

Electronics

Precision cutting, drilling, milling of micro components

Precision cutting and milling of micro components navigate a complex landscape of challenges. With tools operating at microscopic tolerances across diverse materials, consistency is paramount. Material-specific intricacies, tool wear, and heat-induced alterations elevate the technical demands. Balancing these with economic efficiency and staying ahead of evolving designs is crucial.

Industries

Precision cutting of surgical needles for the MedTech industry

In the MedTech arena, precision cutting and micromachining of surgical needles stand out as vital processes. These techniques, blending engineering precision with medical necessity, ensure that surgical needles meet the highest standards of sharpness, consistency, and finish, catering to the demands of advanced surgical procedures.

MedTech

Gear cutting operations for the watchmaking industry

In the watchmaking industry, gear cutting demands unparalleled precision and intricacy. Even slight imperfections can disrupt accurate timekeeping, especially given the precious materials and tiny size of the gears. Coupled with the aesthetic requirements of luxury timepieces, this task requires highly specialized micro machining expertise.

Watchmaking

Industries

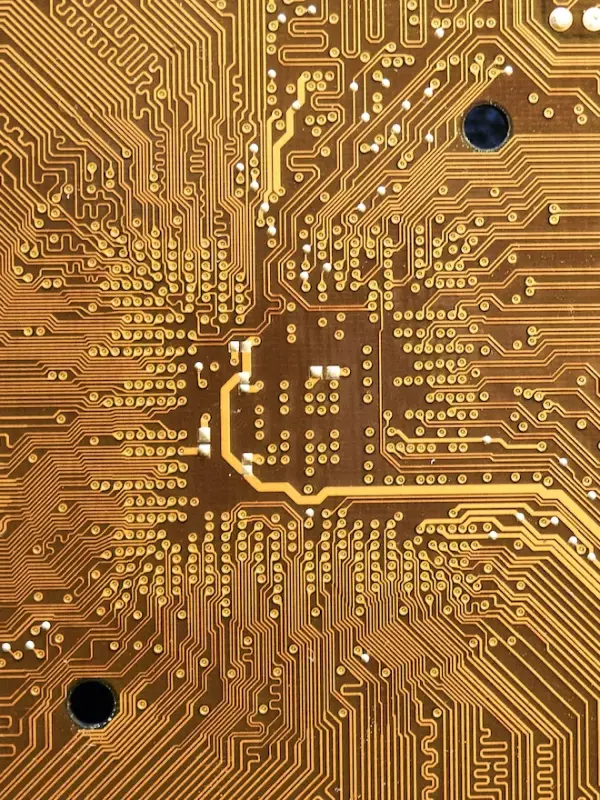

Drilling and routing of composites and non-ferrous materials for printed circuit boards (PCB) industry

Composites and non-ferrous materials offer interesting properties in the PCB industry. However, these materials require intricate handling to prevent defects and ensure PCB integrity. Posalux dives into these complexities and solutions micro-machining these advanced materials dedicated to high-tech electronics.

Electronics

Turning of contact pins (wires, bars and tubes) for semiconductors testing industry

The key challenge in turning and micromachining contact pins (wires, bars, and tubes) for the semiconductor testing industry lies in achieving microscopic precision while ensuring optimal electrical performance. These pins must be meticulously crafted to maintain consistent dimensions, intricate geometries, and exceptional surface finishes, all while guaranteeing reliable connectivity for accurate semiconductor testing.

Electronics

SEMICON

Testing

Let’s discuss your micro-machining operations

If you are looking for a high-tech production system as well as a partner to process state-of-the-art micro-machining, you are in the right place.

.webp)

.webp)